- Overview of On-Demand Logistics Application

- Market Direction

- A Comprehensive View of the Costs Involved in Developing an On-Demand Logistics App

- On Demand Logistics App Development Cost Breakdown by Complexity

- On Demand Logistics App Development Cost Breakdown by Stage

- Overview of How to Estimate the Costs

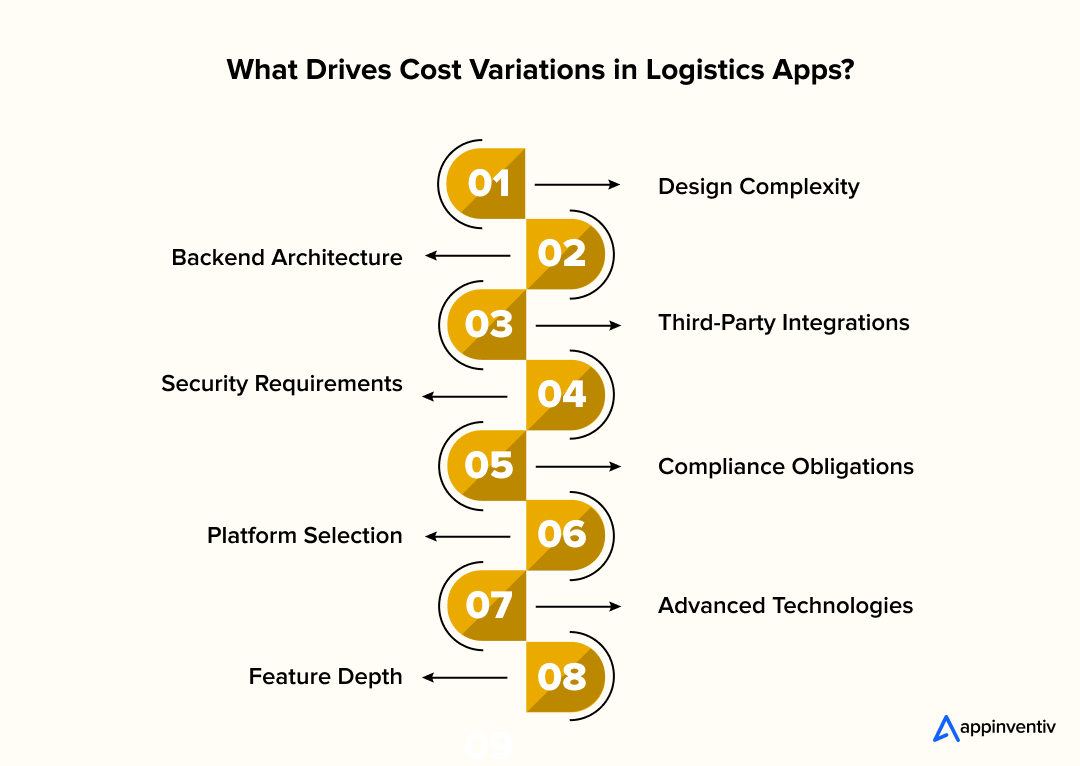

- Factors Affecting Logistics App Development Cost

- 1. Complexity of Design

- 2. Complexity of Backend Development

- 3. Third Party Integrations

- 4. Security Measures

- 5. Compliance Measures

- 6. Platform Selection

- 7. Technologies Used

- 8. Complexity of Features

- Hidden On-Demand Logistics App Development Costs

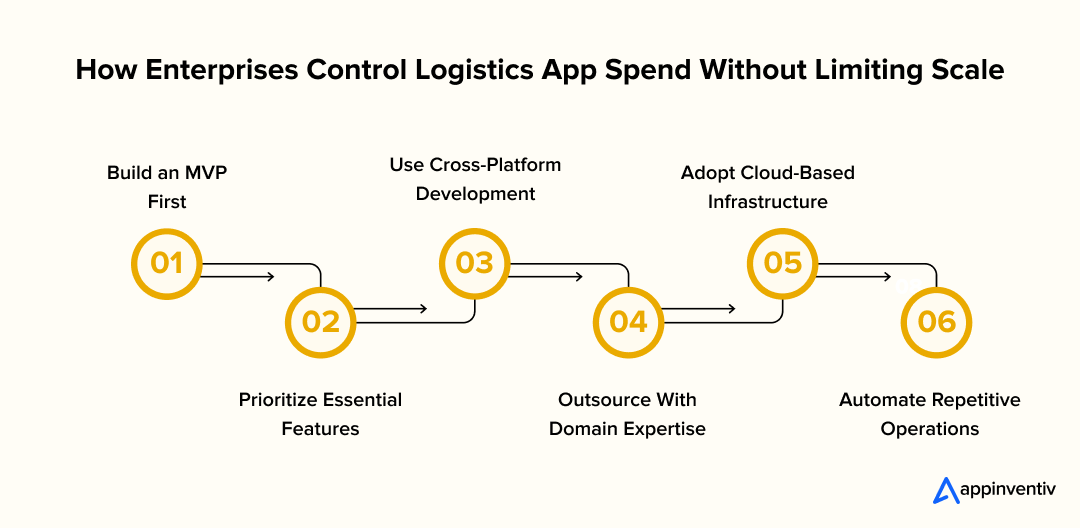

- Ways to Optimize On-Demand Logistics App Development Costs

- Developing an MVP (Minimum Viable Product)

- Prioritizing Necessary Features

- Leveraging Cross-Platform Development

- Outsourcing to Cost-Effective Regions

- Cloud-Based Solutions

- Automating Repetitive Tasks

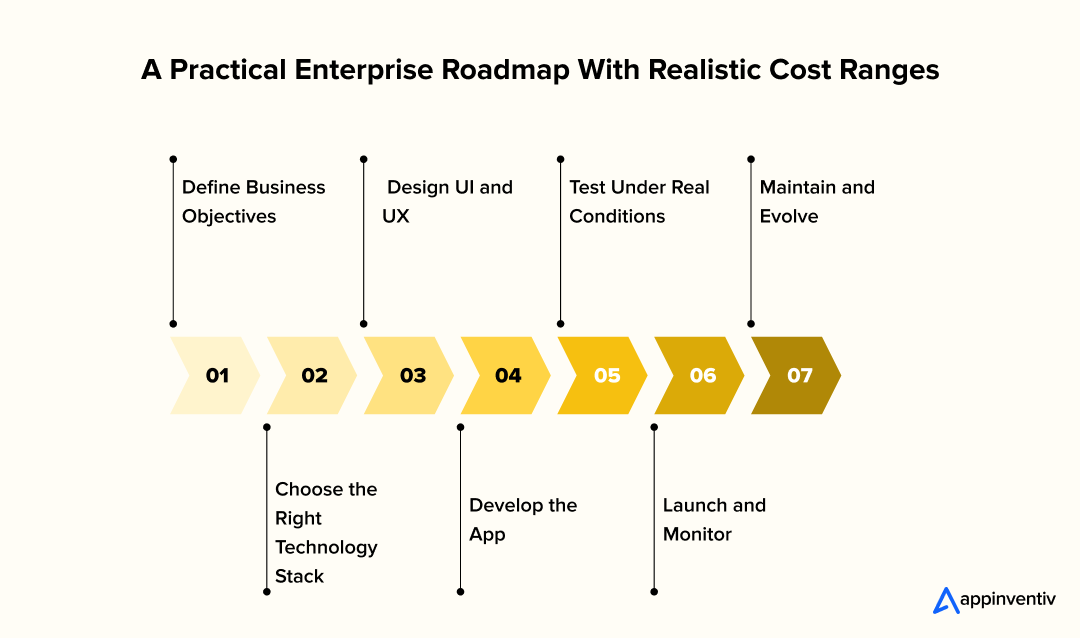

- How to Develop an On-Demand Logistics App?

- Step 1: Define Business Objectives and Requirements

- Step 2: Choose the Right Technology Stack

- Step 3: Design the User Interface and User Experience (UI/UX)

- Step 4: Develop the App

- Step 5: Test the App

- Step 6: Launch the App

- Step 7: Post-Launch Maintenance and Updates

- Ways to Make a Better-than-Average On-Demand Logistics App

- 1. Focus on Superior UI/UX Design

- 2. Implement Advanced Features with AI and Machine Learning

- 3. Real-Time Tracking and Notifications

- 4. Integrate IoT for Smart Logistics

- 5. Enhance Security Features

- 6. Scalability and Flexibility

- 7. Seamless Integration with Existing Systems

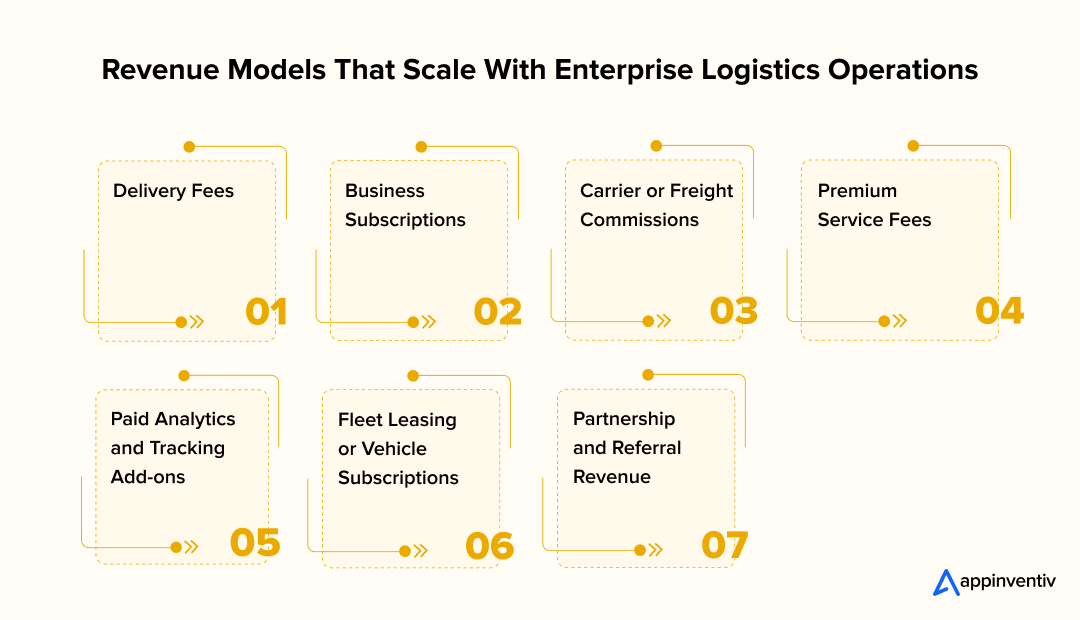

- How On-Demand Logistics Apps Make Money?

- 1. Delivery Fees

- 2. Subscription Models for Businesses

- 3. Commission from Freight Partners

- 4. Service Fees for Premium Features

- 5. In App Purchases for Tracking or Analytics

- 6. Fleet Leasing or Vehicle Subscription

- 7. Partnership Revenue

- Why Partner with an On-Demand Logistics App Development Company Like Appinventiv?

- Frequently Asked Questions

Key takeaways:

- On-demand logistics app development cost typically ranges from $30,000 to $300,000 depending on features, tech stack, integrations, and scale.

- The real ROI comes from efficiency gains such as reduced manual work, AI-driven route optimization, and systems that perform reliably during peak demand.

- Enterprise-grade logistics apps require investment in backend scalability, security, compliance, and integrations with ERP, WMS, and payment systems.

- Costs continue after launch with maintenance at 15 to 20 percent per year, plus hosting, marketing, data storage, and licensing.

- The smartest way to control budget is to build MVP first, prioritize essential features, use cross-platform development, and adopt cloud infrastructure for flexible scaling.

Most logistics leaders hit a moment where spreadsheets, calls, and disconnected tools stop scaling with the business. Orders increase, delivery windows tighten, and small delays start showing up in customer complaints.

The on-demand logistics app market reflects this shift. It is expected to grow from $23.3 billion in 2025 to $138.2 billion by 2035. That growth comes from teams like yours looking for faster dispatching, real-time tracking, and systems that hold up during peak demand instead of breaking under it.

When you look at building an app, logistics app development cost typically ranges from $30,000 to $300,000. The number moves based on what you need, core features, system complexity, and the technology stack. For enterprise leaders, the real question is not just cost. It is whether the platform improves efficiency, reduces manual work, and helps control operating expenses as volume grows.

This blog breaks down what drives the cost of on demand logistics app development and how to estimate it realistically. If you are planning a custom logistics platform or comparing vendors, understanding these factors will help you make decisions that support long term scale, not short-term fixes.

Our logistics platforms have helped enterprises cut transportation costs by up to 40% using AI-driven routing and real-time visibility.

Overview of On-Demand Logistics Application

Supply chain decision makers often reach a point where traditional tools can no longer support scale. Calls to drivers, manual status checks across multiple systems, and spreadsheet based coordination create delays that become noticeable in daily performance and in customer experience.

On demand logistics and transportation management apps address this operational gap. They provide a connected system where shippers, carriers, and internal teams view logistics activity in real time and respond as conditions change. Dispatch adjustments, pickup window changes, and reroutes can be executed within a single platform instead of across fragmented tools.

Key Benefits for Enterprise Operations

- Real time tracking: Teams have immediate visibility into shipment progress without relying on manual calls or scattered data sources.

- Automated scheduling: Delivery assignments adjust automatically when orders arrive late or volume increases, which reduces operational intervention.

- Route optimization: Routing dynamically adapts to distance and traffic conditions to support delivery accuracy and control variable transportation costs.

Collectively, these capabilities reduce operational friction. They enable teams to focus on maintaining throughput and meeting delivery commitments rather than managing administrative work.

Market Direction

Logistics operations are evolving toward higher order density, faster fulfillment expectations, and increased demand for transparency. Legacy systems that depend on manual coordination are not built to scale in such environments. Enterprises are therefore adopting platforms that provide flexibility, automation, and the ability to maintain service levels during peak load and unexpected volume shifts.

Applications in the market already demonstrate this shift. Freight matching platforms and last mile delivery apps show how real time visibility and automated execution have become baseline expectations rather than differentiators.

A parallel challenge was identified by a global equipment manufacturer that lacked real time visibility across its supply chain. Appinventiv delivered a platform with live tracking and AI based analytics, allowing teams to make informed operational decisions rather than reacting after delays surfaced. The improvement in coordination resulted in measurable cost efficiencies and more predictable daily performance.

Also Read: Building a Logistics Management System: The Why’s and How’s

A Comprehensive View of the Costs Involved in Developing an On-Demand Logistics App

In practice, the logistics app development cost usually falls between $30,000 and $300,000. That range reflects differences in feature depth, technical complexity, and how much customization your operations require.

On Demand Logistics App Development Cost Breakdown by Complexity

Logistics application development pricing varies mainly based on how advanced the app needs to be. A basic product supports straightforward delivery flows, while more complex platforms handle optimization, analytics, and fleet-level coordination. As features grow, so does the investment.

| Complexity Level | Cost Range | Features |

|---|---|---|

| Basic | $30,000 – $80,000 | Real-time tracking, simple payments, and basic delivery scheduling |

| Medium | $80,000 – $120,000 | Route optimization, automated scheduling, advanced tracking, multi-user access |

| Enterprise Logistics Software Development Cost | $150,000 – $300,000 | AI-driven optimization, predictive insights, fleet management, and complex system integrations |

Also Read: A Comprehensive Guide to Estimating Custom Software Development Costs

On Demand Logistics App Development Cost Breakdown by Stage

Every phase adds its own share to the total budget. Early planning sets direction, design shapes usability, and development does the heavy lifting. Launch and maintenance make sure the app works reliably once real users depend on it.

| Development Stage | Cost Range | Time Estimate | What does it include? |

|---|---|---|---|

| Planning | $5,000 – $10,000 | 2 to 3 weeks | Research, requirement discussions, early prototypes |

| Design | $10,000 – $30,000 | 3 to 6 weeks | UI and UX design, wireframes, and user feedback sessions |

| Development | $50,000 – $200,000 | 3 to 6 months | Front-end and back-end build, databases, API integrations |

| Launch | $5,000 – $10,000 | 1 to 2 weeks | Testing, deployment, app store submissions |

| Maintenance | 15% to 20% | Ongoing | Ongoing updates, fixes, and feature improvements |

Taken together, this breakdown gives a clearer picture of where money and time are actually spent. It helps teams plan realistically, compare vendors with confidence, and avoid surprises once development is underway.

Overview of How to Estimate the Costs

A simple way to estimate logistics mobile app development cost is to break work into stages and calculate effort for each one.

Total cost = (Hourly rate × hours per stage) + maintenance + platform fees

Example:

If your development partner charges $100 per hour and a stage takes about 500 hours, that phase alone costs $50,000. Add maintenance and any platform-related fees to reach a more realistic total.

Factors Affecting Logistics App Development Cost

Cost conversations often start once teams have seen an early demo or mapped a workflow. It is usually at that point when questions arise about why one estimate sits at the lower end of the spectrum while another is significantly higher. The difference rarely comes from a single feature. It comes from the depth of the system, how many moving parts it must coordinate, and how reliably it needs to perform under pressure.

Logistics software development is shaped by two forces: what the operation requires and what the technology must support to make that possible. Advanced capabilities such as automated routing, AI based forecasting, or large scale tracking add value but require additional effort to design, build, and maintain. The long term benefit is that once these systems are established, they scale without needing to increase headcount or expand manual workflows.

1. Complexity of Design

Logistics app design costs rise when the app needs to do more than display static screens. Interactive dashboards, live maps, and responsive interfaces all take time to build and test. In logistics apps, design work often centers on clarity.

When dispatchers glance at a screen during peak hours, they need to understand shipment status instantly. Achieving that level of simplicity requires thoughtful design and solid backend coordination.

2. Complexity of Backend Development

The backend keeps everything running when usage spikes. It manages data flow, user roles, and integrations with external systems. For apps handling large volumes of location and order data, backend design quickly becomes one of the largest cost drivers.

Many teams use microservices with tools like Docker or Kubernetes to keep systems modular and scalable. Cloud platforms such as AWS or Google Cloud support this approach and help teams grow capacity without rebuilding core components.

Also Read: How Cloud in Logistics Business Can Unlock Hidden Revenue Streams

3. Third Party Integrations

Most logistics apps rely on outside services. Payments, maps, tracking, and notifications rarely live inside a single system. Each integration adds effort, especially when licensing or customization is involved.

Costs can be controlled by using pre-built frameworks or open source alternatives for routing and tracking. This reduces custom development while still supporting essential workflows.

4. Security Measures

Security becomes a serious concern the moment someone asks who can see what’s inside the system. Logistics apps move sensitive information all day, from customer details to shipment locations and payments. That makes basics like encryption, login controls, and access limits non negotiable.

Most teams avoid building security from the ground up. Managed services from cloud providers (AWS KMS or Azure Key Vault) take care of a lot of heavy lifting, such as handling encryption keys and access policies. This keeps systems safer without turning security into a separate engineering project.

5. Compliance Measures

Compliance often enters the conversation when the app starts touching customer data at scale. Regulations like GDPR or CCPA shape how information is stored, shared, and reviewed. These rules affect everyday design choices, not just legal checklists.

Many teams lean on cloud platforms that already include compliance tools. Features like role based access and data masking reduce manual work and help avoid problems later, especially as the product grows.

6. Platform Selection

Platform choices usually show their impact months after development begins. Native apps for iOS and Android run fast but require teams to maintain two separate builds. That can stretch both budget and timelines.

Cross platform tools like React Native or Flutter help teams move quicker by sharing most of the code. For logistics apps that depend on live updates and GPS data, this approach often delivers the right balance between performance and efficiency.

Also Read: Most Popular Cross-Platform App Development Frameworks in 2025 and Beyond

7. Technologies Used

Advanced features are appealing, but they come with tradeoffs. AI, machine learning, and IoT unlock smarter routing, better tracking, and improved fleet control. They also demand more planning, deeper expertise, and stronger infrastructure.

Machine learning work depends on specialized skills and ongoing tuning. IoT integrations introduce hardware and cloud coordination. Teams that plan for these realities early tend to avoid surprises once development is underway.

8. Complexity of Features

Feature scope often drives the biggest cost swings. Basic tracking and scheduling are relatively straightforward. Advanced analytics, real-time reporting, and fleet-level optimization require deeper expertise.

Systems that process live data streams or large datasets use tools like Apache Kafka or Apache Spark. These choices improve performance at scale but increase build time and overall investment.

Hidden On-Demand Logistics App Development Costs

Logistics app development keeps evolving once real users start relying on it. Small fixes, infrastructure tweaks, and operational needs quietly add to the budget. When these costs are planned upfront, they are manageable. When they are not, they feel unexpected.

| Hidden Cost | Cost Range | Description |

|---|---|---|

| App Maintenance | 15 to 20 % each year | Fixes and updates that surface once drivers, operators, and customers use the app daily. |

| App Hosting | $5,000 to $20,000 per year | Cloud costs increase as data builds up and usage rises during peak delivery periods. |

| App Promotion and Marketing | $10,000 to $100,000 per year | Ongoing spend to keep the app visible once the initial launch attention fades. |

| Legal and Licensing Fees | $5,000 to $15,000 | Compliance reviews and licenses that come into play as the app expands into new markets. |

| Data Storage and Backup | $2,000 to $10,000 per year | Secure storage and backups are needed as shipment history and operational data accumulate. |

None of these costs appear overnight. They build gradually as the app becomes part of daily operations. Teams that plan for them early stay in control, while others are forced to adjust budgets later when costs surface unexpectedly.

Ways to Optimize On-Demand Logistics App Development Costs

Logistics mobile app development cost overruns do not come from one big mistake. They happen slowly. A feature sounds useful in a meeting, a timeline stretches by a week, then another. Before long, the budget feels tighter than expected.

Keeping costs under control is knowing when to say not yet. Teams that stay close to real operational needs tend to spend more intentionally and get better results without trimming quality.

| Cost Optimization Strategy | Potential Cost Reduction |

|---|---|

| Developing an MVP | Saves around 30% to 50% by building only what is needed to get started. |

| Prioritizing Necessary Features | Cuts 20% to 40% by skipping features that do not support daily operations. |

| Leveraging Cross-Platform Development | Lowers costs by 20% to 40% by avoiding duplicate Android and iOS builds. |

| Outsourcing to Cost-Effective Regions | Reduces hourly rates by 30% to 60% in regions like Eastern Europe and India. |

| Cloud-Based Solutions | Lowers infrastructure spend by 15% to 30% by scaling only when needed. |

| Automating Repetitive Tasks | Reduces operational effort by 20% to 30% by removing manual backend work. |

Developing an MVP (Minimum Viable Product)

An MVP helps teams stay grounded. Instead of guessing every future requirement, you build only what supports real work today. Many teams realize this after launch, when they see which features get used constantly during busy hours and which ones are rarely needed.

Prioritizing Necessary Features

Not every feature earns its keep. Some look impressive but see little real use. Focusing on essentials keeps spending aligned with how the app is actually used. Live tracking, simple routing, and reliable payments usually matter more than advanced options early on.

Leveraging Cross-Platform Development

Supporting two platforms separately adds coordination overhead. Cross-platform tools like React Native or Flutter reduce that burden. Teams can release updates faster and avoid repeating the same work twice, which helps when changes are frequent.

Outsourcing to Cost-Effective Regions

Lower rates can help, but experience matters more. Teams that understand logistics workflows reduce back and forth and avoid costly rework. Clear communication and shared expectations often make a bigger difference than location alone.

Cloud-Based Solutions

Cloud services give you flexible spending. You pay for what you use, not what you might need someday. This matters when volumes fluctuate, like during end of month spikes or seasonal demand.

Automating Repetitive Tasks

Manual backend work adds friction over time. Automating tasks like reporting or reconciliation reduces errors and frees teams to focus on operational decisions. The benefits usually show up quietly, through smoother days and fewer fire drills.

See how enterprises use modular architecture, MVP-first builds, and AI selectively to control spend and still future-proof operations.

How to Develop an On-Demand Logistics App?

Teams do not start with a perfect plan. They start with pressure. Orders are increasing, systems feel slow, and someone asks if an app could fix this. From there, things need structure, cost, and scope drift quickly.

Below is the same step-by-step path many enterprises follow when building an on-demand logistics app, along with realistic cost ranges at each stage.

Step 1: Define Business Objectives and Requirements

Cost Range: $5,000 to $10,000

This step usually begins with conversations, not documents. Operations explains where delays happen. Leadership talks about scale. IT flags constraints. Your job here is to turn all of that into clear priorities. When teams skip this, features get added later at a much higher cost.

Step 2: Choose the Right Technology Stack

Logistics App Cost Based on Tech Stack: $10,000 to $50,000

At the beginning, technology decisions often feel far removed from day to day work. They usually come up in planning meetings or slide decks. Their impact shows itself later, when an app feels sluggish during peak hours or when infrastructure bills start rising.

Many teams choose cloud platforms like AWS or Google Cloud because they can scale without long setup cycles.

When timelines are tight, cross platform tools such as React Native or Flutter help teams ship faster. If routing or forecasting is part of the plan, AI tends to come up early because it influences how the system will behave over time.

Step 3: Design the User Interface and User Experience (UI/UX)

Cost Range: $10,000 to $30,000

Design is where assumptions get tested. What looks fine in a meeting may fail during a busy shift. Dispatchers need clarity. Drivers need simplicity. Designers focus on layouts that make sense at a glance, especially for tracking and scheduling screens that get checked repeatedly during the day.

Step 4: Develop the App

Cost Range: $50,000 to $200,000

This is the longest phase. Front-end screens are built. Backend systems take shape. Integrations with payments, maps, and tracking services are added. Teams often choose modular setups so parts of the system can scale without touching everything else.

Step 5: Test the App

Cost Range: $5,000 to $20,000

Testing is usually the moment when confidence gets tested. Someone runs through the app as if it were a real workday, orders coming in quickly, screens switching fast, users logging in at the same time.

That is when small cracks start to show. Things that looked fine in demos behave differently under pressure. Catching those issues here saves a lot of time, money, and stress compared to discovering them once customers are already relying on the app.

Step 6: Launch the App

Cost Range: $5,000 to $10,000

Launch day itself is usually calm. There is no big moment, just a final review, a submission, and careful monitoring. The first feedback often comes from a small group of users who notice edge cases that no test ever revealed, simply because they are working under real conditions that no one could fully simulate.

Step 7: Post-Launch Maintenance and Updates

Cost Range: 15 to 20 % of total development cost per year

Once people rely on the app, work does not stop. Bugs get fixed. Performance is tuned. New needs emerge. Teams that plan for ongoing updates avoid disruption and keep the app aligned with how operations actually run.

Most teams understand the theory behind building a logistics app. The real learning happens when you see how it works in production, during peak hours, across regions, and with real operational pressure.

A good example is Appinventiv’s work with Americana. The goal was to support last-mile delivery across multiple restaurant brands operating throughout the MENA region. By building an AI-powered delivery platform, Appinventiv helped central teams manage fleets more effectively while giving each brand the flexibility it needed.

The result was smoother dispatching, fewer delays during busy meal periods, and higher customer satisfaction across locations.

Ways to Make a Better-than-Average On-Demand Logistics App

Logistics apps look fine during a demo. Problems usually show up later, on a busy slot when orders pile up, drivers are calling in, and someone just wants a clear answer fast. That is where average apps fall short.

Logistics costs already eat up 30% of delivery budgets. Building a better app is less about chasing trends and more about fixing the everyday pain points teams deal with. The companies that get this right focus on usefulness first and trends second.

1. Focus on Superior UI/UX Design

Good design is not about looking modern. It is about helping someone get their job done quickly. Dispatchers should not have to click through five screens to check a delivery. Drivers should not struggle to find their next stop.

Clear maps, readable status updates, and layouts that adapt to different devices make a real difference. Many teams improve usability by watching how people actually use the app during a shift and adjusting based on that, not assumptions.

2. Implement Advanced Features with AI and Machine Learning

AI in logistics only matters when it solves a real problem. Route planning is a good example. Instead of relying on static rules, apps can learn from past deliveries and suggest better routes over time.

Some systems adjust routes during the day based on traffic, weather, or load changes. These improvements might seem small, but over hundreds of deliveries, they reduce fuel use, delays, and support calls.

Also Read: 10 Use Cases and Examples of How Machine Learning is Transforming the Logistics Industry

3. Real-Time Tracking and Notifications

Logistics tracking app development should focus on answering questions before they are asked. When a shipment enters a zone or gets delayed, the right people should know without digging through logs.

Geo-fencing and live GPS data help teams stay ahead of issues. Notifications work best when they are relevant and timely. Too many alerts get ignored. The goal is clarity, not noise.

4. Integrate IoT for Smart Logistics

Physical goods do not move digitally, so visibility matters. Sensors can show if a shipment gets too warm or stops moving unexpectedly. RFID tags help track assets across warehouses and transit points.

When this data feeds into a central system, teams can spot problems early. Fixing an issue mid-route is usually far cheaper than explaining it after delivery.

Also Read: IoT in Supply Chain and Logistics – Benefits, Use Cases & Challenges

5. Enhance Security Features

Security is rarely visible when it works, but it is costly when it fails. Logistics apps handle sensitive shipment and customer data every day. Encryption and access controls should be standard, not optional.

Some teams use tamper-resistant records to track transactions and handoffs. Combined with strong login controls, this reduces risk without slowing daily work.

6. Scalability and Flexibility

Usage does not grow in a straight line. One promotion or seasonal spike can stress systems quickly. Apps built in small, independent parts handle this better.

Cloud platforms help scale up when demand rises and scale back when things quiet down. This keeps systems stable without paying for unused capacity.

7. Seamless Integration with Existing Systems

A logistics app never runs in isolation. It has to fit into whatever systems your team already uses, like ERP software, warehouse management tools, and reporting dashboards that people rely on every day.

When those connections are set up properly, things feel noticeably smoother. Data moves on its own. Numbers line up without someone double checking them in a spreadsheet. Teams spend less time fixing mismatches and more time responding to what the data is actually telling them.

You usually notice the difference in small ways. Fewer phone calls asking for updates. Fewer steps to complete routine tasks. Fewer surprises during the day. When work feels calmer and more predictable, that is when the app is really doing its job.

How On-Demand Logistics Apps Make Money?

The way a logistics app makes money usually becomes a real question once usage starts growing. At first, the focus is on getting deliveries out the door. Then finance asks how this scales and whether the model holds up when volumes double. That is where a clear revenue approach matters.

As on-demand logistics continues to expand, apps have more than one way to earn. The strongest models tend to align closely with how businesses already operate and pay for logistics today.

1. Delivery Fees

This is often the first revenue stream teams think about. Fees are tied directly to each delivery, which makes them easy to understand and explain. Pricing might depend on distance, cargo type, or weight.

Some apps keep it simple with flat fees. Others adjust pricing based on conditions like traffic or urgency, which reflects real-world delivery costs. Tiered pricing also works well when deliveries vary widely in complexity.

2. Subscription Models for Businesses

Many platforms offer subscriptions to companies that use the app regularly. These plans are usually based on delivery volume or access to advanced features such as priority scheduling or smarter routing.

Different tiers give businesses options as they grow. For the app provider, subscriptions create predictable revenue instead of relying only on per-delivery charges.

3. Commission from Freight Partners

Platforms that connect shippers with carriers often rely on commissions. Each completed transaction generates a percentage for the app.

This model fits well when the platform acts as a marketplace, especially for freight or high-value shipments. As transaction volume increases, revenue scales naturally with it.

4. Service Fees for Premium Features

Some services are worth paying extra for. Faster deliveries, added security, or access to dedicated drivers often fall into this category.

Apps may charge separate fees for these options. A rush delivery or guaranteed delivery window is a common example of when businesses are willing to pay for when timing matters.

5. In App Purchases for Tracking or Analytics

Once teams start relying on the app day after day, questions naturally follow. Where are we losing time? Which routes cost more than they should? That is when deeper insights start to matter.

Detailed reports, live dashboards, and performance views give operations teams something concrete to work with. They can spot patterns, fix inefficiencies, and make decisions with more confidence.

Offering these features as optional add ons gives businesses flexibility. They pay for the level of visibility they actually need, not a one size fits all package.

6. Fleet Leasing or Vehicle Subscription

Apps that manage vehicles can also generate revenue through short-term leasing. This works well during peak seasons when demand rises unexpectedly.

Instead of buying new vehicles, businesses can rent them through the app for a few days or weeks. Charging by the hour or day creates flexibility for customers and a steady income for the platform.

7. Partnership Revenue

Most logistics apps do not need to do everything on their own. Teams already work with packaging vendors, warehouses, and insurance providers as part of daily operations, so it makes sense to connect those services rather than rebuild them.

When an app points users to trusted partners, everyone benefits. Businesses get quick access to services they already need, and the app earns a referral fee in return.

Over time, these connections turn into a practical network of services that work together, instead of a single tool trying to handle everything alone.

Validate whether delivery fees, subscriptions, or AI-powered insights make sense for your logistics volumes and margins.

Why Partner with an On-Demand Logistics App Development Company Like Appinventiv?

Anyone who has worked in logistics knows that good software is only part of the equation. The real challenge in logistics software development services is understanding how work actually happens, where delays creep in, and what costs teams lose sleep over.

Technology should make those problems easier, not introduce new ones. Since logistics already consumes a large part of operating budgets, the choices made during product design end up shaping margins and day to day performance far more than most teams expect.

Appinventiv brings more than 10+ years of hands-on experience in logistics and transportation app development, with over 250 platforms delivered across industries. We have worked with brands such as Americana, IKEA, Adidas, Edamama, and 6th Street. A 95% customer satisfaction rate across logistics projects reflects how closely we stay aligned with real business needs.

Our teams have delivered AI-driven route optimization solutions that helped clients reduce logistics costs by up to 40%. For supply chain platforms, we maintain a 99.90% SLA, which matters when your operations depend on systems being available during peak hours, not just in demos.

Partnering with Appinventiv as your on-demand app development company means working with a team that understands both technology and logistics realities. You get access to modern platforms, experienced guidance, and delivery teams focused on building systems that perform reliably as your business grows.

The goal is simple. Help you run operations more efficiently while delivering a better experience to your customers.

Frequently Asked Questions

Q. What are some examples of on-demand logistics apps?

A. If you look at how goods actually move today, a few familiar names come up quickly. Platforms like Uber Freight, Postmates, Delhivery, Lalamove, and Porter are widely used because they solve very specific problems.

They help teams track shipments as they move, match loads with available carriers, adjust pricing when conditions change, and schedule deliveries without long back and forth calls. At the enterprise level, many companies go a step further and build their own on-demand logistics platforms, shaped around their routes, partners, and internal processes rather than relying only on off the shelf tools.

Q. What are the different types of logistics apps?

A. Logistics apps tend to grow out of real operational needs. Some focus on quick, on-demand deliveries. Others help match freight with carriers or manage fleets on the road. There are also apps built for warehouse operations, last mile delivery, or tracking assets across locations.

Larger enterprises often bring several of these together into one platform, so dispatching, tracking, reporting, and ERP integrations all live in the same place. That kind of setup gives teams a clearer picture of what is happening from pickup to final delivery.

Q. How to choose an app development company for logistics app development?

A. This decision usually matters more than any single feature. You want a team that understands logistics beyond screens and APIs. Look at whether they have built systems that handle live tracking, routing changes, or fleet coordination. Past projects, client conversations, and how they explain tradeoffs often tell you more than sales decks.

Q. How can I keep app development costs within budget?

A. Most budget overruns start with good intentions. One extra feature here, another there. Teams that stay within budget usually start small. An MVP focused on essentials helps keep scope in check. Cross-platform development saves time, and working with experienced teams in cost-effective regions can stretch budgets further without sacrificing quality.

Q. How much does logistics app development cost?

A. In practice, the logistics mobile app development cost applies to the same range again, roughly $30,000 to $300,000. Apps near the lower end focus on core workflows. Costs rise as soon as you add AI routing, deep analytics, or third-party integrations. These features take longer to build and require more specialized skills.

Q. How long does it take to build a logistics app?

A. Most builds land in the 4 to 6 month window. Shorter timelines work for limited functionality. Once fleet management, predictive insights, or complex integrations are involved, schedules naturally extend. Much of that time goes into making sure the app holds up when usage spikes.

Q. How much does AI-driven route optimization add to logistics app development cost?

A. AI routing usually adds about 20% to 40% to development costs. The work goes beyond code. Teams need data, testing cycles, and infrastructure that can handle real-time decisions. The upside shows later, when routes improve, fuel costs drop, and planners spend less time fixing avoidable issues.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How to Build a Warehouse Management System in Australia: Cost, Architecture & Implementation

Key takeaways: Before you build a Warehouse Management System (WMS) in Australia, check how things work in your warehouse right now. Find the problems that slow you down. You'll need to create the system design. Then choose what technology to use. Connect it to the tools you already have. Train your team so they know…

Computer vision is no longer a futuristic concept confined to sci-fi books and movies. The technology is everywhere, subtly reshaping the way users interact with technology. From facial recognition on smartphones to quality inspections on factory floors, computer vision helps machines interpret and understand images, videos, and other visual inputs. This powerful technology has proven…

Route Planner App Development - Costs, Benefits, Features

In the complex world of logistics, where cost-effectiveness and on-time delivery are crucial, route planning is a prominent challenge that can significantly impact the business's bottom line. For fleet managers and drivers alike, navigating the intricate web of roads, traffic, and constantly shifting variables can be an enormous undertaking. This is where route planner apps…