- Understanding the Role of Machine Learning in Manufacturing

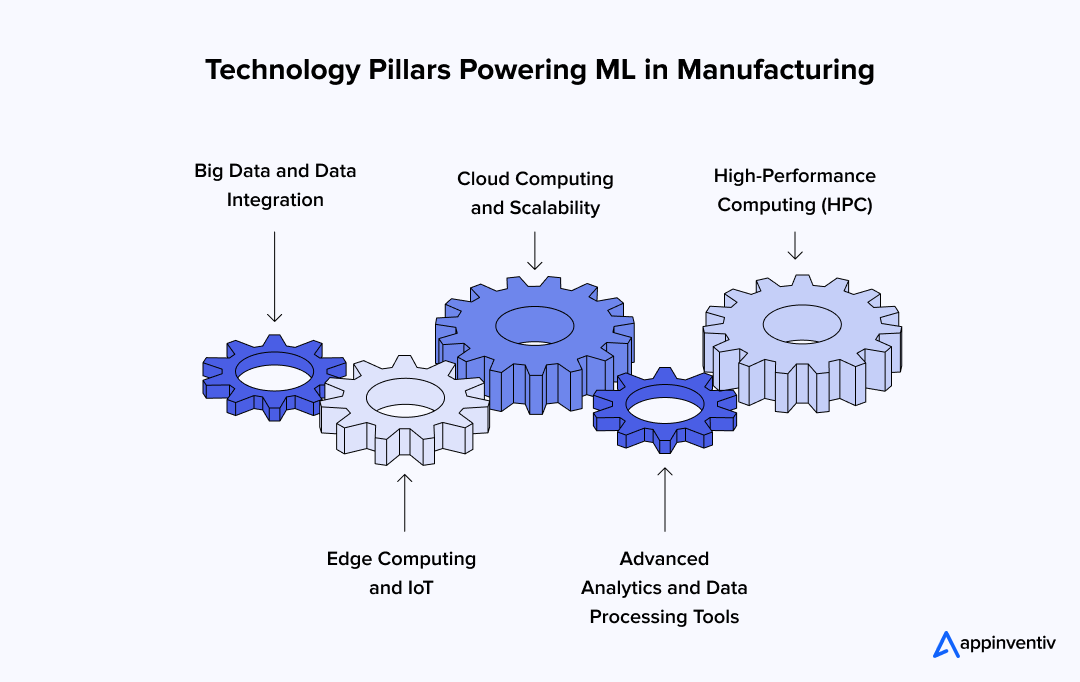

- Technology Foundations and Enablers of Machine Learning in Manufacturing

- 1. Big Data and Data Integration

- 2. Edge Computing and IoT

- 3. Cloud Computing and Scalability

- 4. Advanced Analytics and Data Processing Tools

- 5. High-Performance Computing (HPC)

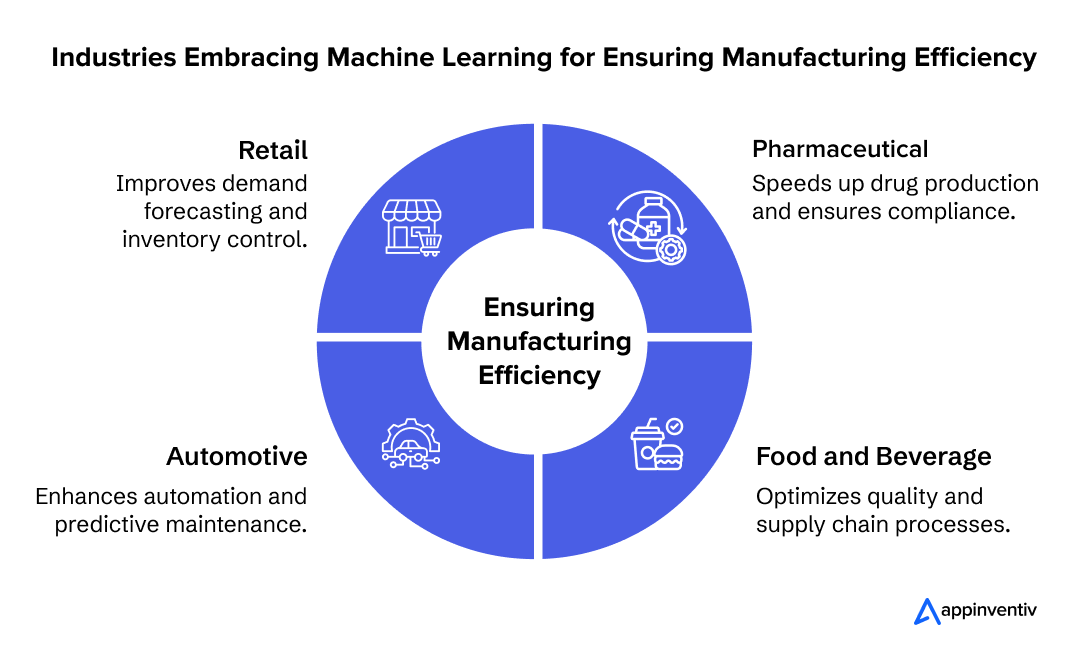

- Top Industry Verticals Leveraging Machine Learning For Manufacturing

- Pharmaceutical

- Food and Beverage

- Automotive

- Retail

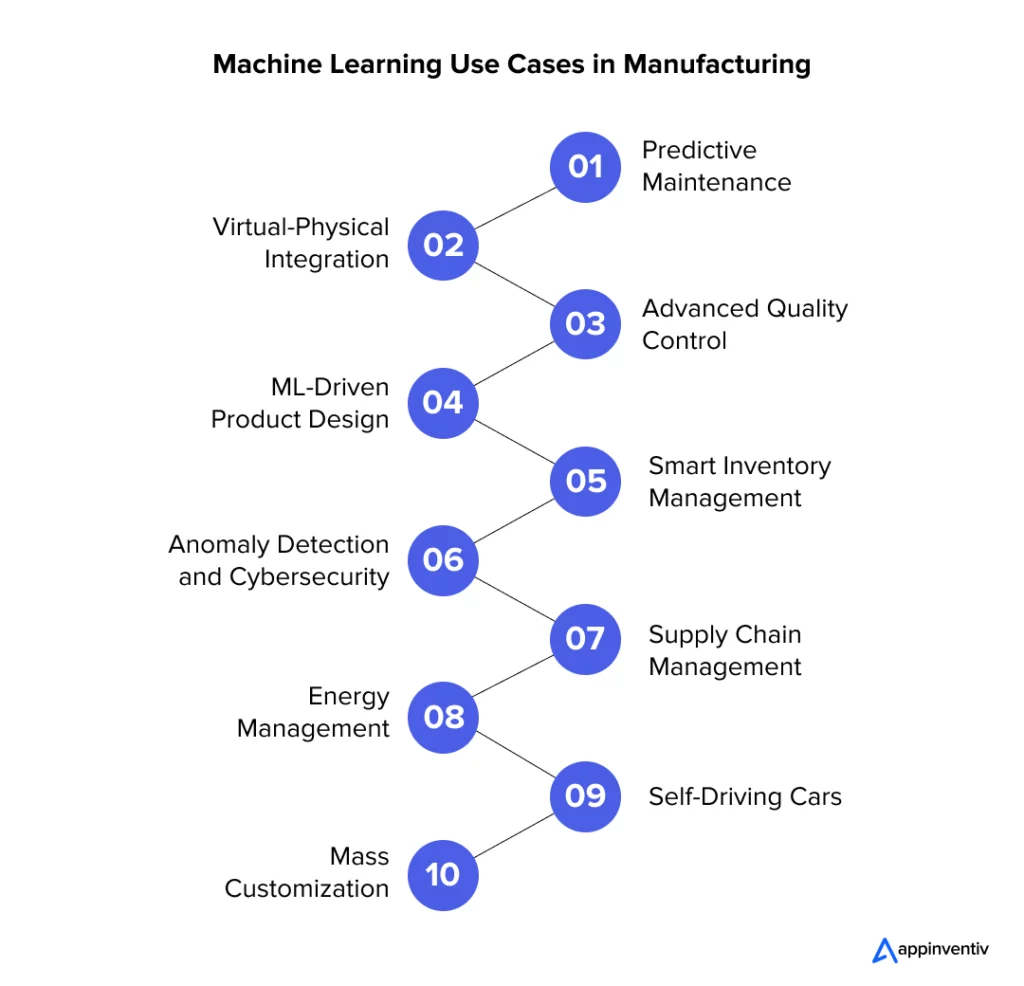

- Machine Learning for Manufacturing: Use Cases and Examples

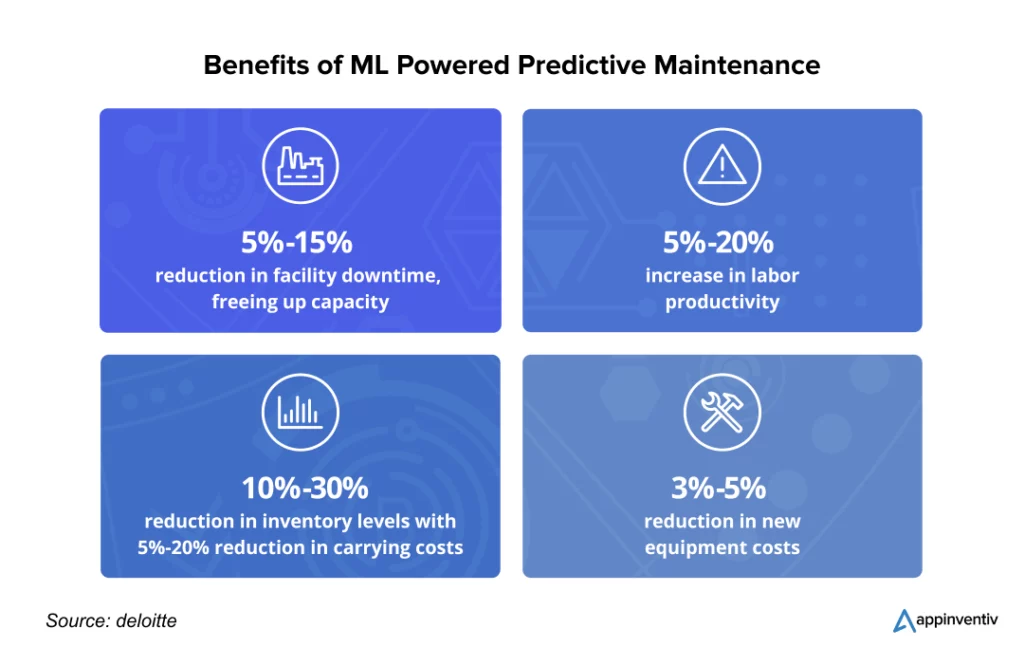

- Predictive Maintenance

- Virtual-Physical Integration

- Advanced Quality Control

- Supply Chain Management

- ML-Driven Product Design

- Smart Inventory Management

- Anomaly Detection and Cybersecurity

- Self-Driving Cars

- Energy Management

- Mass Customization

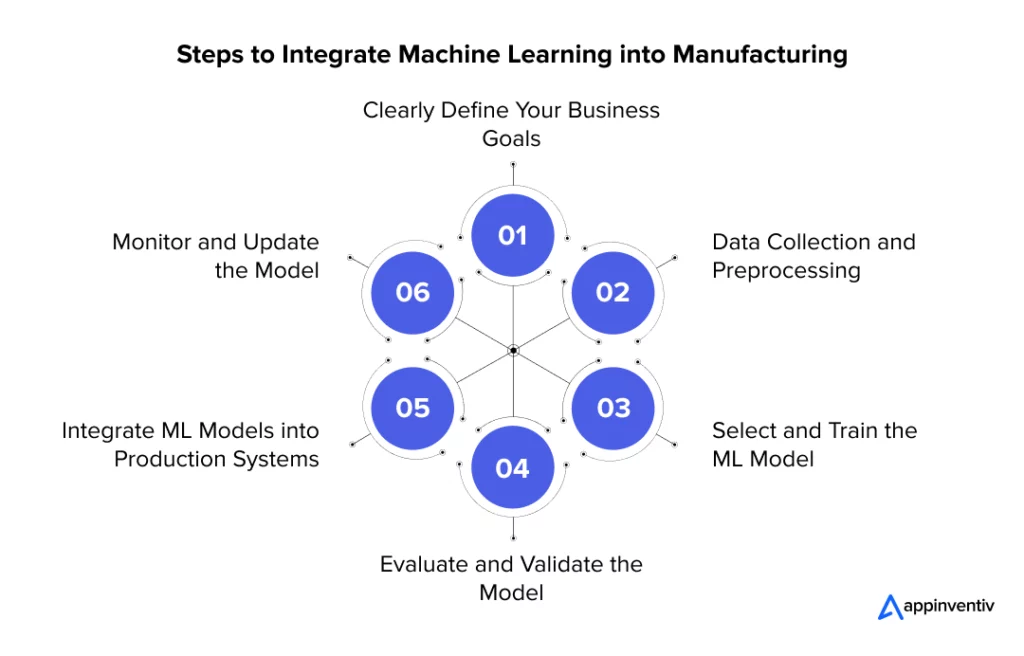

- The Roadmap for Integrating Machine Learning into Manufacturing

- Clearly Define Your Business Goals

- Data Collection and Pre-processing

- Select and Train the ML Model

- Evaluate and Validate the Model

- Integrate ML Models into Production Systems

- Monitor and Update the Model

- Practical Solutions to Common Machine Learning Adoption Challenges

- High Implementation Costs

- System Integration Challenges

- Data Quality and Availability

- Model Interpretability and Explainability

- Workforce Management and Human-Robot Collaboration

- Limited Skilled Talent in Machine Learning

- Data Security and Privacy Concerns

- Resistance to Change

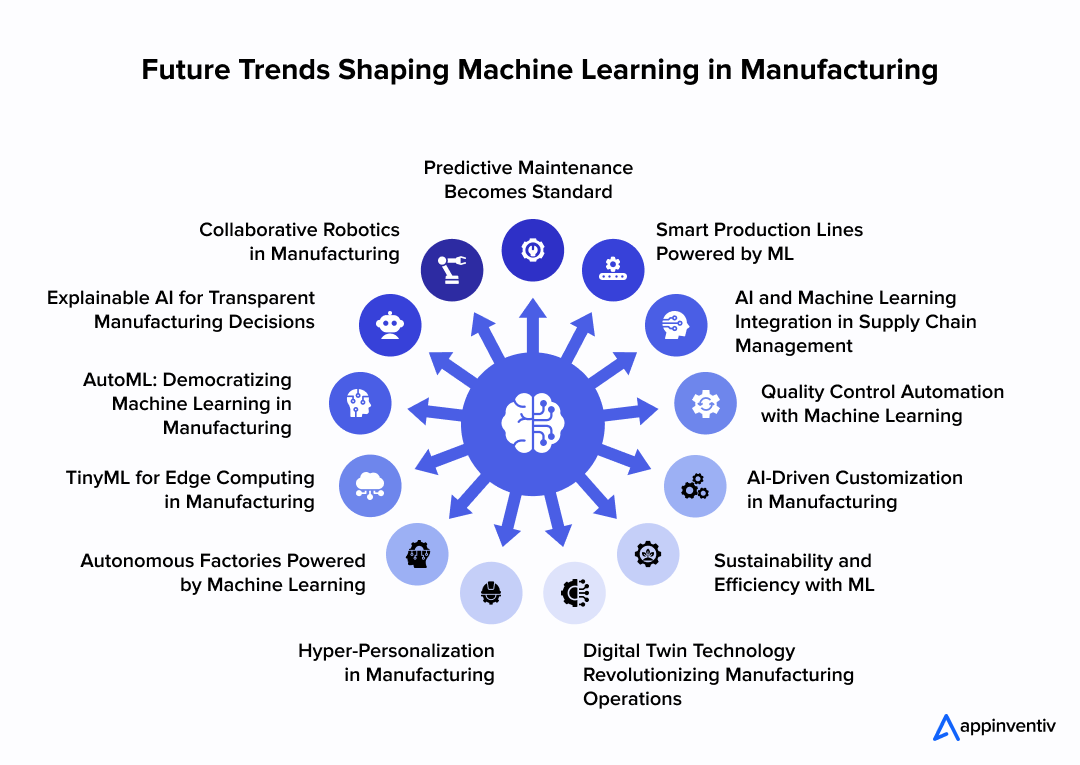

- Future of Machine Learning in Manufacturing

- Predictive Maintenance Becomes Standard

- AI and Machine Learning Integration in Supply Chain Management

- Smart Production Lines Powered by ML

- Quality Control Automation with Machine Learning

- AI-Driven Customization in Manufacturing

- Sustainability and Efficiency with ML

- Digital Twin Technology Revolutionizing Manufacturing Operations

- Hyper-Personalization in Manufacturing

- Autonomous Factories Powered by Machine Learning

- TinyML for Edge Computing in Manufacturing

- AutoML: Democratizing Machine Learning in Manufacturing

- Explainable AI for Transparent Manufacturing Decisions

- Collaborative Robotics in Manufacturing

- Get Started with Manufacturing Machine Learning with Appinventiv

- FAQs

Key takeaways:

- Machine learning is revolutionizing manufacturing with real-time, data-driven decision-making.

- ML reduces downtime, streamlines supply chains, and improves product quality through predictive analytics and automation.

- Industry leaders like General Motors, Siemens, and Adidas use ML for predictive maintenance, digital twins, and mass customization.

- ML is driving efficiency across sectors like automotive, food & beverage, pharma, and retail.

- Successful ML integration needs clear goals, high-quality data, and continuous performance monitoring.

- Adoption challenges like high costs, poor data quality, and system integration can be addressed with cloud solutions, strong governance, and expert guidance.

- The future of ML in manufacturing includes smart factories, sustainable operations, and personalized mass production.

Imagine this: production delays, unplanned maintenance, and quality issues are eating into your bottom line. As a business leader, you know that efficiency is key, but traditional methods just don’t cut it anymore. The challenge is clear—how do you streamline operations while minimizing risks and costs? The answer might lie in something you’ve been hearing a lot about lately: machine learning (ML).

Machine learning in manufacturing is quickly becoming the driving force behind smarter manufacturing operations. For manufacturers, this shift is no longer about experimentation it’s about practical machine learning implementation in manufacturing environments, integrated with existing production systems, data pipelines, and operational workflows.

By analyzing large sets of data and making predictions in real-time, ML allows manufacturers to foresee challenges, optimize processes, and keep things running smoothly. It’s no longer just about automating tasks; it’s about creating a system where decisions are data-driven, precise, and proactive.

So why is now the perfect time for manufacturers to consider ML? The reality is that industries are evolving faster than ever. The businesses that will embrace the power of machine learning and manufacturing today are the ones that will have a competitive edge tomorrow. With ML, you’re not just solving immediate problems—you’re setting your company up for long-term growth and sustainability. The benefits are clear: reduced downtime, optimized supply chains, and improved quality control are just the beginning.

For large-scale manufacturers, the real value lies in enterprise machine learning systems that connect machines, production lines, supply chains, and decision-making into a unified intelligence layer.

This blog will explore exactly how machine learning is already making waves in the manufacturing world. We’ll dive into practical use cases and real-world examples that show how ML is transforming everything from predictive maintenance to production line optimization. By the end of it, you’ll have a clear understanding of why ML is no longer a luxury—it’s a business necessity.

So, if you’re ready to explore the future of manufacturing, let’s jump in and discover how machine learning can help drive your business forward.

We can help you integrate machine learning into your manufacturing workflows—designed for precision, speed, and real-time decision-making.

Understanding the Role of Machine Learning in Manufacturing

Machine Learning (ML) is no longer a futuristic concept—it’s actively reshaping the manufacturing landscape. By harnessing vast amounts of data, ML empowers manufacturers to predict equipment failures, optimize production processes, and enhance product quality. This shift from traditional methods to data-driven decision-making is a cornerstone of Industry 4.0, ushering in an era of smarter, more efficient manufacturing.

The role of ML in manufacturing is multifaceted. Predictive maintenance, for instance, utilizes historical data to forecast equipment failures before they occur, minimizing downtime and reducing maintenance costs. ML algorithms can also analyze production data in real-time to identify inefficiencies, enabling manufacturers to adjust processes promptly and maintain optimal performance. Furthermore, ML aids in quality control by detecting anomalies in products, ensuring that only items meeting the highest standards reach consumers.

In real-world manufacturing environments, these capabilities are enabled through machine learning systems integrated with existing enterprise infrastructure, such as MES, ERP, SCADA, and IoT platforms. Successful adoption depends not only on algorithms, but on data readiness, system interoperability, and deployment strategies aligned with operational constraints.

Market trends underscore the growing significance of AI/ML in manufacturing. According to PwC’s 2025 AI Business Predictions, nearly half (49%) of technology leaders reported that AI was “fully integrated” into their companies’ core business strategies in the last year. This integration is not just about adopting new technologies but about transforming business models to leverage AI’s full potential. The report emphasizes that AI’s value is realized not only through groundbreaking innovations but also through incremental improvements that collectively enhance productivity, speed to market, and revenue.

For manufacturing organizations, this shift means moving beyond isolated AI pilots toward machine learning systems embedded across production, quality, and supply chain operations, where insights directly influence day-to-day decision-making.

The economic impact of AI in manufacturing is also substantial. McKinsey’s research indicates that Gen AI could add up to $4.4 trillion in productivity growth potential across various industries . This potential is particularly evident in manufacturing, where AI applications can lead to significant cost savings, improved efficiency, and accelerated product development cycles.

However, the journey towards AI maturity is ongoing. McKinsey’s 2025 State of AI report highlights that while 92% of companies plan to increase their AI investments, only 1% of leaders describe their AI deployments as “mature”. This gap underscores the importance of not only investing in AI technologies but also in developing the necessary infrastructure, skills, and strategies to fully integrate AI into manufacturing operations.

In manufacturing environments, these gains are realized through use cases such as predictive maintenance, yield optimization, defect detection, and demand forecasting when machine learning models are deployed within scalable enterprise architectures.

Now that we’ve explored how machine learning is reshaping the manufacturing landscape, it’s essential to understand the technology foundations and enablers that make these advancements possible. In this section, we’ll dive into the core technologies that empower ML to drive transformation in manufacturing, laying the groundwork for successful implementation.

For manufacturers, this maturity gap often stems from challenges in data readiness, system integration, workforce enablement, and deployment strategy, making structured machine learning implementation critical to long-term success.

Technology Foundations and Enablers of Machine Learning in Manufacturing

For businesses looking to leverage machine learning in manufacturing, understanding the underlying technology foundations is key. However, value is unlocked only when these technologies operate together as part of a cohesive enterprise machine learning system, integrated with existing manufacturing infrastructure. By aligning data, compute, and deployment layers, manufacturers can move from experimentation to scalable, production-grade ML implementations.

1. Big Data and Data Integration

Machine learning thrives on data, and integrating vast amounts of it from machines, sensors, and production lines is essential. For manufacturers, having a reliable data infrastructure allows artificial intelligence models to draw from real-time information, making predictive maintenance and process optimization more accurate and impactful.

In enterprise manufacturing environments, this often involves integrating ML pipelines with MES, ERP, SCADA, and IoT platforms, ensuring consistent data flow across plants and business units.

2. Edge Computing and IoT

The power of IoT in manufacturing is undeniable, connecting machines and systems in real-time. When paired with edge computing, manufacturers can process data locally, reducing latency and enabling quicker decision-making—vital for maintaining operational efficiency and minimizing downtime.

3. Cloud Computing and Scalability

As businesses scale, so do their data needs. Cloud computing offers manufacturers the ability to scale their ML initiatives without the hefty upfront costs of on-premises infrastructure. This flexibility empowers manufacturers to quickly deploy ML models, store large datasets, and run complex analyses without worrying about capacity limitations.

[Also Read: Cloud Manufacturing Software – Benefits, Types, Development Process and Cost Analysis]

4. Advanced Analytics and Data Processing Tools

With the right analytics tools, manufacturers can sift through mountains of data to uncover valuable insights. These platforms are critical for optimizing production, improving quality control, and identifying inefficiencies—helping businesses stay competitive in an increasingly data-driven market.

5. High-Performance Computing (HPC)

For more complex ML applications, high-performance computing (HPC) is the backbone that allows businesses to process large datasets at speed. Whether it’s deep learning for quality control or real-time data processing, HPC ensures that manufacturers can run sophisticated models and get actionable insights quickly.

While each of these technologies plays a critical role, successful machine learning implementation in manufacturing depends on how well they are architected together. Fragmented deployments often lead to stalled pilots, whereas unified enterprise systems enable scalability, security, and long-term ROI.

Top Industry Verticals Leveraging Machine Learning For Manufacturing

Machine learning in manufacturing is transforming the sector by driving efficiency, enhancing quality control, and enabling predictive maintenance across industries. However, the impact varies by vertical, depending on regulatory requirements, production complexity, and data maturity. Below are key industries where enterprise machine learning systems are delivering measurable operational and business outcomes.

Pharmaceutical

Pharmaceutical manufacturing uses ML to streamline drug discovery, optimize formulations, and improve production processes. Algorithms accelerate R&D by predicting chemical interactions, while ML in the healthcare & pharmaceutical industry ensures compliance with regulatory standards and enables predictive equipment maintenance.

Real-World Example: Pfizer uses machine learning to streamline its drug discovery process and improve production efficiency. By applying ML algorithms, the company can predict how drugs interact at a molecular level, significantly reducing R&D time.

At scale, these capabilities are supported by enterprise ML platforms integrated with R&D systems, quality management, and manufacturing execution systems (MES).

Food and Beverage

The food sector employs ML to ensure consistent quality, optimize supply chains, and manage inventory. Automated sorting systems powered by ML reduce waste and improve product grading, while predictive analytics assist in accurate demand forecasting.

Real-World Example: Nestlé uses machine learning to improve its supply chain operations and predict demand. ML helps optimize the production process by enhancing inventory management and minimizing waste, leading to cost savings and improved operational efficiency.

Successful implementations rely on real-time data pipelines across production lines, supply chains, and inventory systems to support fast decision-making.

Automotive

The automotive sector applies machine learning for predictive maintenance, quality assurance, and optimizing assembly lines. ML-powered robotics aid in manufacturing precision components, while advanced data analytics enhance supply chain operations. Autonomous vehicle technologies also rely on ML for real-time decision-making.

Real-World Example: General Motors uses machine learning for predictive maintenance in its manufacturing facilities. By predicting when machinery needs maintenance, GM has reduced unplanned downtime, improving overall production efficiency.

In large automotive plants, ML models are typically deployed within enterprise architectures that connect robotics, sensor data, and predictive analytics across facilities.

Retail

Machine learning in retail enhances defect detection, predictive maintenance, and pattern recognition within textile manufacturing. It optimizes production schedules, improves fabric quality, and helps predict consumer trends, leading to better product designs and more informed decision-making.

Real-World Example: H&M leverages machine learning to predict consumer demand and optimize inventory. By analyzing purchasing patterns, H&M can adjust its production processes to better align with market trends, reducing overproduction and waste.

These use cases depend on scalable machine learning systems that align production planning with downstream demand forecasting and inventory platforms.

Machine Learning for Manufacturing: Use Cases and Examples

Machine learning in manufacturing is reshaping the industry with its diverse applications and advantages. From predictive maintenance to optimized supply chains, machine learning applications in manufacturing are driving innovation and productivity across the industry. Here are some of the most remarkable applications of machine learning in manufacturing with their real-world examples:

Predictive Maintenance

Predictive maintenance is one of the key applications of machine learning in the manufacturing industry. ML models can efficiently analyze vast amounts of sensor data from equipment to identify patterns that indicate impending failures. By forecasting when a machine is likely to fail, manufacturers can perform maintenance just in time to prevent costly breakdowns.

Real World Example: General Motors, one of the biggest vehicle manufacturers in the US, is one of the earliest advocates of leveraging ML, AI, IoT, and other emerging technologies. GM uses AI and ML to monitor the health of its assembly-line robots.

Using machine learning for manufacturing process optimization, GM can efficiently identify early signs of equipment wear, preventing unplanned downtime and extending machinery lifespan. As a result, GM reduced unexpected downtime by 15% and saved around $20 million annually in maintenance costs.

At scale, predictive maintenance requires enterprise machine learning systems integrated with IoT platforms, MES, and asset management tools to deliver consistent results across facilities.

Virtual-Physical Integration

ML-enabled digital twins, which are virtual replicas of physical assets, create dynamic models of manufacturing systems and are one of the most important machine learning use cases in manufacturing. These models enable real-time monitoring, simulation, and optimization. This integration allows manufacturers to carry out instant diagnostics, predict system performance, identify potential issues before they occur, and fine-tune operations.

For instance, you can develop virtual prototypes of physical production to spot potential issues early on. Additionally, you can anticipate maintenance needs, preventing unexpected breakdowns and minimizing downtime.

Real World Example: Siemens, a world-renowned company is one of the leading machine learning in manufacturing examples that businesses can take inspiration from. The firm uses digital twins to simulate entire production lines and enhance processes. This approach has minimized operational disruptions and enhanced efficiency.

These capabilities are typically enabled through cloud-based ML architectures that connect real-time plant data with simulation and analytics engines.

Advanced Quality Control

Traditional quality control methods can miss subtle defects. ML-powered inspection systems use advanced image recognition and sensor data to detect defects and anomalies in real-time, surpassing the accuracy and speed of human inspectors. This ensures higher product quality and reduces the risk of defective products reaching customers.

Real World Example: Fanuc and Preferred Networks, Inc. (PFN), a leader in robotics, integrates ML into its robotic arms to detect tiny defects during the assembly process, reducing the production of defective products and enhancing customer satisfaction.

In enterprise manufacturing, ML-powered quality inspection systems are deployed as part of production-grade computer vision pipelines integrated with shop-floor operations.

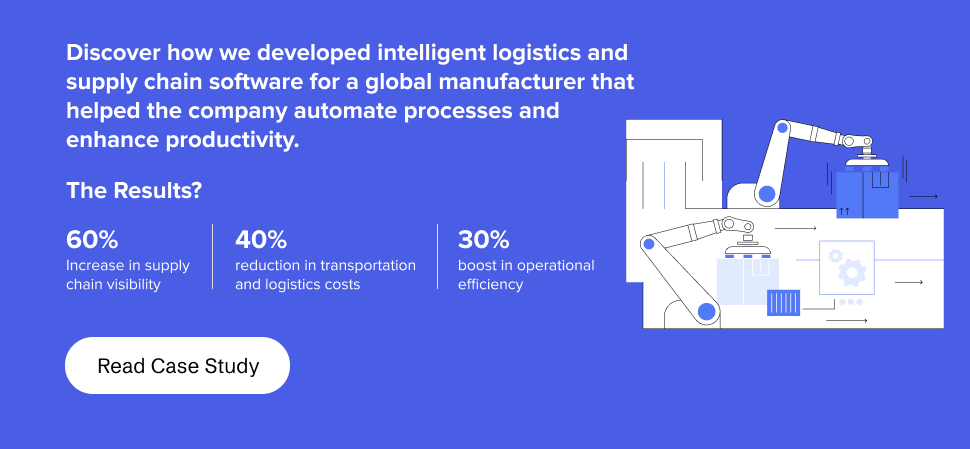

Supply Chain Management

One of the notable applications of machine learning in manufacturing is supply chain management. The rise of IIoT technologies is set to transform smart supply chains, revolutionizing manufacturing operations. While automation is just the beginning, the future holds the promise of fully “cognitive” supply chains. These advanced systems will leverage AI and ML to automatically analyze extensive datasets and manage complex supply chains, including shipments, inventory, consumer preferences, market trends, and weather forecasts.

Real World Example: DHL leverages ML and advanced data analytics to predict logistics demand spikes during peak seasons, automating workflows, optimizing resource allocation, reducing delays, and ensuring a more efficient supply chain.

Such outcomes depend on machine learning models embedded within enterprise supply chain and logistics systems, rather than standalone analytics tools.

You may like reading: AI-Based Demand Forecasting: Optimizing Supply Chains

ML-Driven Product Design

Machine learning in design leverages generative design algorithms to create optimized product designs based on predefined criteria such as material strength, size, weight, and cost. This speeds up the design process and results in more innovative and efficient products.

With the new-age ML-driven designs, automakers can quickly explore countless design options for future vehicles, selecting the most optimal ones to streamline production and speed up delivery timelines.

Real World Example: Automotive leaders like Nissan and Volkswagen leverage machine learning technology to rapidly generate impressive and innovative designs, transforming their creative processes with unprecedented speed.

These ML-driven design workflows are often supported by enterprise data platforms that connect engineering, manufacturing, and supply chain teams.

Also Read: How to Use AI to Design Better Mobile App User Experience?

Smart Inventory Management

Inventory management is not easy in manufacturing. With a vast number of products and components stored at warehouses, understocking and overstocking become serious challenges. Machine learning for manufacturing offers a solution that automates key aspects of warehouse management.

Real World Example: Amazon uses machine learning in its logistics operations to manage real-time inventory and gain a competitive edge in the market. The company optimizes its warehouse operations by analyzing customer demand, inventory levels, and shipping routes, enhancing efficiency, reducing costs, and shortening delivery times.

At scale, this requires centralized ML systems that align warehouse operations with demand forecasting and production planning.

Related Article: 10 Ways to Unlock the Power of AI in Inventory Management

Anomaly Detection and Cybersecurity

Modern manufacturing companies heavily rely on advanced technologies like IoT, AI, cloud computing, and other digital systems, which are the prime targets of cyberattacks. Traditional cybersecurity measures may fall short of addressing the burgeoning challenges of cyberattacks.

Machine learning models can efficiently detect anomalies in network traffic and operational data. They can identify potential cybersecurity threats or process irregularities before they cause significant harm.

Real World Example: Rolls-Royce employs machine learning for manufacturing to monitor its digital infrastructure, identifying possible cyber threats in real-time and protecting sensitive data and operations.

Enterprise manufacturers rely on ML-driven anomaly detection systems integrated across IT and OT environments to ensure operational resilience.

Self-Driving Cars

Machine learning and AI are at the forefront of the evolution of self-driving cars, which are projected to account for 10 to 15% of global car sales by 2030. These technologies enable vehicles to navigate autonomously by processing data from sensors, cameras, and radar in real time, allowing them to identify objects, interpret road signs, and understand road conditions.

This enhances road safety and accelerates manufacturing processes, from automating assembly lines to optimizing conveyor belts, thus reducing time-to-market for new vehicles.

Real World Example: Waymo, an automotive giant, uses advanced ML and AI to power its autonomous vehicle technology. Its self-driving cars have accumulated millions of miles of road experience, leading to a significant reduction in accidents and an efficient transportation experience.

Also Read: Benefits and Use Cases of AI in the Automotive Industry

Energy Management

In energy-intensive manufacturing processes, machine learning algorithms can significantly enhance energy management. By analyzing data from various parameters such as temperature, lighting, and movement within a facility, these technologies can create predictive models to forecast future energy consumption. This approach enables manufacturers to optimize energy use, identify inefficiencies, lower greenhouse gas emissions, and reduce overall consumption, contributing to a more sustainable operation.

Real World Example: Google DeepMind partnered with National Grid to utilize ML to optimize energy management. The goal is to improve the efficiency of the electricity grid by forecasting and balancing energy demand through sophisticated ML algorithms.

These models are most effective when deployed within enterprise energy management and sustainability platforms.

Mass Customization

Machine learning in manufacturing enables the business leaders to offer personalized products at scale. By analyzing extensive customer data and preferences, ML algorithms tailor production processes to meet individual specifications while maintaining operational efficiency. This capability enhances customer satisfaction by providing bespoke solutions and optimizes production workflows.

Real World Example: Adidas uses AI and ML to manage its “Speedfactory” operations, allowing it to produce custom footwear in days rather than weeks. This approach has led to a significant increase in customer satisfaction due to the personalized fit and design.

Successful mass customization depends on machine learning systems tightly integrated with production planning, CRM, and supply chain platforms.

While these use cases highlight the potential of machine learning in manufacturing, real value is realized only when these capabilities are implemented through scalable, secure, enterprise-grade ML systems aligned with business objectives.

The Roadmap for Integrating Machine Learning into Manufacturing

Implementing machine learning in manufacturing is not just a technical exercise it is a strategic transformation that impacts operations, data infrastructure, and decision-making. A structured implementation roadmap helps manufacturers move from isolated pilots to scalable, enterprise-grade machine learning systems that deliver measurable business outcomes.

Clearly Define Your Business Goals

Start by clearly outlining your goals for implementing machine learning in your manufacturing processes. Whether it’s improving maintenance, enhancing quality, or optimizing schedules, ensure these goals align with your business priorities.

Identify the key challenges you face and set measurable KPIs, such as uptime, yield rate, or cost reduction, to track the success of your ML efforts.

Data Collection and Pre-processing

Collect relevant data from various sources, including sensors, machinery logs, and production records. The quality of this data is crucial to the success of your ML model, so ensure it is clean and formatted properly.

Pre-process the data by handling missing values, normalizing them, and removing outliers to improve model performance and accuracy.

In enterprise environments, this often requires consolidating data across MES, ERP, SCADA, and IoT platforms to ensure consistency and reliability.

Select and Train the ML Model

Start by selecting the machine learning model that best addresses your problem. For predictive maintenance, consider supervised learning; unsupervised learning may be more suitable for anomaly detection, and reinforcement learning works well for optimizing processes like supply chains.

Once the model is chosen, historical data will be used to train it. Split the data into training and testing sets to assess accuracy and focus on selecting the most relevant features.

Evaluate and Validate the Model

Test the trained model’s performance with unseen data to ensure it can generalize well. Use cross-validation techniques to confirm that the model works consistently across different datasets.

If the model isn’t performing as expected, revisit data pre-processing, feature engineering, or model selection to improve its accuracy.

Integrate ML Models into Production Systems

After validation, integrate the model into your production systems. This may involve collaboration with IT teams to ensure the model is compatible with existing software.

Set up systems for real-time predictions, such as automating maintenance schedules or quality control checks, to improve operational efficiency and decision-making.

For large manufacturers, integration typically involves deploying ML models within secure, production-grade enterprise architectures that align IT and OT systems.

Monitor and Update the Model

Ongoing monitoring is essential to maintain the model’s performance. Track its effectiveness and watch for any decline in accuracy over time. As new data comes in, periodically retrain the model to ensure it stays relevant and adapts to changes in your manufacturing processes.

At scale, this monitoring is supported by centralized MLOps frameworks that ensure governance, security, and performance across plants.

While this roadmap outlines the core steps, many manufacturers face challenges in execution due to data silos, legacy systems, and operational constraints. Successful machine learning implementation in manufacturing often requires expert guidance to design, integrate, and scale enterprise ML systems without disrupting production.

Practical Solutions to Common Machine Learning Adoption Challenges

Machine learning adoption in manufacturing presents unique challenges due to legacy systems, data silos, and operational constraints. However, with the right strategies and enterprise-grade implementation approaches, manufacturers can overcome these hurdles and unlock long-term business value.

High Implementation Costs

Problem: The cost of developing and implementing machine learning solutions is another common obstacle, as it often involves substantial investment in infrastructure and expertise.

Solution: Cloud-based machine learning platforms provide a cost-effective alternative, eliminating the need for upfront infrastructure investments. Starting with small pilot projects allows organizations to evaluate the potential impact of machine learning before scaling. Open-source tools and frameworks also offer a cost-efficient way to build models without compromising quality or functionality.

For large manufacturers, cost optimization often depends on designing scalable enterprise ML architectures that can be reused across plants rather than rebuilt for each use case.

System Integration Challenges

Problem: Integrating machine learning into existing systems and workflows can be complex and technically challenging.

Solution: Organizations can simplify this process by utilizing APIs and middleware to connect ML solutions with current software. Engaging third-party experts can further streamline deployment and minimize disruptions. Choosing scalable, integration-ready ML platforms ensures smoother adoption and reduces compatibility issues.

In manufacturing environments, this often involves integrating ML models with MES, ERP, SCADA, and shop-floor systems without disrupting production.

Data Quality and Availability

Problem: The lack of high-quality, reliable data is a critical hurdle in adopting machine learning. Machine learning models require extensive datasets, but these are often incomplete, unstructured, or inconsistent.

Solution: To overcome this, organizations should implement effective data governance strategies to ensure data accuracy and reliability. Preprocessing methods like data cleaning, normalization, and transformation are essential to prepare datasets for training.

Model Interpretability and Explainability

Problem: Understanding and trusting the predictions of machine learning models, especially in critical fields like healthcare and finance, is a persistent challenge.

Solution: This can be addressed using simpler, more interpretable models, such as decision trees or linear regression, for specific use cases. For complex models, explainability tools like LIME (Local Interpretable Model-Agnostic Explanations) and SHAP (SHapley Additive exPlanations) can make predictions more transparent.

Workforce Management and Human-Robot Collaboration

Problem: A key challenge in adopting machine learning in manufacturing is managing the workforce while introducing new automation technologies, especially in environments where robots and humans need to collaborate.

Solution: One solution is to focus on human-robot collaboration, where robots assist workers in tasks, enhancing productivity without replacing the workforce. Companies can provide training to employees, enabling them to work alongside machines effectively. This approach fosters a positive transition to automation, improves efficiency, and allows for a collaborative work environment, ensuring the workforce feels empowered rather than displaced.

Limited Skilled Talent in Machine Learning

Problem: The shortage of skilled machine learning professionals can hinder the adoption of ML technologies in manufacturing, as companies struggle to find employees with the necessary expertise.

Solution: To overcome this challenge, companies can collaborate with external consultants and ML experts. Additionally, organizations can leverage AutoML tools that automate many aspects of model creation and fine-tuning, reducing the dependency on highly specialized talent.

Data Security and Privacy Concerns

Problem: With the increasing reliance on data, particularly in industries like healthcare and finance, concerns over data security and privacy are significant barriers to the widespread adoption of machine learning.

Solution: Implementing strong data encryption, securing data access protocols, and complying with privacy regulations (such as GDPR) are essential to address these concerns. Using federated learning, where data remains decentralized and models are trained without sharing raw data, is another effective way to protect sensitive information while still benefiting from machine learning insights.

For manufacturers operating across multiple plants, securing both IT and OT data environments is critical to maintaining operational resilience.

Resistance to Change

Problem: Employees and management may resist adopting machine learning technologies due to fear of the unknown or concerns about the technology disrupting their roles.

Solution: To combat resistance, businesses should focus on education and communication, clearly explaining the benefits of machine learning in improving productivity and reducing repetitive tasks. Offering training programs and demonstrating how ML enhances job functions can help employees feel more comfortable with the transition, positioning them as active participants in the process rather than passive subjects of change.

While these solutions provide a clear path forward, implementing them in real-world manufacturing environments requires careful planning, system integration, and execution expertise. Many manufacturers partner with experienced ML providers to accelerate deployment, reduce risk, and ensure enterprise-scale success.

Future of Machine Learning in Manufacturing

As we look toward the future of manufacturing, machine learning (ML) is poised to become an even more integral part of the industry’s evolution. With the rise of AI-driven technologies, ML will continue to revolutionize production processes, pushing efficiency, cost savings, and innovation to new heights. Here’s a look at some key AI and machine learning trends in manufacturing that will shape the future of the industry.

Predictive Maintenance Becomes Standard

Predictive maintenance is already a game-changer, but its role will expand significantly in the coming years. Machine learning algorithms will become increasingly capable of predicting equipment failure with even greater accuracy. Predictive maintenance using machine learning in factories will soon become the backbone of proactive maintenance strategies, minimizing unexpected failures and maximizing equipment lifespan.

By continuously analyzing data from machines, ML can forecast potential breakdowns, allowing manufacturers to address issues before they lead to expensive downtimes. The future will see more automated maintenance systems that autonomously trigger repairs and part replacements based on real-time data analysis.

Tip: To leverage predictive maintenance, ensure that your systems are collecting high-quality data from every stage of the production process. The more data your machines generate, the more precise your predictions will be.

AI and Machine Learning Integration in Supply Chain Management

Machine learning will play an increasingly pivotal role in optimizing supply chain management. AI-driven tools will analyze data across the entire supply chain, predicting demand fluctuations, optimizing inventory levels, and even identifying suppliers that can offer the best prices based on historical data. This integration of ML into manufacturing supply chains will result in cost reductions, quicker response times, and more agile operations.

Tip: Invest in machine learning solutions that connect the dots across your entire supply chain, from raw materials to end-user delivery. This holistic approach will give you a competitive edge in an ever-evolving market.

Smart Production Lines Powered by ML

The future of manufacturing lies in intelligent, self-optimizing production lines. With machine learning in production, factories will become increasingly automated, with systems that adapt in real-time to changes in workflow, machine performance, and even market demands. These “smart factories” will be able to self-correct in case of errors, optimize resource use, and reduce waste—resulting in higher efficiency and lower operational costs.

Tip: Start experimenting with small-scale smart systems in your production lines to understand how they can adapt to your specific needs. Over time, scale them up as you identify the best practices for automation.

Quality Control Automation with Machine Learning

Machine learning will increasingly take over the role of quality control in manufacturing. AI-powered computer vision systems will inspect products during production, identifying defects, inconsistencies, and quality issues that human inspectors might miss. As machine learning algorithms improve, these systems will become more precise and faster, ensuring that only the highest-quality products make it to the consumer.

Tip: Look into implementing ML-driven quality control systems that integrate seamlessly with your existing production processes. These systems can operate 24/7, ensuring consistent product quality without manual intervention.

AI-Driven Customization in Manufacturing

As consumer demands for personalized products rise, ML will enable greater customization in manufacturing. By analyzing customer preferences, usage data, and other variables, manufacturers will be able to create highly personalized products at scale. This trend, known as mass customization, will allow businesses to meet the growing demand for unique, tailored products while maintaining cost efficiency.

Tip: To capitalize on mass customization, explore how ML can help you better understand customer needs through data analysis and predictive analytics. This will allow you to adjust production quickly and offer more customized options to your clients.

Sustainability and Efficiency with ML

Manufacturers will increasingly turn to machine learning to drive sustainability efforts. ML can analyze energy consumption patterns, optimize resource usage, and minimize waste during production processes. As global pressure mounts for more sustainable practices, ML will be at the forefront, helping businesses meet environmental standards and reduce their carbon footprint while maintaining profitability.

Tip: Implement machine learning solutions that focus on energy efficiency and waste reduction. This not only aligns with sustainability goals but also reduces operating costs in the long run.

Digital Twin Technology Revolutionizing Manufacturing Operations

Digital Twin technology, powered by machine learning and AI, will become a major trend in the manufacturing industry. A Digital Twin is a virtual replica of a physical asset, process, or system. It allows manufacturers to simulate, predict, and optimize performance in real-time without impacting the actual production line. By integrating ML with Digital Twins, manufacturers can anticipate issues before they arise, optimize machine performance, and monitor real-time data from multiple sources to make faster, more informed decisions.

As the manufacturing landscape becomes more connected, the use of Digital Twins will expand beyond single machines to entire factory ecosystems. This will allow businesses to simulate complex manufacturing processes, improve efficiency, and test new strategies without the risks of physical experimentation. Machine learning will continuously analyze the performance of the Digital Twin, improving the accuracy and reliability of the simulations over time.

Tip: Begin by experimenting with Digital Twin technology in specific areas of your operation, like machine health monitoring or production line optimization. As you gain insights, expand its use across your entire facility to unlock deeper insights and smarter decision-making.

Hyper-Personalization in Manufacturing

Hyper-personalization is set to become a major trend, driven by machine learning’s ability to analyze consumer behavior and preferences at scale. Businesses will increasingly use ML algorithms to create products tailored to individual customer needs, while maintaining high production efficiency. Machine learning in manufacturing allows companies to gather and process data from multiple sources, enabling the customization of products on a mass scale, without the complexities and costs associated with traditional bespoke manufacturing.

Tip: Embrace hyper-personalization by integrating ML-driven customer insights into your production lines. This will allow you to offer personalized products while optimizing production costs and maintaining scalability.

Autonomous Factories Powered by Machine Learning

The future of manufacturing lies in the creation of autonomous factories where machines and robots operate independently, continuously optimizing production without human intervention. ML algorithms will enable factories to autonomously adjust production schedules, maintenance schedules, and supply chain logistics. These self-optimizing systems will drive significant improvements in efficiency, reduce human error, and enable 24/7 operations.

Tip: Start small with automation in areas like quality control or predictive maintenance. As your system matures, gradually scale to more complex processes for a fully autonomous production line.

TinyML for Edge Computing in Manufacturing

TinyML, which refers to running machine learning models on small, low-power devices, will be an exciting advancement for manufacturing. These low-cost, energy-efficient devices can be embedded in machines and sensors directly on the factory floor. By enabling edge computing, TinyML allows for real-time, on-site analysis, reducing the need for cloud-based processing and ensuring faster decision-making in manufacturing environments.

Tip: Explore integrating TinyML into your factory equipment to make your production processes more responsive and energy-efficient, especially in remote or resource-constrained environments.

AutoML: Democratizing Machine Learning in Manufacturing

AutoML (Automated Machine Learning) is the next frontier in simplifying the integration of AI/ML in manufacturing. With AutoML, businesses no longer need highly specialized data scientists to build complex ML models. This technology automates the process of selecting, training, and tuning machine learning models, making it accessible to manufacturers with limited ML expertise. As AutoML becomes more refined, it will empower even smaller manufacturers to harness the power of ML for a wide range of use cases—from predictive maintenance to supply chain optimization.

Tip: Invest in AutoML tools to unlock the potential of machine learning across various functions, without requiring deep technical knowledge in data science.

Explainable AI for Transparent Manufacturing Decisions

As AI becomes increasingly prevalent in manufacturing, the need for explainable AI (XAI) will grow. Unlike traditional “black box” AI, explainable AI offers transparency into how decisions are made, making the results of machine learning models more understandable and trustworthy. In manufacturing, this is especially crucial for quality control, safety, and regulatory compliance. XAI will allow manufacturers to trace decisions, identify potential issues, and ensure accountability across operations.

Tip: Begin integrating explainable AI tools into your production systems to enhance trust and transparency, and to meet the increasing demand for compliance and safety in manufacturing environments.

Collaborative Robotics in Manufacturing

Collaborative robots, or cobots, will work alongside human operators to streamline production processes. These robots, powered by AI and machine learning, will be designed to interact safely and effectively with humans, assisting in repetitive tasks or handling dangerous operations. As manufacturing environments become more dynamic and complex, cobots will improve flexibility, efficiency, and safety, allowing human workers to focus on higher-level tasks.

Tip: Integrate cobots into your workflow to automate repetitive, high-risk tasks, while freeing up human workers to engage in more value-added operations. This collaboration will enhance both safety and productivity.

While these trends highlight where manufacturing is headed, realizing their value depends on how effectively machine learning is implemented today. Manufacturers that invest early in scalable, enterprise-grade ML architectures and clear implementation roadmaps will be best positioned to adapt, innovate, and lead in the next decade.

Let’s help you lead the next wave with ML-driven manufacturing software built for what’s next.

Get Started with Manufacturing Machine Learning with Appinventiv

Machine learning is transforming manufacturing, offering powerful tools to enhance efficiency, solve critical challenges, and improve the bottom line across departments. Whether you are a CTO, Head of Manufacturing, Operations Leader, or Digital Transformation Owner, integrating machine learning into manufacturing operations requires more than just models—it demands enterprise-ready architecture, system integration, and execution expertise.

However, to leverage the maximum potential of machine learning in manufacturing, it is essential to set clear business objectives and partner with a reputed machine learning development company.

At Appinventiv, we help manufacturers move from experimentation to enterprise-scale machine learning implementation. Our teams design, integrate, and deploy ML systems that work seamlessly across production lines, data platforms, and existing enterprise infrastructure—without disrupting ongoing operations.

We offer manufacturing-focused AI and machine learning services, including predictive maintenance systems, quality inspection automation, supply chain intelligence, and production optimization designed to integrate seamlessly with MES, ERP, IoT, and OT environments.

Whether you need to develop a custom ML model or implement machine learning across existing manufacturing systems, we help you design, integrate, and scale enterprise-grade ML solutions aligned with your operational goals.

Talk to our experts to explore how machine learning can be implemented effectively within your manufacturing operations to deliver measurable business outcomes.

FAQs

Q. What are the advantages of machine learning in manufacturing?

A. The benefits of machine learning in manufacturing processes are innumerable and undeniable, revolutionizing the industry in various ways. Here are some of the most remarkable benefits of AI/ML in manufacturing:

Reduce Cost: AI/ML helps reduce costs by optimizing inventory, automating tasks, planning maintenance, extending equipment life, and minimizing defects.

Improve Quality: ML algorithms enhance product quality by detecting and addressing defects swiftly, leading to fewer returns and a stronger reputation.

Enhance Efficiency: Machine learning analyzes large datasets to streamline processes, cut downtime, and ensure a smooth production flow, thus improving efficiency.

Improve Worker Safety: ML-powered predictive analytics and sensor systems improve worker safety by identifying patterns in the workplace and monitoring equipment health conditions.

Informed Decision-Making: Machine learning in the manufacturing industry enables real-time data analysis, allowing for quick adjustments in production, inventory management, and quality control to stay ahead of market changes.

Q. How to implement machine learning in manufacturing?

A. Implementing machine learning (ML) in manufacturing can be a transformative journey. Here’s a quick roadmap to get started:

- Data Collection: Gather data from various manufacturing processes, machines, and systems.

- Focus Areas: Identify key use cases such as predictive maintenance, quality control, or process optimization.

- Choose Tools: Select ML platforms that integrate seamlessly with existing systems.

- Model Training: Train models using historical data to make predictions and test them in real-world settings.

- Scalability: Ensure your solution can scale with your growing data needs.

Q. What is the primary role of machine learning (ML) in manufacturing?

A. The primary role of machine learning (ML) in manufacturing is to enhance operational efficiency by enabling data-driven decision-making, optimizing processes, and predicting outcomes. ML algorithms analyze vast amounts of data from production lines, sensors, and machinery to detect patterns, predict equipment failures, and optimize workflows. This leads to improved predictive maintenance, reduced downtime, and more consistent product quality. By leveraging the deep connection of machine learning and manufacturing, businesses can streamline their operations, lower costs, and stay competitive in a fast-evolving industry, ultimately driving growth and innovation.

Q. How do I evaluate ROI on ML-driven predictive maintenance solutions?

A. Evaluating ROI on ML-driven predictive maintenance can be done by considering:

- Reduced Downtime: Savings from fewer unplanned maintenance events.

- Cost of Maintenance: Savings on maintenance and repairs through proactive interventions.

- Improved Equipment Lifespan: Extended life of machinery through timely maintenance.

- Increased Productivity: Enhanced efficiency from minimized disruptions.

Q. How can machine learning be integrated into legacy factory systems?

A. Integrating ML into legacy systems can be streamlined by:

- Data Integration: Connecting older machines to modern data systems.

- Pilot Programs: Start with small ML use cases like predictive maintenance.

- Cloud-Based Solutions: Use cloud-based platforms to avoid hardware upgrades.

- API Integration: Leverage APIs to connect ML solutions with legacy systems.

- Continuous Improvement: Regularly update and retrain models to optimize processes.

Q. How long does it take to implement ML-based predictive maintenance or quality control in a manufacturing setting?

A. With Appinventiv, you can expect an initial pilot / proof-of-concept phase to take about 6-10 weeks. This includes goals definition, data gathering from sensors/machines, initial model training, and small-scale deployment. Full implementation—integrated into production systems, real-time monitoring, quality control usually spans 3 to 6 months, depending on complexity, number of machines or lines, and infrastructure readiness.

Q. What data do I need to start with ML solutions in manufacturing (e.g. predictive maintenance, anomaly detection, smart inventory)?

A. You will need:

Historical machine logs & sensor data (temperature, vibration, usage etc.)

Production / operational data (throughput, downtime, quality defects)

Inventory & supply chain records (stock levels, lead times, parts usage)

Product design or specification data (when doing quality control or optimization)

Appinventiv can help you assess your existing data, clean & preprocess it, and set up pipelines so it’s usable for ML.

Q. What are the risks & challenges in applying ML in manufacturing, and how does Appinventiv mitigate them?

A. Some of the key challenges and how Appinventiv addresses them are:

High upfront cost & infrastructure → We start with pilot projects to prove value and use cloud/hybrid setups to minimize heavy infrastructure investment.

Data quality & availability → Our team performs data audits, cleans inconsistent data, and integrates multiple sources like IoT sensors, ERP, and logs.

Integration with legacy systems → We use APIs, middleware, and modular architectures to ensure smooth compatibility and incremental roll-outs.

Model interpretability & trust → We use interpretable models when required, apply explainability tools, and set up continuous monitoring for reliability.

Talent shortage & resistance to change → Appinventiv brings in expert teams, trains internal staff, and introduces phased onboarding to ease adoption.

Data security & privacy → We ensure compliance with global standards, implement strong encryption, and safeguard sensitive data throughout the process.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Top Machine Learning Trends the C-Suite Needs To Watch in 2026

Key takeaways: C-suite focus shifts from “doing AI” to providing clear P&L, risk, and efficiency impact from machine learning in 2026. Nine ML trends matter most: agentic AI, multimodal, decision intelligence, governance, edge, MLOps, responsible AI, domain models, and AI security. Executives should treat ML as a portfolio: near-term run-the-business bets, change-the-business bets, and non-negotiable…

10 Use Cases and Examples of How Machine Learning is Transforming the Logistics Industry

The widespread adoption of ML has resulted in the explosion of data from sensors, customer interactions, and digital platforms across different domains. More and more businesses are leveraging machine learning in logistics to improve their strategic decision-making expertise centered around tailoring customer experience, improving productivity, increasing engagement, and preventing fraud. According to the McKinsey Global…

Key takeaways: Machine learning in retail is reshaping the industry through smarter recommendations, dynamic pricing, and real-time personalization. AI & ML deliver measurable ROI, helping brands boost conversions by up to 40% and unlock multiple operational advantages. Successful ML implementation in retail requires high-quality data, scalable infrastructure, and continuous model optimization. With 10+ years of…