- The Unprecedented Benefits of RFID in Manufacturing

- Unmatched Inventory Accuracy

- Real-Time Visibility

- Reduced Labor Costs and Errors

- Improved Supply Chain Agility

- Enhanced Security and Loss Prevention

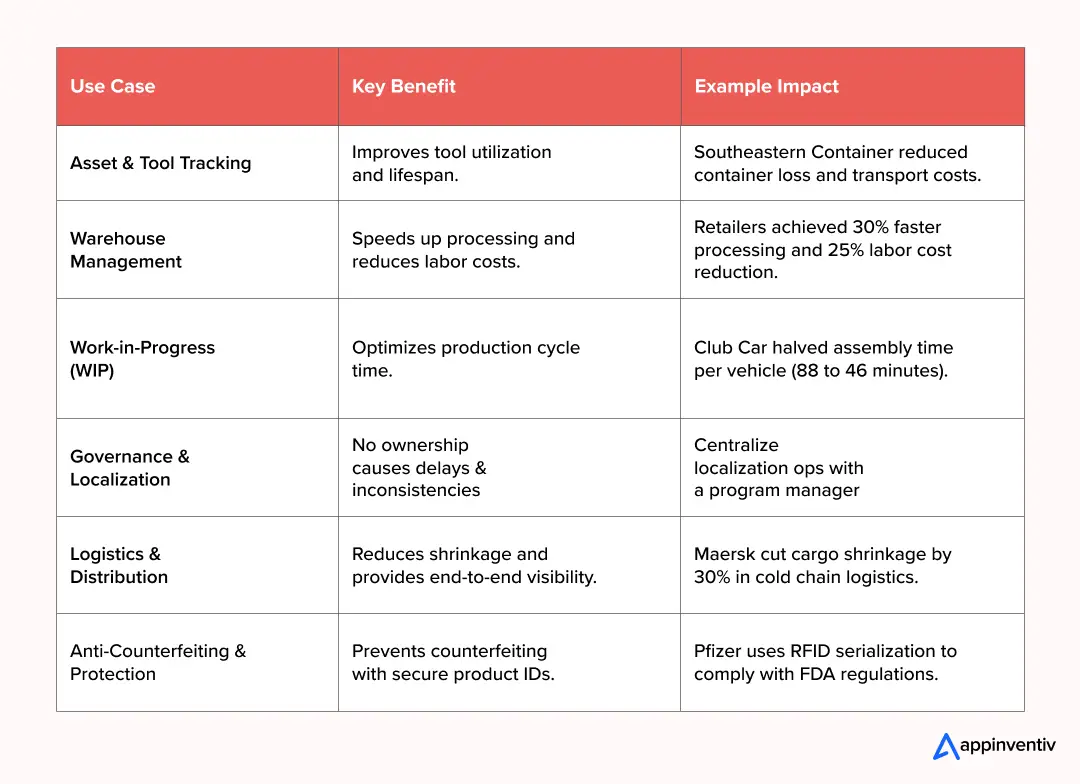

- Game Changing Use Cases of RFID in The Manufacturing Industry

- Asset and Tool Tracking

- Warehouse Management and Automation

- Work-in-Progress (WIP) Tracking

- Logistics and Supply Chain

- Anti-Counterfeiting and Brand Protection

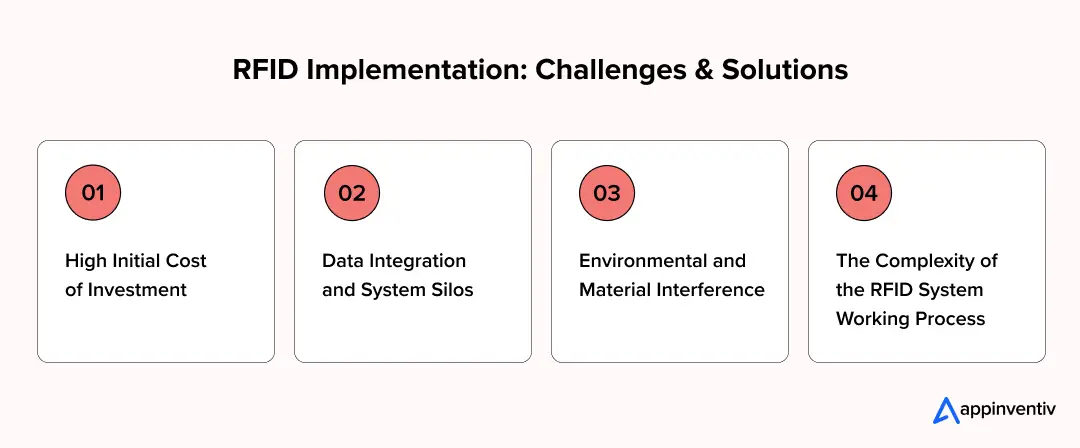

- Challenges in RFID Implementation for The Manufacturing Sector and How to Overcome Them

- Challenge 1: High Initial Cost of Investment

- Challenge 2: Data Integration and System Silos

- Challenge 3: Environmental and Material Interference

- Challenge 4: The Complexity of the RFID System Working Process

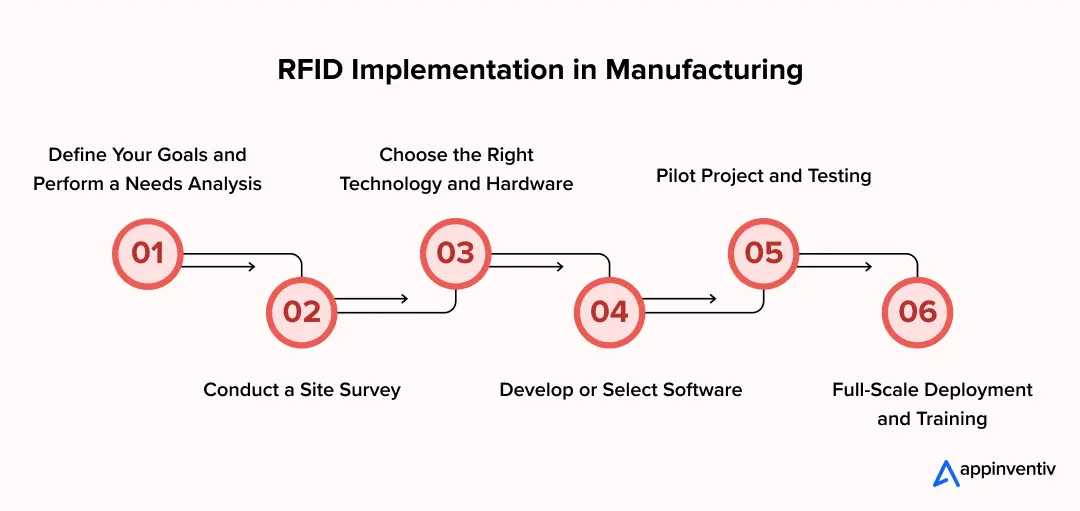

- How to Implement RFID in Manufacturing: A Step by Step Process

- 1. Define Your Goals and Perform a Needs Analysis

- 2. Conduct a Site Survey

- 3. Choose the Right Technology and Hardware

- 4. Develop or Select Software

- 5. Pilot Project and Testing

- 6. Full-Scale Deployment and Training

- A Look at What's Next: The Future of RFID in Supply Chain Management & Manufacturing

- Blockchain Integration for Enhanced Trust

- The Rise of the Ambient IoT

- Next-Gen RFID and Sensor Technology

- Key Features and the Working Process of RFID Technology in Manufacturing

- Key Features and Functionalities of RFID Solutions

- RFID System Working Process

- Partner with Appinventiv: Your Gateway to Seamless RFID Implementation Excellence

- Why Global Manufacturing Leaders Trust Appinventiv

- Real-World Proof: Appinventiv’s Supply‑Chain & Logistics Success Story

- Frequently Asked Questions

Key Takeaways

- RFID technology offers real-time tracking of materials and goods, allowing manufacturers to optimize operations, identify bottlenecks, and improve workflow efficiency.

- RFID’s real-time data empowers manufacturers to quickly adapt to demand fluctuations, shipment delays, and other disruptions, fostering quicker decision-making and better partner/customer relationships.

- Real-world examples like Southeastern Container and Club Car demonstrate how RFID optimizes asset tracking, warehouse management, and production cycle times, leading to faster processing and reduced costs.

- The integration of RFID with IoT and AI is set to revolutionize manufacturing by providing even deeper insights, enabling predictive maintenance, and creating smarter, more automated systems for the next generation of industry operations.

Manufacturing has always focused on precision, efficiency, and scale. Past generations worked on perfecting assembly lines and making production processes better. Today’s industry leaders know that factory floors are just one part of the equation. The real challenge, and the biggest opportunity, sits within complex, often messy inventory and supply chain networks that directly hit your bottom line. Markets where agility creates competitive advantages and visibility unlocks new value require technological cores that can control this complexity.

Forward-thinking organizations are discovering that intelligent automation delivers transformative results across their entire operational ecosystem. This represents a fundamental transformation rather than minor adjustments, led by RFID in manufacturing.

Operations leaders who need peak performance face constant pressure to deliver clear results such as:

- Speed up processes while keeping quality standards, cutting time-to-market by 30%

- Make accuracy better across complex supply chain networks, stopping costly errors that hurt profit margins

- Get deeper insights into every item’s lifecycle that gets produced, preventing stockouts that cost manufacturers millions

RFID implementation turns these challenges into strategic opportunities. These connected systems where components, products, and assets share status information in real time give you control like never before. These smart systems make hidden things visible, giving teams instant decision-making data that speeds growth, cuts waste, and builds the foundation for tomorrow’s smart AI-based manufacturing excellence.

Must Read: A Guide to Managed IT Services for Manufacturing

Just like components and assets now communicate in real time, we can help you transform every hidden element of your supply chain into crystal-clear competitive intelligence

The Unprecedented Benefits of RFID in Manufacturing

RFID in manufacturing adoption has evolved beyond simple asset tracking into smart factory cornerstones. Benefits span widely and impact bottom lines directly, from reducing human error to optimizing resource allocation.

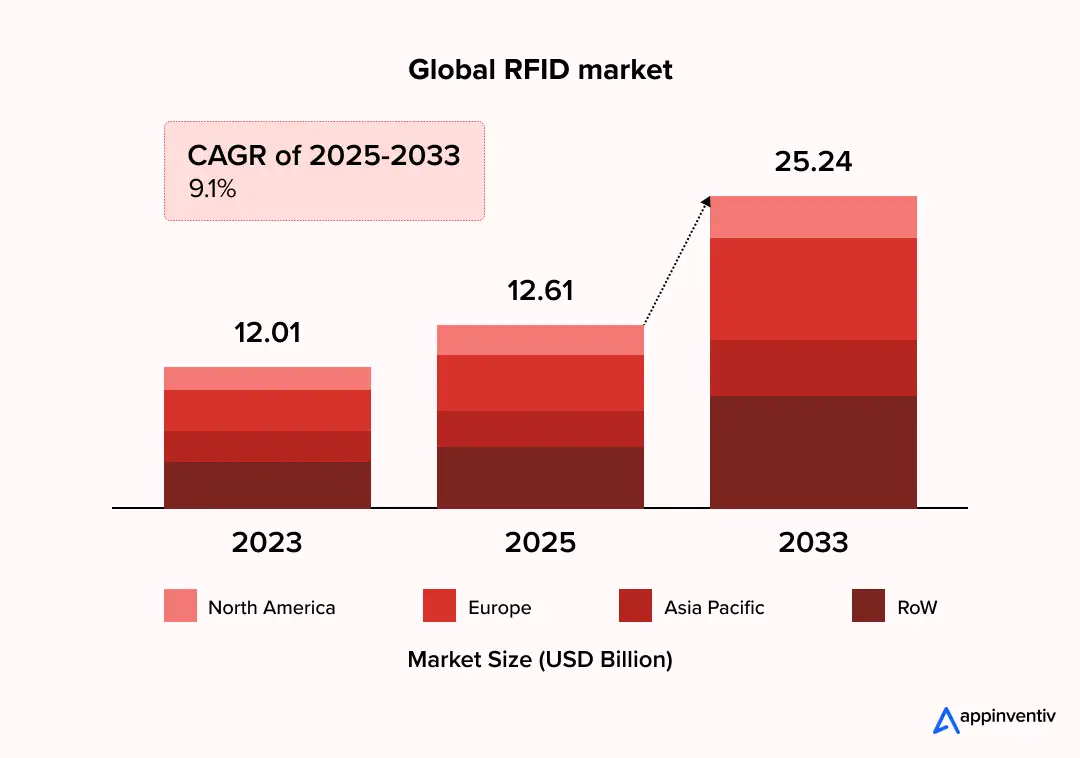

According to MarketsandMarkets, the global RFID market reaching $25.24 billion by 2033, driven by increasing real-time visibility demand. This growth indicates that RFID for manufacturing represents strategic imperatives rather than niche technology. The technology delivers precision and automation levels that manual systems and barcodes cannot match.

Here are some of the key benefits that are transforming operations:

Unmatched Inventory Accuracy

Manual inventory counts are well-known for taking too much time and making mistakes. With RFID in inventory management, factories get accuracy rates that reach 99.9%, much higher than the 60-80% accuracy typical with traditional barcode systems. This removes guesswork while giving a single source of truth for stock levels.

Better accuracy leads directly to fewer stockouts, lower safety stock needs, and better demand forecasting. This becomes especially important in complex assembly settings where having the right parts at the right times stays critical.

Related Read: 10 Use Cases & Examples of Machine Learning in Manufacturing

Real-Time Visibility

An RFID tracking system for manufacturing delivers instant, end-to-end operational views. Raw materials get tracked from facility entry, work-in-progress monitoring occurs on production lines, and finished goods follow movements to warehouses and beyond.

Real-time data proves invaluable for identifying bottlenecks and preventing delays before they occur. Knowing exact locations and the status of every item at any moment empowers operational excellence, helping RFID for manufacturers optimize every workflow stage.

Reduced Labor Costs and Errors

By automating identification and data capture processes, RFID in manufacturing greatly cuts down manual scanning and data entry needs. This frees workers to focus on more strategic, value-added tasks.

It also reduces human-related errors, which cost money through recalls, reworks, and unhappy customers. For example, in large warehouses, single team members with handheld RFID readers do inventory counts in much less time than barcode scanner methods.

Improved Supply Chain Agility

Better visibility offered by RFID in supply chain management helps manufacturers react quickly to problems. Whether facing sudden demand jumps or shipment delays, you have data to reroute, re-prioritize, and keep operations running.

This quick response gives powerful abilities in unstable global markets. Knowing exact shipment locations and arrival times allows good communication with partners and customers, building trust and reliability.

Enhanced Security and Loss Prevention

RFID technology in manufacturing gives a detailed digital record of every item’s path, making it hard for products to go missing. This cuts shrinkage, prevents loss of valuable items and boosts overall security by providing clear tracking, which matters a lot for high-value or regulated products.

In the automotive sector, for instance, RFID can stop the theft of expensive parts and components from the factory floor.

Game Changing Use Cases of RFID in The Manufacturing Industry

The impact of RFID isn’t theoretical; it’s being proven in real-world applications across various sectors. The RFID use cases in supply chain, logistics and inventory management are diverse, showcasing the technology’s versatility and immense potential for businesses. Here are some of the most practical use cases of RFID in the manufacturing industry.

Asset and Tool Tracking

Complex factories face a common problem. Tools disappear. Equipment goes missing. Even returnable transport items like pallets and bins vanish, causing delays and forcing unnecessary capital spending.

Here’s where RFID for manufacturers changes everything – real-time asset location tracking means you always know where things are. High-value tools benefit most from this approach through better utilization rates, longer equipment life, and maintenance that happens automatically on schedule.

Example: Southeastern Container, a Coca-Cola supplier, uses RFID to track reusable plastic containers across its manufacturing network, cutting container loss and reducing transport costs with ROI achieved within two years.

Warehouse Management and Automation

The major gains achieved via RFID in the manufacturing industry happen right on the warehouse floor. RFID enables bulk scanning where hundreds of items on a single pallet get counted within seconds, no line of sight required. This accelerates inbound and outbound logistics while improving picking accuracy and optimizing space utilization.

Here’s a practical example: a single RFID portal at warehouse doors automatically confirms entire shipments as forklifts pass through. What used to require a team of workers for several hours now get completed in mere seconds.

Example: Major retailers implementing RFID report 30% faster processing times and reduce labor costs by 25%, with some achieving 99.9% inventory accuracy.

Work-in-Progress (WIP) Tracking

Production lines benefit tremendously when RFID for manufacturing tracks parts and components moving between stations. You get detailed cycle time data, bottleneck identification becomes automatic, and the right components stay available at each assembly stage.

This level of precise control proves essential for just-in-time manufacturing models, where even small delays create cascading effects throughout entire production schedules.

Example: Club Car, a golf cart manufacturer, used RFID tracking to reduce assembly time from 88 minutes to 46 minutes per vehicle through precise WIP tracking.

Logistics and Supply Chain

RFID in supply chain management delivers comprehensive end-to-end visibility once products leave manufacturing facilities. Every movement gets automatically recorded from truck loading through distribution center arrival.

Example: Major logistics companies including UPS, FedEx, and DHL are driving sector momentum, with Maersk reporting a 30% reduction in cargo shrinkage after adopting IoT-linked RFID solutions for cold chain logistics.

Anti-Counterfeiting and Brand Protection

Counterfeiting poses serious threats to industries like pharmaceuticals and luxury goods. Applications of RFID in the manufacturing industry enable companies to assign unique, cryptographically secure digital identities to each individual product.

RFID implementation in manufacturing ensures instant authentication throughout supply chains, from distribution centers to retail points of sale, ensuring only genuine products reach consumers. Pharmaceutical companies increasingly rely on RFID to meet regulatory requirements while combating fake drug infiltration into legitimate markets.

Example: Pfizer and other major pharmaceutical companies use RFID-enabled serialization to comply with the FDA’s Drug Supply Chain Security Act, with the pharmaceutical anti-counterfeit packaging market expected to reach $168.08 billion by 2030.

Challenges in RFID Implementation for The Manufacturing Sector and How to Overcome Them

While the applications and advantages of RFID technology in manufacturing are obvious, its implementation is not without its challenges. These hurdles can sometimes deter companies from adopting the technology. However, with the right strategic approach and a capable partner, these obstacles can be easily overcome.

Challenge 1: High Initial Cost of Investment

The cost to build an RFID software for manufacturing appears steep initially, especially for enterprise-wide rollouts. This includes reader costs, tags, infrastructure requirements, and RFID software development expenses. Smaller and medium-sized manufacturers often find that this upfront investment creates significant barriers to adoption.

Solution: Full-scale RFID software development and deployments aren’t always necessary. Phased approaches or pilot projects can effectively mitigate these risks. Also, even if the cost to build a custom solution seems initially higher, it significantly outperforms off-the-shelf products for complex enterprises and yields lucrative outcomes in the long run.

Challenge 2: Data Integration and System Silos

Integrating a new RFID system with existing enterprise resource planning (ERP) or warehouse management systems (WMS) can be tough. Disconnected data flows can wipe out the benefits of real-time tracking, creating new operational gaps.

Solution: The key is to build custom RFID manufacturing solutions that can work smoothly with what you have. Your RFID platform should have strong APIs or middleware that can easily connect with your older systems to handle the high volume of real-time RFID data.

Challenge 3: Environmental and Material Interference

RFID signals can get affected by liquids, metals, and certain types of electromagnetic interference, which are common in manufacturing settings. If not handled, this can cause unreliable reads and hurt the system’s effectiveness.

Solution: This problem can be fixed by picking the right types of RFID systems in manufacturing and hardware for your specific setup. Different frequencies (LF, HF, UHF) and tag types (passive, active, semi-passive) work better in different conditions.

For example, UHF tags work great for long-range scanning but can have trouble with metal, while on-metal tags are made specifically to fix this problem. Proper placement of readers and antennas, based on a professional site survey, is also key to getting consistent and accurate reads.

Challenge 4: The Complexity of the RFID System Working Process

Understanding the RFID system working process can feel tough for those who don’t know the technology well. This can create a skills gap among your workers and lead to a slow and hard setup.

Solution: Working with a reputed company specializing in delivering manufacturing IT services is the best way to handle this complexity. It means you should hunt for a team that not only knows the technology but also has deep knowledge in the manufacturing sector. They can give you a clear, step-by-step setup plan, offer hands-on training for your team, and provide ongoing support to make sure the transition goes smoothly. This outside expertise can speed up your time-to-value and make sure your team knows how to use the new system well.

Don’t let technical complexities hold you back. Leverage the industry-tested expertise that turns RFID challenges into clear operational advantages.

How to Implement RFID in Manufacturing: A Step by Step Process

Implementing an RFID for manufacturing requires a structured and deliberate approach. A well-defined plan is crucial for a successful and profitable deployment. Here is a Step-by-step process for RFID implementation in manufacturing:

1. Define Your Goals and Perform a Needs Analysis

Before you buy or build a single tag or reader, you must clearly define what you want to achieve. What specific problem are you trying to solve? Is it inventory accuracy, asset tracking, or improving supply chain visibility? A comprehensive needs analysis should identify key pain points and the metrics you will use to measure success.

2. Conduct a Site Survey

A thorough assessment of your facility is critical. This includes identifying potential sources of signal interference (e.g., large metal machinery, water tanks) and determining the best locations for readers and antennas. This step is non-negotiable and provides the blueprint for a reliable system.

3. Choose the Right Technology and Hardware

Based on your goals and site survey, select the appropriate RFID technology in manufacturing. This involves choosing the right tags, readers, and antennas for your specific use cases. The decision will be based on factors like read range, the materials of your products, and the environmental conditions of your facility.

4. Develop or Select Software

The software is the brain of the system, transforming raw tag data into actionable business intelligence. You can either build a custom solution or choose a pre-built platform. This is where a company specializing in RFID tracking software development can be a significant asset, as they can tailor a solution that seamlessly integrates with your existing IT infrastructure and addresses your unique operational needs.

5. Pilot Project and Testing

Before a full rollout, test the system in a controlled environment. A pilot project in one section of the factory or a single production line allows you to fine-tune the system, identify any unforeseen issues, and prove its value before committing to a larger investment. This phase is crucial for building internal confidence and ensuring the successful deployment of the technology at the larger scale.

6. Full-Scale Deployment and Training

Once the pilot is successful, roll out the system across the entire operation. At this stage, comprehensive training for your team is essential to ensure adoption and maximize the system’s benefits. The training should cover everything from how to use handheld readers to how to interpret data from the dashboards.

Related Read: How Business Intelligence for Supply Chain Boosts Efficiency

A Look at What’s Next: The Future of RFID in Supply Chain Management & Manufacturing

The future of RFID in supply chain management isn’t just incremental improvements. It represents a complete paradigm shift. RFID’s convergence with next-gen technologies will unlock unprecedented efficiency levels. We’re talking about the integration of Internet of Things (IoT), artificial intelligence (AI), and blockchain in supply chain management. These tech trends create entirely new possibilities for supply chain intelligence.

Blockchain Integration for Enhanced Trust

RFID combined with blockchain creates secure, tamper-proof product journey records. This spans from factory floor to customer delivery, where value lies in ensuring authenticity and preventing counterfeiting. Thus, trust in supply chains becomes measurable. Take the pharmaceutical industry as an example. Here, RFID and blockchain together create a fully transparent chain of custody tracking. Every drug package gets monitored from production to patient, and verification becomes automatic.

The Rise of the Ambient IoT

Every object can join a connected network. This vision becomes reality as RFID in the manufacturing industry spreads wider. Tag costs continue dropping, and soon every single item will carry an embedded digital identity. Raw materials and finished products alike get real-time tracking throughout their lifecycle. New business models emerge from this capability and automation reaches previously impossible levels.

Next-Gen RFID and Sensor Technology

The next RFID evolution integrates sensors directly into tags that monitor environmental conditions continuously. Temperature, humidity, and pressure tracking becomes standard for industries handling sensitive goods. Quality and integrity get maintained throughout the entire supply chains, representing a genuine game-changer for product safety.

Must Read: How Technology in Supply Chain Can Surpass Challenges

Key Features and the Working Process of RFID Technology in Manufacturing

To truly understand this technology’s transformative power, manufacturing leaders must first grasp the key features of RFID in manufacturing. These capabilities form the foundation of successful digital transformation in manufacturing across production facilities worldwide.

Key Features and Functionalities of RFID Solutions

Effective RFID solutions need several must-have features that determine how well they work:

- Real-time Tracking: Watching assets and inventory in real-time gives you the main value. This lets you spot problems right away and make quick decisions. Without real-time data, your operations are always behind market needs.

- Scalability: Systems must grow with your business. This means moving smoothly from small pilot projects to company-wide setups across multiple sites. Global growth needs the same built-in flexibility that separates top solutions from basic ones.

- Customizable Dashboards: Data only helps when it’s shown in useful, ready-to-use formats. Custom interfaces give you quick KPI insights made for your specific needs. Whether you’re tracking inventory turnover rates or watching key asset locations, important metrics become easy to see.

- Automated Alerts: Smart systems tell staff about serious operational situations before they become problems. Low stock levels send immediate alerts, lost assets get marked right away, and other key events create automatic responses. This turns simple tracking into complete management intelligence.

RFID System Working Process

Understanding the fundamental technology architecture reveals why RFID delivers such remarkable results. But you should also understand the RFID system working process to learn how the system operates through elegant simplicity:

- RFID tags containing microchips and antennas attach to items throughout your facility

- When tags enter reader proximity, radio waves activate the embedded technology

- Unique identification codes transmit back to central systems automatically

- Data integrates seamlessly with existing enterprise software platforms

This automated data collection creates comprehensive operational visibility while eliminating manual scanning bottlenecks. The process provides unprecedented accuracy across complex supply chains, making every component, from raw materials to finished goods, trackable and accountable.

Custom RFID software solutions amplify these benefits through tailored functionality. Professional RFID tracking software development enables businesses to address current operational challenges while building robust foundations for future growth. The technology simultaneously solves immediate problems and delivers long-term strategic advantages that strengthen market positioning.

Partner with Appinventiv: Your Gateway to Seamless RFID Implementation Excellence

As manufacturing executives deal with Industry 5.0 changes, putting RFID technology in place needs more than just tech skills; it needs a strategic software development partner who can help you overcome your specific operational problems. Appinventiv, a global leader in manufacturing IT services, is here to guide your RFID setup journey from idea to full rollout.

With over 10 years of expertise in manufacturing technology and a team of 1,600+ tech experts, Appinventiv has successfully delivered 3,000+ digital products across 35+ industries, including manufacturing. Our complete approach covers everything from initial feasibility checks to after-deployment improvements. This makes sure your RFID setup delivers clear ROI from day one.

Why Global Manufacturing Leaders Trust Appinventiv

- Award-Winning Innovation: Deloitte Technology Fast 50 India awards (2023 & 2024), ranking #1 in the Digital & Cloud Tech category. Also recognized as “The Leader in AI Product Engineering & Digital Transformation” by The Economic Times.

- Complete RFID Ecosystem: End-to-end capabilities covering IoT integration, cloud infrastructure, AI-powered analytics, and blockchain security, all key parts for advanced RFID rollouts.

- Scalable Solutions: From pilot programs to company-wide setups, our solutions grow with your manufacturing operations while keeping performance standards across multiple facilities.

- Quality Assurance: ISO 9001:2008 certified operations make sure we deliver consistent, high-quality results that meet international standards for manufacturing IT setups.

Real-World Proof: Appinventiv’s Supply‑Chain & Logistics Success Story

To illustrate our capabilities beyond theory, consider a recent engagement: a global heavy‑equipment manufacturer partnered with Appinventiv to overhaul its supply‑chain and logistics operations. Their legacy systems were struggling with unstructured data, mismatched mainframe inputs and ERP interfaces. Also, frequent manual fixes for goods‑receipt and sales‑order errors caused serious delays.

What Appinventiv delivered:

- A robust supply‑chain logistics management solution combining AI‑powered RPA and analytics.

- Automation of repetitive data‑validation and error‑resolution workflows. Bots scan for multiple error types, reconcile records, and trigger resolution workflows including notifications to stakeholders, eliminating manual intervention.

- Full visibility into process execution, with root‑cause analysis baked into analytics dashboards, enabling continuous optimization of supply‑chain workflows.

Quantifiable Impact:

- 60% increase in supply‑chain visibility.

- 40% reduction in transportation and logistics costs.

- 30% uplift in overall operational efficiency

Ready to revolutionize your inventory management and supply chain visibility? Connect with Appinventiv today to explore how our RFID implementation expertise can drive operational excellence for your organization.

Frequently Asked Questions

Q. What is RFID in manufacturing and how does it work?

A. RFID (Radio Frequency Identification) in manufacturing is a technology that uses radio waves to automatically identify and track objects, such as raw materials, components, or finished products.

It involves RFID tags (small, embedded microchips) attached to items, which communicate with RFID readers to transmit data about their location, status, or condition. This system enables real-time tracking, inventory management, and asset visibility, helping manufacturers streamline operations, reduce errors, and improve supply chain efficiency.

Q. How does RFID software improve supply chain visibility?

A. RFID software creates full supply chain visibility by automatically getting real-time data at every step, from raw materials to finished goods delivery. Manual tracking systems can’t give instant updates like RFID does on inventory locations, shipment status, and production progress across multiple sites.

This clear visibility helps manufacturing executives spot problems early, make better buying decisions, cut stockouts, and boost supplier performance. The result is better operational control, quicker response to market needs, and big cost cuts through smart supply chain strategies.

Q. What is the ROI of RFID software in manufacturing?

A. RFID software usually delivers 15-25% ROI within 12-18 months through multiple value drivers. Manufacturing executives see quick cost cuts from removing manual data entry, cutting inventory loss, and better stock levels. Worker productivity goes up 20-30% through automated tracking processes. Supply chain gains include faster order handling, fewer stockouts, and better supplier compliance.

Other benefits include better quality control, less counterfeiting, and improved rule following. While starting RFID software development costs range from $50,000-$500,000 based on size, the operational savings and competitive edges create big long-term value for manufacturing companies.

Q. How does RFID improve real-time inventory tracking?

A. RFID changes inventory tracking by giving instant, automated visibility into stock levels and locations across manufacturing sites. Manual counts or barcode scanning can’t match this. RFID readers watch tagged items all the time without human help, updating inventory systems in real-time.

This lets manufacturing executives get accurate stock data right away, remove costly counting mistakes, and cut inventory problems by up to 95%. Real-time tracking helps just-in-time manufacturing, stops production delays from stockouts, improves warehouse work, and allows smart buying decisions that boost operational efficiency and cut working capital needs.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

RPA in Manufacturing Industry: Challenges, Use Cases, ROI

Key takeaways: RPA shows the strongest impact in high-volume coordination work such as invoice-to-PO matching, ERP–WMS inventory reconciliation, and order status updates across systems. For well-scoped workflows, RPA typically shows operational impact within 8–12 weeks, driven by less rework, fewer data mismatches, and faster reconciliations. In manufacturing, RPA programs usually range from $40,000 to $600,000,…

10 Use Cases, Benefits, and Examples of How Cobots are Transforming the Manufacturing Industry

Key takeaways: Cobots work next to human workers, taking care of repetitive jobs like welding and assembly, boosting efficiency and reducing physical strain. This teamwork is changing traditional manufacturing. The cobot market is expected to hit $11.64 billion by 2030, showing the growing move toward automation and the increasing need for flexible, collaborative robots. Companies…