- Understanding the AI in Manufacturing Market: A Glimpse into the Future

- Types of AI Technologies in Manufacturing: A Quick Insight

- Machine Learning (ML)

- Computer Vision

- Natural Language Processing (NLP)

- Robotics And Automation

- Digital Twins

- Predictive Analytics

- How is AI Used in Manufacturing: Understanding the Use Cases of Turning Innovation into Measurable Results

- Predictive Maintenance

- Quality Control and Inspection

- Supply Chain Optimization

- Energy Efficiency Management

- Generative Design and Product Innovation

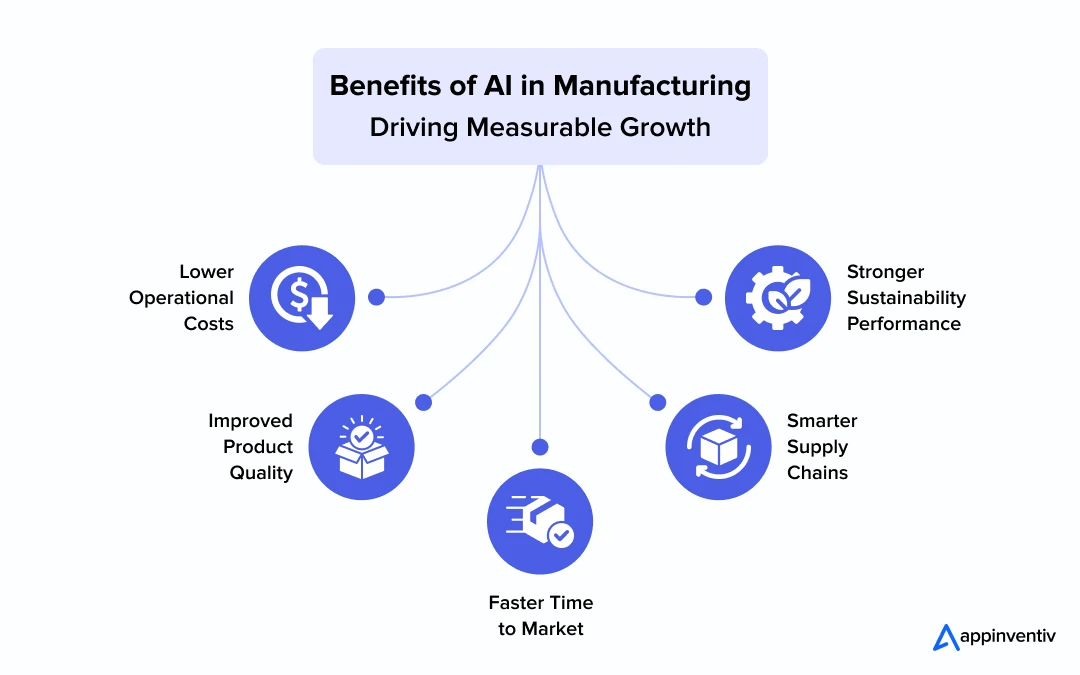

- Benefits of AI in Manufacturing: Why the ROI is Hard to Ignore

- Lower Operational Costs

- Improved Product Quality

- Faster Time to Market

- Smarter Supply Chains

- Stronger Sustainability Performance

- Improved Safety and Compliance

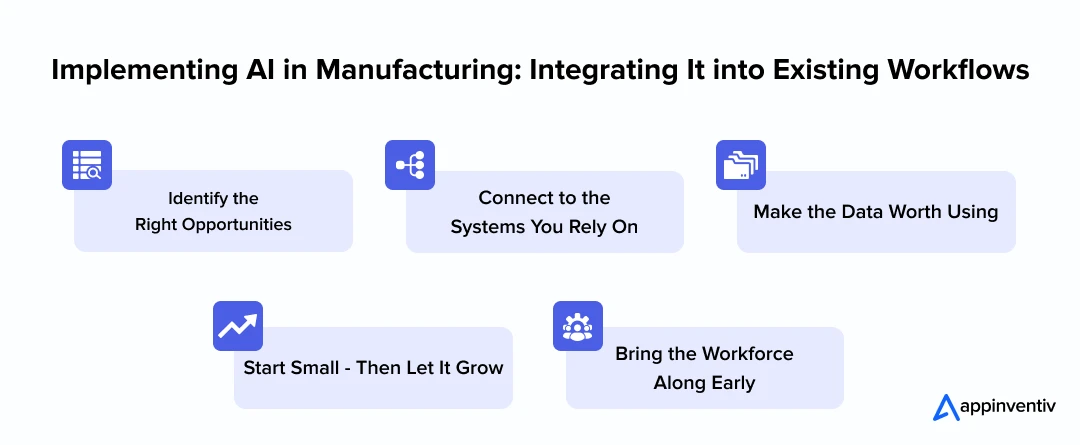

- Implementing AI in Manufacturing: Integrating It into Existing Workflows

- Identify the Right Opportunities

- Connect to the Systems You Rely On

- Make the Data Worth Using

- Start Small — Then Let It Grow

- Bring the Workforce Along Early

- Challenges in Scaling AI in Manufacturing

- The ROI of AI in Manufacturing: What Business Leaders Should Expect

- Operational Efficiency Gains

- Cost Reduction

- Revenue Growth

- Quality Improvement

- Scalability

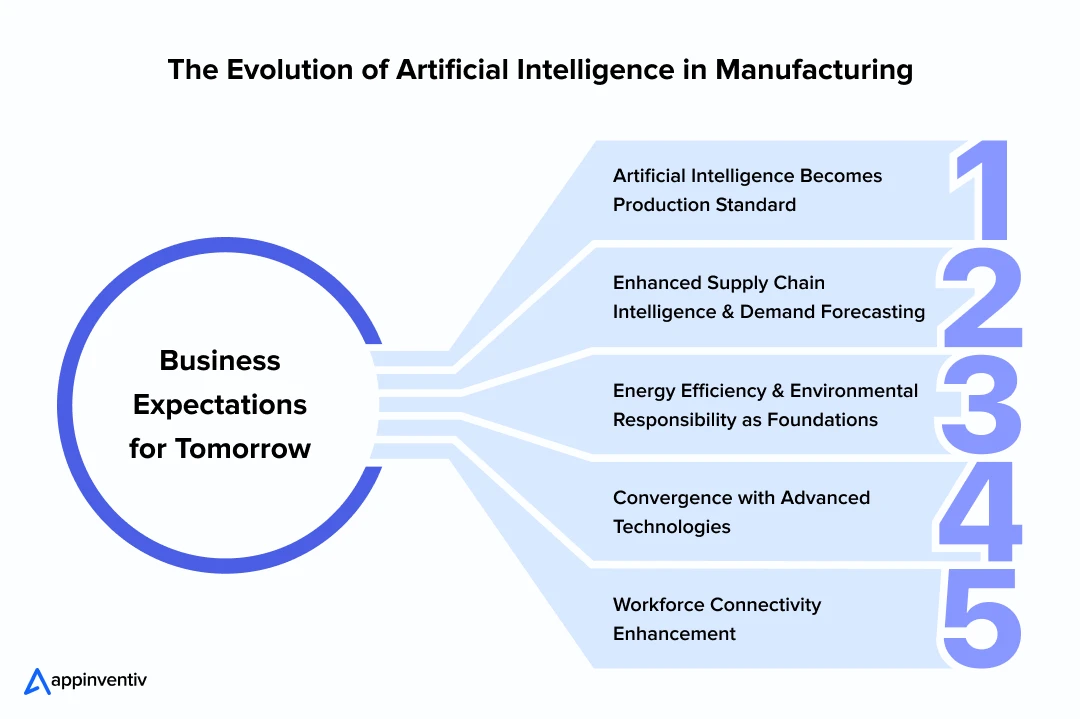

- The Evolution of Artificial Intelligence in Manufacturing: Business Expectations for Tomorrow

- Artificial Intelligence Becomes Production Standard

- Enhanced Supply Chain Intelligence and Demand Forecasting

- Energy Efficiency and Environmental Responsibility as Foundations

- Convergence with Advanced Technologies

- Workforce Connectivity Enhancement

- Why Appinventiv Represents the Ideal Partnership for AI in Manufacturing Implementation

- FAQs

Key takeaways:

- AI in manufacturing is shifting from pilots to full-scale adoption.

- Predictive maintenance, quality checks, supply chain optimisation, and energy efficiency drive ROI.

- Linking AI with MES, ERP, and legacy systems is critical for success.

- Clear goals and accurate data are the backbone of AI adoption.

- Scaling AI means addressing data issues, skills gaps, and system integration.

- AI will soon be a standard in production, supply chains, and sustainability.

Artificial intelligence in manufacturing is not some futuristic dream that’s waiting to arrive. It has been quietly shaping the manufacturing sector for years, long before the current wave of AI headlines. From predictive maintenance to automated quality checks, the use of AI in manufacturing has already proven its worth in making operations faster, leaner, and more reliable. The shift now is not about discovering AI but about learning how to use AI for manufacturing in ways that bring measurable returns, rather than just impressive demonstrations.

For many manufacturers, the difference between hype and real transformation comes down to focus. AI manufacturing solutions are at their best when they are solving specific, high-value problems like reducing downtime, improving yield, optimising energy use and not when they are implemented as one-off experiments.

If we look at the artificial intelligence in manufacturing market today, the competition is no longer between those who use AI and those who don’t. It’s between companies using AI for manufacturing to drive clear, tangible gains, and those that treat it as a side project.

In this guide, we will break down exactly how AI and manufacturing can work together to achieve tangible returns. We’ll look at the impact of AI in manufacturing industry settings, explore case studies, examine the market trends, and highlight practical AI use cases in manufacturing that companies can implement today. The focus will be on strategies, not just technology, helping you move past the hype and into a phase where AI becomes a driver of sustained business value.

From predictive maintenance to smart supply chains, we help you unlock measurable ROI.

Understanding the AI in Manufacturing Market: A Glimpse into the Future

AI in manufacturing has moved far beyond experimental pilots and isolated projects. The artificial intelligence in manufacturing market is now expanding at a pace that few other industrial technologies can match. It is no longer reserved for early adopters. It has become a central focus for manufacturing leaders who want to strengthen their competitive position, improve efficiency, and create new revenue streams.

According to Grand View Research, the global AI in manufacturing market was valued at $5.32 billion in 2024. It is projected to reach $47.88 billion by 2030 with a compound annual growth rate of 46.5 percent between 2025 and 2030. This growth reflects how AI manufacturing solutions are being used to cut downtime, use resources more effectively, and support faster, data-driven decisions across operations.

Generative AI in manufacturing is speeding up this transformation. A McKinsey survey found that 79 percent of executives are familiar with the technology and 22 percent use it regularly. In manufacturing and supply chain operations alone, it could reduce costs by as much as half a trillion dollars. From rapid product design to AI-powered demand forecasting, companies using Artificial intelligence in manufacturing are finding real financial and operational gains.

Gartner forecasts show this momentum will continue. AI software spending in the manufacturing and natural resources market is expected to grow 19.3 percent in 2024 to reach $19.6 billion and is projected to hit $34.5 billion by 2027. For many manufacturing CIOs, AI and machine learning in manufacturing have shifted from experiments to essential investments directly linked to business outcomes.

However, there is still a gap between vision and results. A BCG global survey of almost 1,800 manufacturing executives found that while 89 percent plan to integrate AI into their production networks and 68 percent have already begun, only 16 percent have met their AI goals. Scaling AI in factories and across supply chains remains a challenge. The benefits are clear, but the time to act is now. Delay risks giving the advantage to competitors who are already moving ahead.

Types of AI Technologies in Manufacturing: A Quick Insight

AI in manufacturing comes in different forms, each handling a specific part of the production cycle. Some improve speed, some focus on quality, and others help plan for what’s ahead — together, they can transform how a factory runs.

Machine Learning (ML)

Machine learning services utilize past and live production data to spot patterns, predicting breakdowns, adjusting line speeds, and reducing material waste.

Computer Vision

Computer vision development services combines cameras with AI to “see” what’s being made catching defects, checking alignment, and keeping quality under control without slowing output.

Natural Language Processing (NLP)

Makes it easier for workers to talk to machines from asking a voice assistant for maintenance logs to reporting an issue on the spot.

Robotics And Automation

Brings flexibility to robots letting them handle different parts, work safely with people, and adjust to changes without reprogramming every time.

Digital Twins

Creates a virtual copy of machines or processes engineers can test ideas, troubleshoot problems, or plan upgrades without halting production.

Predictive Analytics

Looks ahead using data trends planning maintenance before failures happen, balancing inventory, and keeping production on track.

How is AI Used in Manufacturing: Understanding the Use Cases of Turning Innovation into Measurable Results

Manufacturing companies are using artificial intelligence right now to fix problems that hurt their profits, quality standards, and delivery schedules. The best AI applications in manufacturing work behind the scenes to make core operations better – like catching machine problems before they happen, making sure products meet quality requirements, or keeping supply chains running without hiccups.

Predictive Maintenance

Equipment breaking down unexpectedly costs manufacturing companies serious money. With AI and ML in manufacturing, factories analyze real-time sensor data to figure out exactly when parts might fail. AI manufacturing solutions catch small changes in vibration, temperature, or power use that people miss, so maintenance teams can fix things before machines stop working.

Real example: General Motors runs AI-powered manufacturing systems on their assembly lines. The system learns how each machine normally operates, then flags problems early. This cuts down on shutdowns and saves maintenance money.

To connect predictive systems with MES or ERP platforms, companies are now exploring AI API integration for industrial automation to streamline real-time insights.

Quality Control and Inspection

Quality problems hurt both company reputation and sales. AI tools for manufacturing now use computer vision to check every product coming off the line, catching tiny defects as they happen. This smart manufacturing AI approach means only good products get shipped, cutting waste and customer returns.

Real example: BMW built AI manufacturing solutions into their body panel checking process. High-res cameras and machine learning in manufacturing spot problems instantly, so workers can fix issues before products move to the next step.

Supply Chain Optimization

Companies using AI for manufacturing need supply chains that work consistently. AI applications in manufacturing can predict what customers will order, track how well suppliers perform, and optimize when deliveries happen. Materials show up exactly when needed, reducing extra inventory and storage costs.

Real example: Siemens uses AI for manufacturing to predict component demand across their worldwide plants. It is one of the examples of AI in manufacturing that shows how good forecasting prevents overstocking while avoiding expensive production delays.

[Also Read: The Role of Artificial Intelligence in Supply Chain Management]

Energy Efficiency Management

Energy bills are huge expenses in the artificial intelligence in manufacturing market. AI-powered manufacturing systems study how energy gets used, find waste, and suggest changes that cut energy use without slowing production. This saves money and helps the environment.

Real example: Schneider Electric runs AI solutions in manufacturing to watch energy use across their facilities. The data helps teams adjust equipment settings and processes, creating real savings and lower emissions.

Generative Design and Product Innovation

Generative AI in manufacturing lets design teams create and test hundreds of product options virtually. This makes innovation faster, cuts material costs, and often produces better-performing designs.

Real example: Airbus uses AI and manufacturing design tools to develop aircraft parts that weigh less but stay strong. By improving designs digitally, Airbus is one of the AI in manufacturing examples that wastes less material, shortens production time, and boosts efficiency.

Benefits of AI in Manufacturing: Why the ROI is Hard to Ignore

AI in the manufacturing industry produces results that actually matter to your bottom line. Smart manufacturers using AI manufacturing solutions with clear business objectives see productivity gains, waste reduction, and better operational control.

Lower Operational Costs

AI and ML in manufacturing prevent expensive equipment breakdowns through predictive maintenance and optimize how machines perform. Catching problems before they shut down production saves serious money on emergency repairs and keeps everything running.

Improved Product Quality

AI tools for manufacturing spot defects faster and more reliably than manual inspection processes. This cuts down on rework, reduces scrap materials, and prevents warranty issues while maintaining consistent quality standards.

Faster Time to Market

Generative AI in manufacturing accelerates design cycles and testing phases, letting companies move from concept to finished products much quicker without sacrificing performance or reliability.

Smarter Supply Chains

AI applications in manufacturing forecast customer demand with better accuracy, optimize inventory levels, and streamline supplier relationships. This prevents both material shortages and expensive excess inventory buildup.

Stronger Sustainability Performance

AI-powered manufacturing reduces energy consumption and optimizes material usage, helping companies achieve environmental goals while cutting operational expenses.

When AI gets tied to specific business metrics, the benefits extend well beyond fancy technology – it becomes a competitive advantage that drives real growth and profitability over time.

Improved Safety and Compliance

AI systems can monitor equipment, processes, and worker environments in real time to detect hazards before they cause incidents. They also help maintain compliance by tracking regulatory requirements, automating reporting, and ensuring quality standards are consistently met.

Implementing AI in Manufacturing: Integrating It into Existing Workflows

For most manufacturers, adding AI doesn’t start with shiny new equipment. It starts with the systems and routines already in place. The trick is not to rip out what’s working but to slip intelligence into the everyday flow the places where a small change can make a big difference.

Identify the Right Opportunities

Not every process in a factory needs AI, and chasing too many at once is a fast way to waste money. Look for the nagging issues everyone complains about machines that keep breaking, inspections that bottleneck the line, supply schedules that always seem off. When the first project solves a problem people actually care about, AI earns its place quickly.

Connect to the Systems You Rely On

If AI sits in its own corner, it’s just another tool nobody checks. The real impact comes when AI manufacturing solutions tap into your MES, ERP, and quality systems so data moves between them without anyone having to lift a finger. That’s when the insights show up where they’re useful in front of the people making the calls.

Make the Data Worth Using

Machine learning in manufacturing will chew through whatever data it’s fed. If that data is wrong, the output will be too. This is the unglamorous work: calibrating sensors, cleaning old logs, getting operators to enter information consistently. It’s not exciting, but it’s what makes AI trustworthy on the shop floor.

Start Small — Then Let It Grow

Trying to roll AI across an entire plant in one shot almost always backfires. Pick one production line, one process, one clear target. When it works there, expand it. The success from the first run will make the next rollout easier — and you’ll avoid the kind of disruption that kills momentum.

Bring the Workforce Along Early

AI in the manufacturing industry isn’t going to replace the people running the place, but it will change how they work. If teams see it as a black box making decisions over their heads, adoption will stall. If they see it as a tool that helps them get ahead of problems, they’ll push for it themselves. That’s when the technology really takes root.

Bringing AI into a factory isn’t a one-off upgrade. It’s a steady layering of intelligence into the systems and habits that keep production moving. Done right, it feels less like a technology project and more like the factory simply got sharper over time.

Challenges in Scaling AI in Manufacturing

Even with the clear benefits of AI in the manufacturing industry, scaling it across plants and supply chains is rarely straightforward. Many manufacturers find that what works in a pilot project doesn’t always translate smoothly to full operations. Understanding the common roadblocks and how to deal with them can make the difference between an AI manufacturing solution that delivers ROI and one that stalls halfway.

| Challenge | What It Means | Practical Solution |

|---|---|---|

| Poor Data Quality and Access | AI and ML in manufacturing rely on accurate, consistent data. Incomplete records, uncalibrated sensors, and siloed systems limit the effectiveness of AI applications in manufacturing. | Audit existing data sources, calibrate sensors, and connect AI tools for manufacturing to MES, ERP, and quality systems for real-time, reliable inputs. |

| Integration with Legacy Systems | Older factory systems often don’t “speak the same language” as modern AI manufacturing solutions, creating delays and added costs. | Use middleware or API layers to bridge AI in manufacturing industry platforms with legacy equipment, reducing disruption to production. |

| Skills and Workforce Readiness | Without the right skills, even the best AI manufacturing companies struggle to get teams to use AI insights effectively. | Provide training programs for operators, engineers, and managers on AI tools for manufacturing, focusing on how to apply them in daily work. |

| High Initial Costs and Unclear ROI | Implementing AI in factories can seem expensive, especially if ROI is not defined upfront. | Start with a high-impact, low-risk pilot such as predictive maintenance, measure results, and expand only after proving the business case. |

| Security and Compliance Risks | AI-powered manufacturing increases data exchange across systems, raising cybersecurity and regulatory risks. | Follow industry compliance standards, secure networks, and apply role-based access controls to protect sensitive production and customer data. |

No matter the use case, we deliver AI manufacturing solutions built for real results.

The ROI of AI in Manufacturing: What Business Leaders Should Expect

In manufacturing, AI should not be seen as just another tech upgrade. It needs to prove its worth in numbers. The goal is simple if it doesn’t improve performance, reduce waste, or grow revenue, it’s not doing its job. A well-planned ROI approach ensures that every investment is backed by measurable results.

Here’s where businesses see the biggest returns:

Operational Efficiency Gains

Fewer production stoppages, faster changeovers, and smoother workflows that keep output high without adding extra resources.

Cost Reduction

Lower maintenance bills, less scrap, and smarter energy use that all add up to real savings.

Revenue Growth

Quicker product launches, faster market response, and new service opportunities that increase top-line growth.

Quality Improvement

Better defect detection and more consistent production standards, leading to fewer returns and happier customers.

Scalability

Solutions that can be rolled out to multiple sites or production lines without a drop in performance.

The Evolution of Artificial Intelligence in Manufacturing: Business Expectations for Tomorrow

Manufacturing’s relationship with artificial intelligence continues evolving rapidly. However, the genuine transformation extends beyond technological advancement alone it encompasses how manufacturers will leverage these capabilities throughout the coming decade. As systems reach maturity and AI manufacturing solutions gain broader accessibility, emphasis shifts from isolated initiatives toward comprehensive intelligence integration spanning production, supply chains, and product development. Manufacturing executives benefit from understanding emerging trends when determining current investment priorities.

Artificial Intelligence Becomes Production Standard

Within upcoming years, AI and ML in manufacturing will shed their “experimental project” status. These technologies will become integral to standard production methodologies, mirroring today’s automation integration. From predictive maintenance through AI-powered quality control, such tools will constitute default factory workflows. For organizations implementing AI in manufacturing, competitive differentiation will emerge from system utilization effectiveness rather than mere possession.

Enhanced Supply Chain Intelligence and Demand Forecasting

AI applications in manufacturing are positioned to revolutionize supply chain durability. Rather than responding to disruptions reactively, AI-powered manufacturing will predict challenges, redirecting orders or modifying production schedules before issues materialize. AI and Machine learning in manufacturing will enhance demand predictions using near-instantaneous market intelligence, enabling tighter inventory management without shortage risks.

Energy Efficiency and Environmental Responsibility as Foundations

Tomorrow’s AI for manufacturing industry operations will connect directly with sustainability objectives. AI manufacturing solutions will oversee energy consumption at detailed levels, eliminating waste and reducing expenses while supporting regulatory and environmental compliance. Throughout the sector, this transition from optional enhancement to mandatory requirement affects both compliance and corporate reputation.

Convergence with Advanced Technologies

Generative AI services will develop collaborative relationships with robotics, Internet of Things, and sophisticated analytics, establishing highly responsive production facilities. AI tools for manufacturing will unify design, scheduling, and production within continuous feedback systems, shortening product launch timelines and supporting expanded customization capabilities.

Workforce Connectivity Enhancement

Artificial intelligence in manufacturing influence extends beyond machinery alone. Conversational AI for manufacturing will provide operators with immediate guidance, while AI-driven training systems will develop team capabilities dynamically. Rather than eliminating positions, the future of AI in manufacturing will demonstrate technology’s role in empowering personnel to make superior, accelerated decisions.

Why Appinventiv Represents the Ideal Partnership for AI in Manufacturing Implementation

Selecting an appropriate partner for adopting Artificial intelligence in manufacturing industry carries equal importance to technology selection itself. As a leading Manufacturing IT services firm, we have collaborated with manufacturers across various scales, developing AI manufacturing solutions that integrate smoothly within established systems and operational frameworks. From AI-powered manufacturing analytics through machine learning in manufacturing quality control, our methodology emphasizes quantifiable results rather than theoretical experiments destined for storage.

Our team comprehends factory environment complexities legacy systems maintaining critical operations, information flowing from diverse sources, and personnel requiring dependable tools.

As a leading AI development services firm, our approach to AI applications in manufacturing targets high-impact challenge resolution, whether optimizing energy consumption, enhancing product quality standards, or constructing intelligent supply chain frameworks. Each AI manufacturing project we complete receives customization matching client objectives, infrastructure capabilities, and implementation timelines.

A notable illustration involves our collaboration with an international manufacturer seeking enhanced supply chain management and transparency. Through AI and analytics solutions implementation, we developed comprehensive systems monitoring inventory levels, demand variations, and supplier performance continuously. This initiative achieved 60% improved visibility throughout their supply chain network, enabling accelerated, more confident decision-making while minimizing delays and surplus inventory accumulation. Such outcomes demonstrate why Appinventiv maintains trusted status among companies using AI for manufacturing for competitive advantage preservation.

Our expertise extends beyond technical implementation. We recognize that successful AI in manufacturing integration requires understanding operational nuances, workforce considerations, and business continuity requirements. Get in touch with us to ensure your AI manufacturing solution delivers sustainable value rather than temporary improvements.

FAQs

Q. How is AI used in manufacturing?

A. AI in manufacturing finds application throughout complete production cycles spanning product conception through final delivery. Manufacturing organizations implement AI manufacturing solutions for predictive maintenance protocols, quality assurance processes, supply chain optimization, and energy resource management.

Machine learning in manufacturing enables analysis of extensive operational datasets, pattern recognition capabilities, and decision guidance that enhances operational efficiency while reducing expenditures.

Q. How could AI transform the manufacturing industry?

A. AI can help manufacturing companies work faster, make better decisions, and reduce costs. Here’s how it can create real change:

- Predict equipment failures before they happen to cut downtime

- Optimise supply chains for cost, speed, and reliability

- Improve quality control by detecting defects in real time

- Automate repetitive tasks to free workers for higher-value jobs

- Forecast demand more accurately to reduce waste and overproduction

- Enable flexible production lines that adapt quickly to market changes

Q. Which kind of AI is used for maintenance and quality checks in digital manufacturing?

A. Maintenance applications primarily utilize predictive analytics driven by machine learning in manufacturing methodologies. These systems continuously monitor sensor information to identify preliminary equipment failure indicators. Quality assessment procedures employ computer vision AI tools for manufacturing to examine products during real-time production, detecting minor defects before items complete the manufacturing line.

Q. How can a manufacturing firm best utilise computer technology to help run the supply chain?

A. Manufacturing enterprises can leverage AI applications in manufacturing to enhance supply chain transparency and operational responsiveness. Through integration of AI-powered manufacturing analytics with enterprise resource planning and inventory management systems, organizations achieve improved demand forecasting accuracy, optimized inventory maintenance, and enhanced supplier coordination. This approach minimizes operational delays, reduces storage expenses, and maintains uninterrupted production workflows.

Q. What major changes have manufacturers taken to make resource transformation more efficient?

A. Numerous companies using AI in manufacturing have transitioned toward data-driven resource management strategies. This encompasses AI-powered manufacturing systems that optimize energy utilization, minimize material waste generation, and refine production scheduling precision. Generative AI in manufacturing additionally supports product redesign initiatives to reduce material requirements while preserving performance standards, accelerating resource transformation processes and improving sustainability outcomes.

Q. How can generative AI be used in manufacturing?

A. Generative AI can help manufacturers design, plan, and produce more efficiently while reducing errors and costs. Here are some ways it can be applied:

- Create and test product designs digitally before physical production

- Optimise production schedules for speed and resource use

- Generate synthetic data to train quality control and inspection systems

- Automate creation of maintenance instructions and training materials

- Simulate complex manufacturing processes to identify improvements

- Customise product features quickly to meet specific customer needs

Q. What are some examples of companies using AI in manufacturing?

A. Many global manufacturers are already using AI to improve efficiency, quality, and production speed. Some notable examples include:

- Siemens – Uses AI for predictive maintenance, process optimization, and energy efficiency in factories.

- General Electric (GE) – Applies AI-driven analytics to monitor equipment performance and reduce downtime.

- Tesla – Integrates AI in robotics, quality checks, and real-time production adjustments in its gigafactories.

- BMW – Uses AI for automated visual inspections, supply chain planning, and personalized vehicle manufacturing.

- Foxconn – Employs AI-powered automation to enhance productivity and precision in electronics manufacturing.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How Generative AI Strategy Implementation Can Help Enterprises Improve ROI

Key takeaways: Enterprise generative AI implementation rates now exceed 80%, yet fewer than 35% of programs deliver board-defensible ROI. The 2026 shift is from chatbots to autonomous AI agents embedded inside core enterprise workflows. High-performing organizations achieve 6–12 month payback by combining RAG architectures, LLMOps cost governance, and human-in-the-loop controls. Generative AI strategy business implementation…

How Intelligent Pharmacy Automation Systems Drive ROI- Benefits, Features, Implementation

Key takeaways: Intelligent pharmacy automation systems reduce manual work. They also help teams improve accuracy and handle daily tasks in a steady, predictable way. The main financial gains come from lower labor costs, better inventory control, fewer error-related expenses, and new service lines that support steady revenue. High-volume sites usually see quicker payback. Many reach…

How Much Does it Cost to Develop a Generative AI App?

Key Takeaways The cost of Generative AI application development ranges between $40,000 to $400,000+, depending on complexity, integrations, and security needs. McKinsey reports 64% of companies say AI is driving their innovation, emphasizing the strategic role of generative AI. Choosing the right generative AI model stack and optimizing data governance can significantly reduce project costs…