- How RPA Works Inside Manufacturing Operations

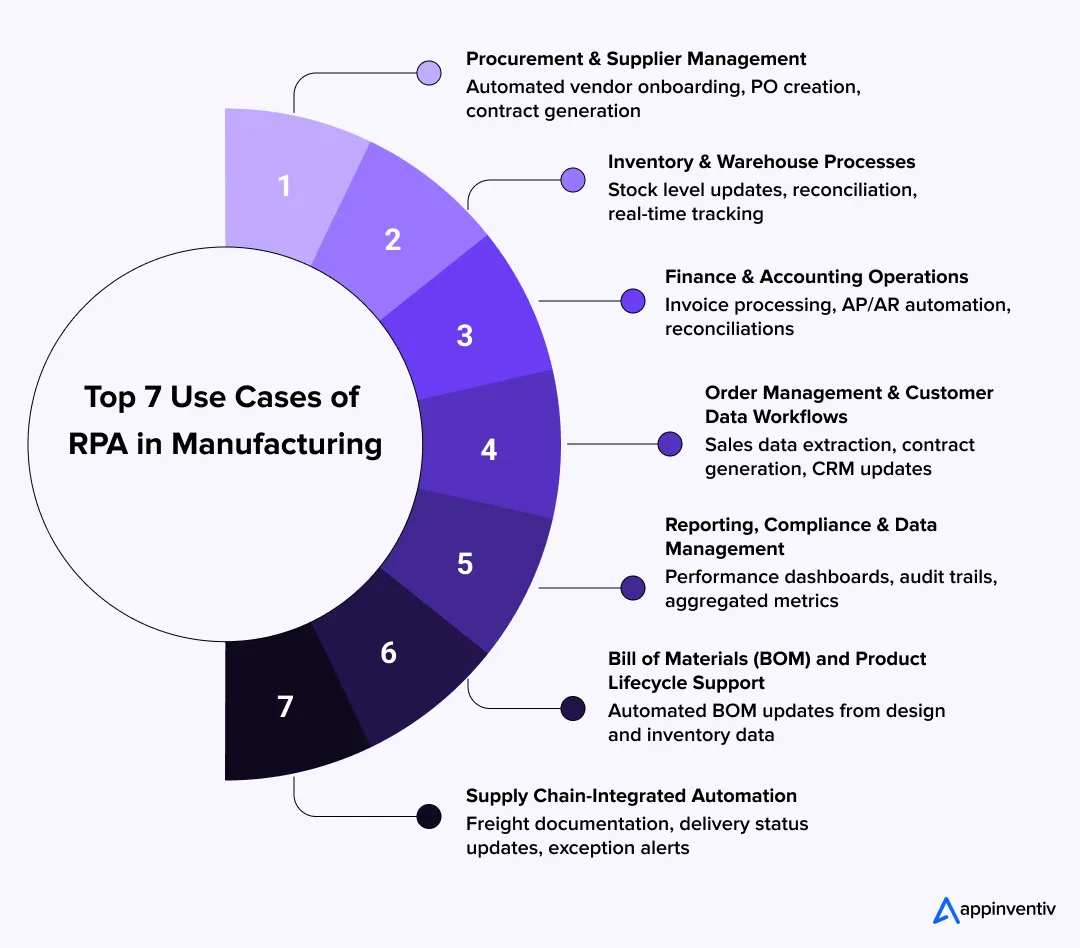

- What Are Some High-Impact RPA Use Cases in Manufacturing?

- Procurement and Supplier Management

- Inventory and Warehouse Processes

- Finance and Accounting Operations

- Order Management and Customer Data Workflows

- Reporting, Compliance, and Data Management

- Bill of Materials and Product Lifecycle Support

- Supply Chain–Integrated Automation

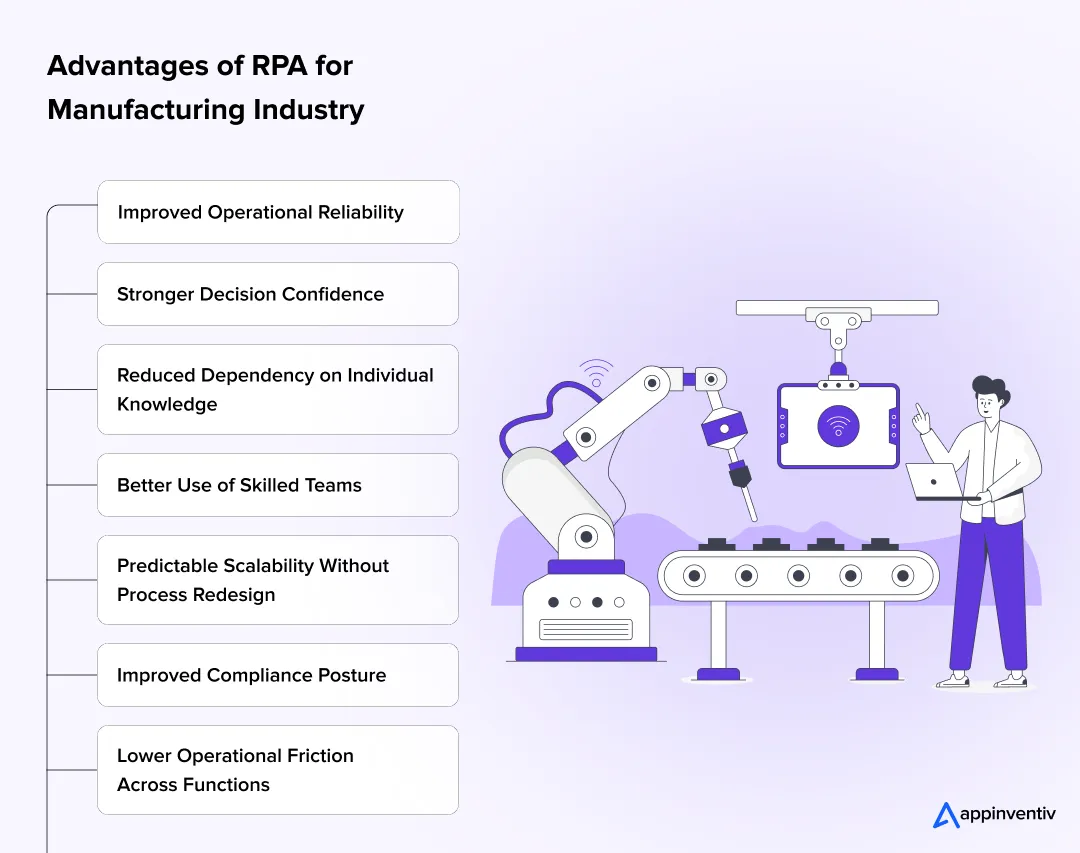

- Benefits of RPA in Manufacturing Operations

- Improved Operational Reliability

- Stronger Decision Confidence

- Reduced Dependency on Individual Knowledge

- Better Use of Skilled Teams

- Predictable Scalability Without Process Redesign

- Improved Compliance Posture

- Lower Operational Friction Across Functions

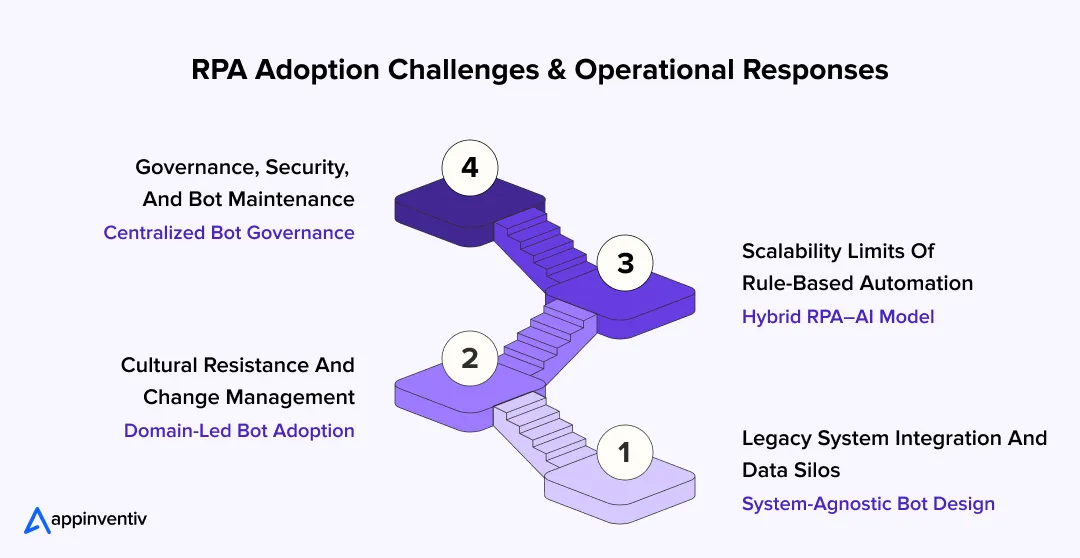

- Challenges Manufacturers Face in RPA Adoption and How to Address Them

- Challenge 1: Process Variability Hidden Behind “Standard” Workflows

- Challenge 2: Overreliance on RPA to Fix Structural System Issues

- Challenge 3: Fragile Bots Caused by UI and Interface Changes

- Challenge 4: Scaling Without Governance

- Challenge 5: Underestimating Change Management

- Challenge 6: Limited Visibility Into Automation Performance

- Cost of Implementing RPA in Manufacturing and Expected Timelines

- What Actually Drives RPA Cost in Manufacturing

- Typical Cost and Timeline by Project Complexity

- One-Time Spend Versus Ongoing Commitment

- Making the Business Case: ROI and Value Measurement in Manufacturing RPA

- Hard ROI: Where Measurable Gains Come From

- Soft ROI: Operational Value That Matters Long-Term

- Payback Timelines in Manufacturing RPA Programs

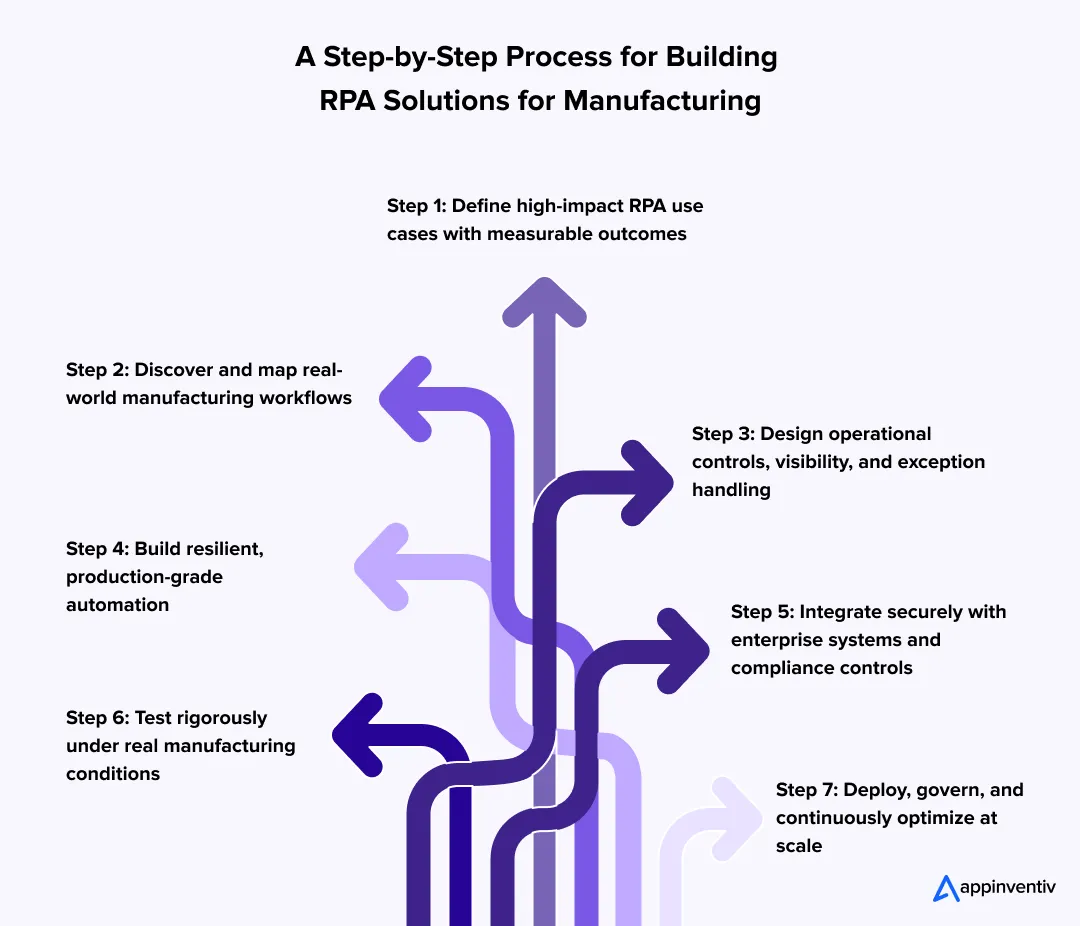

- Best Practices for Building Powerful RPA Solutions in Manufacturing: A Step-by-Step Process

- Step 1: Define high-impact RPA use cases with measurable outcomes

- Step 2: Discover and map real-world manufacturing workflows

- Step 3: Design operational controls, visibility, and exception handling

- Step 4: Build resilient, production-grade automation

- Step 5: Integrate securely with enterprise systems and compliance controls

- Step 6: Test rigorously under real manufacturing conditions

- Step 7: Deploy, govern, and continuously optimize at scale

- Future Outlook: How RPA in Manufacturing Is Likely to Evolve

- How Manufacturing Enterprises Translate RPA Strategy Into Execution With Appinventiv

- FAQs

Key takeaways:

- RPA shows the strongest impact in high-volume coordination work such as invoice-to-PO matching, ERP–WMS inventory reconciliation, and order status updates across systems.

- For well-scoped workflows, RPA typically shows operational impact within 8–12 weeks, driven by less rework, fewer data mismatches, and faster reconciliations.

- In manufacturing, RPA programs usually range from $40,000 to $600,000, with costs shaped more by process variability and system sprawl than bot count.

- With 3000+ solutions delivered and a 95% client satisfaction rate, Appinventiv builds manufacturing RPA that remains stable under scale, audits, and real operational pressure.

In many manufacturing organizations, the biggest operational delays do not originate on the shop floor. They emerge quietly between systems.

A production schedule sits in one platform. Supplier confirmations arrive through email portals. Inventory updates lag in the ERP. Finance reconciles numbers days later, often manually. None of these gaps look critical on their own, but together they slow decision-making, inflate working capital, and introduce risk that compounds over time.

This is where RPA in manufacturing begins to make sense, not as a futuristic automation play, but as a corrective layer for operational disconnects that already exist.

Manufacturers have spent decades investing in ERP, MES, PLM, and supply chain software. Yet many processes still depend on people moving data between systems that were never designed to work in real time with each other. Robotic process automation in manufacturing addresses this exact problem. It automates the handoffs, validations, and reconciliations that teams perform daily, often under time pressure and with limited visibility.

What makes RPA in the manufacturing industry relevant today is not speed alone. It is predictability. When data moves consistently, schedules stabilize, inventory becomes trustworthy, and financial reporting reflects reality rather than estimates.

This guide examines how robotic process automation for manufacturing actually works in practice, where it delivers value, and where its limits begin.

Leverage Appinventiv’s enterprise delivery approach to ensure stability, compliance, and long-term scalability.

How RPA Works Inside Manufacturing Operations

In manufacturing settings, robotic process automation for manufacturing is rarely about automation for its own sake. It is about execution discipline.

RPA works by following explicit instructions. A bot logs into a system. It reads specific fields. It applies rules that are already known and accepted by the business. Then it performs an action. Nothing more.

This matters because manufacturing environments are rarely greenfield. They are layered. An ERP handles planning. A MES controls execution. A warehouse system tracks movement. Finance systems close the loop. These platforms often do not share data cleanly or at the right moment.

Robotic process automation in manufacturing steps into those gaps.

For example, when inventory data changes in one system but not another, a bot can validate the difference and update records automatically. When supplier invoices arrive in different formats, RPA can extract values, check them against purchase orders, and flag exceptions before they reach finance.

In practical RPA manufacturing deployments, bots usually operate in three ways:

- Scheduled execution, such as daily reconciliations or report generation

- Event-driven execution, triggered by transactions or status changes

- Exception monitoring, where bots surface issues instead of acting blindly

What separates robotics process automation in manufacturing from traditional integrations is its tolerance for complexity. It works even when systems are old, interfaces are rigid, or processes vary slightly between plants.

The role of RPA in the manufacturing industry is therefore operational, not architectural. It enforces consistency without forcing large-scale system replacement.

As organizations mature, RPA is sometimes combined with intelligence layers. This is where RPA and AI in manufacturing begin to take shape. AI helps interpret inputs like documents or anomalies. RPA executes the follow-through. The responsibilities remain distinct.

At its core, robotic process automation in the manufacturing industry is about reliability. Processes run the same way every time. Data moves when it should. And people stop acting as the glue between systems.

What Are Some High-Impact RPA Use Cases in Manufacturing?

RPA delivers value in manufacturing when it removes coordination work that quietly slows execution. These are not edge cases or experimental workflows. They are routine processes that scale poorly when handled manually and improve immediately when stabilized.

Procurement and Supplier Management

Procurement workflows are rarely uniform. Suppliers use different formats, portals, and approval cycles. As volume increases, manual onboarding and contract handling become bottlenecks rather than safeguards.

RPA supports procurement teams by standardizing execution without forcing suppliers onto a single system.

Common automation scenarios include:

- Automated vendor onboarding using predefined data validation rules

- Purchase order creation based on approved requisitions

- Contract generation and updates using standardized templates

- Cross-checking supplier details against compliance and risk databases

This reduces onboarding time and prevents procurement teams from becoming administrative gatekeepers.

Inventory and Warehouse Processes

Inventory accuracy depends on timely updates across multiple systems. In reality, warehouse platforms, ERPs, and planning tools often update on different schedules.

RPA brings consistency by acting as a reconciliation and synchronization layer.

Typical use cases include:

- Automated stock level updates across ERP and WMS

- Inventory reconciliation to identify mismatches early

- Real-time or near-real-time alerts for shortages and overstock situations

These automations help planners rely on inventory data instead of padding forecasts as a hedge against uncertainty.

Finance and Accounting Operations

Finance teams in manufacturing handle high transaction volumes with little tolerance for error. Manual processing slows closes and increases exposure to disputes.

RPA is finance widely applied across both payables and receivables.

Common finance automations include:

- Invoice processing with PO matching

- Accounts payable approvals and posting

- Accounts receivable updates based on shipment or delivery confirmation

- Reconciliations across finance, sales, and logistics systems

This shortens financial cycles while improving accuracy and audit readiness.

Order Management and Customer Data Workflows

Order workflows often cut across CRM, ERP, pricing engines, and fulfillment systems. Manual handling introduces delays that customers experience directly.

RPA reduces friction by ensuring data moves cleanly between systems.

Typical automations include:

- Sales data extraction from CRM platforms

- Order validation against pricing and inventory rules

- Contract generation for standardized sales agreements

- Automated CRM updates based on order and fulfillment status

This improves order accuracy and shortens order-to-cash timelines.

Reporting, Compliance, and Data Management

Manufacturing data is plentiful but fragmented. Generating usable reports often means pulling data from multiple systems and reconciling it manually.

RPA helps standardize reporting without creating new data silos.

Common use cases include:

- Automated performance dashboard updates using aggregated system data

- Audit trail generation across quality, production, and finance systems

- Scheduled compliance reporting for internal and external stakeholders

The value lies in consistency, not speed alone.

Bill of Materials and Product Lifecycle Support

BOM accuracy is critical, yet updates often lag behind design or inventory changes. Even small discrepancies can disrupt production runs.

RPA supports BOM management by synchronizing updates across systems.

Typical applications include:

- Automated BOM updates based on approved design changes

- Validation of component availability against inventory systems

- Synchronization between PLM, ERP, and procurement platforms

This reduces rework and prevents downstream production errors.

Supply Chain–Integrated Automation

Logistics workflows involve multiple third parties, documents, and status updates. Manual handling creates blind spots, especially during disruptions.

RPA helps maintain visibility and continuity across the supply chain.

Common automations include:

- Freight documentation generation and validation

- Delivery status updates from logistics partners

- Exception alerts for delays, damage, or missing documentation

This ensures that operational teams respond to issues early rather than after customer impact.

Also Read: RFID in Manufacturing: Transforming Inventory and Supply Chain

Benefits of RPA in Manufacturing Operations

The value of RPA in manufacturing is not limited to task automation. Its real impact shows up in how organizations operate once routine execution becomes predictable and less dependent on manual coordination.

When applied thoughtfully, RPA examples in manufacturing change the shape of work rather than just the speed of work.

Improved Operational Reliability

Manufacturing environments depend on timing. When data updates are delayed or inconsistent, even well-designed processes begin to fail. RPA introduces consistency into execution by ensuring that defined steps happen the same way every time.

This reliability reduces the number of “small surprises” that accumulate into production delays, missed commitments, or last-minute firefighting.

Stronger Decision Confidence

Leaders make decisions based on the information available at the time, not on perfect data. When operational data moves slowly or arrives incomplete, decisions become cautious and reactive.

RPA improves the freshness and alignment of data across systems. As a result, planning, procurement, and finance teams operate with greater confidence, not because data is flawless, but because it is dependable.

Reduced Dependency on Individual Knowledge

In many manufacturing organizations, critical workflows rely on a few experienced individuals who understand how systems really work. When those individuals are unavailable, processes slow down.

RPA captures execution logic in a structured way. This reduces dependency on tribal knowledge and makes operations more resilient to turnover, growth, or reorganization.

Better Use of Skilled Teams

Manufacturing talent is increasingly scarce, especially in operational and analytical roles. When skilled staff spend time on repetitive administrative work, the organization pays twice: once in labor cost and again in lost insight.

RPA allows teams to redirect effort toward planning, optimization, and problem-solving. Over time, this shift has a noticeable effect on operational maturity.

Predictable Scalability Without Process Redesign

Growth often exposes weaknesses in process design. What works at one plant or region breaks when volumes double or new suppliers are added.

RPA supports scalability by absorbing increased transaction volume without forcing immediate process redesign. This gives organizations time to modernize thoughtfully rather than react under pressure.

Improved Compliance Posture

Compliance issues rarely stem from intent. They arise from missed steps, incomplete records, or inconsistent execution.

RPA strengthens compliance by enforcing process discipline and maintaining consistent records. This reduces risk exposure and simplifies audits without adding administrative overhead.

Lower Operational Friction Across Functions

Manufacturing organizations are cross-functional by nature. When systems fail to align, friction emerges between teams rather than within systems.

By stabilizing data movement and execution, RPA reduces the number of handoffs that require explanation, follow-up, or correction. The result is quieter operations, not just faster ones.

Appinventiv’s Insight

These benefits compound over time. Individually, they may appear incremental. Together, they shift how manufacturing organizations function under pressure.

Challenges Manufacturers Face in RPA Adoption and How to Address Them

Most RPA initiatives in manufacturing do not fail because the technology falls short. They struggle because expectations are misaligned with how manufacturing organizations actually operate.

The challenges for RPA in manufacturing are rarely visible during pilot stages. They surface later, once automation moves beyond a few controlled processes and starts interacting with real-world complexity.

Challenge 1: Process Variability Hidden Behind “Standard” Workflows

Manufacturers often assume their processes are standardized because they use the same ERP across plants. In practice, workflows vary subtly by location, product line, or customer requirement. These variations are usually handled informally by experienced staff.

RPA exposes this inconsistency quickly. Bots follow rules exactly. When processes deviate, automation breaks.

Solution:

Before automation begins, processes must be observed, not documented theoretically. Successful teams invest time in understanding how work is actually executed, including edge cases and workarounds. Standardization does not need to be perfect, but it must be intentional.

Challenge 2: Overreliance on RPA to Fix Structural System Issues

There is a temptation to use RPA as a permanent workaround for deeper system limitations. This is especially common with aging ERP or supply chain platforms that lack flexibility.

While robotic process automation in manufacturing can stabilize workflows, it is not a substitute for system modernization when architectural constraints become dominant.

Solution:

Position RPA as a tactical layer, not a long-term patch. Leading organizations maintain a clear boundary between what RPA should automate and what requires platform-level change. This prevents automation from becoming brittle or overextended.

Challenge 3: Fragile Bots Caused by UI and Interface Changes

Manufacturing systems evolve. Interfaces change with upgrades, security patches, or vendor updates. Bots that rely heavily on screen elements rather than stable logic are vulnerable to these changes.

When bots fail silently, operational teams lose trust in automation.

Solution:

Design bots with resilience in mind. Wherever possible, use stable identifiers, backend triggers, and validation layers. Ongoing monitoring and scheduled maintenance should be treated as operational requirements, not optional support tasks.

Challenge 4: Scaling Without Governance

Many RPA programs begin with isolated successes. Teams build bots quickly to solve local problems. Over time, automation sprawl emerges, with duplicated logic, unclear ownership, and inconsistent standards.

At scale, this becomes a risk rather than an advantage.

Solution:

Introduce governance early, even if the program is small. Define ownership, version control, access rights, and change management processes. Governance does not slow automation; it keeps it sustainable.

Challenge 5: Underestimating Change Management

RPA alters how work flows through the organization. Even when automation removes tedious tasks, teams may resist change if communication is unclear or trust is lacking.

In manufacturing environments, where continuity matters, this resistance can stall adoption.

Solution:

Position RPA as operational support, not workforce replacement. Involve domain experts in bot design and validation. When teams see automation reflecting their expertise rather than overriding it, adoption improves significantly.

Challenge 6: Limited Visibility Into Automation Performance

Once bots are deployed, many organizations struggle to measure how well they perform. Without visibility, small issues grow unnoticed until they disrupt operations.

This lack of insight undermines confidence at leadership levels.

Solution:

Treat RPA like any other operational system. Track execution rates, exception volumes, and failure patterns. Visibility turns automation from a black box into a managed capability.

Cost of Implementing RPA in Manufacturing and Expected Timelines

When cost discussions come up, most manufacturing leaders are not trying to optimize for the lowest number. The real concern is control. How much effort will this actually take, how quickly will it settle into daily operations, and what level of attention will it demand over time.

That uncertainty exists because the cost of RPA implementation in manufacturing is shaped by operational reality, not by tooling alone. Volume, process spread, and system age all play a role. Still, across large manufacturing programs, the range is fairly consistent.

In practical terms, most RPA initiatives land between $40,000 and $600,000. This typically covers process analysis, bot build, testing, deployment, and the initial period where automation is monitored and adjusted.

What pushes cost upward is rarely the number of bots. It is the condition of the workflows they touch. Fragmented systems, regional process variations, and exception-heavy scenarios add far more effort than scale alone.

What Actually Drives RPA Cost in Manufacturing

Before looking at estimates, it helps to understand why some automations remain inexpensive while others expand quickly in scope.

In manufacturing environments, cost is most often influenced by:

- Process variability, especially when the same workflow behaves differently across plants or regions

- System spread, with older platforms requiring more careful handling

- Exception volume, which increases design, testing, and fallback logic

- Security and compliance controls, particularly in regulated manufacturing sectors

- Post-deployment upkeep, which is often underestimated during planning

A single, stable workflow in one system is relatively straightforward. A cross-functional process spanning procurement, inventory, finance, and logistics is not.

Typical Cost and Timeline by Project Complexity

To ground expectations, the table below reflects what manufacturers usually encounter in live environments, not idealized scenarios.

| Project Complexity | Scope Description | Estimated Cost | Typical Timeline |

|---|---|---|---|

| Low Complexity | Single function, stable workflow, limited systems | $40K–$100K | 6–10 weeks |

| Medium Complexity | Multiple workflows, 2–3 systems, moderate exceptions | $100K–$300K | 3–6 months |

| High Complexity | Enterprise-scale automation across plants and functions | $300K–$600K | 6–12 months |

These timelines account for more than development. Testing, validation, and early tuning are part of the effort. Manufacturing operations rarely allow automation to be deployed without close oversight.

One-Time Spend Versus Ongoing Commitment

Another area where expectations often drift is lifecycle cost. RPA is not a one-off purchase. It behaves more like an operational system.

Upfront investment usually includes:

- Process discovery and validation

- Bot design and build

- Integration and testing cycles

- Deployment and early stabilization

Ongoing effort typically covers:

- Monitoring and routine maintenance

- Adjustments after system or interface changes

- Performance tuning as volumes grow

- Governance, access control, and change management

Manufacturers that plan for this from the start tend to scale RPA with fewer disruptions. Those that do not often experience friction once automation moves beyond the pilot stage.

Making the Business Case: ROI and Value Measurement in Manufacturing RPA

In manufacturing, ROI is rarely reduced to a single savings figure. Leadership teams look for signs that automation is reducing friction, improving control, and making operations more predictable. Cost savings matter, but they are evaluated alongside operational stability.

RPA typically creates value by removing work that was previously accepted as unavoidable. The impact builds quietly, then becomes visible across multiple functions in the form of hard ROI and soft ROI.

Hard ROI: Where Measurable Gains Come From

Hard ROI in manufacturing RPA usually comes from efficiency, not workforce reduction. Automation removes repetitive effort and reduces the cost of errors that occur when data moves manually between systems.

Common sources of measurable return include:

- Reduced manual processing time in finance, procurement, and order workflows

- Fewer errors and rework caused by data inconsistencies

- Faster cycle times in reporting, reconciliation, and transaction handling

These gains often start small but compound over time into meaningful cost avoidance.

Soft ROI: Operational Value That Matters Long-Term

Soft ROI is harder to quantify but often more influential in manufacturing environments. As execution becomes more consistent, teams spend less time resolving issues and more time planning.

Manufacturers typically see soft ROI through:

- Fewer escalations linked to delayed or incorrect data

- Improved audit readiness and compliance confidence

- Reduced reliance on a small number of highly experienced individuals

These outcomes improve resilience, even if they do not appear directly in financial reports.

Payback Timelines in Manufacturing RPA Programs

For well-scoped processes, RPA payback is usually fast. Many manufacturers begin seeing operational impact within 8 to 12 weeks, particularly for high-volume, rule-based workflows.

Broader programs take longer to mature as governance and optimization come into play. While this extends timelines, it also strengthens long-term returns.

Understand what drives investment, how long deployment typically takes, and how manufacturers justify RPA at scale.

Best Practices for Building Powerful RPA Solutions in Manufacturing: A Step-by-Step Process

Building effective RPA solutions in manufacturing requires the same discipline as building any enterprise-grade software system. The focus is not speed of automation, but durability under real operating conditions. The steps below reflect how scalable RPA solutions are designed, delivered, and sustained in complex manufacturing environments.

Step 1: Define high-impact RPA use cases with measurable outcomes

Every strong RPA program starts with clarity. The objective is not to automate tasks, but to solve operational problems that have a visible cost or risk attached to them.

At this stage, teams define:

- The exact process scope and boundaries

- Expected outcomes such as cycle-time reduction, error reduction, or backlog clearance

- Transaction volumes and peak-load scenarios

- Exception types that must be handled versus escalated

Clear success criteria at this stage prevent automation from drifting into low-value territory later.

Step 2: Discover and map real-world manufacturing workflows

Manufacturing processes often look standardized on paper but behave differently across plants, shifts, or regions. This step focuses on uncovering how work is actually executed.

Effective discovery includes:

- Observing workflows across systems and locations

- Identifying manual workarounds and informal corrections

- Mapping system dependencies and timing gaps

- Documenting exception paths and recovery steps

This insight becomes the foundation for stable automation.

Step 3: Design operational controls, visibility, and exception handling

RPA solutions do not require customer-facing interfaces, but they do require operational clarity. The development team must understand what the automation is doing, when it fails, and how to intervene.

Design considerations include:

- Run-status visibility and execution logs

- Structured exception queues with clear reason codes

- Human approval points where required

- Alerts and escalation paths tied to operational ownership

This step ensures automation integrates smoothly into day-to-day operations.

Step 4: Build resilient, production-grade automation

In manufacturing, automation must tolerate delays, partial failures, and inconsistent data without disrupting operations. RPA solutions should be engineered for resilience, not ideal conditions.

Best practices during build include:

- Modular bot design for easier maintenance

- Validation before any system write-back

- Retry logic and safe re-execution paths

- Secure credential handling with least-privilege access

This approach reduces post-deployment instability.

Step 5: Integrate securely with enterprise systems and compliance controls

RPA rarely operates in isolation. Bots must function within existing enterprise security, audit, and compliance frameworks.

This step typically involves:

- Integration with ERP, MES, WMS, PLM, and finance platforms

- Identity and access management for bot users

- Audit logging and traceability standards

- Data protection and regulatory alignment

Automation that cannot be governed or audited will not scale.

Step 6: Test rigorously under real manufacturing conditions

Testing must reflect operational reality, not demo scenarios. Manufacturing environments introduce variability that automation must handle predictably.

Robust testing covers:

- Exception-heavy scenarios and incomplete data

- High-volume and peak-load execution

- System latency and downtime handling

- Recovery behavior after mid-process failures

If failure behavior is unclear, the solution is not ready.

Step 7: Deploy, govern, and continuously optimize at scale

RPA software for manufacturing should be rolled out in controlled stages and treated as a long-term operational capability.

Ongoing practices include:

- Phased deployment across plants or functions

- Performance monitoring and exception analysis

- Governance for bot ownership and change management

- Continuous refinement based on operational data and ROI

This is how RPA evolves from isolated automation into a scalable enterprise capability.

Also Read: How to Develop a Manufacturing Production Scheduling Software

Validate your use cases, system readiness, and execution plan before committing to large-scale automation.

Future Outlook: How RPA in Manufacturing Is Likely to Evolve

In manufacturing, automation does not advance through bold leaps. It settles in, proves its value, and then quietly expands its role.

RPA is increasingly being treated as a permanent operational layer rather than a short-term efficiency tool. The focus is shifting from automating more tasks to automating the right ones, especially processes that must remain stable under volume spikes, supplier disruption, or regulatory pressure.

One noticeable trend is the tighter coupling of RPA with adjacent technologies. Optical character recognition is becoming standard for handling supplier documents and logistics paperwork. Analytics platforms are being layered in to monitor exceptions and performance patterns. In more mature environments, lightweight AI models in manufacturing are used to interpret inputs, while RPA continues to handle execution. This separation of judgment and action keeps automation controllable.

There is also more attention on governance than before. As automation spreads across plants and regions, manufacturers are tightening standards around bot ownership, monitoring, and change control. This is less about risk avoidance and more about keeping automation manageable.

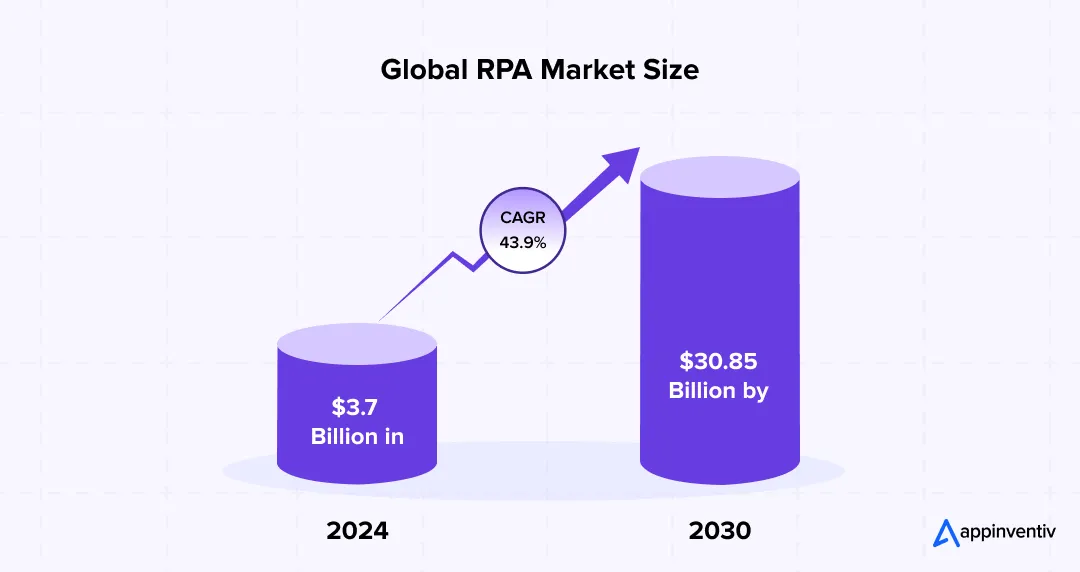

From a market perspective, this steady adoption is reflected in broader investment patterns. Grand View Research estimates the global robotic process automation market exceeded $3.7 billion in 2024 and is poised to reach $30.85 billion by 2030, with manufacturing and supply chain operations among the consistent contributors.

RPA is unlikely to replace core manufacturing systems. Its value lies elsewhere. It absorbs complexity, reduces coordination work, and gives organizations room to modernize without rushing.

In manufacturing, technology that does its job quietly tends to last.

Also Read: Machine Learning in Manufacturing: Use Cases & Real World Examples

How Manufacturing Enterprises Translate RPA Strategy Into Execution With Appinventiv

RPA in manufacturing rarely fails because of technology. It struggles when automation is designed in isolation from how plants, systems, and compliance requirements actually operate. Appinventiv’s role typically sits at that intersection between intent and execution.

Our approach to RPA is shaped by working in environments where downtime is costly, data integrity matters, and automation has to coexist with legacy systems rather than replace them overnight.

What manufacturing teams usually see when working with Appinventiv is a focus on building RPA as an operational capability, not a collection of bots.

That shows up in a few consistent ways:

- Compliance-first delivery

Manufacturing automation often touches financial records, supplier data, and operational systems. Appinventiv follows ISO-aligned practices and holds 10+ industry certifications, ensuring RPA solutions remain auditable, secure, and aligned with regulatory expectations from day one. - Engineering depth beyond bot development

RPA solutions are designed to integrate cleanly with ERP, MES, WMS, finance, and legacy platforms. This reduces fragility and avoids the “quick-win bots” that break as soon as systems change. - Built for scale, not just pilots

With 1600+ technologists and delivery teams operating across 5+ international offices and 6+ strategically positioned regional hubs, Appinventiv supports RPA programs that expand across plants, regions, and functions without losing governance or control. - Operational resilience as a design goal

Automation is built to handle exceptions, system latency, and real-world variability. This is reinforced by experience transforming 500+ legacy processes, where stability matters more than speed.

Performance and trust are reflected in long-term outcomes rather than short-term delivery metrics:

- 3000+ digital solutions designed and delivered across complex enterprise environments

- 95% client satisfaction rate and 90% repeat clientele, indicating sustained partnerships

- 100M+ app downloads achieved for clients globally, demonstrating the ability to operate at scale

- Recognition through the Deloitte Fast 50 India (2023 and 2024) and inclusion among APAC’s High-Growth Companies by Statista and the Financial Times

Appinventiv also brings experience working within regulated and public-sector environments, supported by 5+ strategic federal partnerships. This strengthens our ability to design RPA solutions that meet strict governance, reporting, and accountability standards.

Today, Appinventiv’s robotic process automation services support operations across 74+ countries, helping manufacturing organizations introduce automation that fits existing systems, respects operational realities, and evolves alongside broader digital transformation efforts in manufacturing.

For manufacturing leaders, this translates into RPA programs that scale quietly, remain compliant, and improve control without adding operational risk.

Contact us now and take your manufacturing business to the next level.

FAQs

Q. How long does it take to deploy RPA in a manufacturing process?

A. Timelines for RPA development for manufacturing vary based on scope, but in most manufacturing environments, deployment follows a predictable range:

- 6–10 weeks for well-defined, single-process automations with limited system touchpoints

- 3–6 months for cross-functional or multi-system RPA implementations that require deeper testing and governance.

Q. How does RPA improve production accuracy and quality control?

A. RPA improves accuracy by enforcing consistency across systems that support production and quality functions:

- Eliminates manual data re-entry between ERP, MES, and quality systems

- Ensures predefined validation rules are applied the same way every time

- Reduces delays that cause production decisions to rely on outdated data

The result is fewer discrepancies and more reliable quality reporting.

Q. How does RPA enhance efficiency across manufacturing processes?

A. RPA enhances efficiency by removing the coordination work that slows manufacturing operations. Bots handle repetitive actions such as data transfers, reconciliations, and status updates across systems. This shortens cycle times, reduces backlogs, and allows teams to focus on planning, exception handling, and continuous improvement rather than routine execution.

Q. How much does it cost to implement RPA in manufacturing?

A. The cost of implementing RPA in manufacturing typically falls between $40,000 and $600,000. Smaller automations involving a single workflow sit at the lower end, while enterprise-grade programs spanning multiple systems, plants, or regions require higher investment. Cost is driven more by process variability and integration depth than by the number of bots alone.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

RFID in Manufacturing: Transforming Inventory and Supply Chain Management

Key Takeaways RFID technology offers real-time tracking of materials and goods, allowing manufacturers to optimize operations, identify bottlenecks, and improve workflow efficiency. RFID's real-time data empowers manufacturers to quickly adapt to demand fluctuations, shipment delays, and other disruptions, fostering quicker decision-making and better partner/customer relationships. Real-world examples like Southeastern Container and Club Car demonstrate how…

10 Use Cases, Benefits, and Examples of How Cobots are Transforming the Manufacturing Industry

Key takeaways: Cobots work next to human workers, taking care of repetitive jobs like welding and assembly, boosting efficiency and reducing physical strain. This teamwork is changing traditional manufacturing. The cobot market is expected to hit $11.64 billion by 2030, showing the growing move toward automation and the increasing need for flexible, collaborative robots. Companies…