- Deconstructing the Mechanics: How RFID Technology Delivers Asset Intelligence

- How RFID Works:

- The Core Components of RFID Systems

- Type of RFID Systems: Active vs. Passive

- Understanding Frequency Bands and Their Operational Implications (LF, HF, and UHF)

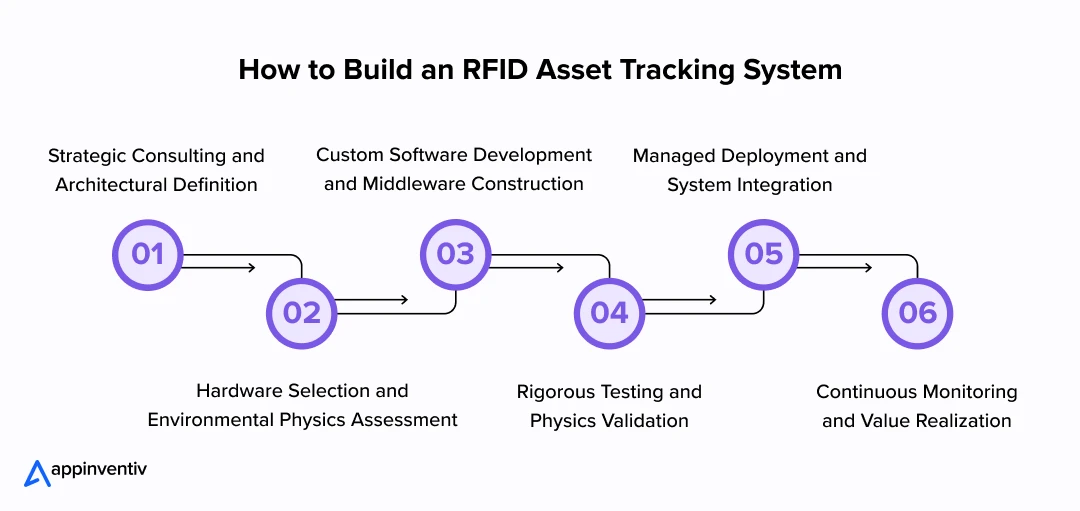

- A Strategic Blueprint: How to Build Your Enterprise-Grade RFID Asset Tracking System

- Phase 1: Strategic Consulting and Architectural Definition

- Phase 2: Hardware Selection and Environmental Physics Assessment

- Phase 3: Custom Software Development and Middleware Construction

- Phase 4: Rigorous Testing and Physics Validation

- Phase 5: Managed Deployment and System Integration

- Phase 6: Continuous Monitoring and Value Realization

- Architecting the Digital Core: The Essentials of RFID Software

- Key Features of an Enterprise-Grade Platform

- Tech Stack for RFID Asset Tracking Systems

- Anticipating Headwinds: Navigating the Challenges of RFID Deployment

- 1. The Data Problem: Collision and Overload

- 2. The Integration Problem: Data Silos and Legacy Systems

- 3. The Compliance Problem: Regulatory and Security Hurdles

- 4. The Physics Problem: Interference from Metal and Liquid

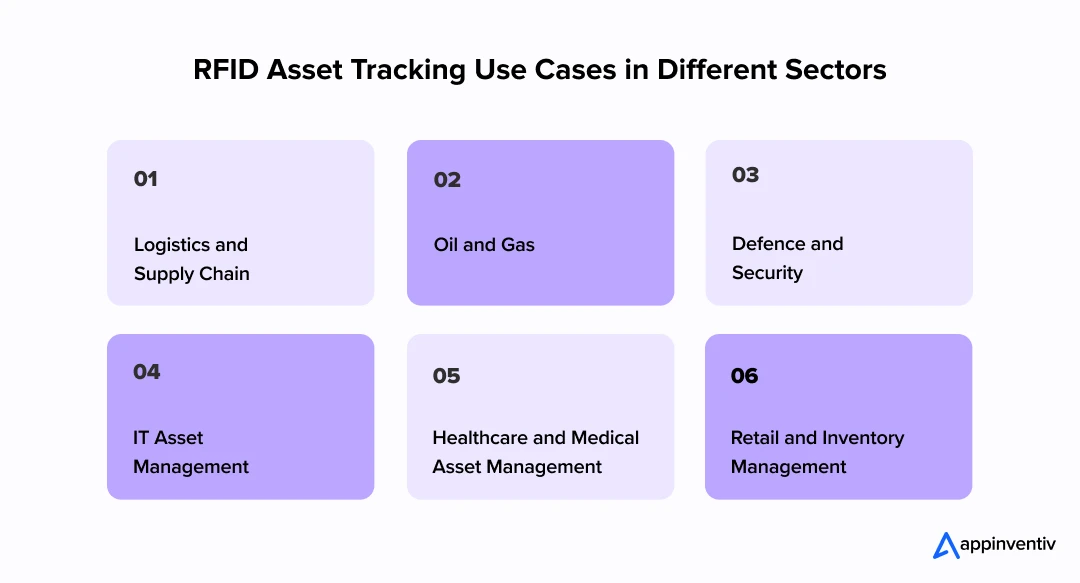

- From Theory to Practice: RFID Asset Tracking Use Cases in the UAE's Key Sectors

- Logistics and Supply Chain

- Oil and Gas

- Defence and Security

- IT Asset Management

- Healthcare and Medical Asset Management

- Retail and Inventory Management

- Analyzing the Investment: Deconstructing RFID Asset Tracking Cost in the UAE

- Financial Modeling: Deconstructing the Investment and ROI

- The Horizon: Future Trajectories for RFID and Asset Management

- From Fiction to Action: Partnering with Appinventiv for Your RFID Solution Development

- FAQs

Key takeaways:

- The success of an RFID asset tracking system is dictated by the quality of the custom software and middleware, which must transform voluminous raw tag data into actionable intelligence.

- Implementation of RFID systems requires a managed, multi-stage process, moving logically from Integration Consulting and architectural design to Continuous Monitoring and Optimization, which is the only way to guarantee a scalable ROI.

- Any RFID asset tracking deployment in the UAE requires mandatory pre-planning for adherence to the TDRA (formerly TRA) frequency standards and strict compliance with local data sovereignty laws.

- The RFID asset tracking cost in the UAE ranges between AED 150,000 to AED 1,400,000 ($40,000 to $400,000) or more.

- The RFID asset tracking cost that UAE enterprises face should be viewed as an investment. A phased pilot is the most effective method to prove ROI before a large-scale rollout.

As businesses in the UAE continue to embrace next-gen technologies, the demand for efficient, scalable, and reliable systems to track assets is higher than ever. It simply means that for industries such as manufacturing, logistics, healthcare, and retail, managing physical assets accurately is no longer a luxury; it is a dire necessity of the time.

This is where RFID (Radio Frequency Identification) comes in as a powerful solution to meet this need, providing real-time visibility and automated tracking of assets. An RFID asset tracking system bridges the physical-digital divide, offering granular, real-time visibility that is simply unattainable with legacy methods.

The technology’s global adoption underscores this game changing capabilities; as Grand View Research reports, the global radio frequency identification technology market, valued at $20.10 billion in 2024, is projected to surge to $47.63 billion by 2030, growing at a formidable 15.8% CAGR.

However, building an effective RFID asset tracking system in the UAE is more than just purchasing tags and scanners. It requires careful planning, a clear understanding of the technology, and attention to the region’s unique regulatory and operational requirements.

But worry not. This blog serves as your architectural answer to the query, “How to build an RFID asset tracking system that delivers tangible, transformative value?”. We will move beyond a superficial overview to delineate the strategic planning, technical architecture, software requirements, and crucial regulatory hurdles you must navigate.

The RFID market will soar to $47.63 billion by 2030. Don’t miss out on this game-changing technology. Build a custom RFID asset tracking solution for your business today.

Deconstructing the Mechanics: How RFID Technology Delivers Asset Intelligence

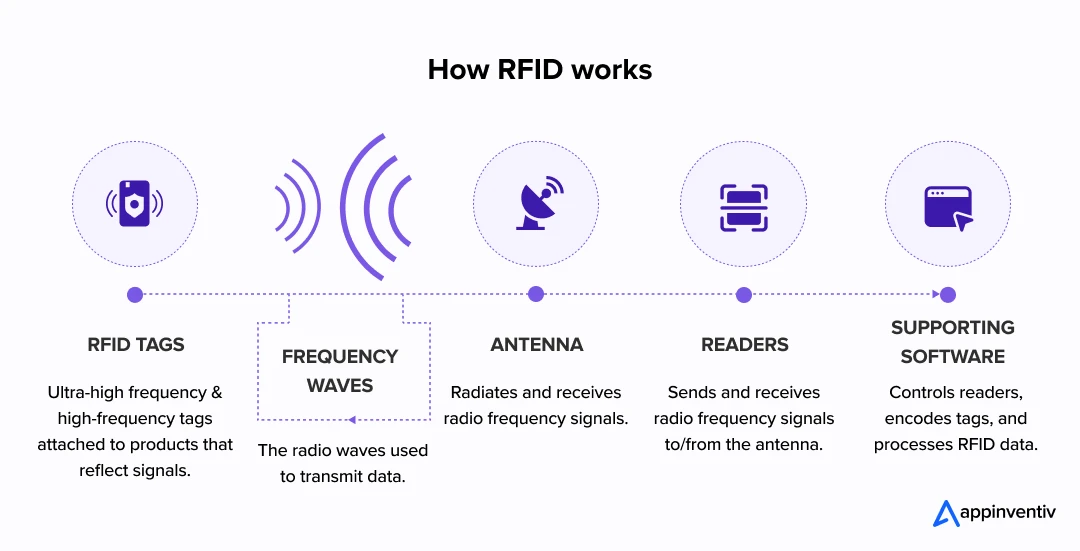

Before you architect an RFID system, you must understand its fundamental components and how it works. At its simplest, RFID is a method of wireless communication that uses radio waves to identify, track, and manage objects. Unlike a barcode, it does not require a direct line of sight and can scan hundreds of items simultaneously.

How RFID Works:

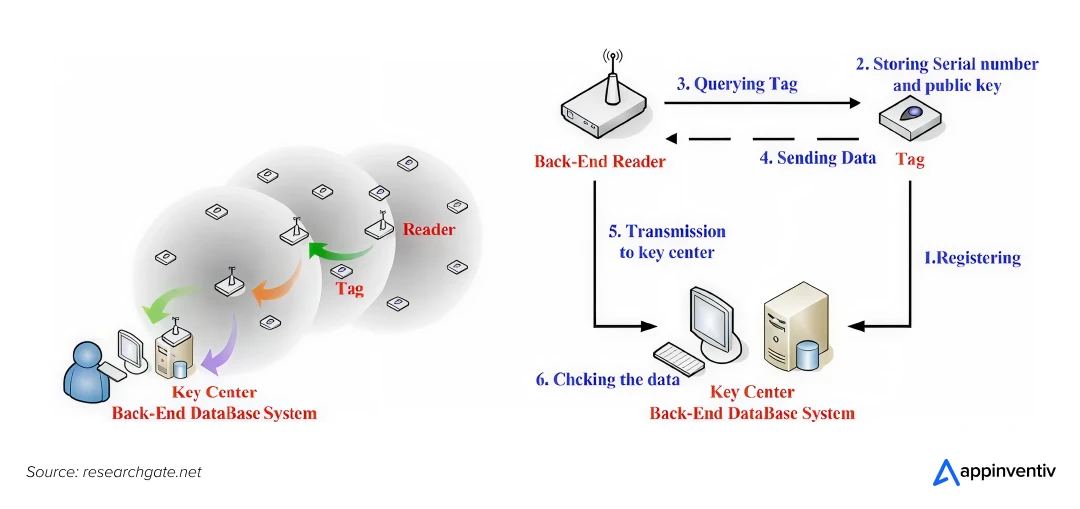

The operational sequence of an RFID system is critical to understand for successful development and deployment.

- RFID Tag Activation: When an RFID reader emits radio waves, the RFID tags within its range “wake up” and send data back to the reader.

- Data Transmission: The RFID tag transmits its stored data (typically a unique identifier) to the reader, which then processes it.

- Information Processing: The reader sends the data to the backend system (often an ERP or asset management software), which processes the information for inventory management, location tracking, or other operational tasks.

- Simultaneous Scanning: Multiple tags can be scanned at once without the need for line-of-sight, allowing for faster asset tracking and greater efficiency.

This entire process occurs in milliseconds, enabling the continuous, real-time data streaming necessary for immediate asset visibility.

The Core Components of RFID Systems

An RFID asset tracking system in the UAE is comprised of three core elements:

- RFID Tags (The “Identifier”): These are the data carriers. Each tag contains a microchip that stores a unique identifier (like a digital license plate) and an antenna to transmit this data. They are affixed to the assets you need to track.

- RFID Readers (The “Scanner”): These are the nerve center of the hardware. A reader emits radio waves, which “wake up” any tags within its range. The tags then broadcast their unique IDs back to the reader. Readers can be fixed (installed at checkpoints, portals, or on production lines) or handheld (used for mobile audits).

- Antennas (The “Bridge”): The antenna converts the reader’s electrical signal into radio waves that are broadcast to the tags. A reader’s antenna defines the shape and reach of the “read zone.”

Type of RFID Systems: Active vs. Passive

The single most important hardware decision you will make when building an RFID asset tracking system in the UAE is choosing between Active and Passive RFID.

Passive RFID

These tags have no internal power source. They are powered entirely by the radio waves from the reader.

Pros: Inexpensive (often cents per tag), small, and have a long lifespan (decades).

Cons: Shorter read range (from a few centimeters to ~10-15 meters in ideal conditions).

Best For: High-volume, item-level tracking, inventory management, and rfid it asset tracking system applications where assets are scanned at known chokepoints.

Active RFID

These tags incorporate a small battery. This battery powers the tag’s chip and enables it to actively broadcast its signal.

Pros: Extremely long read range (100+ meters), higher data storage, and can integrate sensors (e.g., for temperature, humidity).

Cons: Significantly more expensive (dollars to tens of dollars per tag), larger, and have a finite battery life (3-10 years).

Best For: High-value asset tracking over large areas, such as rfid asset tracking for oil and gas (tracking vehicles and heavy equipment in a laydown yard) or tracking containers in a port.

Understanding Frequency Bands and Their Operational Implications (LF, HF, and UHF)

RFID operates across different frequencies, each with unique properties:

- Low Frequency (LF): Short read range, slow data rate, but excellent at reading through materials like water and animal tissue. Used for livestock tracking.

- High Frequency (HF): Access control (like hotel key cards), and NFC (Near Field Communication) payments.

- Ultra-High Frequency (UHF): This is the dominant frequency for modern asset tracking. It offers the best of both worlds: a long read range (up to 15 meters with passive tags) and a high data-read speed. When we discuss building an RFID asset tracking in the UAE, we are almost exclusively referring to UHF technology, which has specific regulatory guidelines.

The mandatory UHF frequency band for use in the UAE, as regulated by the TDRA (Telecommunications and Digital Government Regulatory Authority), is 865.6–867.6 MHz.

Also Read: How Al Agents Are Reimagining Work in the ME & How to Build Them Right

A Strategic Blueprint: How to Build Your Enterprise-Grade RFID Asset Tracking System

Successfully deploying an RFID asset tracking system UAE-wide requires a disciplined project management approach, where the enterprise defines requirements and holds the software development partner accountable for delivering complex integration and software functionality. Here is a structured, six-phase methodology to build RFID asset tracking solutions that drive transformative results:

Phase 1: Strategic Consulting and Architectural Definition

The initial commitment must focus on discovery and architectural planning, ensuring the project aligns with strategic business goals.

- Integration Requirements: The architecture team must map out all data flows, identifying precisely which data points (asset ID, timestamp, location) will be transmitted and how they will update the master records in existing systems.

- TDRA Pre-Assessment: Before any hardware is purchased, its compliance with UAE TDRA standards, specifically the authorized UHF frequency band (865.6–867.6 MHz), must be confirmed to mitigate regulatory risk.

- Define Business Case & Success (KPIs): Establish a baseline. Your goal might be “Increase inventory accuracy from 65% to 98%” or “Reduce time to locate critical equipment from 2 hours to 2 minutes.” This aligns with expert advice on tech implementation.

A chief AI officer at a luxury goods company, in a McKinsey report on AI in the GCC, stated, “The premise of everything we do is that every use case must have a clear definition of success. If it’s successful, it moves to the business team for ownership. If not, we stop and move on.” This principle is 100% applicable to RFID.

Phase 2: Hardware Selection and Environmental Physics Assessment

Since RFID is a physical technology, a specialized physical survey is non-negotiable for project success.

- Site Survey Mandate: You must contract for a professional Radio Frequency (RF) site survey. This survey identifies environmental challenges (metal reflection, liquid absorption) that could degrade performance, dictating the necessary placement of readers and antenna type.

- Tag and Hardware Specification: Based on the survey, the correct blend of ruggedized, metal-mount tags for RFID asset tracking for fixed assets and high-performance readers must be meticulously specified.

Phase 3: Custom Software Development and Middleware Construction

This is the largest capital expenditure and the core value creation phase, requiring deep software engineering expertise.

- Agile Development: Your RFID asset tracking solutions provider in the UAE must utilize an agile methodology to build the custom RFID asset tracking software. They should prioritize a microservices architecture hosted on a scalable cloud platform (e.g., AWS or Azure) that complies with data sovereignty requirements.

- Intelligent Middleware Build: The core logic of the middleware must be engineered to handle the high-volume data stream, employing custom business rules (e.g., “ignore all reads from antennas 1 and 2 if a read is detected on antenna 3,”) to enhance accuracy.

Phase 4: Rigorous Testing and Physics Validation

After development, the system must be validated against its real-world physical and digital constraints.

- Scenario-Based QA: The enterprise must mandate that testing goes beyond basic functionality. This should involve real-world stress tests that validate read accuracy under high-traffic conditions and against known interference points identified in the site survey.

- Security Audit: A third-party security audit on the application and the integration APIs is essential, particularly for sensitive deployments like RFID asset tracking for defence. This ensures that asset location data is encrypted both in transit and at rest.

Phase 5: Managed Deployment and System Integration

This is the critical phase where the system transitions from pilot to production.

- Seamless Integration Cutover: The technology partner must manage the final RFID integration with ERP for asset tracking. They must ensure a zero-downtime cutover that immediately replaces manual data entry with the automated RFID data stream.

- Change Management: Comprehensive training must be rolled out to all operational staff, demonstrating that the new system transforms their role from auditors to proactive managers of exceptions. This is critical for user adoption.

Phase 6: Continuous Monitoring and Value Realization

The commitment to the RFID asset tracking solutions must extend beyond the initial go-live to guarantee sustained ROI.

- Proactive Performance Monitoring: The enterprise needs to establish robust DevOps pipelines for continuous monitoring of software latency, reader network health, and data flow integrity.

- Feature Optimization: Leveraging the accumulated data, the enterprise should mandate periodic feature refinement sprints. They can use machine learning algorithms to refine business logic and unlock further benefits of RFID asset tracking.

Are you ready to take control of your assets with RFID technology? Partner with Appinventiv to design and implement a custom RFID solution for your business today.

Architecting the Digital Core: The Essentials of RFID Software

The true intelligence of a modern RFID asset tracking system resides in the software tech stack and features that sit between the physical world (tags/readers) and the business layer (ERP/WMS). Leaders must mandate that this software is developed for scalability, performance, high velocity, and resilience.

Key Features of an Enterprise-Grade Platform

To realize the full benefits of RFID asset tracking for enterprises, the core application must be custom-developed to include proprietary logic and advanced features:

| Feature | Mandated Strategic Value |

|---|---|

| Real-Time Location System (RTLS) | This feature provides instant asset location, dramatically reducing the non-productive time employees spend searching for tools, equipment, or high-value RFID IT asset tracking system components. |

| AI-Driven Anomaly Detection | The system must leverage AI and machine learning to learn normal movement patterns and instantly flag deviations, effectively turning the tracking system into a theft and security deterrent. |

| Audit & Compliance Engine | Your RFID software must automatically generate an immutable, time-stamped log of all asset movements, simplifying regulatory audits and providing financial proof of asset existence. |

| Integration Flexibility | Needs an open API design that supports RFID integration with ERP for asset tracking and other mission-critical systems (WMS, CMMS). |

| AI analytics and Reporting | Gives you real insights and detailed reports on asset usage, performance, and trends. This kind of data helps you figure out how to allocate resources better, run things more efficiently, and even predict when maintenance is coming up. |

| Asset Lifecycle Management | The software must be the single source of truth. It should track an asset from “Procurement” to “In-Service” to “Under-Maintenance” to “Disposal.” |

| Custom Alerts and Notifications | Enables pre-emptive action by notifying users of maintenance due dates or unauthorized movement of assets from defined secure zones. |

| Inventory Management | Offers an easy-to-use dashboard that shows real-time stock levels, helping manage inventory and prevent costly stock-outs or surpluses. |

| Security and Data Protection | Must be built with solid encryption and access controls to ensure compliance with data privacy laws, particularly the UAE Federal PDPL (Personal Data Protection Law), which governs how data is processed and secured |

Tech Stack for RFID Asset Tracking Systems

The tech stack is the backbone of your RFID system. It is a crucial decision that determines what works and what doesn’t, and thus, is the main component you should choose cautiously. Here is what you should look for when choosing the right tech stack:

- Cloud Platform: AWS or Azure for scalable infrastructure, IoT services (like AWS IoT Core), and data storage.

- Data Processing: Services like Kafka or AWS Kinesis to handle the high-velocity stream of read data.

- Database: A combination of SQL (for structured asset data) and NoSQL (like DynamoDB or MongoDB) for handling massive volumes of read-events and logs.

- Mobile: Native (Swift/Kotlin) or cross-platform (Flutter/React Native) apps for handheld readers.

How to Choose the Right Tech Stack: Here’s what you should consider when picking a tech stack:

- Scalability: Make sure you choose technologies that can actually grow with you. Your asset volumes will probably increase over time, and you need systems that can handle that.

- Integration: Check that your stack plays well with what you’re already using; your ERP, CRM, whatever you’ve got. Integration matters more than people think.

- Security: Always put this first. Choose technologies with real security teeth to keep your sensitive asset data safe.

- Cost-effectiveness: Find something that fits your budget but doesn’t make you compromise on what you actually need. It’s about balance.

Anticipating Headwinds: Navigating the Challenges of RFID Deployment

Successfully implementing an RFID asset tracking system requires anticipatory planning to mitigate technical failure points. Overcoming the inherent challenges of building RFID asset tracking systems demands specialized software solutions and rigorous physical validation.

1. The Data Problem: Collision and Overload

A single fixed reader can generate an overwhelming volume of redundant data from multiple tags communicating simultaneously (collision).

- The Challenge: Network saturation and data lag occur when raw reads flood the enterprise network, leading to missed tags and system inefficiency.

- The Mandated Solution: You must deploy intelligent custom middleware engineered to implement anti-collision protocols and filter the data stream, ensuring only clean, actionable business events are transmitted to the core system.

2. The Integration Problem: Data Silos and Legacy Systems

Legacy ERP and WMS platforms are not architected for the high-velocity, continuous data stream produced by an RFID system.

- The Challenge: The system’s data risks becoming isolated, requiring manual reconciliation and nullifying the primary financial benefit of automated tracking.

- The Mandated Solution: Mandate an API-first architecture for the RFID integration with ERP for asset tracking. Utilize robust custom gateways to facilitate real-time, bi-directional data synchronization without modifying core legacy systems.

3. The Compliance Problem: Regulatory and Security Hurdles

Failure to adhere to local spectrum regulations or secure asset location data can expose the enterprise to fines and security breaches.

- The Challenge: Operating outside TRA-approved frequencies or neglecting data sovereignty requirements poses significant legal and operational risk, particularly for sensitive RFID asset tracking in the UAE projects.

- The Mandated Solution: Pre-verify that all deployed hardware possesses TRA certification, and architect the software with end-to-end encryption, ensuring asset data is secured in compliant, local cloud regions.

4. The Physics Problem: Interference from Metal and Liquid

Industrial environments, especially in RFID asset tracking for oil and gas or large logistics hubs, feature pervasive metal and liquid that distort or absorb radio waves, leading to unreliable reads.

- The Challenge: Read accuracy severely degrades due to signal reflection and absorption, compromising the system’s foundational reliability.

- The Mandated Solution: You must specify specialized on-metal tags and enforce a meticulous site survey to fine-tune antenna power and placement, ensuring signal integrity in challenging environments.

From Theory to Practice: RFID Asset Tracking Use Cases in the UAE’s Key Sectors

A successful deployment of RFID asset tracking in the UAE yields specialized value across the Emirates’ core industries. Here is how:

Logistics and Supply Chain

The immense logistics centers dependent on RFID asset tracking in Dubai must use the technology to automate shipping verification and receiving at high volumes. This acceleration of throughput allows for better utilization of assets and dramatically reduces costly container dwell time.

Oil and Gas

Deploying RFID asset tracking for oil and gas is critical for safety and compliance. It tracks high-value, high-risk items like drilling components and specialized tools across vast, harsh environments, automating certification checks and minimizing catastrophic asset loss.

Defence and Security

In RFID asset tracking for defence, the system’s utility is in chain-of-custody documentation and Foreign Object Debris (FOD) prevention. The system must verify that every tool or part used in maintenance is accounted for before an asset is deployed, a process that cannot tolerate manual failure.

IT Asset Management

An RFID IT asset tracking system provides an instantaneous inventory of server racks, network gear, and laptops, simplifying financial audits and ensuring compliance with software licensing agreements.

Healthcare and Medical Asset Management

RFID tracking system in healthcare helps in real-time location tracking of critical, mobile medical equipment like infusion pumps, ventilators, and wheelchairs. This results in reducing the time nurses spend searching for equipment (often 30+ minutes per shift), improving asset utilization (reducing the need to buy or rent surplus equipment), and ensuring life-saving devices are locatable in an emergency.

Retail and Inventory Management

This is a classic use case. Manual inventory counts are slow and notoriously inaccurate. With item-level RFID tagging for apparel, electronics, or high-value goods, a full-store inventory count to be completed in minutes with a handheld reader, rather than days. This directly reduces stock-outs, boosts sales, and improves supply chain forecasting.

Analyzing the Investment: Deconstructing RFID Asset Tracking Cost in the UAE

The question of “how much” is complex, as the RFID asset tracking cost in the UAE varies dramatically based on scale and complexity. The cost of implementing an RFID system in the UAE varies depending on several factors, including the scale of deployment, the type of RFID tags used, and the complexity of integration with existing systems.

On average, RFID implementation in asset management systems in the UAE can range from AED 150,000 to AED 1,400,000 ($40,000 to $400,000) or more for larger enterprises. Here’s an estimate of RFID project development costs based on project complexity.

| Project Complexity | Cost Range (USD) | Cost Range (AED) | Estimated Timeline |

|---|---|---|---|

| Small-Scale Implementation | $40,000 – $100,000 | AED 150,000 – AED 350,000 | 3 – 6 months |

| Medium-Scale Implementation | $100,000 – $250,000 | AED 350,000 – AED 900,000 | 6 – 9 months |

| Large-Scale Implementation | $250,000 – $400,000 | AED 900,000 – AED 1,400,000 | 9 – 12+ months |

Financial Modeling: Deconstructing the Investment and ROI

Though enterprise RFID asset tracking cost in the UAE is a substantial investment, businesses can expect good ROI in just a few months of successful implementation. The return is calculated based on three core areas:

- Direct Loss Mitigation: For high-value assets (such as those in RFID asset tracking in Dubai’s specialized trade free zones), reducing a 5% annual loss rate to a fraction of a percent often pays for the entire system within two years.

- Productivity Gains: The system’s ability to perform a full inventory check in minutes instead of days dramatically frees up skilled labor for higher-value tasks, fundamentally lowering operating expenditure.

- Accuracy and Forecasting: The improved inventory accuracy (often rising from a manual 60-70% to 99%+) improves working capital efficiency by reducing the reliance on costly buffer stock and enabling precise financial forecasting.

Also Read: Agentic AI for Driving ROI in Dubai: CXO Guide

With an initial investment ranging from AED 150,000 to AED 1,400,000, RFID can save you millions in the long run. Let’s discuss how we can help you reduce asset loss & improve efficiency.

The Horizon: Future Trajectories for RFID and Asset Management

The benefits of RFID asset tracking are already clear, but the technology is not standing still. The future is about convergence.

RFID + AI/ML: The next-generation RFID asset tracking solutions will use artificial intelligence and Machine Learning (ML) to analyze asset movement patterns, enabling the system to move from simply reporting where an asset is, to predicting where it needs to be or identifying high-risk usage behavior.

RFID + IoT: Future solutions will integrate RFID data with sensor readings (Internet of Things) for condition monitoring, such as temperature and humidity, essential for cold chain logistics.

Sensor-Enabled Tags: Next-generation tags are miniaturized with embedded sensors that report environmental conditions, offering a level of data granularity that supports true predictive maintenance. This capability will significantly enhance the benefits of RFID asset tracking in industrial or pharmaceutical environments.

Edge Computing: Processing the torrent of raw tag data closer to the source (at the reader or local gateway) using edge computing reduces network latency and bandwidth costs. This is critical for scaling a seamless RFID asset tracking system UAE-wide.

From Fiction to Action: Partnering with Appinventiv for Your RFID Solution Development

Building a sophisticated RFID asset tracking system requires a tech partner that is fluent in both the physical world of radio frequencies and the digital world of enterprise software architecture. This is Appinventiv’s core competency.

We are a full-spectrum Enterprise Software Development Company in Dubai that architects and builds the high-performance software “brain” to power your asset tracking strategy. Our approach to bringing your project of RFID asset tracking in the UAE is built on our deep enterprise experience.

- Software-Centric: We’ve delivered over 1,000 digital solutions across the Middle East regions. And we understand that the true value of an RFID asset management tracking system is unlocked through flawless RFID integration with ERP for asset tracking.

- Process-Driven: Our team of 1600+ tech experts follows a proven methodology, from initial discovery and process mapping to scalable deployment and ongoing support.

- UAE-Ready: We understand the technical and regulatory landscape, ensuring your solution is not only powerful but fully compliant with TRA standards from day one.

- Proven Partnerships in the UAE: In our 10+ years of regional experience, we’ve partnered with 35+ industries, supporting 500+ enterprise workflow modernizations. Our portfolio includes leading UAE and global brands such as KFC, Adidas, Edamama, Pizza Hut, IKEA, and 6th Street, backed by a 95% client satisfaction rate.

We build the custom dashboards, the intelligent middleware, and the mobile applications that transform raw tag reads into the business intelligence you need to lead your industry.

Real-World Impact: A UAE Enterprise Case Study

Don’t believe us? Here is an example of our work with a UAE client that illustrates the kind of results an enterprise can expect when partnering with us:

The Client Challenge: A large industrial firm operating across Abu Dhabi and Dubai needed real-time visibility into thousands of high-value tools and specialized equipment across multiple sites, wasting over 500 man-hours monthly on tool location searches.

The Solution Delivered: We designed and deployed a custom RFID asset tracking software solution. This included bespoke middleware, seamless RFID integration with ERP for asset tracking, and the implementation of fixed, high-frequency UHF readers at all facility choke points.

Measurable Results:

- 99.8% inventory accuracy achieved within 90 days.

- 70% reduction in equipment search time for critical assets.

- 40% decrease in the annual “loss and write-off” budget for high-value tools.

- Automated regulatory audit reporting, reducing compliance man-hours by 85%.

Your Next Move: Seizing the Asset Visibility Advantage

The implementation of an RFID asset tracking system UAE-wide is accelerating. The question for leaders is no longer if this technology will be adopted, but when and by whom. Enterprises that continue to rely on manual processes and “best-guess” asset management will inevitably be outpaced by competitors who have embraced real-time, automated visibility.

So, why wait? Partner with us now and build an RFID asset tracking system to propel your business to greater heights.

FAQs

Q. How much does it cost to implement an RFID asset tracking system in the Middle East?

A. The RFID asset tracking cost UAE enterprises face varies widely, depending on various factors.

On average, the cost to build an RFID asset tracking system in the UAE ranges from AED 150,000 to AED 1,400,000 ($40,000 to $400,000)

Q. How does RFID asset tracking integrate with ERP systems for asset management?

A. RFID integration with ERP for asset tracking (like SAP or Oracle) is handled by a software layer called “middleware.” The RFID readers send raw tag data to the middleware, which cleans, filters, and interprets it (e.g., “Tag 123 just left Dock 4”). The middleware then communicates this business event to the ERP via an API, updating the asset’s status, location, or chain of custody in real-time.

Q. What are the key benefits of deploying an RFID tracking solution for assets in UAE enterprises?

A. The primary benefits of RFID asset tracking include:

- Drastically improved inventory accuracy (often from 70% to 99%+)

- Reduced labor costs by automating manual audits

- Enhanced asset utilization (finding items faster)

- Loss prevention by alerting when high-value assets leave a secure area

- Automated compliance and audit trails.

Q. Are RFID systems in compliance with UAE data privacy laws?

A. Yes, provided they are implemented correctly. The RFID asset tracking in the UAE must adhere to the UAE’s data protection laws.

This primarily means ensuring that any personal data (if you are tracking assets assigned to an individual) is handled with consent and that all data, including simple asset location data, is stored securely.

Partnering with a reputed enterprise software development company that understands data sovereignty and can deploy your RFID asset tracking software within UAE-based data centers is essential for compliance.

Q. Which RFID tag type is best for tracking fixed assets in UAE conditions?

A. For RFID asset tracking for fixed assets, the UHF (Ultra-High Frequency) Passive, ruggedized, on-metal tags are mandatory. The tags must be rated for high heat resistance, and their selection must be preceded by a site survey to determine optimal placement and antenna specifications.

Q. How does an enterprise ensure TDRA compliance for an RFID asset tracking project in the UAE?

A. Enterprises must select a technology partner that can provide TDRA compliance documentation for all reader and antenna models. Furthermore, the RFID asset tracking software must be configured to electronically limit the transmitter power to the specific maximum Effective Radiated Power (ERP) allowed for the $865\text{ MHz}$ frequency band in the UAE.

Q. What is the value of an RFID IT asset tracking system over simple barcode scanning?

A. An RFID IT asset-tracking system provides bulk reading capabilities, allowing hundreds of IT assets to be scanned simultaneously without line of sight. This is essential for audit acceleration and physical security, offering a level of automation and speed that manual or barcode systems cannot approach.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Key Takeaways Use a scorecard-driven RFP and a technical assessment to compare vendors on capability, compliance, and delivery risk. Local partners provide regulatory and cultural alignment; hybrid teams often pair that with offshore cost efficiency. Start with a scoped pilot or MVP, milestone-based contracts, and clear IP/SLAs to reduce procurement risk. Require demonstrable security controls,…

A Strategic Framework for Proof of Concept Software Development

Key takeaways: Most enterprise PoCs fail due to a lack of decision clarity, not technical feasibility or innovation potential. A disciplined PoC framework reduces delivery risk before budgets, teams, and timelines are committed. Enterprise-grade PoCs validate feasibility, compliance, and scale assumptions under realistic operating constraints. Clear success metrics and governance turn PoCs into reliable inputs…

Top UK Software Development Trends Shaping 2026: Insights for Business Leaders

Key takeaways: 2026 is about fixing friction, not chasing trends. UK software teams are prioritising reliability, clarity, and systems that are easier to change over flashy new tooling. AI is becoming background support, not the main act. Its value shows up in routine work like testing, reviews, and documentation, while people still make decisions. Architecture…