- Role of AI in the Logistics Industry: Understanding the Components Redefining Logistics Operations

- Predictive Analysis

- Computer Vision

- Autonomous Vehicles

- Big Data

- Generative AI

- Uncovering the Benefits of AI in Logistics

- Enriching Data Quality

- Enhanced Safety

- Timeless Delivery

- Reduced Operation Costs

- Better Transportation Prediction

- Improved Resource Management

- Customized Customer Experiences

- Use Cases of AI in Logistics: Understanding the Applications

- Route Optimization

- Inventory Management

- Predictive Maintenance

- Freight Matching

- Demand Forecasting

- Examples of Businesses Leveraging AI in Logistics and Supply Chain

- Amazon

- DHL

- FedEx

- UPS

- Maersk

- How Logistics Companies Can Start Embracing AI Innovation: A Step-by-Step Process

- Locate Major Issues

- Compare And Choose

- Plan AI Implementation

- Start Small and Grow

- Train And Support Staff

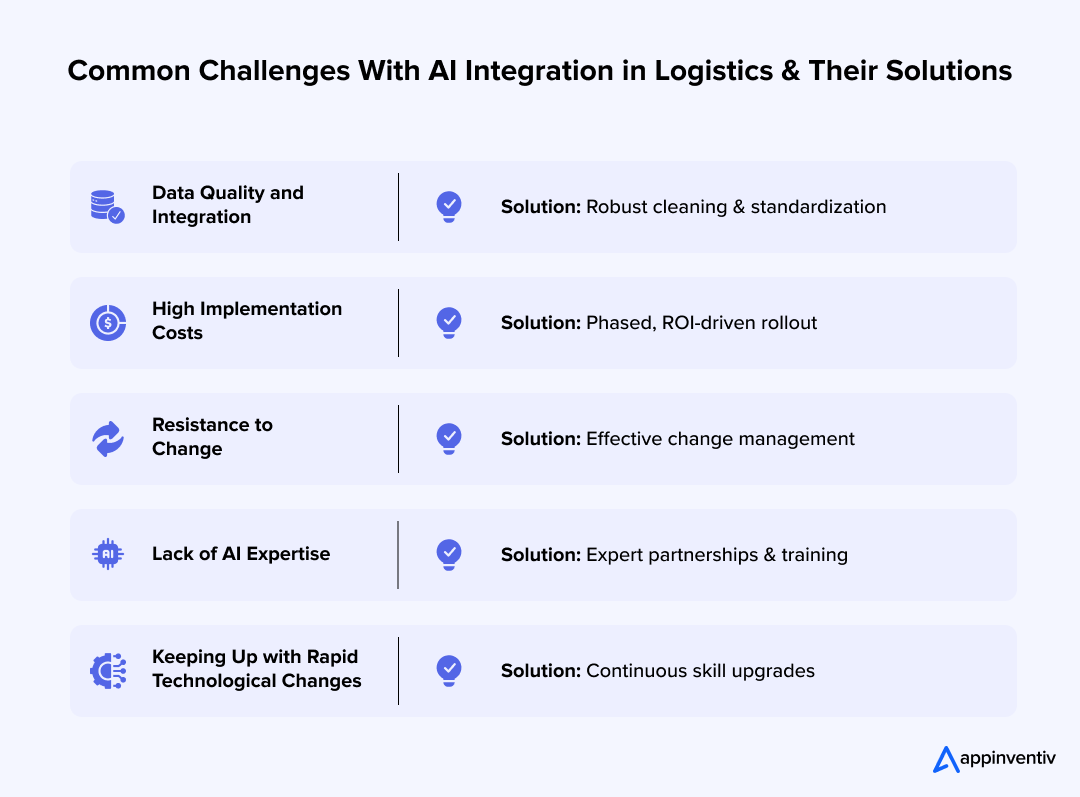

- Challenges Associated With AI in Logistics

- Data Quality and Integration

- High Implementation Costs

- Resistance to Change

- Lack of AI Expertise

- Keeping Up with Rapid Technological Changes

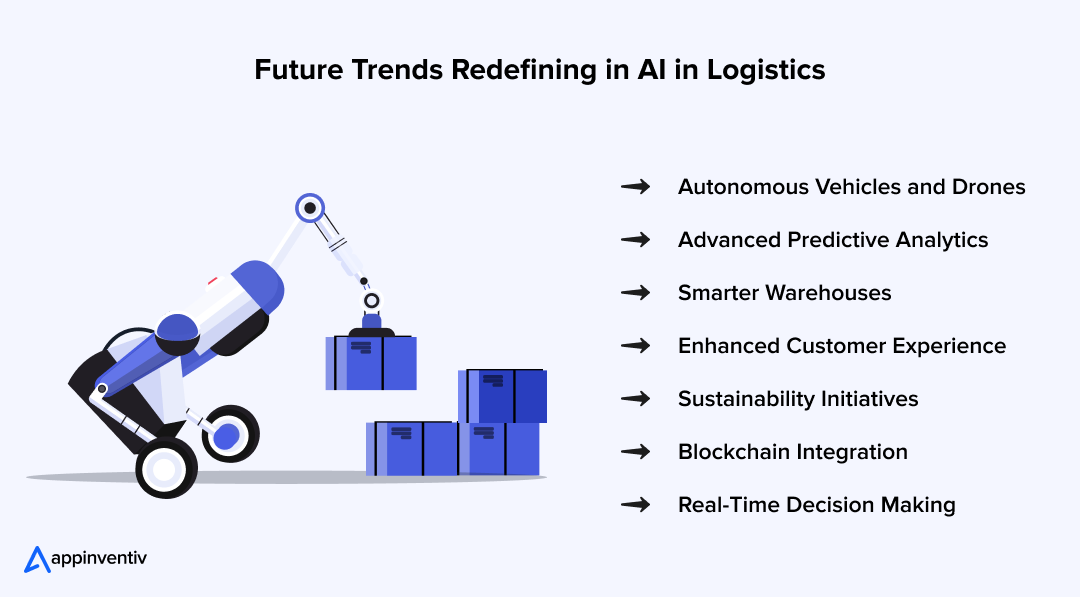

- What is the Future of AI in Logistics?

- Autonomous Vehicles and Drones

- Advanced Predictive Analytics

- Smarter Warehouses

- Enhanced Customer Experience

- Sustainability Initiatives

- Blockchain Integration

- Real-Time Decision Making

- How is Appinventiv the right partner for leveraging AI in logistics operations?

- FAQs

Artificial Intelligence (AI) has been a game-changer over the past decade, revolutionizing various sectors with its ability to analyze vast amounts of data, automate processes, and enhance decision-making.

From healthcare to finance, AI’s impact has been profound, but one of the most transformative effects can be seen in the logistics industry. By integrating AI technologies, logistics businesses have streamlined operations, reduced costs, and improved efficiency and customer satisfaction.

In logistics, AI’s role also extends to optimizing route planning, automating warehouses, and forecasting demand with unprecedented accuracy. Technologies like machine learning, predictive analytics, and autonomous vehicles are not just futuristic concepts but are currently in action, reshaping how products are moved and managed globally.

For instance, AI-driven predictive analytics helps companies anticipate demand fluctuations, while computer vision systems streamline the sorting and tracking of shipments.

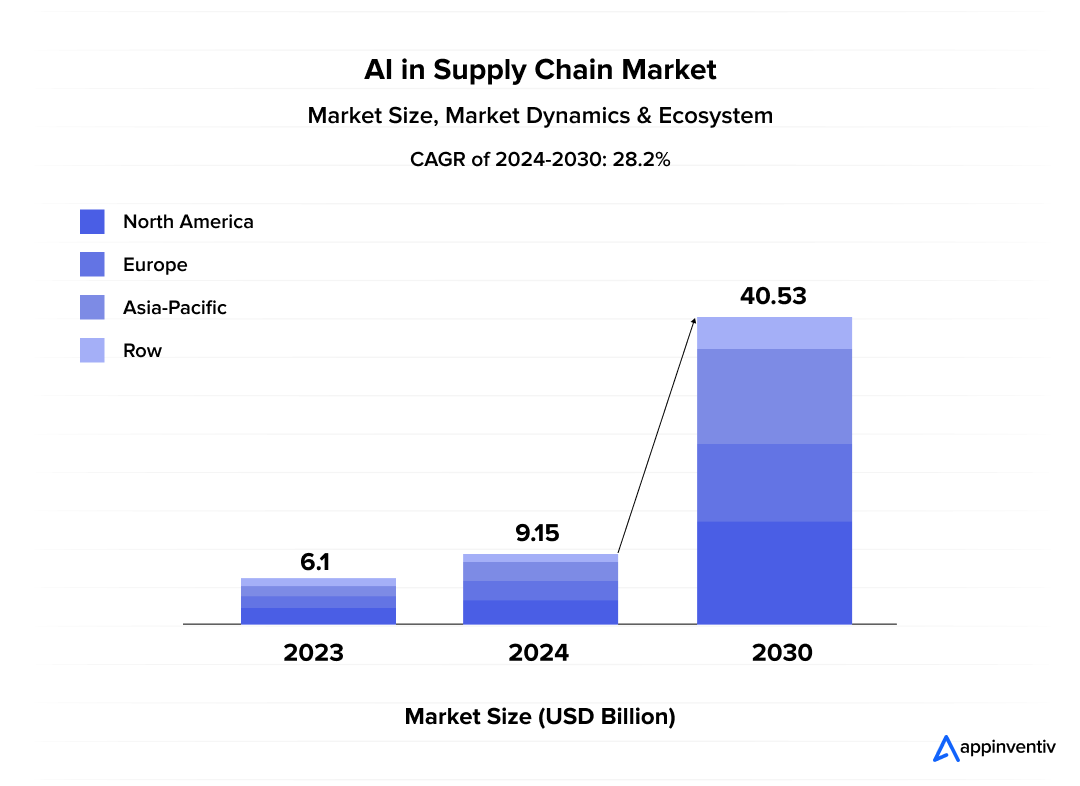

One key factor driving AI in the supply chain market is the growing demand for AI solutions in logistics and supply chain risk management. According to Markets and Markets, the AI in the logistics and supply chain market is projected to grow from USD 9.15 billion in 2024 to reach USD 40.53 billion by 2030, growing at a CAGR of 28.2% from 2024 to 2030.

This blog will delve into AI’s key benefits and use cases in logistics, highlighting how these technologies enhance current operations and pave the way for new capabilities. Let’s unpack the specific components of AI that are making a difference and discuss real-world applications that showcase AI’s potential to revolutionize the industry.

Role of AI in the Logistics Industry: Understanding the Components Redefining Logistics Operations

AI has fundamentally shifted the landscape of the logistics industry, transforming it into a more efficient and predictive sector. Integrating AI helps companies navigate the complexities of supply chain management, from forecasting and inventory management to delivery and customer service.

By harnessing the power of AI, logistics operations are becoming more efficient and adaptable to the market’s changing demands. This adaptability is crucial when consumer expectations continuously evolve and the pressure to deliver faster, more accurate services constantly increases.

Brands working at neighborhood scale are also moving toward hyperlocal delivery app development to match one hour delivery expectations in dense urban zones.

Simply put, leveraging AI in logistics is emerging as the smart pathway for business success:

- A 2024 survey by Zogby Strategies and Xometry revealed that 97% of manufacturing CEOs plan to integrate AI into their operations within the next two years.

- Research from McKinsey & Company shows that early adopters of AI-powered supply chain software enjoy 15% lower logistics costs and 35% improved inventory levels compared to their peers.

- DHL’s Logistics Trend Radar reports that AI grew by 50% in 2023, with explosive compounded growth projected through 2030.

These impressive figures highlight the strategic benefits of embracing AI in logistics, driving cost savings, efficiency, and competitive advantage. Let’s now explore the key AI technologies powering these transformative changes in the industry.

Predictive Analysis

One of the standout components of AI in logistics is predictive analysis. This technology uses historical data and machine learning algorithms to forecast future trends and behaviors, allowing companies to manage inventory and optimize supply chains proactively. For example, predictive analysis can anticipate peak demand periods, adjust stock levels accordingly, and suggest the best delivery vehicle routes to minimize delays and fuel consumption.

Computer Vision

Computer vision technology equips AI systems to interpret the environment visually within a logistics setting. This capability is especially useful for inspecting and sorting packages, identifying damage, and ensuring shipments meet quality standards. By integrating computer vision, logistics companies can automate the scanning and tracking of goods, significantly speeding up processing times and reducing the reliance on manual labor.

Autonomous Vehicles

Autonomous vehicles are redefining delivery processes by enabling goods to be transported with minimal human intervention. These vehicles use AI to navigate routes and handle real-time obstacles, making deliveries faster and more cost-effective. From drones delivering packages to self-driving trucks transporting goods across states, autonomous vehicles are a significant step towards smarter, more autonomous logistics operations.

[Also Read: AI in Transportation – 10 Benefits and Use Cases for Modern Enterprises]

Big Data

Big data refers to the enormous data generated from various logistics activities. AI excels in processing and analyzing this data to extract meaningful insights, which can be used to improve everything from route planning to customer delivery times. Big data analytics help logistics companies become more responsive and predictive, tailoring their operations to meet specific demands and conditions.

Generative AI

Generative AI in the supply chain and logistics industry is pioneering new ways to address complex logistical challenges. It can simulate different supply chain scenarios, predict outcomes, and recommend the most efficient actions. Generative AI is particularly useful in scenario planning and risk management, providing logistics companies with the tools to build more resilient and flexible operations.

“I feel like the more exciting opportunities of AI in manufacturing will come from things that we couldn’t even attempt to do before, like capacity sharing between manufacturers, improving visibility in supply chains, even sharing of trucks in a logistics chain.”

By Alexandra Brintrup, Professor at the University of Cambridge’s Institute for Manufacturing

While AI offers powerful capabilities for logistics optimization, implementing modern supply chain automation requires a holistic approach that combines multiple technologies working together seamlessly.

We hope the above components of AI have helped you understand the answer to the question, “How is artificial intelligence used in the logistics industry?” Let’s now move on and understand how leveraging AI in logistics benefits the companies in detail below.

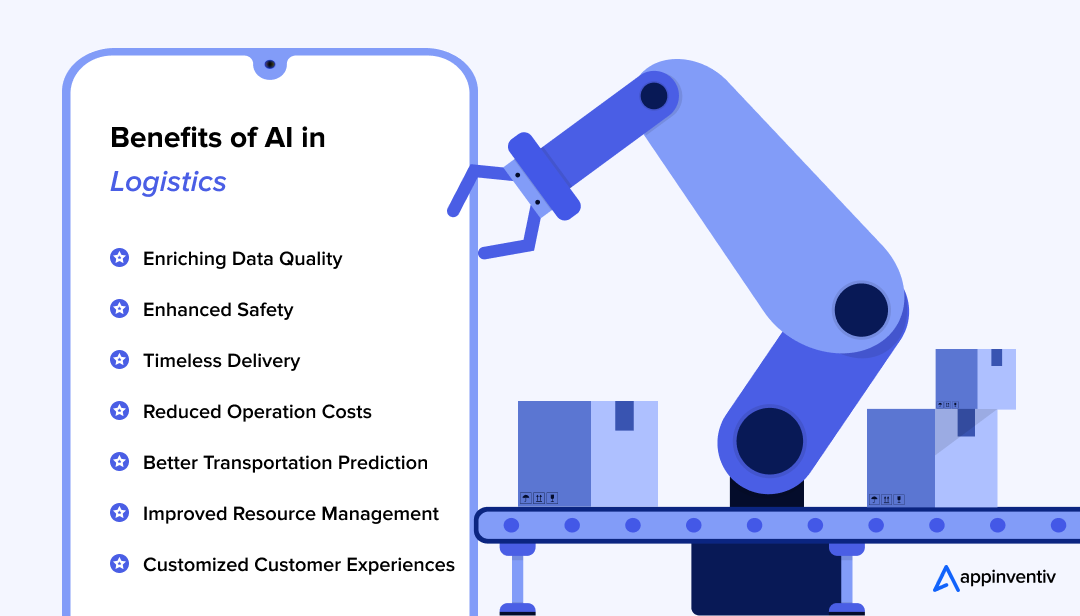

Uncovering the Benefits of AI in Logistics

Artificial intelligence (AI) in logistics has witnessed rapid growth and has become integral and indispensable to companies. According to TechCo, by 2035, AI will increase logistics productivity by more than 40%. They help boost management capabilities and organize work in the enterprise or startup. Here are some of its advantages that demonstrate how AI logistics solutions are improving the sector:

Enriching Data Quality

A study by McKinsey & Company indicates that AI-powered logistics management systems can improve services by 65%. The main advantage of AI’s use in logistics will always be the data quality it helps to ascertain. AI capabilities like NLP and ML in logistics assist in accurately gathering and organizing the enormous amounts of information that go into logistics organizations daily. NLP can understand commonly used words, phrases, and even jargon, and ML can connect these essential ideas to build context and learn as these words change.

AI is more accurate than ever thanks to faster and better global connections. When used in logistics, it will allow for the best possible data utilization in shipping. AI maximizes resources and reduces costs by preventing dangers and developing more effective solutions.

Enhanced Safety

AI-based automated technologies make intelligent planning and effective warehouse management possible, improving worker and material safety. AI may also examine data on workplace safety and alert manufacturers to potential dangers. It can update operations, record stocking parameters, and perform essential feedback loops and preventative maintenance. This enables manufacturers to respond quickly and forcefully to maintain the safety and compliance of warehouses.

Timeless Delivery

One of the major benefits of AI in logistics and supply chain is timely delivery. AI systems can help reduce reliance on manual efforts, resulting in a faster, safer, and more intelligent overall process. This makes it easier to fulfill the promise of prompt delivery to the consumer. Traditional warehouse processes are accelerated by automated technologies, with the least effort required to meet delivery deadlines.

Reduced Operation Costs

Automated intelligent processes can operate without errors for extended periods, decreasing the number of mistakes and workplace incidents from customer service to the warehouse. With their increased speed and accuracy, warehouse robots are more productive.

Better Transportation Prediction

Transportation forecasting, powered by AI and machine learning, predicts price variations and future capacity in logistics markets. This technology enables companies to proactively manage their shipping needs, securing accommodations at favorable prices. AI collects extensive market data, improving the efficiency of supply chain integration and shortening the traditional timeline for transportation planning.

Improved Resource Management

Overall improvement in resource management is one of the leading benefits of artificial intelligence in logistics. AI optimizes resource use throughout the logistics chain, from predictive equipment maintenance to route optimization for delivery vehicles. This cuts down on wastage and ensures that every aspect of the logistics process is as efficient as possible, leading to significant cost savings and environmental benefits.

Customized Customer Experiences

By leveraging AI to analyze customer data and purchasing patterns, logistics companies can offer personalized experiences, anticipate customer needs, and optimize inventory accordingly. This level of customization enhances customer satisfaction and loyalty, which is critical in a competitive market.

While implementing AI-powered solutions, businesses should also evaluate the cost of developing delivery management software to create comprehensive logistics ecosystems.

After looking at the major advantages that highlight the role of artificial intelligence in logistics, let’s move ahead and understand in detail various AI use cases in logistics.

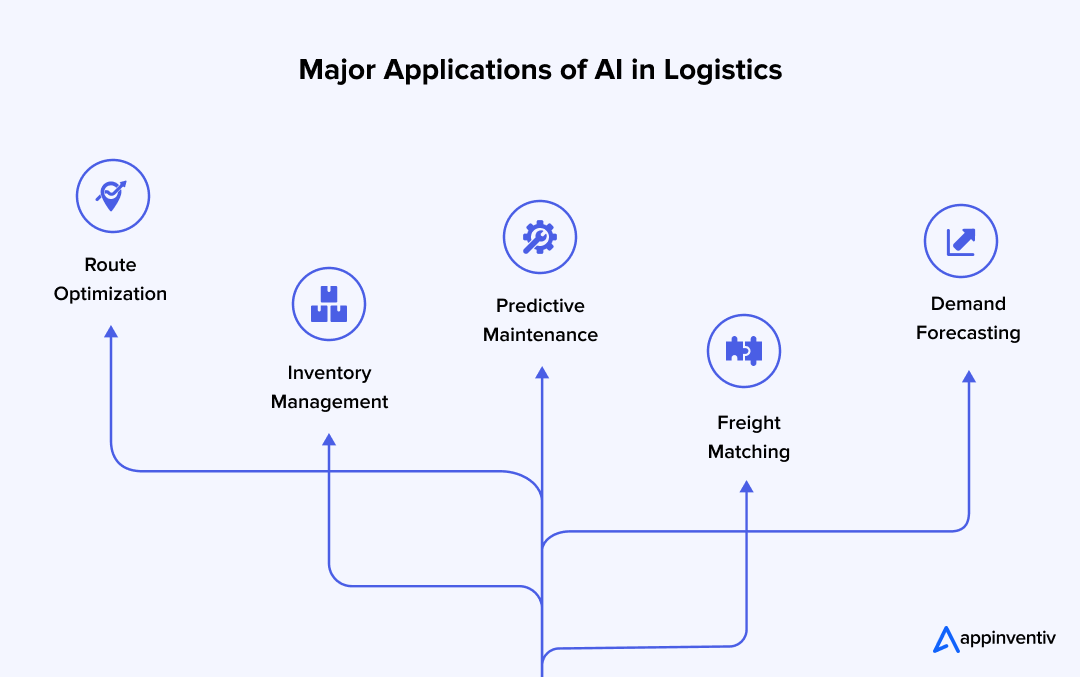

Use Cases of AI in Logistics: Understanding the Applications

AI rapidly transforms the logistics industry, offering increased efficiency and accuracy across various operations. By automating complex processes and analyzing large datasets, AI enables logistics companies to meet the modern demands of speed and reliability more effectively. Let us look at the major use cases of AI in logistics and supply chain below.

Route Optimization

AI optimizes delivery routes by analyzing traffic patterns, weather conditions, and delivery schedules to suggest the most efficient paths. This use of AI not only reduces fuel consumption and delivery times but also helps minimize logistics operations’ carbon footprint.

According to the World Economic Forum, AI adopters in logistics and transportation report fuel savings exceeding 15% annually, making a tangible difference in operational efficiency. Efficient routing ensures vehicles spend less time on the road, reducing wear and tear and maintenance costs.

Inventory Management

Artificial intelligence in logistics systems enhances inventory management by predicting the optimal stock levels based on historical data, seasonality, and trending consumer demands. This prevents overstocking or stockouts, ensuring that warehouses maintain the right amount of inventory to meet demand without tying up excessive capital. Automated inventory systems can also detect and alert managers about discrepancies and potential issues in real time, enabling quick resolution and maintaining system integrity.

Predictive Maintenance

According to McKinsey & Company, Predictive maintenance typically reduces machine downtime by 30% to 50% and increases machine life by 20% to 40%. Equipment downtime can lead to significant disruptions in logistics. AI-driven predictive maintenance is one of the leading applications of AI in logistics, and it can help analyze data from machinery to predict potential failures before they occur. This allows logistics companies to perform maintenance only when necessary, preventing unexpected equipment failures and prolonging the lifespan of their assets. It reduces downtime and maintenance costs, ensuring smooth operations and higher productivity.

Freight Matching

AI in the logistics industry streamlines the process of matching freight with the appropriate transportation means by analyzing variables such as shipment size, location, and delivery windows. This optimization leads to better asset utilization, reduced transportation costs, and enhanced service delivery. It allows carriers to maximize their cargo loads and routes efficiently, reducing empty miles and increasing profitability.

Demand Forecasting

AI enhances demand forecasting by analyzing market trends, consumer behavior, and economic indicators to predict future product demand. This accuracy in forecasting helps logistics companies plan better, from stocking warehouses to scheduling deliveries. It ensures that resources are allocated efficiently, and companies can adjust their real-time strategies based on predictive insights, reducing waste and improving service delivery.

According to a McKinsey & Company survey, 20% of executives we surveyed have implemented AI and machine learning for some type of supply-chain planning activity, and demand planning in one of them.

Now that you have a clear idea of the use of AI in logistics, let’s examine the real-world AI in logistics examples below in detail.

Examples of Businesses Leveraging AI in Logistics and Supply Chain

Numerous logistics companies worldwide are successfully implementing AI to enhance their operations. Let’s look at real-world examples of how businesses harness artificial intelligence in logistics to drive efficiency, reduce costs, and improve service delivery.

Amazon

Amazon leads in incorporating artificial intelligence in the logistics industry, employing highly automated systems in warehouses and during delivery. The company uses AI to predict what customers will buy, find the fastest delivery routes, and manage stock levels efficiently. Furthermore, Amazon harnesses generative AI to transform logistics, optimize routes, and deploy smarter robots to boost same-day shipping. This has helped the brand enhance its warehouse efficiency and product placement, setting new standards in speed and sustainability for package delivery.

DHL

DHL Supply Chain announced its three key technology priorities in 2024: Orchestration, Robotics, and Artificial Intelligence (AI) to drive further efficiency, agility, and sustainability within the supply chain to enhance its management.

- Orchestration: DHL Supply Chain achieves orchestration by leveraging advanced data analytics and machine learning to create a centralized system. This system optimizes operations and resource allocation, automates workflows, and dynamically adapts to real-time changes in demand.

- Robotics: DHL Supply Chain leverages robotics as a transformative force in warehousing and distribution. The company deploys over 7000 robots globally to scale its operations.

- Artificial Intelligence: DHL Supply Chain aspires to integrate AI in all its operations to unlock the full potential of orchestration and robotics. This will take systems and processes to the next level.

“The more we can use robots to complete repetitive or distant tasks in highly predictable, structured environments, the more we free our employees to leverage their unique human capabilities.”

By Tim Tetzlaff, Global Head of Accelerated Digitalization, DHL Supply Chain

FedEx

FedEx is one of the leading AI in logistics examples that integrates the said technology to improve operations. It focuses on predictive vehicle maintenance and uses robots for sorting in distribution centers. FedEx Surround, another initiative, uses AI in transportation and logistics operations to track real-time shipments, enhancing overall logistical performance and efficiency.

UPS

UPS utilizes AI in logistics operations to optimize delivery routes and streamline network planning, customer service, and equipment maintenance. Their ORION system uses AI to determine the best delivery paths, considering traffic and weather conditions, which helps reduce driving distances and fuel use.

Maersk

Maersk employs AI to make its shipping operations more efficient and safe. AI is used for predictive maintenance of ships and containers, optimizing routes for better fuel efficiency, and managing cargo space effectively. This approach ensures safer and more reliable shipping operations.

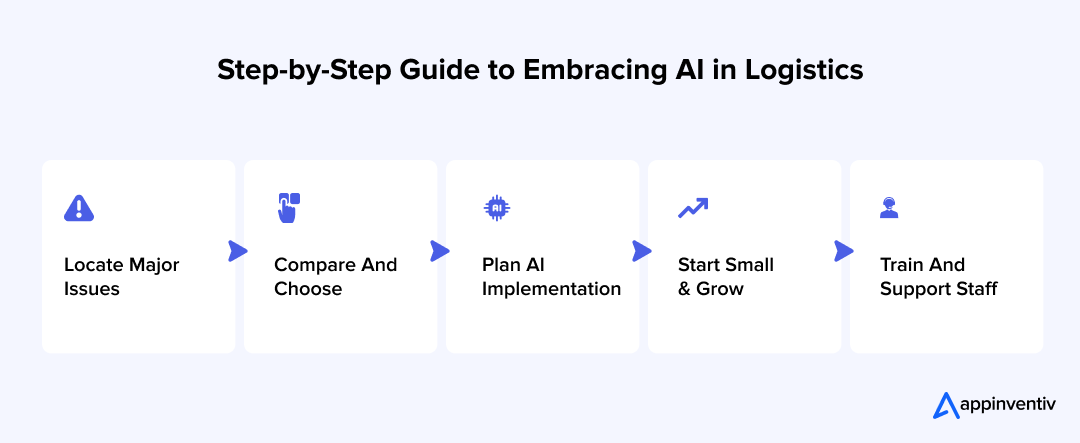

How Logistics Companies Can Start Embracing AI Innovation: A Step-by-Step Process

AI technology is revolutionizing logistics companies’ operations, helping them work smarter and deliver better services. If you want to bring AI into your logistics operations, here’s a straightforward step-by-step guide to get you started.

Locate Major Issues

The first thing you need to do before integrating AI into your logistics is identify the supply chain gaps. They may involve supply chain management, warehouse efficiency, or equipment maintenance. Once you know which department requires assistance, you can use AI to equip it with better efficiency and hassle-free functioning. You may focus your efforts and resources by recognizing AI’s most significant impacts.

Compare And Choose

Before making a choice, it is essential to compare all the available options to find the right one that fits your requirements. It would be best to choose an AI solution for your manufacturing needs to meet your needs and ambitions. For instance, you should consider features such as technical capabilities, integration with existing systems, and vendor support and training. Another critical aspect is to choose the development partner wisely. Look for a partner who can understand your pain areas and innovate AI solutions for the logistics sector to meet your needs, as Appinventiv does.

Plan AI Implementation

With a clear ambition and the right partner, you should plan its implementation in your supply chains. This plan should include a technology implementation schedule, an investment budget, and a training and onboarding strategy. Consider how you will quantify AI implementation success and what metrics you will use to track progress. A clear vision will make your implementation path more straightforward and effective.

Start Small and Grow

As tempting as it is to adopt AI throughout all your logistical operations, there is some chance it may not function as planned. Taking it slowly with a pilot project or small-scale implementation is generally more beneficial. Before rolling out the technology company-wide, test it. Once the test results are positive, you may implement it gradually on a large scale.

Train And Support Staff

After implementation, AI can automate many logistics activities, but your staff must be ready to work with it. There will be multiple challenges initially, but such issues can be addressed with appropriate guidance from the team. To bridge such gaps, enterprises and startups must offer AI systems and general AI training for all their employees.

Challenges Associated With AI in Logistics

Although numerous examples of AI in logistics reflect its transformative role in the sector, its applications and advantages are not without challenges. Let’s look at some of the most common challenges and their solutions for using AI for logistics:

Data Quality and Integration

Challenge: AI systems require vast amounts of high-quality data from various sources. This involves collecting, cleaning, and ensuring that the data is accurate and up-to-date so that AI systems can perform effectively.

Solution: Invest in data cleaning and standardization processes to ensure AI systems can access accurate, consistent, and up-to-date information.

High Implementation Costs

Challenge: The initial cost of adopting AI and logistics solutions, including the necessary equipment and software, and hiring skilled workers, can be very expensive, especially for smaller logistics companies.

Solution: To manage costs, businesses should adopt a phased approach to AI implementation, starting with smaller pilot projects that demonstrate ROI before scaling up.

Resistance to Change

Challenge: Employees and management may resist the adoption of AI for logistics due to the fear of job displacement, lack of understanding, or reluctance to change traditional processes.

Solution: To overcome resistance, clearly communicate the benefits of AI for logistics and provide training to help everyone understand the use of the new technology.

Lack of AI Expertise

Challenge: Finding and hiring people who can work with AI can be difficult. This expertise is crucial for developing and maintaining effective AI systems.

Solution: Consider partnerships with AI service providers who offer expertise and support as part of their solutions.

Keeping Up with Rapid Technological Changes

Challenge: AI technology evolves quickly, and staying updated with the latest developments can be challenging, making existing solutions outdated.

Solution: Stay flexible and keep learning. Regular training sessions and attending industry seminars can help your team keep up with new AI trends and technologies.

What is the Future of AI in Logistics?

The future of AI in logistics is set to transform how supply chains work, making them more efficient and adaptive. Here’s what the impact on AI on logistics can bring for the businesses:

Autonomous Vehicles and Drones

Businesses can anticipate a rise in autonomous vehicles and drones, enabling quicker and more cost-effective delivery solutions, particularly in densely populated urban areas or remote locations. These technologies will facilitate seamless deliveries by reducing reliance on human drivers and minimizing traffic delays.

Advanced Predictive Analytics

AI will advance its ability to utilize machine learning models for more accurate demand forecasting and inventory management. This will allow logistics operations to effectively balance supply with demand, optimize stock levels, and enhance route planning based on comprehensive real-time data and consumer behavior insights.

Smarter Warehouses

Robots and automated warehouse systems will speed up the process of sorting, packing, and shipping items. These smart systems can quickly adjust to new orders and minimize mistakes, ensuring customers get what they ordered faster.

Enhanced Customer Experience

AI will help personalize how customers receive their packages. It could predict when you need something before you order it and offer updates and choices on how you get your deliveries. This means better service and happier customers.

Sustainability Initiatives

AI will help make logistics greener. By planning better routes and improving how trucks are loaded, AI can help reduce fuel use and pollution. It might also help develop better packaging that’s easier on the environment.

Blockchain Integration

Blockchain can work with AI to make shipping more transparent and secure. AI can analyze data to ensure goods are genuine, reduce fraud, and check that everything meets legal standards.

Real-Time Decision Making

AI will be able to make quick decisions about shipping and deliveries, reacting to delays, weather, or sudden changes in demand. This means logistics operations can quickly adapt, avoiding disruptions and maintaining smooth service.

How is Appinventiv the right partner for leveraging AI in logistics operations?

Whether you are a startup or a well-established company in logistics management, partnering with Appinventiv can help you integrate and implement the right AI tool to take your organization to the next level. As a leading logistics software development company, we excel in what we do. We understand the unique challenges and opportunities within the logistics sector, and our expertise in AI-driven solutions positions us as an ideal partner for enhancing your logistics operations.

Here are several key advantages of partnering with us:

- Custom AI Solutions: We develop tailored AI development services that integrate seamlessly with your existing logistics systems, enhancing efficiency and scalability.

- Expertise and Experience: Our team of seasoned professionals has extensive experience in the logistics sector, enabling us to address your unique challenges effectively.

- Advanced Analytics and Data Management: We transform complex data into actionable insights, empowering your decision-making and operational efficiency.

- Scalable and Flexible Solutions: Our AI solutions adapt to your business growth and changing market demands, ensuring long-term relevance and effectiveness.

- Continuous Support and Optimization: We provide ongoing support and regular enhancements to keep your AI systems performing at their best.

For instance, we have created a digital solution with AI and analytics for one of our clients, a global construction and mining equipment manufacturer. Our solution helped them improve their supply chain visibility by 60% while increasing operational efficiency by 30%. Leverage our expertise and streamline your organization’s supply chains. Contact us now.

FAQs

Q. How is artificial intelligence used in logistics?

A. AI can optimize supply chain management by enhancing forecasting accuracy, improving inventory management, and optimizing transportation routes. By analyzing data from various sources, AI identifies patterns and predicts future trends, allowing companies to adjust their strategies proactively. This reduces costs by minimizing wastage and enhances delivery efficiency, ensuring products are moved through the supply chain at optimal times.

Q. What are the most promising AI use cases in logistics?

A. Some of the most impactful AI use cases in logistics include real-time route optimization, automated warehouse operations, and predictive vehicle maintenance. AI also enhances customer service through chatbots and predictive parcel tracking, improving customer communication and satisfaction. These applications streamline operations, reduce costs, and improve the responsiveness of logistics services.

Q. How does the integration of AI technologies help in reducing costs within logistics operations?

A. AI helps logistics companies cut down costs by automating processes, improving decision-making and optimizing resource usage across the supply chain. For instance:

- Route optimization lowers fuel and travel costs

- Predictive maintenance reduces repair expenses

- Warehouse automation cuts down on labor costs

- Inventory forecasting prevents overstocks and stockouts

- Real-time tracking minimizes losses and delays

- Smart scheduling improves fleet and driver utilization

Q. What is the impact of artificial intelligence on logistics operations?

A. The impact of AI on logistics is significant, improving operational efficiency and accuracy across the board. AI enables better demand forecasting, allowing companies to align their inventory with actual market needs, reducing overstock and stockouts. Additionally, AI enhances route planning and fleet management, which leads to faster and more cost-effective deliveries. The overall effect is a more agile and responsive logistics operation that adapts quickly and efficiently to changes.

Q. What is an example for artificial intelligence in logistics?

A. There are multiple examples of how artificial intelligence is transforming logistics. Let us help you understand a few:

- Amazon uses AI to predict what customers will buy and find the fastest delivery routes.

- DHL uses AI to manage warehouse operations and improve real-time decision making.

- FedEx uses AI to track shipments and keep delivery vehicles running smoothly.

- UPS uses AI to plan shorter delivery routes and save fuel.

- Maersk uses AI to improve shipping safety and make better use of cargo space.

Q. How is AI changing the shipping industry?

A. AI is transforming the shipping industry by making operations more efficient, data-driven, and customer-focused. For example:

- Real-time tracking improves visibility and transparency

- Predictive maintenance reduces downtime and repair costs

- Smart route planning helps in saving fuel and delivery time

- Automated scheduling increases fleet productivity

- AI chatbots enhance customer communication and support

- Demand forecasting helps manage cargo and inventory better

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How AI in Healthcare Administration Cut Staff Workload by 40%

Key takeaways: AI automates claims, scheduling, intake, and documentation, cutting repetitive work and freeing staff to focus on oversight and patient coordination. AI validation tools flag incomplete records before submission, reduce avoidable denials by 10–20%, and improve clean-claim performance, enhancing revenue predictability. EHR and note-processing AI reclaim thousands of staff hours in large health systems,…

How AI Chatbots for eCommerce are Driving 3x More Sales in 2026

Key takeaways: AI chatbots for eCommerce have a direct impact on revenue. When aligned with buying intent, they lift conversions, increase order value, and drive repeat purchases. The strongest impact comes from personalization and guided selling, helping shoppers decide faster and buy with greater confidence. Abandoned cart recovery is a major revenue driver in 2026.…

AI-Powered Booking Optimization for Beauty Salons in Dubai: Costs, ROI & App Development

Key Highlights AI booking optimization improves utilization, reduces no-shows, and stabilizes predictable salon revenue streams. Enterprise salon platforms enable centralized scheduling, customer insights, and scalable multi-location operational control. AI-enabled booking platforms can be designed to align with UAE data protection regulations and secure payment standards. Predictive scheduling and personalization increase customer retention while significantly reducing…