- What is Supply Chain Business Intelligence?

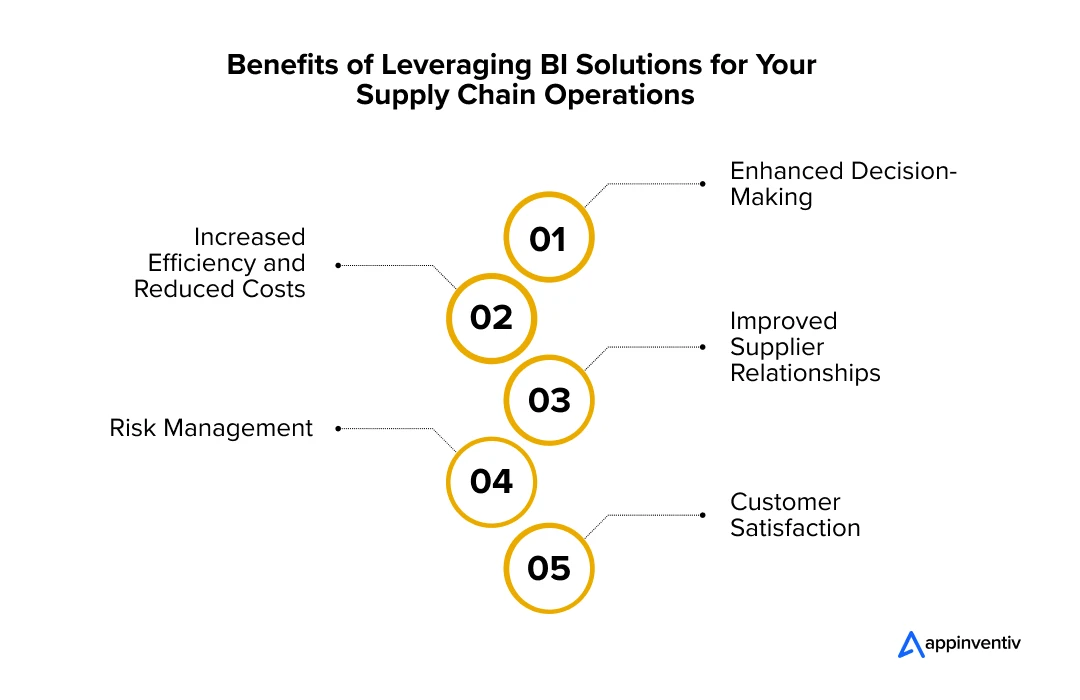

- Benefits of Business Intelligence in Supply Chain

- Enhanced Decision-Making

- Increased Efficiency and Reduced Costs

- Improved Supplier Relationships

- Risk Management

- Customer Satisfaction

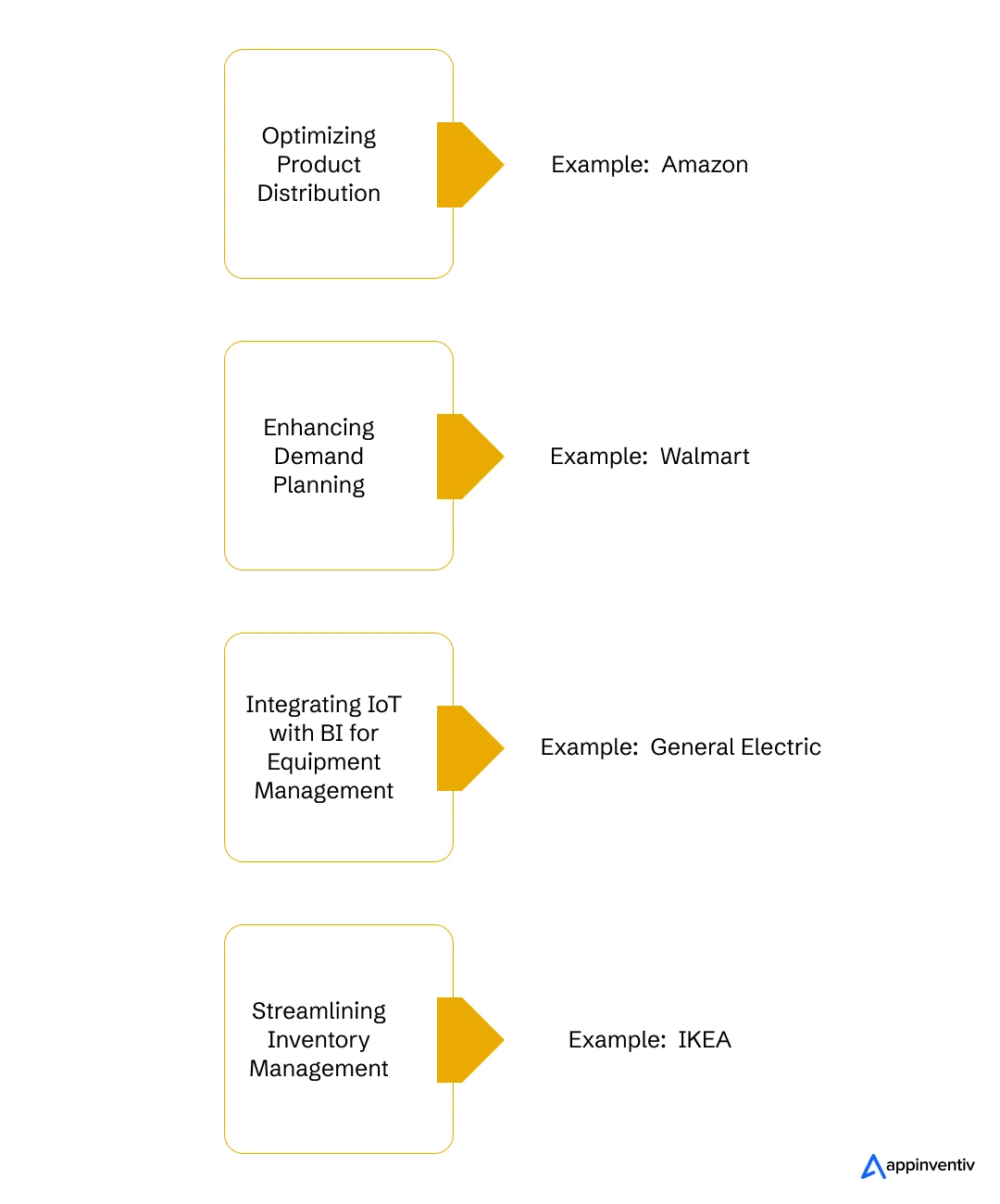

- Use Cases of Business Intelligence in Supply Chain Management

- Optimizing Product Distribution

- Enhancing Demand Planning

- Integrating IoT with BI for Equipment Management

- Streamlining Inventory Management

- Essential Business Intelligence Tools for Supply Chain Management

- Reporting Tools

- Dashboards

- Benchmarking

- Steps to Implement Business Intelligence for Supply Chain Management

- Assess Current Capabilities and Needs

- Define Clear Objectives

- Choose the Right BI Tools

- Develop a Data Management Strategy

- Train Your Team

- Integrate BI Software into Your Supply Chain

- Monitor and Refine

- Review and Scale

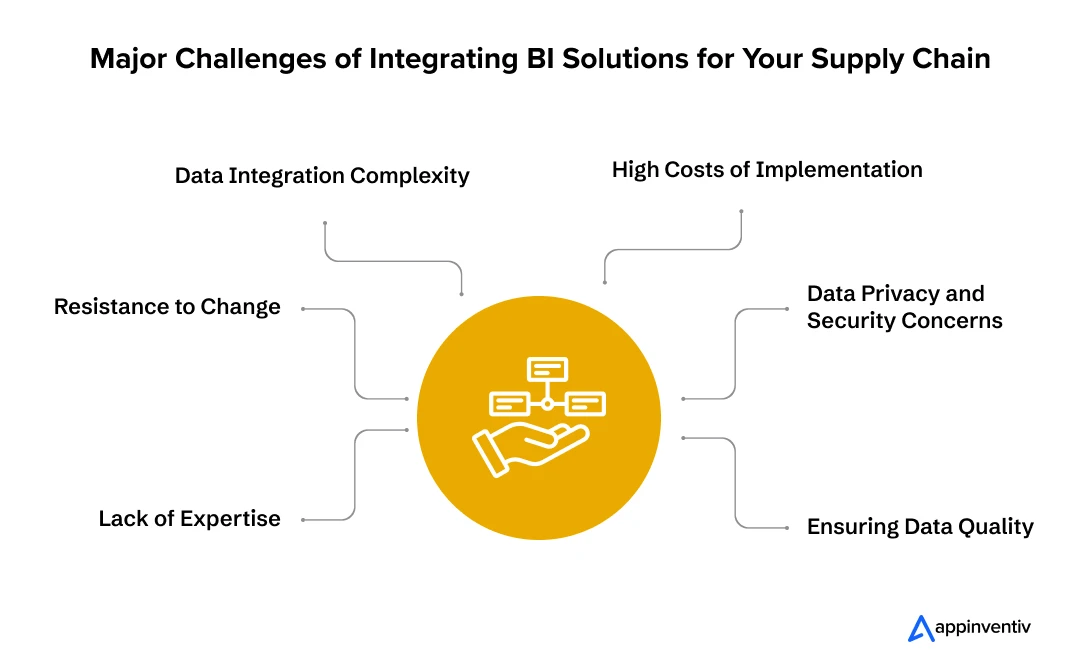

- Challenges of Implementing BI in Supply Chain

- Data Integration Complexity

- High Costs of Implementation

- Resistance to Change

- Data Privacy and Security Concerns

- Lack of Expertise

- Ensuring Data Quality

- Future of Real-Time Business Intelligence in Supply Chain Analytics

- Why Appinventiv Is Your Ideal Partner for Developing BI Solutions to Streamline Supply Chain Management

- FAQs

In an era dominated by data, Business Intelligence (BI) has emerged as a crucial tool for making informed decisions across various industries. BI leverages data collection, analysis, and presentation to improve business operations, making it a vital component in today’s fast-paced market environments.

Regarding supply chain management, BI tools have transformed traditional practices, enabling businesses to respond more swiftly and efficiently to market demands and logistical challenges.

Enterprise business intelligence is more than just a technological advancement that enterprise businesses need to adopt; it is a strategic asset they need to gain a competitive edge. As industries continue to evolve, the role of business intelligence for supply chains will expand beyond simple data management to become a core element of operational strategy and innovation.

- Supply chains usually involve various stages and stakeholders, from production to delivery, which can get complicated.

- BI tools simplify this by providing clear and directly applicable insights, enhancing decision-making, and boosting operational efficiency.

- By analyzing data trends and patterns, businesses can more precisely forecast future scenarios, improve planning, and adapt quickly to market shifts.

Furthermore, BI has enabled a more proactive approach to managing risks within the supply chain. Thanks to sophisticated analytics, companies are better equipped to foresee potential issues and adapt their strategies in real-time. This ability is especially valuable in a global economy, where supply chains are extensive and vulnerable to various international influences, including political changes and environmental factors.

In this blog, we will delve into how Business Intelligence not only adapts to the rapid changes in supply chain management but actively drives these changes. We will discuss specific BI tools and methods at the forefront of transforming the industry, showing how they help streamline operations, reduce costs, and improve service delivery. So, without further ado, let’s begin.

What is Supply Chain Business Intelligence?

Supply chain business intelligence is the strategic use of analytical tools and technologies to draw actionable insights for greater operational efficiency throughout the supply chain. It’s the collection, integration, analysis, and combination of different data sources, from suppliers through manufacturers to distributors, retailers, and customers.

With such data-driven insights, organizations can easily discover prospects for cost cuts, process optimization, and sustainable growth.

Benefits of Business Intelligence in Supply Chain

Business Intelligence in supply chain management refers to using data-driven tools and analytics to enhance the visibility and efficiency of supply chain operations. By gathering data from various sources within the supply chain, BI tools analyze and present this information in a way that helps businesses understand complex scenarios easily. This process involves converting raw data into actionable insights, enabling companies to make informed decisions swiftly and accurately.

According to a McKinsey report titled “The Data-driven Enterprise of 2025,” businesses leveraging Business Intelligence solutions are positioned to transform significantly. Integrating advanced data analytics into their core processes will enhance decision-making and operational efficiency. These enhancements are further expected to streamline supply chain management, improving agility and responsiveness to market changes.

Let us look at the benefits of business intelligence in the supply chain in detail below:

Enhanced Decision-Making

One of the primary benefits of BI in supply chain management is significantly improved decision-making. With access to real-time data and analytics, managers can quickly identify areas that need attention and make informed decisions on improving operations. For example, suppose a particular product is consistently out of stock. In that case, BI can help pinpoint the issue, whether a supplier problem or a forecasting error, and prompt managers to take corrective action.

Increased Efficiency and Reduced Costs

The purpose of business intelligence in the supply chain is to streamline daily processes by automating data analysis. This reduces the manpower needed for manual data entry and review, cutting labor costs and minimizing errors associated with human handling. Additionally, BI can optimize route planning for transportation, reducing fuel costs and improving delivery times, ultimately leading to enhanced customer satisfaction.

Improved Supplier Relationships

Improved supplier relationships are one of the major benefits that can help you understand the importance of business intelligence in the supply chain. Using BI, companies can maintain better relationships with their suppliers by sharing relevant data that allows both parties to understand purchase patterns and inventory needs more clearly. This transparency leads to more reliable supply chains where suppliers and buyers can adjust to changes efficiently and cooperatively.

Risk Management

BI enhances a business’s risk management by providing tools that predict potential supply chain disruptions. For instance, if supply chain business intelligence tools detect a trend that could lead to a shortage of materials, the company can proactively seek alternative suppliers or substitute materials. This forward-looking supply chain risk management approach helps companies avoid crises and maintain steady production and delivery schedules.

Customer Satisfaction

BI plays a crucial role in improving customer satisfaction. By analyzing customer data and feedback, BI tools help companies predict what products will be in demand and when leading to better stock management and fewer out-of-stock items. Additionally, improved delivery times and the ability to quickly resolve issues contribute to a better overall customer experience.

[Also Read: Why is Business Intelligence Important for Your Organization?]

Use Cases of Business Intelligence in Supply Chain Management

BI plays a transformative role in supply chain management by utilizing data to streamline operations and enhance decision-making. Here’s a look at multiple use cases of business intelligence for supply chain management and real-world examples of businesses leveraging these tools effectively to understand the importance of business intelligence in supply chain management.

Optimizing Product Distribution

BI tools are essential for managing and improving product distribution processes. They track delivery timelines, monitor service quality, and analyze logistical costs, helping companies adjust operations in real-time to ensure timely deliveries.

Real Example: Amazon

Amazon uses BI to optimize its massive logistics operations. The BI solution helps Amazon analyze delivery routes, reduce transportation costs, and predict the best shipping methods for packages, ensuring that customers receive their orders as quickly and efficiently as possible.

Also Read: How Much Does it Cost to Develop a Marketplace App Like Amazon?

Enhancing Demand Planning

Demand planning with BI supply chain solutions involves using historical sales data and market analysis to forecast future product demand. This allows companies to adjust their production schedules and inventory levels accordingly, avoiding overproduction or stockouts.

Real Example: Walmart

Walmart, the most famous retail store, leverages the business intelligence model for supply chain management to forecast demand, particularly for seasonal products. By analyzing past sales data and current market trends, Walmart can precisely adjust inventory levels at each store, ensuring they meet local demand without overstocking.

Integrating IoT with BI for Equipment Management

BI increasingly integrates with IoT (Internet of Things) devices in manufacturing to monitor machine performance and maintenance needs. This data-driven approach ensures machinery operates efficiently and helps predict when maintenance is needed, reducing downtime.

Real Example: General Electric

GE uses BI integrated with IoT to monitor and analyze the performance of its industrial equipment. This system predicts maintenance needs and potential breakdowns, ensuring continuous production without unexpected interruptions.

[Also Read: How Business Intelligence is Driving Data-Driven Decisions in Manufacturing]

Streamlining Inventory Management

BI tools provide detailed insights into inventory levels, sales patterns, and supplier performance. This information offered by supply chain business intelligence tools helps businesses maintain optimal stock levels, reducing carrying costs and improving cash flow.

Real Example: IKEA

IKEA effectively manages its global inventory using BI supply chain solutions. The system tracks product levels across stores and warehouses, providing insights that help IKEA maintain the right stock balance while minimizing excess inventory and storage costs.

Essential Business Intelligence Tools for Supply Chain Management

Business Intelligence offers powerful tools for enhancing the productivity and efficiency of supply chain operations. Here’s a breakdown of three key BI tools every supply chain enterprise should consider to optimize their processes:

Reporting Tools

Reporting tools in BI systems help managers and decision-makers understand what’s happening in their operations daily. These tools use data to highlight areas of concern and track performance over time. Using predictive analytics, BI reporting tools can forecast trends and pinpoint operational inefficiencies. This allows companies to address issues before they escalate, ensuring smoother operations proactively.

For instance, a supply chain manager might use these reports to notice a recurring delay in shipment from a particular vendor and adjust the procurement strategy accordingly to avoid future disruptions.

Dashboards

Dashboards are one of the most interactive elements of BI systems, providing a real-time snapshot of the supply chain’s key performance indicators (KPIs). These customizable dashboards allow users to view the most relevant data in an easy-to-understand format. Features like data tables, graphs, and filters make it easier to digest complex information and make quick decisions.

For example, a logistics company might use a supply chain BI solution dashboard to monitor on-time delivery rates and quickly identify routes or drivers that are not meeting the expected standards, enabling fast resolution to maintain service quality.

Benchmarking

Benchmarking tools in BI help businesses compare their performance against industry standards or best practices. This is crucial for staying competitive and identifying areas for improvement. BI-driven benchmarking involves collecting performance data and comparing it against the metrics of industry leaders. This comparison can highlight performance gaps and guide strategic decisions.

A retail company, for instance, might use benchmarking to compare its inventory turnover rate with that of industry leaders, identifying opportunities to enhance its inventory management practices to reduce costs and increase profitability.

Steps to Implement Business Intelligence for Supply Chain Management

Implementing real-time Business Intelligence in supply chain analytics can dramatically enhance operational efficiency and decision-making. Here’s a straightforward step-by-step approach to integrating BI into your supply chain processes:

Assess Current Capabilities and Needs

Begin by evaluating your current data management systems and supply chain processes. Identify areas where BI could improve the most, such as inventory management, demand forecasting, or logistics optimization.

Define Clear Objectives

Set specific, measurable goals for what you want to achieve with BI. Whether it’s reducing delivery times, minimizing costs, or improving product availability, having clear objectives will guide the implementation process.

Choose the Right BI Tools

Select supply chain intelligence software that aligns with your business needs and objectives. Consider factors like scalability, ease of integration with existing systems, user-friendliness, and support services offered by the provider.

Develop a Data Management Strategy

Develop a comprehensive data management plan that includes data collection, storage, and analysis procedures. Ensure that the data quality is high and that the systems in place can handle the volume and variety of data your supply chain generates.

Train Your Team

Provide training for your staff on how to use the new supply chain BI software effectively. This should include the technical aspects of operating the software and understanding how to interpret the data insights to make informed decisions.

Integrate BI Software into Your Supply Chain

Integrate the selected BI software into your supply chain operations. This step might require customizing the software to fit specific supply chain functions or processes.

Monitor and Refine

Once implemented, continuously monitor the BI tools’ performance to ensure they meet your business objectives. Based on feedback and your business’s evolving needs, be prepared to adjust and refine your strategy as needed.

Review and Scale

Regularly review the impact of the supply chain business intelligence software on your supply chain. If successful, consider scaling the solutions to other business areas to maximize your operations’ efficiency and effectiveness.

Challenges of Implementing BI in Supply Chain

Integrating BI into supply chain management involves navigating several significant challenges. Effectively addressing these issues is crucial for leveraging BI’s full potential to enhance operational efficiencies and strategic decision-making.

Data Integration Complexity

Integrating data from various sources and systems can be highly complex, especially when the data exists in different formats or on disparate platforms. This diversity can create obstacles to achieving the unified view BI systems require for accurate analytics.

Solution: Organizations can use advanced middleware or employ integration platforms (iPaaS) to manage this complexity. These solutions facilitate smoother data integration by providing tools that automate the transformation and normalization of data, ensuring it is compatible and consistent across the board.

High Costs of Implementation

The upfront costs associated with implementing BI can be daunting. These costs include purchasing software, upgrading hardware, and training staff. Small to mid-sized enterprises might find these expenses particularly prohibitive.

Solution: To mitigate this challenge, businesses can partner with a dedicated development firm to create scalable, cloud-based BI software that offers subscription models. These models typically require lower initial investment and can be scaled up as the business grows and funds become more available.

Resistance to Change

Adopting new technologies often elicits resistance from employees, particularly if it threatens their roles or increases the complexity of their work routines.

Solution: To overcome this issue, management must engage with staff early. Clear communication about the benefits of BI, combined with comprehensive training programs, can help ease the transition. Highlighting how BI can make their jobs easier and contribute to the company’s success can foster a more receptive environment.

Data Privacy and Security Concerns

With the increasing volume of data handled by organizations in healthcare, finance, eCommerce, and other sectors, security risks and privacy concerns are more pronounced than ever, especially under strict regulations like GDPR, HIPAA, PCI-DSS, etc.

Solution: Companies must implement state-of-the-art security technologies, such as encryption and multi-factor authentication, in their BI software to address these issues related to adopting business intelligence for supply chain management. Regular security training and awareness programs for employees, compliance checks, and data protection impact assessments are essential to maintaining the integrity and confidentiality of data.

Lack of Expertise

Implementing and managing BI systems requires specific skills that may not be present in all organizations. The lack of internal expertise can hinder the effective utilization of BI tools.

Solution: Companies should consider investing in training and development programs for their current staff to bridge this gap. Additionally, hiring a data analytics firm with expertise in BI can provide the necessary knowledge and support to maximize the benefits of the BI system.

Ensuring Data Quality

The accuracy of outputs from supply chain business intelligence solutions is highly dependent on the quality of input data. Inconsistent data can lead to misleading insights, negatively affecting decision-making processes.

Solution: Establishing a robust data governance framework is critical in this regard. Such a framework should include regular audits, validation checks, and routines to clean and update the data. These measures ensure the reliability and accuracy of the data feeding into the BI tools, leading to more dependable analytics.

Future of Real-Time Business Intelligence in Supply Chain Analytics

The future of Business Intelligence in the supply chain industry is set to revolutionize how businesses handle logistics, inventory management, forecasting, and decision-making. Several innovative technologies are expected to drive significant advancements including:

Artificial Intelligence and Machine Learning: AI and machine learning will continue to refine BI capabilities, enabling more accurate predictions and smarter analytics. These technologies will process large datasets much more efficiently than traditional methods, allowing for real-time insights and proactive decision-making.

[Also Read: The Role of Artificial Intelligence in Supply Chain Management]

Internet of Things (IoT): IoT in the supply chain will integrate physical objects with sensors and software, providing a wealth of data that can be used to monitor everything from inventory levels to transportation conditions. This integration will enhance BI solutions by providing a continuous data stream, improving visibility across the supply chain.

Advanced Analytics: As data sources become more complex, advanced analytics powered by BI tools will become increasingly critical. These analytics will handle multi-layered data integration and provide insights that identify patterns, trends, and anomalies, helping businesses continuously optimize their operations.

Blockchain: The transformative power of blockchain in supply chain management will significantly improve transparency and security in supply chain business intelligence. It will create a permanent record of transactions, helping track product origins and ensuring regulatory compliance.

Cloud Computing: More businesses will use cloud-based BI solutions because of their scalability, cost-effectiveness, and remote accessibility. This will allow for more collaborative and integrated supply chain operations, with real-time insights available to all stakeholders.

Automation and Robotic Process Automation (RPA): Automation technologies, such as RPA, will minimize the need for manual data handling, thereby accelerating processes and decreasing errors. This efficiency gain will allow teams to focus more on strategic initiatives than routine tasks.

Why Appinventiv Is Your Ideal Partner for Developing BI Solutions to Streamline Supply Chain Management

Choosing the right partner is crucial when developing business intelligence solutions that optimize supply chain management. As a dedicated Business Intelligence software development firm, our experts can bring expertise and innovation to every project.

Proven Expertise in BI Development: Appinventiv has a rich history of creating powerful BI solutions that transform vast amounts of data into actionable insights. Our team of experts uses state-of-the-art technologies and methodologies to deliver tools that meet and exceed client expectations.

Customized Solutions for Unique Needs: We understand that each business has its own unique challenges and requirements. At Appinventiv, we specialize in developing customized BI solutions tailored to the specific needs of your supply chain operations, ensuring that you receive a product perfectly suited to your objectives.

Advanced Analytical Tools: Leveraging the latest in advanced analytics, we provide clients with superior predictive tools that enhance decision-making. These tools help foresee potential supply chain disruptions and allow for proactive management, keeping your operations smooth and efficient.

Integration Capabilities: Our solutions are designed to seamlessly integrate with existing systems, minimizing disruption and maximizing compatibility. This ensures a smooth implementation process and helps maintain continuity in your supply chain operations.

Commitment to Innovation: We are committed to staying at the forefront of technology. We continuously explore emerging trends and innovations in the BI space to ensure our solutions offer the most advanced capabilities, keeping your business ahead of the curve.

Reach out today to discuss your specific needs and how we can help you achieve your supply chain management goals.

FAQs

Q. How much does implementing the BI in the supply chain cost?

A. The cost to implement Business Intelligence in the supply chain typically ranges from $50,000 to $200,000. This range depends on various factors, including the complexity of the BI system, the deployment scale, the specific features required, and the level of customization needed to integrate the system with existing technologies.

Q. What is supply chain intelligence?

A. Supply chain intelligence strategically uses data and analytics to optimize the supply chain process. It involves gathering and analyzing data from various supply chain stages to make informed decisions that enhance efficiency, reduce costs, and improve overall supply chain performance.

Solutions powered by Business intelligence for supply chain management provide engaged data through reports and dashboards that help vendors, production managers, and distributors track machinery and shipments.

The role of business intelligence in supply chain management also includes monitoring logistics by analyzing timely returned orders and the reasons for returns. This helps identify order patterns and can personalize products.

Q. What is the difference between Business Intelligence (BI) and Business Analytics (BA)?

A. As BI becomes more prominent, there has been a rising confusion between Business Intelligence and Business Analytics.

In simple words, BI utilizes present and past data to drive current business decisions, whereas BA analyses only historical data to drive current business needs. For detailed insights, refer to our blog on Business Intelligence vs Business Analytics.

How Business Intelligence in Manufacturing is Driving Data-Driven Decisions

As the manufacturing sector becomes increasingly intricate, leveraging data effectively has never been more critical. Manufacturers today navigate a labyrinth of processes, technologies, and human capital, all while striving for greater efficiency and innovation. This is where business intelligence for manufacturing emerges as a game-changer. By transforming complex datasets into actionable insights, BI enables organizations…

How Business Intelligence in Healthcare is Improving Patient Care

Healthcare generates a staggering 30% of the world’s data, yet 97% of it goes unused (Source: Forbes). In an era where data holds the key to better patient outcomes, BI or business intelligence in the healthcare industry is transforming decision-making. From predictive analytics that prevent hospital readmissions to real-time dashboards that enhance clinical workflows, BI…

How data mining helps in business intelligence

Data is the life-powering proverbial blood that empowers the corporate economy of the 21st century. And although it may incite fanciful scenarios to mind with a mere mention, the truth is data is key to unlocking human productivity in every sphere of life. Climate change, business failures, epidemics, and crop production, all can be understood…