- Getting Real Returns from Artificial Intelligence in Manufacturing

- Finding Your AI (for Manufacturing) Sweet Spots

- Building a Data Foundation That Works for AI in the Manufacturing Industry

- Making AI (Manufacturing) Work with Existing Systems

- Solving the AI Manufacturing Talent Problem

- Working with AI Partners

- Security in the AI Era

- New Attack Surfaces

- Bridging IT and OT Security

- Protecting Your Data

- Building Resilient AI Systems

- Managing Vendors and Compliance

- Moving from AI Vision to AI Manufacturing Reality

- Questions Manufacturing Leaders Ask

- Q. How long before we see real returns from AI investments?

- Q. How do we handle integration risks when connecting AI to existing manufacturing systems?

- Q. What should a manufacturing AI readiness assessment cover?

- Q. What data infrastructure is essential for manufacturing AI at scale?

- Q. How do we keep AI implementations ethical while meeting operational requirements?

- Q. What are the most common AI applications in manufacturing today?

- Q. How is AI used in manufacturing market evolving?

- Q. What's the impact of AI in manufacturing on workforce requirements?

- Q. How do we choose the right AI tools for our manufacturing operations?

- Q. What role does artificial intelligence play in modern manufacturing?

- Q. How do we measure success with AI in the manufacturing initiatives?

Your AI Manufacturing Reality Check:

- Integration that actually works – Connect AI to your existing MES and ERP systems without expensive overhauls or operational disruptions.

- Real ROI roadmap – From predictive maintenance that pays for itself in 6 months to supply chain optimization delivering 25% forecast improvements

- Security without paranoia – Practical frameworks that protect both your data and production lines without shutting down operations

- Sound examples – Real manufacturers solving real problems, not theoretical case studies from consulting firms

- Stop the expensive hiring mistakes – Partner with AI experts who actually understand manufacturing operations, not generic tech consultants.

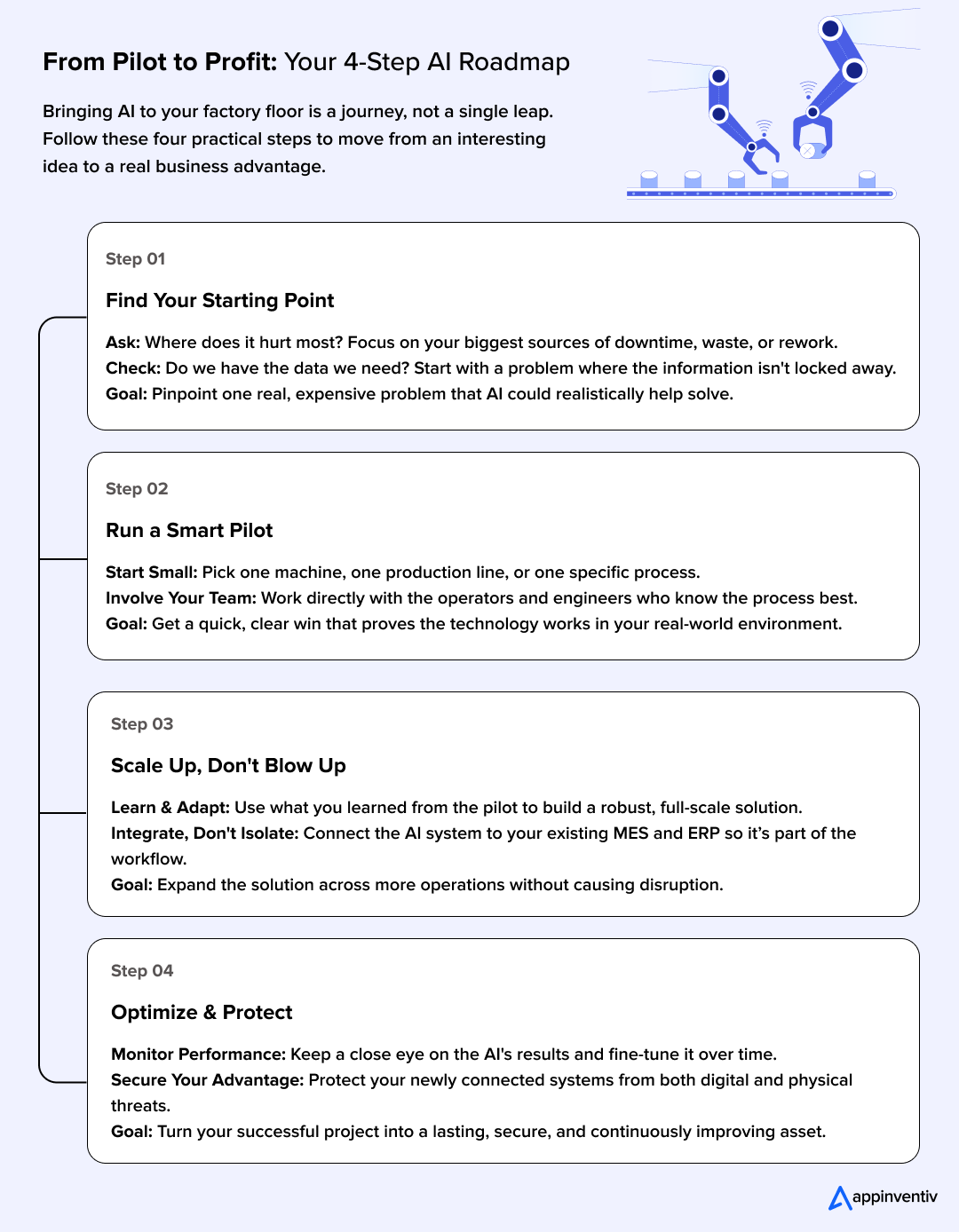

From pilots to profit: A practical roadmap for manufacturing leaders.

The conversation around AI in manufacturing has changed. You’re no longer asking if you should adopt AI—you’re trying to figure out how to make it actually work at scale, secure it properly, and get real returns.

I’ve worked with dozens of manufacturing CTOs and CIOs over the past few years. The challenges are always the same: pilots that never scale, talent shortages that slow everything down, and security concerns that keep you up at night.

Here’s what I see happening: manufacturers spend months on impressive demos that showcase AI’s potential. Then they struggle to move beyond the pilot phase. The technology works fine in controlled environments, but scaling AI for manufacturing across enterprise operations is where most projects die.

Three problems kill most manufacturing AI projects:

- ROI gaps – Moving from interesting pilots to measurable business value that affects your bottom line

- Talent shortages – Finding people who understand both AI in manufacturing and your industrial operations

- Security risks – Protecting operations as you connect more systems and devices

This guide covers the practical solutions we’ve used to solve these problems. No theory, just what actually works when implementing AI manufacturing solutions in real industrial environments.

Getting Real Returns from Artificial Intelligence in Manufacturing

Most AI projects fail because companies approach them backwards. They start with technology and look for problems to solve. That’s why your board asks tough questions about AI spending while your competitors quietly pull ahead in the AI in manufacturing market.

Why Pilots Stay Pilots

The biggest ROI killer isn’t failed technology—it’s successful pilots that can’t scale. The facts state: 42% of companies expected to abandon their AI initiatives in 2025, up from 17% in 2024. These projects work great in test environments but fall apart when you try to roll them out across operations. This pattern is common across the AI in the manufacturing sector, regardless of company size or industry segment.

Common scaling problems:

- Systems that work on clean test data but struggle with messy production data

- AI models that need constant tweaking by data scientists

- Solutions that improve efficiency but cost more to maintain than they save

- Projects that work until your production environment changes

Look at typical AI in manufacturing examples: predictive maintenance pilots that work perfectly on one machine but fail when deployed across different equipment types, or quality control systems that excel in lab conditions but struggle with varying lighting and environmental conditions on the factory floor.

Real ROI starts with understanding where inefficiency actually costs you money, not where AI-powered manufacturing applications look most impressive in demonstrations.

Finding Your AI (for Manufacturing) Sweet Spots

Stop chasing shiny AI applications. Start hunting for expensive operational problems.

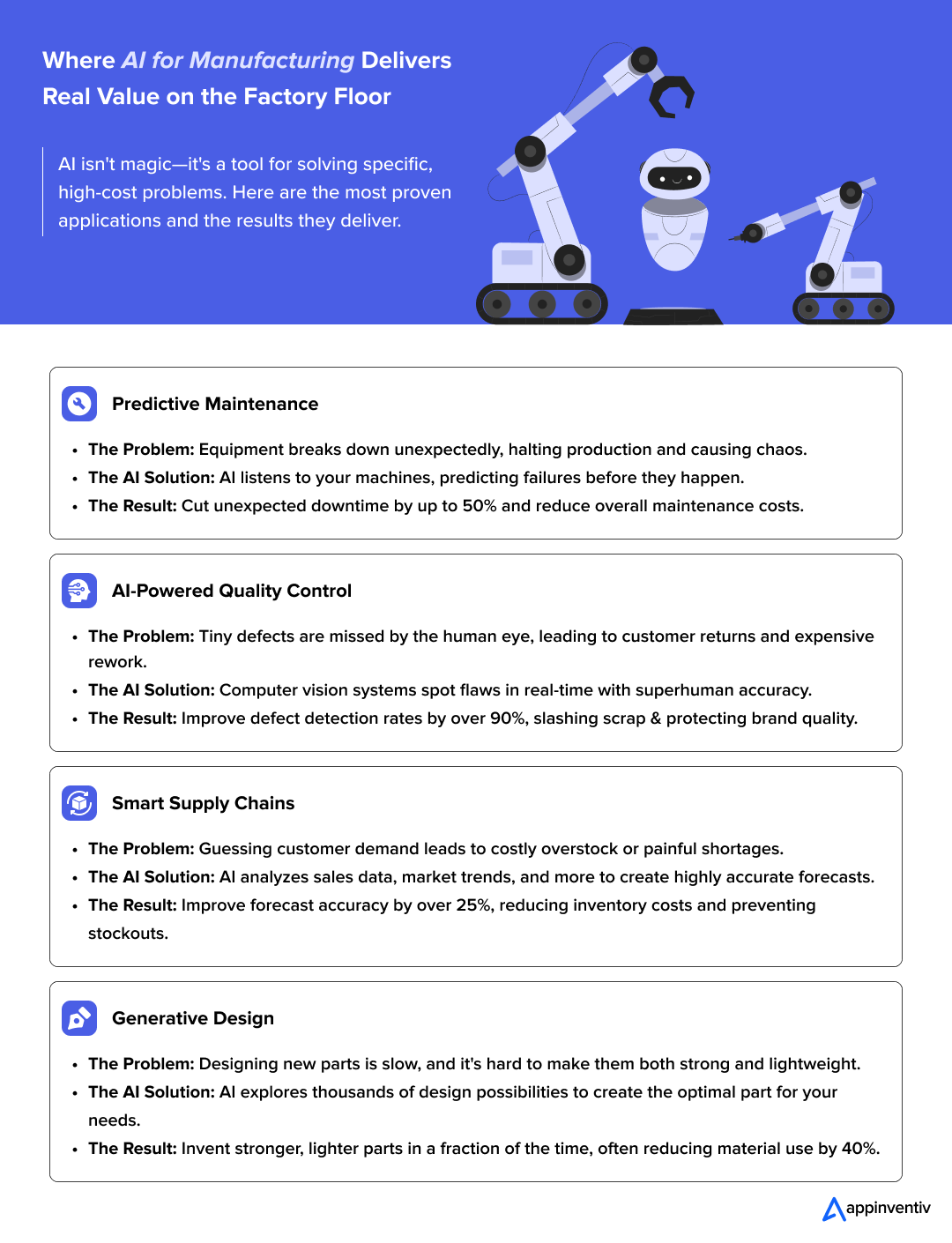

Every manufacturing operation loses money in predictable ways. Equipment breaks down at the worst times. Quality issues create expensive rework. Supply chain disruptions halt production. These pain points represent the real benefits of artificial intelligence in manufacturing when you address them systematically.

Take predictive maintenance—one of the most proven AI applications in manufacturing. Everyone talks about predicting equipment failures. But the real value comes from optimizing your entire maintenance operation. When you connect failure predictions to maintenance scheduling, inventory planning, and production planning, you’re not just preventing downtime—you’re optimizing operations.

Quality control demonstrates another powerful use of AI in manufacturing. Computer vision that spots defects is useful. Computer vision that spots defects and automatically adjusts upstream processes to prevent future defects is valuable. This represents the future of artificial intelligence in manufacturing —systems that don’t just detect problems but actively prevent them.

These AI in manufacturing examples highlight successful AI use cases in manufacturing that move beyond simple automation. The impact of AI in the manufacturing industry becomes significant when you think about AI as part of your operational system, not as a standalone tool. The most effective AI use cases in manufacturing solve multiple connected problems simultaneously rather than addressing isolated inefficiencies.

Some Facts: AI-driven predictive maintenance can increase runtime by 10 to 20%, reduce maintenance costs by up to 10%, and minimize maintenance scheduling time by up to 50%. (source)

Building a Data Foundation That Works for AI in the Manufacturing Industry

Your data determines everything else. Most manufacturers have valuable data trapped in separate systems across operations.

Your MES knows production status. Your ERP knows costs and schedules. Quality systems track defects. Maintenance systems monitor equipment health. The value comes from connecting these data streams intelligently through artificial intelligence in manufacturing applications.

But data integration isn’t just technical—it’s organizational. IT teams understand databases but not production data nuances. Operations teams understand the data, but not the technical requirements for AI and manufacturing systems.

Modern approaches like conversational AI in manufacturing can help bridge this gap by allowing operators to query production data using natural language, making complex data more accessible to non-technical teams. Similarly, generative AI in manufacturing can help create synthetic training data when real production data is limited or sensitive, accelerating model development while protecting proprietary information.

Making AI (Manufacturing) Work with Existing Systems

If your AI project requires replacing existing systems, you’re probably doing it wrong. Modern manufacturing runs on systems that work. The goal is to enhance these systems, not replace them.

This is what AI in the manufacturing industry should actually look like—intelligent enhancement rather than wholesale replacement. The best AI tools for manufacturing act as intelligent connectors between existing systems. They pull data from current systems, add AI insights, and feed actionable information back into existing workflows.

Your operators don’t need new interfaces. Your existing systems don’t need expensive modifications. AI becomes another data source that improves decisions within current processes. This approach reflects how artificial intelligence in the manufacturing industry creates value—by working with established operations rather than disrupting them.

We build systems that connect to what you have, improve what you do, and prepare you for what’s next.

Solving the AI Manufacturing Talent Problem

The talent market for implementing manufacturing AI is brutal. Finding people who understand both AI and industrial operations is nearly impossible. But you don’t need to win the talent war to succeed with AI.

The Hiring Trap

Most leaders approach AI talent like other technical hiring: post jobs, interview candidates, and make offers. This fails because you’re competing against tech companies that offer packages you can’t match.

The best AI talent for manufacturing isn’t necessarily people with computer science degrees. It’s people who understand your operational challenges and can translate them into technical solutions that address how can AI help manufacturing operations improve.

Sometimes that’s a manufacturing engineer who learned Python. Sometimes it’s a data analyst who has spent years understanding your production data. Sometimes it’s a maintenance manager who sees patterns others miss and understands how AI is used in manufacturing environments.

Building Internal Capabilities

Forget hiring a “Head of AI” to transform your organization. Manufacturing AI success requires distributed capabilities across roles and departments.

Start by identifying people in your organization who are naturally curious about technology and understand operational challenges. These aren’t necessarily technical people—they’re problem solvers who can bridge the gap between understanding how AI can help manufacturing and implementing practical solutions.

Train these champions to become translators between AI capabilities and business needs. They identify opportunities and communicate effectively with technical teams.

Your training should be role-specific:

- Manufacturing engineers need to understand what AI can and can’t do, not how to build models

- Maintenance managers need to understand predictive analytics applications, not algorithms

- Quality managers need to understand computer vision possibilities, not technical details

Create internal communities where people share successes, failures, and lessons learned. These become your knowledge base and change engine.

Working with AI Partners

Think about AI partnerships as capability extensions, not vendor relationships. The right partner doesn’t just deliver solutions—they transfer knowledge and build your internal capabilities.

Look for partners with deep manufacturing experience, not just AI expertise. They should understand regulatory requirements, operational constraints, and business models. They should speak your language, not just technical jargon.

The partnership model that works is embedded collaboration. AI partners should work alongside your teams, not in isolation. They should train your people while building systems. The goal is to reduce dependency on external resources over time.

This is how we work at Appinventiv. Our manufacturing AI specialists embed with your teams to build both solutions and capabilities. Through our Artificial Intelligence Development Services, we transfer knowledge while delivering results.

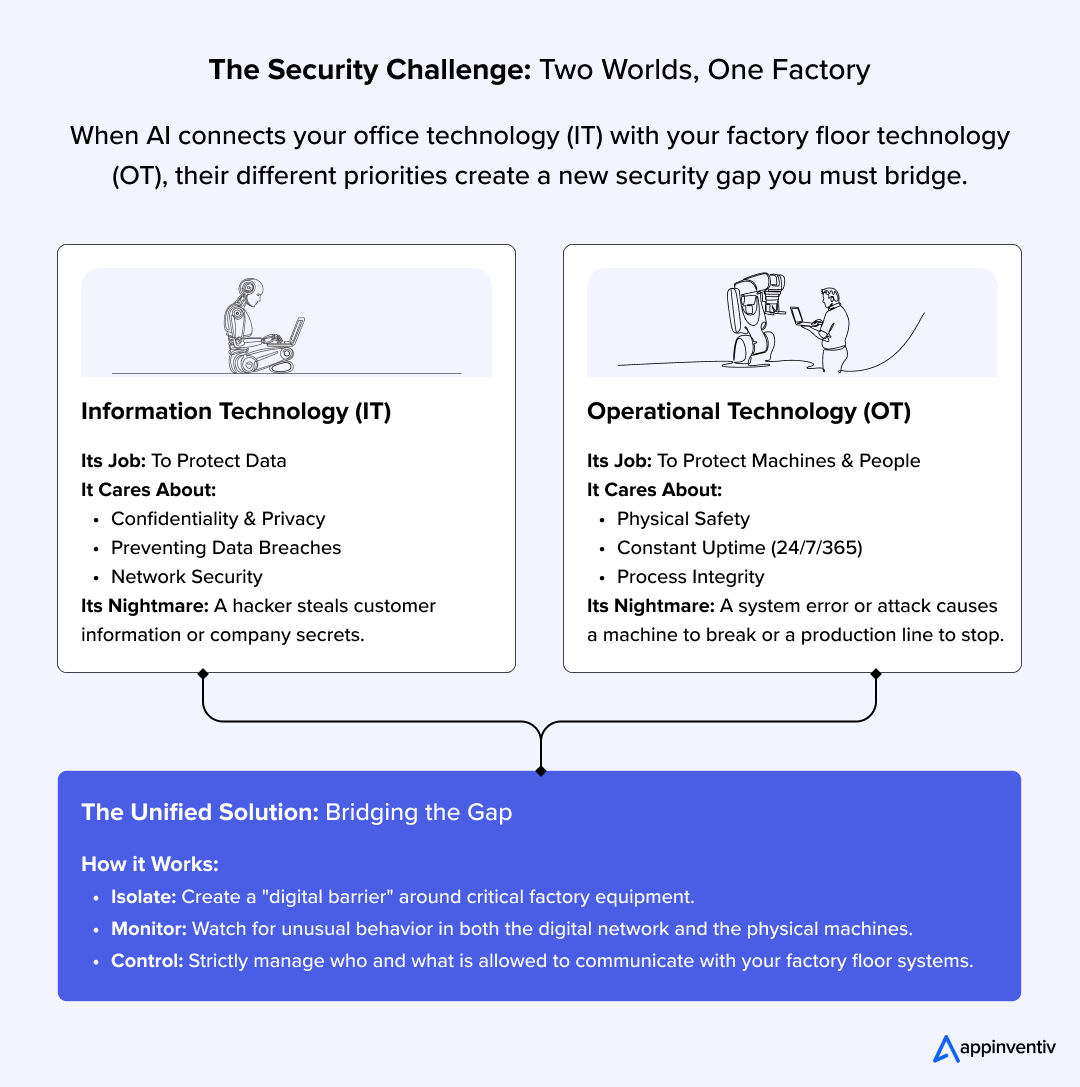

Security in the AI Era

Cybersecurity for manufacturing AI is fundamentally different from traditional IT security. When you add AI to manufacturing operations, you create new attack vectors that didn’t exist before.

New Attack Surfaces

Every AI implementation creates hundreds of new potential entry points. IoT sensors, edge devices, AI-enabled equipment, and data connections all represent vulnerabilities.

The real danger isn’t just more connection points—it’s how AI systems can be weaponized. Adversarial attacks can manipulate AI systems to make wrong decisions while appearing normal. Data poisoning attacks can gradually corrupt AI models, leading to poor decisions that go unnoticed.

The connection of operational technology and information technology, accelerated by AI, creates perfect storm conditions. Production systems designed for reliability are now connected to networks designed for access.

Bridging IT and OT Security

IT security teams understand networks but not manufacturing operations. OT teams understand manufacturing but not cybersecurity. This gap creates blind spots that attackers exploit.

Effective security requires unified approaches addressing both IT and OT needs. This means network segmentation that isolates critical systems while enabling necessary data flows. Access controls that handle manufacturing complexity while remaining operationally feasible.

Monitoring is particularly challenging. Traditional IT security tools don’t understand normal manufacturing patterns, creating false alarms that operators learn to ignore. Manufacturing operators don’t have the cybersecurity expertise to recognize sophisticated attacks.

Pro tip: This requires a unified security posture that aligns with standards like ISA/IEC 62443 to protect industrial control systems.

Protecting Your Data

AI systems are only as trustworthy as their data. In manufacturing, this often includes intellectual property, process parameters, and competitive information.

Traditional perimeter security isn’t enough. You need controls that follow data throughout its lifecycle—from factory floor collection through processing, analysis, storage, and disposal.

Start with encryption, but don’t stop there. You need techniques that protect sensitive information while preserving data utility for AI applications. Governance frameworks that control data access and usage. Audit trails that track how data is used and by whom.

Building Resilient AI Systems

AI system security depends on more than external attack protection. You need systems inherently resilient to manipulation and degradation.

When you understand how AI systems make decisions, you can detect abnormal behavior. Black box AI systems make it nearly impossible to identify compromise or manipulation.

Continuous monitoring and validation of AI performance is essential. You need automated systems that detect when AI models perform outside normal parameters, whether from data changes, model degradation, or malicious manipulation.

Managing Vendors and Compliance

The regulatory parameters for manufacturing AI evolve fast. You need frameworks that adapt to changing regulations while maintaining operational efficiency.

Vendor risk management becomes increasingly critical with the adoption of AI solutions in manufacturing. AI vendors access your most sensitive data and critical systems. Due diligence must include thorough security assessments, not just functional evaluations.

At Appinventiv, security is built into every aspect of our AI development. We understand manufacturing environments require approaches that protect both digital assets and physical operations. Our development methodology ensures every solution can withstand current threats and future challenges while maintaining operational performance.

Read more here- Cybersecurity in Manufacturing.

Moving from AI Vision to AI Manufacturing Reality

Success with manufacturing AI isn’t about technology—it’s about execution across multiple dimensions simultaneously. Organizations that succeed treat AI as a comprehensive business capability, not just a technology deployment.

AI’s competitive advantages in manufacturing are real but not automatic. They require disciplined execution across ROI optimization, talent development, and security implementation.

Your AI journey should be measured in business outcomes, not technology deployments. Focus on use cases that generate measurable value. Build capabilities that compound over time. Create security frameworks that protect competitive advantages.

The goal isn’t implementing AI everywhere—it’s implementing AI where it creates sustainable competitive advantage.

Ready to move beyond AI pilots to real manufacturing value? At Appinventiv, we help manufacturing leaders navigate from AI vision to operational reality. Our approach combines industrial expertise with practical AI capabilities to deliver solutions that drive measurable results.

Check our Artificial Intelligence Development Services

Questions Manufacturing Leaders Ask

Q. How long before we see real returns from AI investments?

A. The timeline depends on your starting point and applications. AI in manufacturing implementations, like predictive maintenance analytics, show results within 6-9 months if you have a decent data infrastructure. Complex AI for manufacturing applications like supply chain optimization typically needs 12-18 months for full value.

Success comes from phased approaches that deliver incremental value at each stage. Most successful AI manufacturing solutions follow a progressive build that demonstrates value continuously rather than waiting for complete deployment.

Q. How do we handle integration risks when connecting AI to existing manufacturing systems?

A. Integration risk starts with architecture planning that treats existing systems as constraints, not obstacles. We use AI and manufacturing approaches that create clean interfaces between AI for manufacturing applications and legacy systems, minimizing modifications to existing infrastructure.

The key is building translation layers that handle integration complexity while maintaining operational stability. This lets you add AI manufacturing solutions without disrupting proven systems.

Q. What should a manufacturing AI readiness assessment cover?

A. Look, a proper assessment needs to dig into four key areas: your tech setup, how well you handle data, whether your people are ready, and if this whole thing actually makes sense for your business goals with artificial intelligence in manufacturing market.

You’ve got to check your current systems, see what connects to what, figure out if your security can handle it, and honestly assess where you’re short on talent. The assessment should point out some easy wins you can grab right away, show you where you’re really behind, and give you a step-by-step plan that actually fits how your operation works with AI for manufacturing.

Q. What data infrastructure is essential for manufacturing AI at scale?

A. Three things you absolutely can’t skip: a system that pulls together all your operational and IT data, something that can handle the massive amount of data manufacturing creates in real time, and rules that keep your data clean, secure, and legal for artificial intelligence in manufacturing market.

Honestly, the specific tech brands matter way less than getting the basics right. You need stuff that grows with you, adapts when things change, and plays nice with what you already have while being rock-solid reliable for AI manufacturing solutions.

Q. How do we keep AI implementations ethical while meeting operational requirements?

A. You’ve got to bake ethics into the whole process from day one with AI for manufacturing. That means making sure your training data represents reality, checking your models regularly for problems, using AI that you can actually explain to people, and having clear rules about how decisions get made.

Bottom line: your AI in the manufacturing systems needs to make decisions that are fair, make sense, and you can defend to regulators and your own people while still getting the job done.

Q. What are the most common AI applications in manufacturing today?

A. The stuff that’s actually working includes predicting when machines will break, using cameras to catch quality problems, making supply chains run smoother, and managing energy better. These AI use cases in manufacturing actually pay for themselves and aren’t rocket science to set up.

The benefits of artificial intelligence in manufacturing industry go way beyond just automating things. You get better decisions, less waste, and safer operations. Car companies are catching defects with computer vision, airplane manufacturers are predicting maintenance issues before they happen – these are real artificial intelligence in manufacturing examples that work.

Q. How is AI used in manufacturing market evolving?

A. The AI in the manufacturing market is finally growing up. Companies looking for AI in the manufacturing sector are done playing around with demos and actually rolling things out for real.

Where we’re heading with the future of artificial intelligence in manufacturing is smarter AI in the manufacturing setups, like generative AI in the manufacturing helping design better products ,and conversational AI in the manufacturing so operators can just ask questions instead of digging through manuals.

Q. What’s the impact of AI in manufacturing on workforce requirements?

A. Here’s the truth: the impact of AI in manufacturing on jobs is about changing what people do, not getting rid of them. AI in the manufacturing projects usually means training your current people for new stuff, not showing them the door.

You need folks who get both the old-school manufacturing side and the new AI tools for manufacturing. This is actually a chance for your manufacturing people to learn artificial intelligence in the manufacturing industry and become even more valuable.

Q. How do we choose the right AI tools for our manufacturing operations?

A. Start with what’s actually broken or costing you money, not what looks cool in a demo. The best AI tools for manufacturing fix real problems that hurt your bottom line.

Look for AI manufacturing solutions that work with what you’ve got and actually deliver what they promise. Pick vendors who understand AI-powered manufacturing challenges in the real world, not just the ones with the fanciest presentations about artificial intelligence in the manufacturing industry.

Q. What role does artificial intelligence play in modern manufacturing?

A. AI in manufacturing is basically the engine behind most serious AI applications in manufacturing. AI use cases in manufacturing cover everything from spotting patterns in quality data to figuring out the best way to schedule production.

The coming together of artificial intelligence and manufacturing more and more depends on advancing AI that gets smarter over time and adjusts when conditions change. That’s really what the future of AI in manufacturing is about.

Q. How do we measure success with AI in the manufacturing initiatives?

A. Success with AI in the manufacturing industry projects comes down to numbers that matter to your business. Track things like equipment running better, fewer quality problems, lower costs, and safer operations.

The benefits of AI in manufacturing show up when you can point to specific improvements you can measure. Keep an eye on both the quick wins from your first AI for manufacturing projects and the bigger strategic advantages from full AI manufacturing solutions.

How to Integrate AI with EHR/EMR Systems for Streamlined Healthcare Operations

Key takeaways: Not adopting AI in EHR/EMR today risks falling behind. AI streamlines EHR workflows, cutting clinical and admin delays. Real-world hospitals are already seeing faster, smarter care with AI. Seamless AI integration needs system checks, data prep, and training. AI in EHR tackles real challenges like bias, cost, and compliance. Custom AI integration costs…

AI Agent-Driven UIs: Replacing App Menus and Buttons

Key takeaways: Challenge: Static menus and buttons also become outdated because people are frustrated by limited, multi-stage navigation. Solution: The AI Agent interacts with the user through a friendly UI that does not require cludgy menus but conversational and context-sensitive navigation. The Way AI Agents Work: AI agents establish a basis of natural language understanding,…

10 Use Cases and Benefits of How AI Agents Are Revolutionizing the Retail Industry

Key takeaways: AI agents in the retail industry are revolutionizing businesses by enhancing customer experience and streamlining operations. From personalized recommendations to predictive analytics, AI offers tangible benefits like increased conversions and reduced costs. AI adoption can lead to scalable growth and a competitive edge in the retail industry. Retailers must consider data strategies, talent…