- Australia’s Shift Toward Cognitive Industrial Ecosystems

- Legacy Automation Constraints

- Evolution Toward Data-Driven Systems

- Beyond Mechanical Repetition: The Logic of Intelligence

- Key Drivers Accelerating AI Adoption in Australian Industrial Automation

- Labour Costs and Skills Gaps

- Productivity and Industry Mandates

- Energy and Sustainability

- Resilience and Compliance Demands

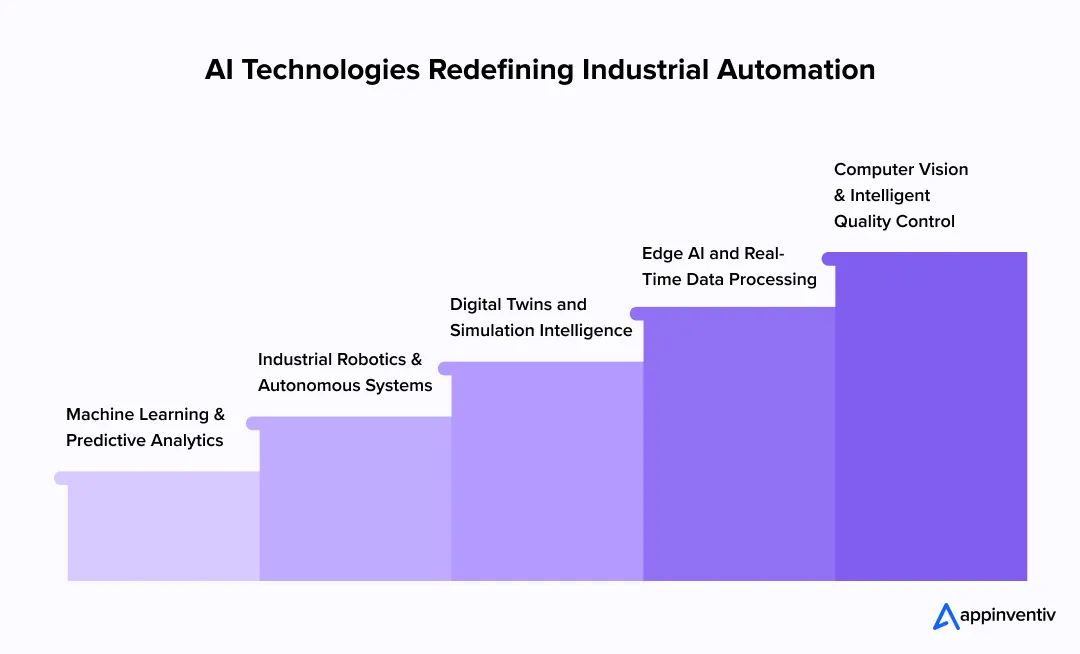

- Core AI Technologies Transforming Industrial Automation

- Machine Learning and Predictive Analytics

- Computer Vision and Intelligent Quality Control

- Industrial Automation and Robotics

- Digital Twins and Simulation Intelligence

- Edge AI and Real-Time Data Processing

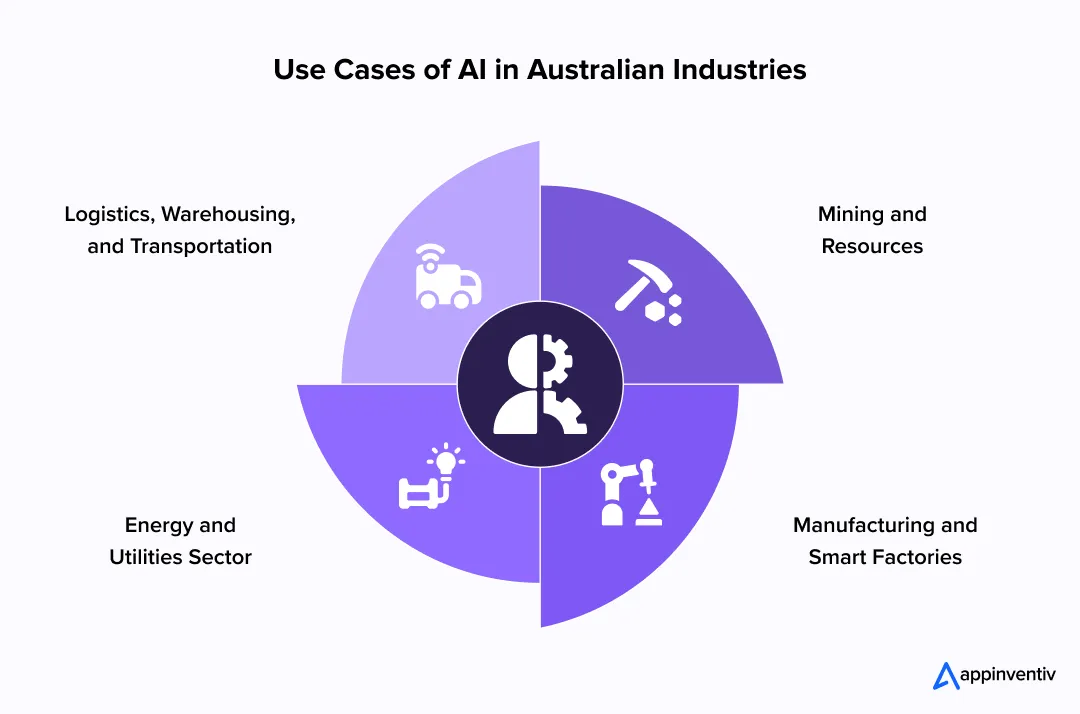

- How AI is Transforming Key Australian Industrial Sectors

- Mining and Resources Industry

- Manufacturing and Smart Factories

- Energy and Utilities Sector

- Logistics, Warehousing, and Transportation

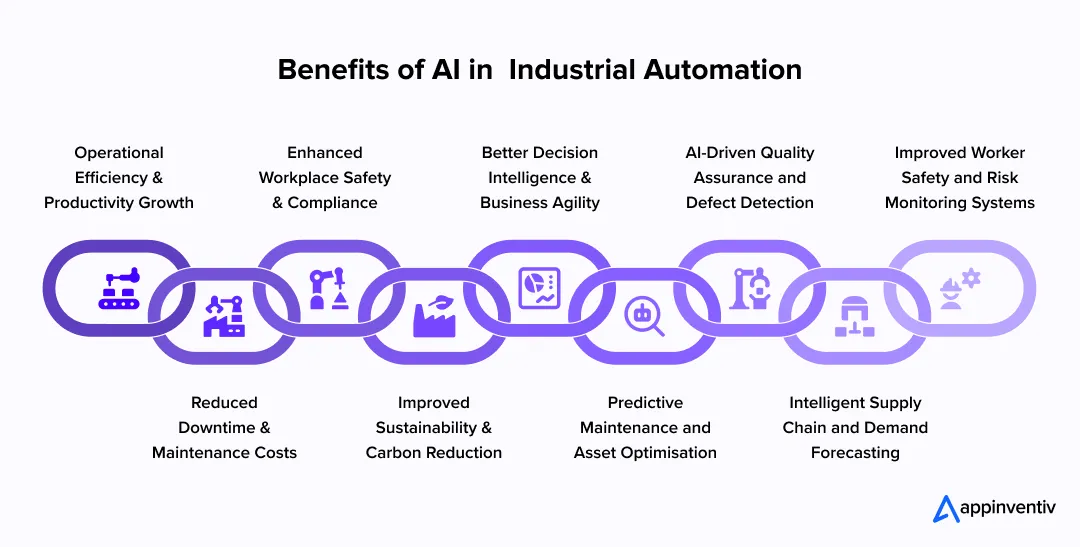

- Business Benefits of AI in Industrial Automation Industry

- Operational Efficiency and Productivity Growth

- Reduced Downtime and Maintenance Costs

- Enhanced Workplace Safety and Compliance

- Improved Sustainability and Carbon Reduction

- Better Decision Intelligence and Business Agility

- Predictive Maintenance and Asset Optimisation

- AI-Driven Quality Assurance and Defect Detection

- Intelligent Supply Chain and Demand Forecasting

- Improved Worker Safety and Risk Monitoring Systems

- Challenges Slowing AI Adoption in Industrial Automation & How to Overcome Them

- Legacy Systems and Data Gaps

- Cybersecurity and Operational Risk

- Skills and Change Management

- Governance and Accountability

- Best Practices for Implementing AI in Industrial Automation

- Conducting Industrial AI Readiness Assessments

- Creating Scalable Data Infrastructure

- Selecting High-ROI Use Cases First

- Building AI Governance and Compliance Frameworks

- Partnering with Industrial AI Development Experts

- Understanding the Cost of AI in Industrial Automation in Australia

- What the Future Looks Like for Australian Industry

- How Appinventiv Supports Industrial Transformation in Australia

- FAQs

Key takeaways:

- AI is shifting industrial automation from rule-based to data-driven decision ecosystems

- Predictive and autonomous operations are improving efficiency and cost optimisation

- Australian industries are leveraging AI to solve workforce, sustainability, and compliance challenges

- Enterprises adopting AI early gain competitive, operational, and economic advantages

Industrial automation in Australia is no longer just an engineering discussion. It has become a board-level concern. Rising operating costs, tighter labour markets, and growing scrutiny around compliance are forcing organisations to question how long legacy automation can realistically hold.

Across mining, manufacturing, energy, and logistics, we see the same pattern. Systems built years ago still run reliably, but they struggle when conditions change. Downtime becomes expensive. Manual intervention increases. Reporting gaps widen. This is where AI in industrial automation in Australia is starting to matter in a very practical sense.

Industrial automation using artificial intelligence in Australia is not replacing existing infrastructure overnight. It is reshaping how decisions are made inside those systems. The shift is less about new machines and more about intelligence layered on top of what already exists.

This blog examines how that transformation is unfolding in practice, where value is being realised, and what Australian enterprises must get right to scale safely.

Ensure governance, security, and accountability are designed into your automation strategy from day one.

Australia’s Shift Toward Cognitive Industrial Ecosystems

The current push for industrial automation using artificial intelligence in Australia responds to three major local headaches: persistent labor shortages, volatile energy prices, and much stricter environmental rules.

Looking at the 2024–2025 landscape, the conversation has moved past simple “smart factories.” Today, it is about building autonomous value chains that actually talk to each other.

Many Australian firms are now walking away from generic, off-the-shelf tools. Instead, they are investing in custom software that plugs directly into their existing legacy controllers (PLCs) and distributed systems.

This move is backed by the National AI Plan 2025, which puts a heavy focus on keeping our data and intelligence local. This ensures critical infrastructure stays under Australian oversight and meets the specific Australian privacy principles.

However, industrial AI automation across Australia is at a transition point. Legacy systems remain operationally critical, but they increasingly struggle to support modern production, safety, and compliance expectations. This gap is driving the adoption of more adaptive automation models.

Legacy Automation Constraints

Most industrial automation systems in Australia were designed for stability, not adaptability. Fixed logic works well when processes stay predictable. The problem appears when inputs change or when operations scale beyond their original design assumptions.

Many industrial automation and control systems still rely on manual overrides during faults. Maintenance teams are called in late, not early. Data exists, but it sits across disconnected systems. This increases downtime risk and makes root-cause analysis slower than it should be.

From an executive perspective, this creates exposure. Costs rise quietly. Resilience weakens over time.

Evolution Toward Data-Driven Systems

AI in industrial automation in Australia introduces a different operating model. Instead of waiting for thresholds to be crossed, systems learn patterns from historical and live data. They flag deviations earlier. They support operators rather than reacting after failures occur.

Machine learning models sit alongside existing PLC and SCADA environments. Computer vision systems monitor quality without fatigue. Industrial automation using IoT connects assets that previously operated in isolation. The result is not disruption, but visibility and control that scales.

Governance plays a role here. Data-rich systems support audit readiness and traceability. That matters more now than it did a decade ago.

Beyond Mechanical Repetition: The Logic of Intelligence

Old-school industrial automation systems in Australia were built for one thing: doing the same task over and over. If a sensor moved an inch out of place, the whole line stopped. AI flips this logic. It adds a layer of actual reasoning. Instead of just shutting down, an AI-boosted system looks at the error, compares it to years of data, and makes an adjustment on the fly. This stops those “nuisance trips” that cost mining and smelting operations millions of dollars every year while helping equipment last longer.

Key Drivers Accelerating AI Adoption in Australian Industrial Automation

The acceleration of industrial automation using artificial intelligence in Australia is not driven by curiosity. It is driven by pressure. Some key elements accelerating the adoption of AI in Australia are:

Labour Costs and Skills Gaps

Skilled industrial talent is limited across Australian industries. The manufacturing sector alone is looking at a gap of 120,000 workers by 2033. Automation is the only way to fill that hole without letting production quality slip.

Productivity and Industry Mandates

Industry 4.0 initiatives and smart manufacturing programs have shifted expectations. Organisations are expected to show progress. Not experiments, but outcomes. AI-backed industrial automation systems in Australia provide measurable improvements that leadership teams can justify.

Energy and Sustainability

Through the Future Made in Australia initiative, the government is putting $22.7 billion on the table. This is nudging companies to use industrial automation using IoT to track and cut their carbon footprint in real-time.

Resilience and Compliance Demands

Supply chain disruptions and regulatory oversight are now permanent realities. Automation systems must adapt quickly and prove compliance continuously. AI enables that through real-time monitoring and structured data trails.

Core AI Technologies Transforming Industrial Automation

AI adoption in industrial environments is not monolithic. Australian enterprises are combining multiple AI technologies to address different layers of automation, from sensing and control to optimisation and planning. The value comes from how these components work together, not from any single tool.

Machine Learning and Predictive Analytics

Most AI use in industrial environments starts with machine learning, but the value is practical rather than theoretical. In Australian operations, models are mainly used to flag when assets are drifting, not when they have already failed.

Maintenance planning shifts away from fixed schedules toward condition-led decisions. This matters in asset-heavy environments where downtime is costly and access to sites is limited.

Computer Vision and Intelligent Quality Control

Visual inspection is one of the first areas where manual processes start to break at scale. Lighting, speed, and fatigue all affect consistency on the floor.

Computer vision systems run continuously and don’t rely on sampling. Defects and safety issues are picked up earlier, and the visual record becomes useful when quality or compliance decisions are challenged later.

Industrial Automation and Robotics

Traditional robotics struggles in Australian facilities where layouts change and processes are rarely uniform. AI allows robots to respond to variation instead of stopping when inputs drift.

This has reduced exposure in high-risk tasks and improved consistency, particularly where skilled labour is hard to retain or replace.

Digital Twins and Simulation Intelligence

Changes in live industrial environments carry risk, especially when downtime is difficult to recover. Digital twins are being used to test assumptions before they reach the floor.

Teams simulate load, failure scenarios, and process changes to understand impact without disrupting production or safety conditions.

Edge AI and Real-Time Data Processing

Connectivity cannot be assumed across all Australian sites. Distance and latency still shape what systems can realistically do.

By processing data closer to the equipment, decisions happen faster and remain under local control. This reduces reliance on constant backhaul while keeping sensitive operational data contained.

How AI is Transforming Key Australian Industrial Sectors

What’s driving AI adoption in the Australian industry isn’t ambition. It’s constraint. Geography, workforce limits, ageing infrastructure, and board-level risk tolerance shape how automation actually lands on the ground. Each sector is leaning into AI differently, based on where pressure shows up first.

Mining and Resources Industry

In Australian mining, distance is the first problem. Sites are remote, connectivity is inconsistent, and downtime escalates quickly because access is slow and expensive. Add FIFO dependency and safety exposure, and traditional automation starts to feel brittle.

AI automation in Australian mining is being used, where it reduces human dependency at the edge. Predictive maintenance models flag failures before assets strand crews. Autonomous drilling and haulage reduce exposure in high-risk zones. Safety systems focus less on reporting and more on early intervention. The example of industrial automation in mining is operational stability, not experimentation, which is why adoption has accelerated across large-scale operations.

Manufacturing and Smart Factories

Australian manufacturers operate under a different set of economics than global mass producers. Labour costs are higher, batch sizes are smaller, and changeovers happen more often. Fixed automation struggles in that environment.

AI-enabled automation in manufacturing supports flexibility rather than volume. Production lines adjust in response to demand signals and quality drift. Vision systems catch defects early because rework is expensive locally. When paired with industrial automation using IoT, manufacturers gain visibility across machines that were never designed to talk to each other. This is how local manufacturers stay viable without chasing scale they’ll never win.

Energy and Utilities Sector

The challenge in Australia’s energy sector isn’t generation. It’s coordination. Renewable inputs fluctuate, infrastructure is ageing, and reliability expectations haven’t softened.

AI automation in the Australian energy sector is being used to predict stress points before they become outages. Grid operators apply machine learning to balance load and forecast faults across distributed assets. For utilities, the appeal isn’t sophistication. It’s fewer surprises. That matters when service reliability and public scrutiny sit under constant review.

Also Read: The Role of Technology in Renewable Energy in Australia

Logistics, Warehousing, and Transportation

Australian logistics runs long and thin. Distances are vast, fuel costs fluctuate, and service expectations continue to tighten. Static routing and manual planning can’t keep up.

AI-driven automation improves responsiveness rather than just efficiency. Route optimisation adjusts in near real time. Warehouse systems prioritise flow over volume. Fleet intelligence reduces idle time and fuel waste. These systems matter because they help operators absorb disruption without adding headcount or margin pressure.

Also Read: How to Build a Warehouse Management System in Australia

Business Benefits of AI in Industrial Automation Industry

For Australian enterprises, the benefits of AI-led automation are rarely about acceleration. They are about control. As operations become more complex and risk exposure increases, AI helps stabilise performance across assets and sites. The value shows up gradually through fewer exceptions, clearer decisions, and more predictable outcomes.

Operational Efficiency and Productivity Growth

Productivity improves when systems stop fighting everyday variation. AI absorbs small shifts in inputs and conditions, helping output remain steady without constant manual correction.

Reduced Downtime and Maintenance Costs

Most outages are preceded by warning signs that go unnoticed. AI makes those signals visible earlier, allowing maintenance to be planned rather than rushed under pressure.

Enhanced Workplace Safety and Compliance

Safety outcomes improve when risk is seen before it escalates. AI draws attention to patterns across equipment and environments that are easy to miss during normal operations.

Improved Sustainability and Carbon Reduction

Energy and material losses often hide inside routine processes. AI exposes where inefficiencies sit, allowing gradual reductions without forcing disruptive operational change.

Better Decision Intelligence and Business Agility

Decision-making improves when uncertainty narrows. AI shortens the gap between what is happening on the ground and what leadership teams can actually see.

Predictive Maintenance and Asset Optimisation

In Australian industries, most failures are not sudden. They drift there. AI is used to catch that drift early, especially where getting people or parts on site takes time. Maintenance becomes planned more often than reactive, which changes how outages are managed.

AI-Driven Quality Assurance and Defect Detection

Manual inspection doesn’t scale well once variability creeps in. Sampling and human intelligence can miss things. AI systems watch everything, all the time. When quality slips, it’s visible early, not after rework starts piling up.

Intelligent Supply Chain and Demand Forecasting

Planning breaks when assumptions lag reality. AI adjusts forecasts as conditions change, reducing late-stage disruption rather than trying to eliminate it entirely.

Improved Worker Safety and Risk Monitoring Systems

Most safety incidents have a lead-up that goes unnoticed. Signals are there, just not obvious. AI watches for those signals across equipment and environments, giving teams a chance to intervene before something escalates.

Challenges Slowing AI Adoption in Industrial Automation & How to Overcome Them

Despite momentum, industrial automation using artificial intelligence in Australia still encounters friction. Most of it is predictable. Let’s uncover them:

Legacy Systems and Data Gaps

Few organisations start with clean data. Sensors are inconsistent. Historians store data in incompatible formats. Critical context lives in spreadsheets or people’s heads.

AI models cannot compensate for missing or unreliable inputs. Addressing this takes time and upfront investment. Organisations that rush past this step often blame the technology later.

Solution: Start with targeted data unification around high-impact assets. Incremental integration delivers value faster than attempting full system replacement upfront.

Cybersecurity and Operational Risk

Industrial automation using IoT expands connectivity. It also expands exposure. Australian enterprises face increasing scrutiny around cyber maturity, particularly where operational technology intersects with IT networks.

Solution: Design AI automation platforms with ASD Essential Eight and Privacy Act compliance expectations to ensure infrastructure security.

Skills and Change Management

AI does not remove people from industrial environments. It changes their role. Operators need to trust system outputs. Engineers need to understand model limitations. Leaders need confidence that decisions remain explainable.

Ignoring this human layer creates resistance that no model accuracy can fix.

Solution: Pair AI deployment with role-based enablement and transparency. Systems must explain recommendations clearly to earn operational trust.

Governance and Accountability

As AI takes on more decision support, questions of accountability emerge. Who owns outcomes when recommendations influence production or safety decisions?

Strong governance frameworks answer this early. Weak ones delay it until something goes wrong.

Solution: Establish clear ownership models, approval thresholds, and align everything with the Voluntary AI Safety Standard. You need to be able to explain why the AI made a certain choice.

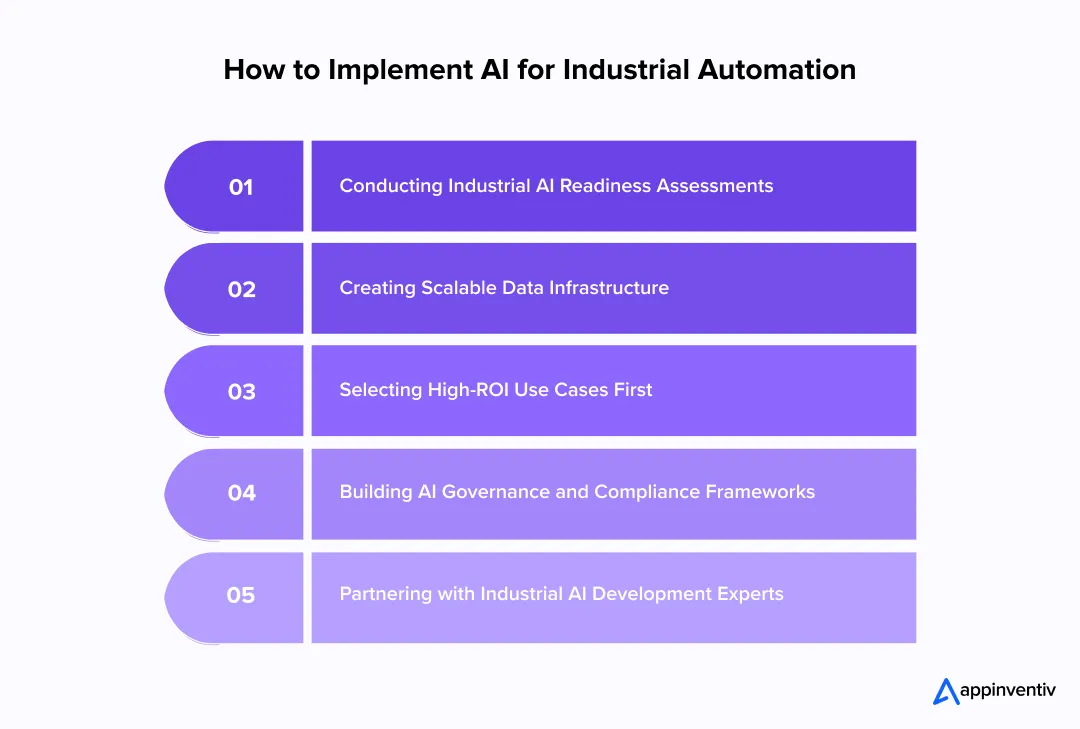

Best Practices for Implementing AI in Industrial Automation

Most AI automation programs succeed or fail before the first model is trained. What matters is how well teams prepare the ground, set limits, and sequence decisions. These practices reflect what tends to hold up under real operating conditions. Here are some practical steps to build an AI model for Australian industrial automation:

Conducting Industrial AI Readiness Assessments

Start by validating where AI can realistically operate within existing industrial conditions, rather than where it looks attractive on paper. Readiness work is about exposing limits early, before deployment decisions harden.

- Identify which assets generate usable data and which only produce noise

- Map operational decisions that already rely on human judgement

- Surface latency, connectivity, and site access limitations early

- Pressure-test assumptions with operations and safety leads, not just IT

Creating Scalable Data Infrastructure

Build data foundations for reliability first, not sophistication. In industrial environments, infrastructure must hold up under real operating constraints before it is scaled or optimised.

- Prioritise stable ingestion from critical assets before expanding scope

- Keep processing close to the edge where connectivity is unreliable

- Define clear data ownership across engineering and operations

- Avoid centralising everything if local decision speed matters

Selecting High-ROI Use Cases First

Sequence AI deployment around problems that already hurt operational performance. Early use cases should prove value quickly and reinforce confidence across operations teams.

- Start with areas where downtime or waste is already visible

- Favour use cases that support existing workflows, not replace them

- Measure outcomes in operational terms, not model accuracy

- Limit pilots to environments where teams are open to change

Building AI Governance and Compliance Frameworks

Establish governance before AI influences live operational decisions. Clear controls and accountability prevent risk from scaling faster than value.

- Define where human override is mandatory and non-negotiable

- Document how models learn, change, and are retired

- Align accountability with operational ownership, not vendors

- Prepare for audit questions before systems go live

Partnering with Industrial AI Development Experts

Select an experienced artificial intelligence development company in Australia based on how they handle complexity under operational pressure. Execution capability matters more than technical credentials in industrial environments.

- Look for experience integrating with ageing control systems

- Assess comfort working around live operations and downtime limits

- Test how partners respond when data quality is poor

- Prioritise execution history over technical claims

Enterprises investing in intelligent automation are reducing downtime, strengthening compliance, and improving operational scalability across complex industrial environments.

Understanding the Cost of AI in Industrial Automation in Australia

The cost to implement AI-driven industrial automation in Australia varies widely. Not because vendors price unpredictably, but because scope and maturity differ.

AI development costs are influenced by data readiness, integration complexity, cybersecurity requirements, and ongoing model maintenance. Initial pilots may appear affordable. Long-term ownership is where real investment sits.

Enterprises that budget only for build costs often struggle later. Those who plan for lifecycle costs tend to see steadier returns.

Also Read: Mobile App Development Cost in Australia: 2026 Guide

Breakdown of Implementation Investment

| Component | Indicative Cost Range (AUD) | Critical Consideration |

|---|---|---|

| AI Model Development | $70,000 – $300,000 | Custom vs. pre-built models |

| System Integration | $120,000 – $450,000 | Legacy PLC/SCADA link-ups |

| Data Infrastructure | $50,000 – $150,000 | Local cloud vs. on-site storage |

| Governance & Security | $40,000 – $100,000 | Privacy Act & ISO 27001 |

What the Future Looks Like for Australian Industry

The future of industrial automation in Australia will not be defined by full autonomy. It will be defined by coordination.

AI systems will increasingly operate alongside humans, supporting decisions rather than replacing judgement. Industrial automation trends point toward adaptive systems that respond to context, regulation, and risk dynamically.

Sustainability goals will also shape adoption. Energy optimisation, waste reduction, and carbon reporting rely on the same intelligence layers driving productivity.

Over time, industrial automation and control systems will become less visible. What will matter is how reliably they support business outcomes.

How Appinventiv Supports Industrial Transformation in Australia

The future of industrial automation in Australia is moving from simple “automated” machines to “autonomous” ecosystems. By 2030, this tech is expected to add $315 billion to our GDP. For leaders, the time to treat AI as a “future” project is over. It is now the foundation of your business.

As an Australian AI consulting company, we bridge the gap between big ideas and the hard reality of the factory floor. We don’t just build AI models; we build intelligent automation ecosystems tailored to sector-specific operational challenges.

We work with Australian enterprises where automation is mission critical. Not experimental. Not optional. Our role is to help organisations modernise industrial environments without losing control. That means respecting existing systems, governance obligations, and operational realities.

Our delivery capabilities include AI platform development, IoT-driven infrastructure modernisation, robotics integration, predictive analytics, digital twin deployment and so on.

In our 10+ years of APAC delivery experience, our delivery footprint includes:

- 3000+ digital assets deployment

- 78% client retention rate

- 35+ industries transformed

- 5+ agile delivery centres across Australia

We operate within enterprise security expectations, maintaining a 99.50% compliance SLA across ISO and SOC2 frameworks. In production environments, we have supported efficiency improvements of up to 35%.

Our focus is not on selling AI. It is on making AI in industrial automation in Australia sustainable, auditable, and valuable over time.

Ready to Modernise Industrial Automation with AI? Consult our Industrial AI Experts.

FAQs

Q. What is industrial automation?

A. Industrial automation refers to the use of control systems, software, and connected machinery to run industrial processes with minimal manual intervention. In Australian enterprises, it focuses on reliability, safety, and repeatable outcomes across complex operating environments.

Q. How are Australian manufacturers using AI to automate industrial operations?

A. Manufacturers in Australia are using AI to predict equipment failures, stabilise production quality, and adjust output based on demand and material variability. AI in industrial automation in Australia is typically layered onto existing control systems rather than replacing them.

Q. What AI technologies work best for legacy industrial systems in Australia?

A. AI tech stacks that work well for legacy industrial systems are:

- Machine learning for predictive maintenance

- Computer vision for quality inspection

- Edge analytics for real-time decisioning

These technologies integrate without disrupting core control logic.

Q. How long does it take to deploy AI automation systems in Australian factories?

A. The timeline for targeted AI automation deployments vary based on data readiness, integration complexity, and governance approvals. On average, the time it takes to deploy AI automation systems in Australia ranges from 4 to 12+ months.

For instance, pilot implementations typically take four to six months, while enterprise-scale deployments may extend beyond twelve months depending on infrastructure readiness.

Q. What is the best tech stack for AI-based industrial automation in Australia?

A. A typical stack includes secure edge computing, scalable data platforms, machine learning frameworks, and integration layers that connect with existing industrial automation and control systems. Strong cybersecurity and compliance tooling are essential parts of the tech stack.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Governance vs. Speed: Designing a Scalable RPA CoE for Enterprise Automation

Key takeaways: Enterprise RPA fails at scale due to operating model gaps, not automation technology limitations. A federated RPA CoE balances delivery speed with governance, avoiding bottlenecks and audit exposure. Governance embedded into execution enables faster automation without introducing enterprise risk. Scalable RPA requires clear ownership, defined escalation paths, and production-grade operational controls. Measuring RPA…

Implementing Retrieval-Augmented Generation in Healthcare Systems: Challenges, Use Cases & ROI

Key takeaways: RAG helps clinicians make better decisions by connecting AI responses to trusted clinical data sources. Healthcare organizations are gradually adopting domain-specific AI to improve efficiency, compliance, and operational clarity. Successful RAG deployment usually depends on strong governance, interoperability planning, and secure data practices. Retrieval-backed AI can ease documentation workload while improving accuracy, productivity,…

How Australian Enterprises Are Using Intelligent Automation to Reduce Operational Cost

Key takeaways: Australian enterprises are using intelligent automation to automate core processes such as reconciliations, approvals, exception handling, and compliance reporting. Intelligent automation initiatives typically range from AUD 70,000 to AUD 700,000, depending on scope, integration depth, and governance needs. When implemented with control, intelligent automation delivers lower operating cost, faster decision cycles, and improved…