- Key Components of Managed IT Services in Manufacturing

- Benefits of Managed IT Services in Manufacturing

- Managed IT Services for Manufacturing Use Cases

- Network Management and Security

- End User Support

- Predictive Maintenance

- The Supply Chain Optimization

- Improvement of Quality Control

- Energy Management

- Data Analytics To Make Better Decisions

- Remote Monitoring and Management

- Cybersecurity Measures

- Business Continuity and Disaster Recovery

- Real World Examples of How Managed IT Services Help Manufacturers

- Example 1: Colonna’s Shipyard

- Example 2: Consumer Products Company

- Steps to Successfully Implement and Integrate Managed IT Services in Manufacturing

- Challenges of Managed IT Services in the Manufacturing Industry

- Trends Shaping the Role of IT Services in Smart Manufacturing

- How Does Appinventiv Come Into the Picture?

- FAQs

Key takeaways:

- The IT services provided can maximize production process efficiency through proactive monitoring, reduced downtime, and faster operations.

- Latent cybersecurity safeguards correspond to the intellectual assets and intelligence within the business relating to business continuity in a virtual reality.

- With fixed-price models, unforeseen IT costs are eliminated, allowing for the consolidation of resources and more accurate budgeting.

- Managed IT services provide flexibility and scalability to infrastructure, allowing it to adapt as the business and market evolve.

- IoT, AI, and cloud computing are being integrated to introduce innovation into the sector, enabling predictive maintenance and making numerous real-time decisions.

In the manufacturing sector, change is constant. From evolving consumer demands to global supply chain shifts, manufacturers are continually under pressure to innovate and optimize their operations.

However, while production lines are modernizing, many manufacturers continue to struggle with one critical component: their technology infrastructure. This often results in inefficiencies, increased downtime, and vulnerability to cyber threats: issues that can significantly hinder progress in an increasingly digital world.

Imagine a factory floor where machines are constantly connected, data flows freely across systems, and operations run smoothly with minimal disruptions. For many manufacturers, this vision is not a distant dream but a reality made possible by managed IT services tailored to the manufacturing industry. The role of these services has grown far beyond basic tech support – they are now at the heart of digital transformation in manufacturing, offering specialized expertise and proactive solutions that keep businesses running at full capacity.

As manufacturers continue to embrace new technologies, such as IoT, AI, and automation, the need for reliable, secure, and efficient IT management becomes more pressing. But whether it’s optimizing operational efficiency, improving security, or ensuring compliance, managed services in manufacturing are becoming indispensable in helping companies thrive in the digital age.

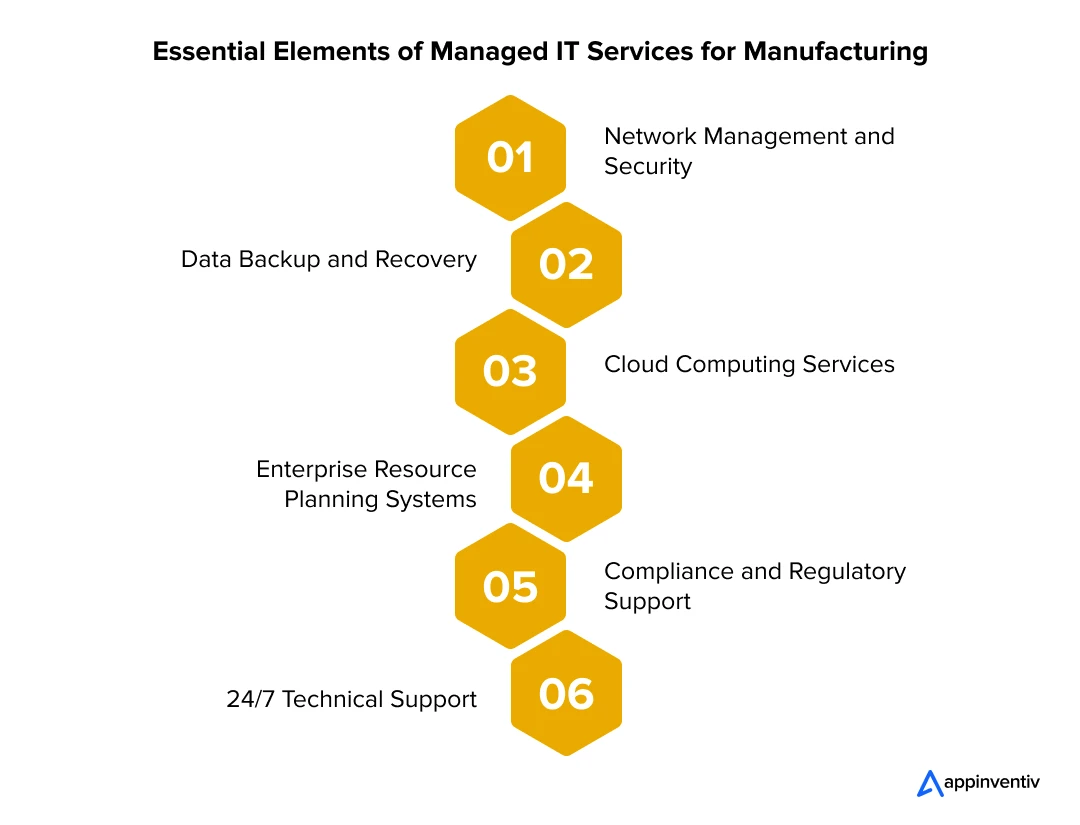

Key Components of Managed IT Services in Manufacturing

Managed IT services play a crucial role in ensuring that manufacturing operations run efficiently, securely, and without disruption. These services encompass several key components that address the specific needs of manufacturers, from maintaining network security to optimizing productivity with cloud-based solutions.

- Network Management and Security: Design and management of secure, high-performance networks to prevent cyber threats and system disruptions.

- Data Backup and Recovery: Regular backups and recovery plans to minimize downtime and safeguard data.

- Cloud Computing Services: Scalable resources and real-time tools to enhance collaboration and operational flexibility.

- Enterprise Resource Planning Systems: Integration of various business processes, optimization of inventory, production, and financial management through manufacturing ERP software development.

- Compliance and Regulatory Support: Assistance with maintaining adherence to industry regulations and standards.

- 24/7 Technical Support: Continuous support to resolve IT issues and ensure minimal operational disruptions.

- Cybersecurity System: Adopting strong policies to guard against cyber attacks, which plays an important role in securing intellectual property and production information.

- IT and Operational Technology (OT): Harmonizing IT systems with the manufacturing systems, where it is possible to see IoT devices and robotics become more integrated with production.

- Supply Chain Management and Visibility: Leveraging analytics and IoT for Supply chain transparency and efficiency.

- Know-How with Technologies of Industry 4.0: Using the innovative technologies of the IoT, AI, big data analytics, and machine learning to become creative.

By implementing key IT components such as network management, cloud solutions, and robust cybersecurity in manufacturing operations, manufacturers can create a strong foundation for success. These critical elements of managed services in manufacturing not only secure and streamline day-to-day activities but also unlock a range of significant benefits. The benefits we are going to discuss in detail next.

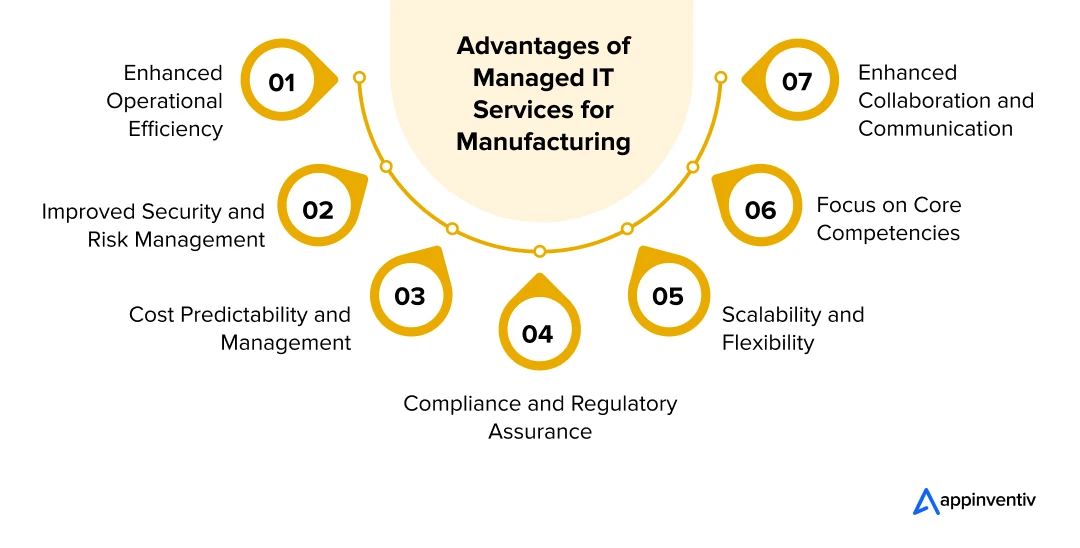

Benefits of Managed IT Services in Manufacturing

Adopting managed services for the manufacturing industry offers substantial benefits that extend beyond simply securing and maintaining systems. These services enable manufacturers to streamline operations, reduce costs, and boost productivity, all while maintaining a focus on their core business objectives.

The integration of MSPs enables manufacturers to leverage cutting-edge technology, maintain compliance, and safeguard their assets in a competitive market.

- Enhanced Operational Efficiency: Managed IT services for manufacturing firms provide proactive monitoring, ensuring systems are running optimally and identifying potential issues before they disrupt production. This reduces downtime and enhances the overall performance of the manufacturing process.

- Improved Security and Risk Management: With the increasing threat of cyberattacks, MSP manufacturing implements robust security measures, such as malware detection, encryption, and continuous monitoring. These safeguards protect sensitive data and intellectual property, ensuring business continuity.

- Cost Predictability and Management: By offering fixed pricing models, the benefits of IT managed services for manufacturing revolve around better prediction of IT costs and elimination of unexpected expenses. This cost-effective approach also optimizes resource allocation, ensuring the business stays within budget while receiving the necessary technological support.

- Compliance and Regulatory Assurance: With stricter regulations, manufacturers need to stay compliant with industry standards. MSPs ensure adherence to necessary regulations, preventing costly fines and ensuring that processes are continuously monitored and audited for compliance.

- Scalability and Flexibility: Another advantage of managed services in the manufacturing industry is in MSPs being able to provide scalable IT solutions that adapt to a manufacturer’s evolving needs. As businesses grow, these services can expand seamlessly, ensuring that infrastructure and technology keep pace with production demands.

- Focus on Core Competencies: By offloading IT management to MSPs, manufacturers can focus on their core competencies, such as production and innovation. This allows them to stay competitive while ensuring IT systems are optimized and secure.

- High Availability and Downtime Reduction: Downtime is expensive, as manufacturers incur as many as 800 hours of equipment downtime per year, at a cost to the industry of billions. Through proactive monitoring, IT Managed Service Providers address this challenge by implementing measures to ensure high availability and remain operational without significant interruption.

- Enhanced Collaboration and Communication: IT Managed services in manufacturing offer cloud-based collaboration tools that improve communication within teams and across departments. This ensures that all stakeholders have access to real-time data, facilitating faster decision-making and reducing inefficiencies.

If there is one thing these advantages of managed services in the manufacturing industry makes evident, it is the fact that incorporating MSPs into the manufacturing space not only provides security and efficiency but also enables long-term growth and sustainability in a rapidly evolving industry.

But in order to truly gauge the benefits of IT managed services for manufacturing, it is critical that we look into applications of the technology in the process-intensive domain.

Let’s look into that next.

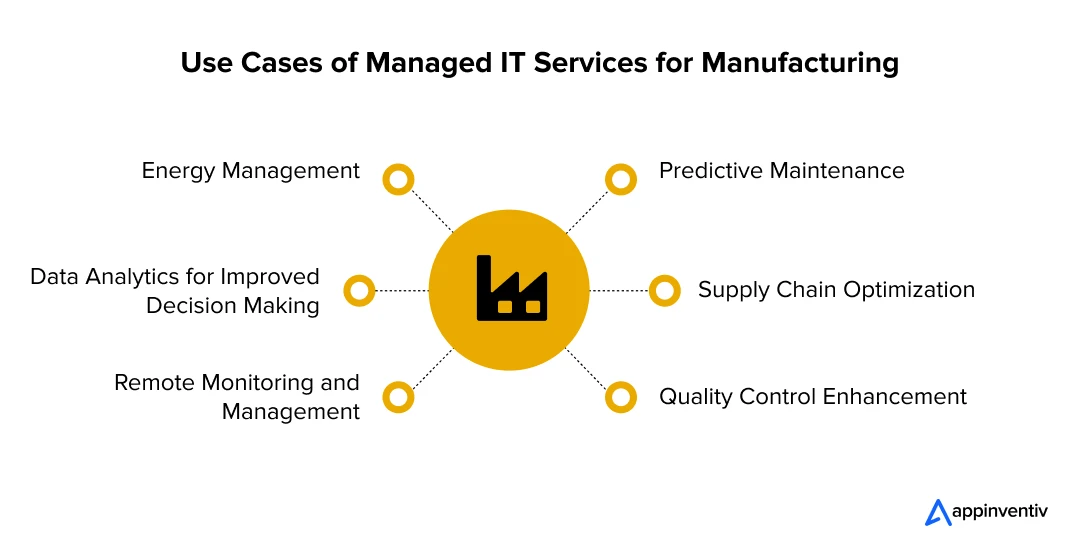

Managed IT Services for Manufacturing Use Cases

Managed IT services are transforming the manufacturing sector by supporting businesses in adopting smart manufacturing technologies while optimizing operations for efficiency and cost savings. These services provide the infrastructure, security, and support necessary for integrating advanced technologies like the IoT, artificial intelligence, and big data analytics into manufacturing operations. By harnessing these technologies, manufacturers can streamline processes, enhance automation, and make informed, data-driven decisions to stay ahead of the competition.

Network Management and Security

The availability of high-performance network infrastructure to support the manufacturing process, the prevention of threats against the computer networks, and the ensured connection of critical networks.

Managed IT services utilize sophisticated network-monitoring software to track performance, identify anomalies, and optimize bandwidth utilization. To protect data, they will apply techniques such as firewalls, intrusion detection systems, and encryption. This further reduces vulnerabilities and ensures swift action against threats, keeping production applications online.

End User Support

Managed IT services provide helpdesks that address services such as software bugs, hardware breakdowns, or network connection issues. They offer both on-site and off-site support, ensuring the problem is solved in the shortest possible time. Employees are empowered to resolve minor issues through training programs and user-friendly ticketing systems, enabling them to handle problems efficiently.

Predictive Maintenance

It involves a data-driven prediction that can anticipate equipment failure before it occurs, etc. Managed IT services combine IoT device sensors and AI analytics to perform real-time equipment monitoring. Machine data is used to forecast potential failures and perform preventive maintenance on machines in advance, enabling proactive maintenance. This reduces mistaken halt and makes equipment last longer, consequently, maximizing production efficiency.

The Supply Chain Optimization

Harmonization of the supply chain procedures to enhance efficiencies and effectiveness, cut down on costs, and ensure the critical delivery of goods and products.

Managed IT services develop manufacturing ERP software that tracks inventory, demand, and logistics. Supply chain performance can be assessed through real-time data analytics, which enhances forecasts and optimizes resources. Automation tools minimize manual errors, ensuring just-in-time delivery and cost reduction.

Improvement of Quality Control

To sustain themselves in this competitive market, manufacturers must consistently maintain high-quality products. Therefore, it is essential to improve product quality continually. This is made possible through continuous real-time monitoring and analysis.

Managed IT services incorporate automated quality control mechanisms to monitor real-time quality in products using machine learning algorithms. The patterns used in data analytics can lead to quality issues, which can be addressed through process improvements. It is also integrated with manufacturing execution systems (MES) to ensure compliance with standards, thereby minimizing waste and rework.

Energy Management

Estimating energy use within production sites is a crucial step in reducing operational expenses and promoting sustainability objectives. However, your IT managed partner helps you achieve this sustainability by installing smart energy monitoring systems, which enable the monitoring of consumption across equipment and facilities.

Using data analytics, inefficiencies can be identified and adjustments made, such as balancing loads or optimizing equipment scheduling to improve efficiency. Its connection to IoT devices enables the implementation of automated energy-saving interventions to reduce costs and mitigate environmental pollution.

Data Analytics To Make Better Decisions

The success of the manufacturing firm lies in how it leverages data and transforms it into actionable insights that facilitate data-driven strategic and operational decisions. The managed IT service partner you choose will make this easy by deploying advanced analytics platforms and big data for manufacturing to gather and process all data associated with production, supply chain, and sales.

These platforms feature intuitive dashboards that provide access to real-time data, enabling informed decisions regarding production planning, resource allocation, and marketing strategies.

Remote Monitoring and Management

Monitoring manufacturing systems and machines to maintain effective operation, and doing so remotely, can sometimes be a tough challenge. However, thanks to managed IT services, you have access to remote monitoring tools that enable you to manage system performance, track equipment status, and maintain network health.

The automated alerts automatically inform technicians of problems detected through remote diagnostics and provide fixes. This minimizes the need for on-site interventions, allowing production to continue uninterrupted and reducing downtime.

Cybersecurity Measures

The digital landscape has evolved significantly, not only in terms of innovations but also in terms of high-risk vulnerabilities, such as cyberattacks. Therefore, you require a reliable system to prevent these attacks and devise effective cybersecurity measures and mitigations for cyber attacks or any kind of industrial espionage.

Here, managed IT services enter the scene by deploying multi-layered cybersecurity solutions, including endpoint protection, network segmentation, and threat intelligence. Vulnerabilities are mitigated through regular security audits and ongoing training for employees.

Business Continuity and Disaster Recovery

Manufacturers should ensure that their manufacturing processes can be restarted quickly in the event of certain breakdowns, such as system failures, hacking attacks, or natural disasters. However, to achieve this, your managed IT partner will develop and maintain disaster recovery plans, which include frequent data backups to protect them in a cloud or non-local area.

They are implementing redundant and failover systems. Frequent recovery testing and the implementation of changes to strategies help reduce downtime and ensure adherence to industry regulations.

By integrating managed IT services tailored to manufacturing use cases, manufacturers can fully realize their potential, improving operational efficiency, reducing costs, enhancing product quality, and driving growth in an increasingly competitive market.

Real World Examples of How Managed IT Services Help Manufacturers

Managed IT services are considered as an essential tool for enhancing efficiency of operations, security, and sustaining competitive position in manufacturing companies. Managed Service Providers for manufacturing make manufacturers capable of tackling sophisticated issues about network stability, cybersecurity risks, and technological integration.

The subsequent real-life examples show how real problems of different manufacturers in a variety of industries are addressed with the help of managed IT services, providing such concrete advantages as increase in efficiency and decrease in downtimes, and financial savings.

Example 1: Colonna’s Shipyard

Challenge:

The problem faced by Colonna is that the Shipyard has expanded. Still, its IT infrastructure was not robust enough to sustain the expansion and meet the needs of modern manufacturing. The firm had to update its systems to be more efficient and reliable.

Managed IT Services in Action:

The existence of the systems, processes, and resources that the company currently uses were evaluated by the MSP, and the future-ready technologies have been implemented to help establish a resilient IT system that focuses on automation, security, privacy, and reliability. This also included the upstreaming of the network, cyber security practices and the use of automation tools to improve the operations insecurity and efficiency.

Result:

This digital transformation enabled Colonna Shipyard to update its IT solutions, making operations more efficient and supporting its growing business through enhanced infrastructure.

Example 2: Consumer Products Company

Challenge:

A large consumer products firm was facing challenges in communication, program management, and the need to automate repetitive tasks, as well as modernize 60 old on-premises applications.

What Managed IT Service Can Do:

- A 24/7 Global Support: 30 people covering Mexico, Spain, and India were involved in level 2/3 incidents and few enhancements.

- Automation Roadmap: It is designed to eliminate manual work, thereby enhancing efficiency.

- DevOps Governance: Adopted the Devops practices and educated the most important professionals about the principles of agility.

- Application Modernization: Moving 60 of the applications into the cloud, consolidation of instances, and a small team of developers was used so that the transition was faster.

- Maturity Model: Developed a managed IT support services maturity model that could be used to benchmark and quantify improvement for business objectives.

Result:

Managed IT services changed the IT picture of the company, which brought on to it more productivity, less expenses, and better services. The entire team was able to complete 40% more work with an equal number of employees compared to the former vendor and solved 4,000 support tickets every year.

As we’ve explored, the implementation of managed IT services offers tangible advantages in various use cases and real world examples. To realize these, however, manufacturers must take careful steps to integrate managed IT services into their operations. By following a structured approach, manufacturers can fully leverage the potential of managed IT services to drive innovation and operational efficiency.

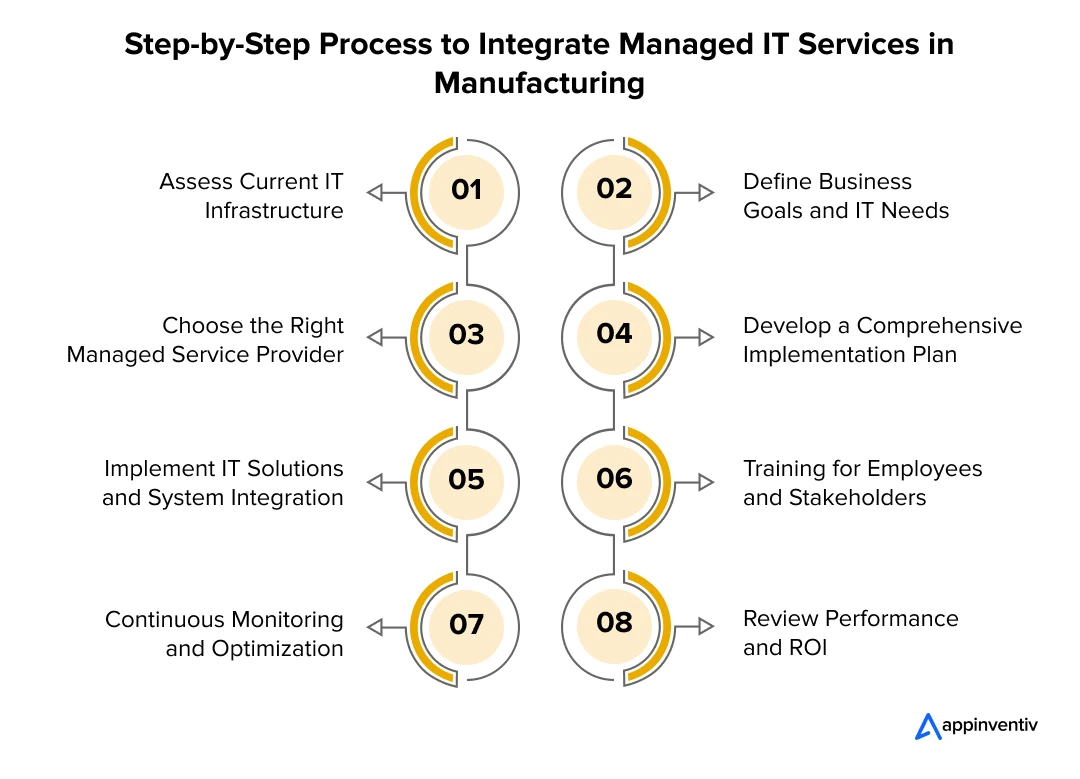

Steps to Successfully Implement and Integrate Managed IT Services in Manufacturing

Implementing manufacturing managed services is a strategic decision that can greatly improve efficiency, security, and cost-effectiveness. However, the process requires careful planning and execution to ensure a seamless transition and optimal outcomes. By following a structured approach, manufacturers can maximize the benefits of their MSP partnership and position their business for long-term success.

Below is a detailed breakdown of the steps involved in successfully integrating MSP into a manufacturing operation.

Assess Current IT Infrastructure

The first step in implementing IT managed services for a manufacturing firm is to evaluate your existing IT infrastructure. This involves a thorough audit of current hardware, software, network systems, and overall data management practices. By understanding where inefficiencies or security risks lie, manufacturers can identify what’s working well and what needs improvement. This assessment provides the foundation for the services the MSP will need to provide.

Define Business Goals and IT Needs

With a clear understanding of your existing systems, the next step is to define your business objectives and the role MSP manufacturing services will play in achieving them. Whether your goal is to improve operational efficiency, reduce downtime, enhance supply chain management, or integrate smart manufacturing technologies, aligning your IT strategy for business goals ensures the implementation will deliver meaningful results.

Choose the Right Managed Service Provider

Selecting the right managed services for the manufacturing industry is pivotal to the success of your implementation. Look for a provider with a proven track record in manufacturing, along with expertise in the technologies and systems that your business relies on. The chosen MSP should offer scalable solutions that can grow with your business and should be committed to ensuring that security, compliance, and support are top priorities.

Develop a Comprehensive Implementation Plan

Once an MSP is selected, the next step is to develop a detailed implementation plan. This plan should outline specific goals, timelines, and milestones to ensure a smooth integration process. It must also address key aspects such as system integration, data migration, and the deployment of new technologies, while accounting for potential disruptions. A well-structured plan would help keep the project on track and ensure that resources are efficiently utilized.

Implement IT Solutions and System Integration

The implementation phase begins once the plan is in place. Here, the MSP will work to deploy the necessary hardware and software, integrate new systems with existing infrastructure, and ensure all security measures are met. This process can be complex, but having an experienced team that excels in managed enterprise IT services for manufacturing firms would ensure that the transition occurs with minimal disruption to daily operations. It’s also important to note that the integration of new technologies must be done in phases to allow for smooth adaptation.

Training for Employees and Stakeholders

Once the systems are in place, training becomes essential to ensure that employees are equipped to effectively use the new technology, moreover a booklet maker can help streamline the training materials. The training module should cover everything from basic functionality to advanced features, ensuring that everyone involved is confident in navigating the new systems. With proper guidelines in place, employees will be able to quickly adapt, reducing the learning curve and optimizing productivity from day one.

Continuous Monitoring and Optimization

Following the successful implementation of managed IT services for your manufacturing company, continuous monitoring is critical to identify and address any emerging issues. Your managed IT services provider can be expected to regularly assess system performance, ensure security protocols are maintained, and identify areas for optimization.

Review Performance and ROI

Lastly, regularly reviewing the performance of the managed IT services is crucial to determine if the goals of the integration are being met. This includes evaluating key performance indicators such as system uptime, cost savings, productivity gains, and process efficiency. By assessing the return on investment, manufacturers will be able to gauge the effectiveness of the efforts and make necessary adjustments to enhance the benefits of IT managed services for manufacturing.

By following these strategic steps, manufacturers can successfully implement managed IT services for manufacturing that not only meet immediate operational needs but also provide long-term benefits such as reduced costs, improved productivity, and enhanced business agility.

While the steps to integrate IT managed services for manufacturing a firm lay a strong foundation for success, the journey is not always straightforward. At Appinventiv, we recognize that even the best-laid plans can encounter unforeseen obstacles. As manufacturers move through the integration process, there are often roadblocks that can delay progress or complicate implementation. In the next section, we will explore some of these common challenges and how they can be effectively addressed to ensure a smooth transition to an optimized IT environment.

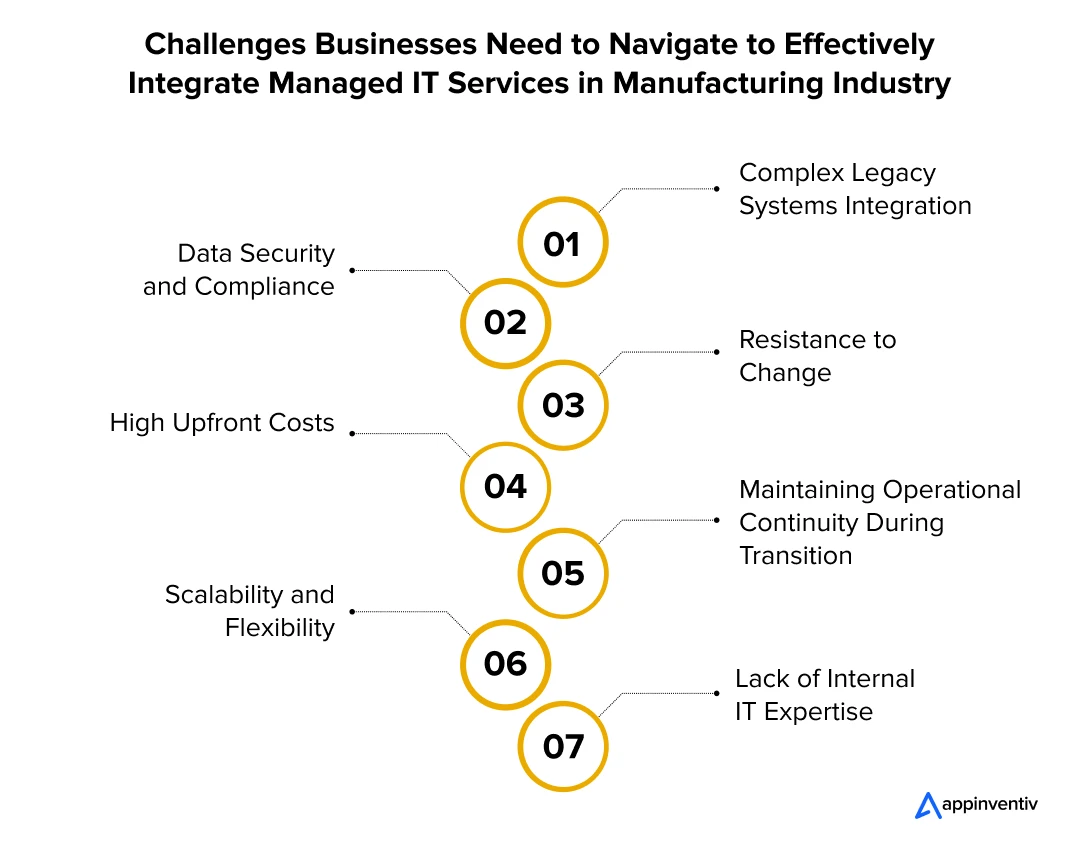

Challenges of Managed IT Services in the Manufacturing Industry

As a managed IT service provider for the manufacturing industry, we are acutely aware of the unique challenges that come with implementing and maintaining IT solutions in this sector. While manufacturing IT services bring significant benefits, navigating the complexities of this domain requires careful planning and consideration. Below, we highlight some of the most common challenges we face and how we address them to ensure smooth IT operations for our clients.

Complex Legacy Systems Integration

One of the key hurdles we encounter is integrating managed IT services with legacy systems. Many manufacturers still rely on outdated hardware and software that were not designed to work with modern technologies. This creates a significant challenge when implementing new IT solutions, as these older systems often need extensive modifications to ensure compatibility with newer platforms.

Instead of a complete overhaul, we focus on assessing existing infrastructure and finding integration points between old and new systems. By making gradual updates, we ensure continued functionality while introducing new technologies, minimizing disruption and reducing the cost of full system replacements.

Data Security and Compliance

In manufacturing, sensitive data such as production schedules, inventory records, and proprietary designs must be handled with the utmost care. With an increase in cyber threats targeting the sector, maintaining data security is more critical than ever. Coupled with this is the constant need to comply with industry regulations regarding data privacy, safety, and quality standards.

As a trusted provider for managed IT services in manufacturing, we work diligently to safeguard our clients’ data by monitoring their systems for vulnerabilities and ensuring that compliance protocols are met, which can sometimes require intricate adjustments to existing security systems.

Resistance to Change

Adopting new technologies in the manufacturing sector often meets with some level of resistance. Employees may be used to already established processes, and changing those workflows can cause apprehension or reluctance. Overcoming this resistance involves clear communication and comprehensive training. We ensure that staff are fully aware of the long-term advantages of new IT systems, helping them understand how these tools will make their jobs easier and more efficient. This transition is key to ensuring that manufacturers reap the full benefits of their manufacturing managed services.

High Upfront Costs

Though IT managed services in manufacturing lead to significant cost savings over time, the initial financial investment can be a barrier for some manufacturers. The costs associated with upgrading infrastructure, training employees, and implementing new systems can be daunting.

To address this, we work closely with clients to develop solutions tailored to their budget, offering scalable options that grow with the business. This helps mitigate the financial strain of the initial investment, ensuring that manufacturers can enjoy the long-term benefits without overwhelming their resources.

Maintaining Operational Continuity During Transition

The implementation of new IT systems often requires downtime, which can disrupt production and lead to operational inefficiencies. To prevent this, we ensure a phased approach to deployment, allowing us to upgrade and integrate systems gradually, with careful attention to maintaining business continuity. Our aim is to minimize disruptions to daily operations, enabling manufacturers to experience the advantages of modern IT without compromising productivity.

Scalability and Flexibility

Another challenge is ensuring that IT solutions are scalable and flexible enough to grow with the business. Manufacturers must be able to adapt quickly to market changes and technological advancements. To address this, we design IT systems that not only meet current operational needs but are also built to scale as the business evolves.

By implementing adaptable managed services for the manufacturing industry, we ensure that companies can continue to expand and integrate new technologies without facing significant infrastructure limitations.

Lack of Internal IT Expertise

For many manufacturers, there’s often a gap in the expertise required to manage advanced IT systems. While some may have an in-house IT team, they may lack the specialized knowledge needed for cutting-edge technologies or security best practices.

As an MSP, we fill this gap by offering expert support, training, and resources to help manufacturers operate their IT systems effectively. Our goal is to empower manufacturers to leverage technology to its fullest potential, even if they don’t have a dedicated IT department.

Despite these challenges of managed IT services in the manufacturing industry, our experience with clients has allowed us to develop tailored solutions that address these pain points. By proactively identifying and addressing these issues, we help manufacturers unlock the full potential of managed IT services, driving efficiency, cost savings, and long-term success in a rapidly evolving industry. Wish to witness our MSP manufacturing efforts first-hand? Let’s talk.

While navigating the challenges of implementing managed IT services for manufacturing firms can seem daunting, it also opens the door to new opportunities. As manufacturers adapt to these obstacles, they are increasingly looking toward emerging trends to drive innovation and efficiency.

In the next section, we will dive into the key trends shaping the future of IT services in manufacturing, highlighting how these trends can help businesses stay ahead of the curve and transform challenges into long-term advantages.

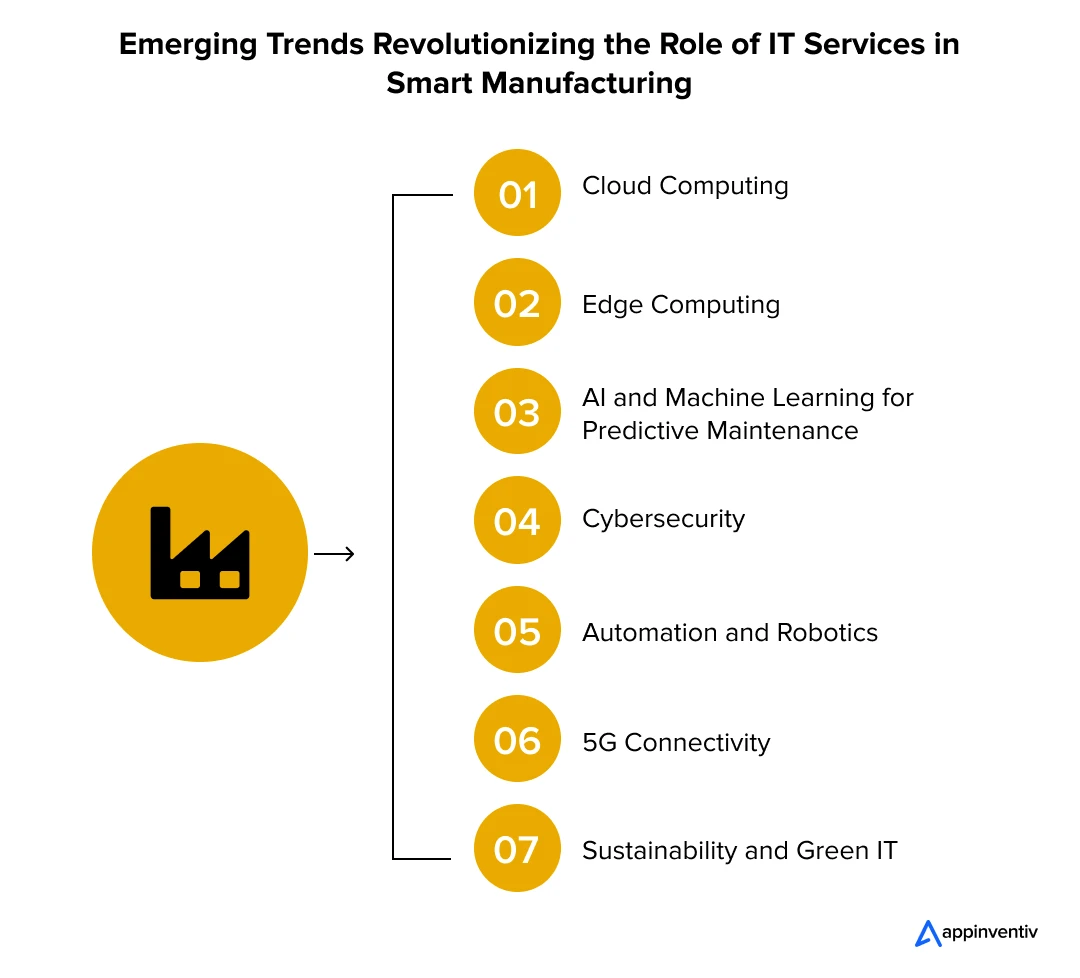

Trends Shaping the Role of IT Services in Smart Manufacturing

It is unquestionable that the manufacturing industry will continue its significant transformation, driven by technological advancements that will enhance efficiency, agility, and innovation. As producers increasingly rely on managed IT services, several key trends will shape the future of the sector, helping businesses stay competitive while optimizing their operations.

- Cloud Computing

Manufacturers will increasingly adopt cloud-based platforms for storing and accessing data. This will offer scalability, cost-efficiency, and real-time data accessibility, simplifying operations by reducing the need for complex on-site infrastructure and enabling manufacturers to streamline their processes.

Also Read: Cloud Manufacturing Software Development – Benefits, Process, Costs - Edge Computing

As IoT devices proliferate, edge computing will become crucial for manufacturers to process data closer to the source. This will reduce latency, enabling faster decision-making and optimizing production lines. Real-time data processing will also become more efficient, ensuring smooth operations across the board. - AI and Machine Learning for Predictive Maintenance

AI in manufacturing will be increasingly used to predict equipment failures before they occur. This proactive approach will reduce unplanned downtime, extend machinery lifespan, and lower maintenance costs, ultimately driving productivity and operational efficiency. - Cybersecurity

As the industry becomes more interconnected, the demand for robust cybersecurity solutions will grow. Manufacturers will implement advanced security measures, including encryption, multi-factor authentication, and AI-based threat detection, to protect critical infrastructure and sensitive data from rising cyber threats. - Automation and Robotics

IT services will enable the integration of automation tools and robotics, allowing manufacturers to streamline their production processes, reduce human error, and improve worker safety. These technologies will not only reduce costs but will also enhance operational efficiency and consistency. - 5G Connectivity

The rollout of 5G networks will revolutionize manufacturing by providing ultra-fast, low-latency connectivity. This will enable real-time communication between machines, devices, and systems, supporting IoT growth and enhancing the efficiency of data collection and analysis on production lines. - Sustainability and Green IT

Manufacturers will focus more on reducing their environmental impact by adopting energy-efficient solutions and sustainable technologies. Managed IT services will help businesses achieve greener operations, from eco-friendly data centers to sustainable supply chain management, supporting both operational goals and corporate social responsibility.

Implementing manufacturing managed services is essential for businesses aiming to stay competitive in today’s tech-driven landscape. While there are challenges during integration, the long-term benefits and growth opportunities far exceed the potential risks of staying behind. By focusing on key IT components and keeping up with industry trends, manufacturers can enhance efficiency, security, and innovation.

How Does Appinventiv Come Into the Picture?

We hope this guide has provided a clear view of how crucial managed IT services are in the manufacturing industry. These services are not just about keeping up with technological trends but in fact, they are about fundamentally transforming operations to enhance efficiency and security.

For manufacturing businesses looking to implement these changes, it’s important to choose a partner who understands the unique challenges of the industry. As a leading manufacturing IT services provider, we understand the evolving demands of the manufacturing industry and specialize in crafting tailored managed IT services to meet these challenges. Our expertise lies in designing scalable, secure, and efficient IT infrastructures that streamline operations and enhance productivity.

We take a hands-on approach to integrating advanced technologies like IoT and cloud computing while modernizing legacy systems to ensure seamless compatibility. Being a dedicated Managed IT services firm, we focus on proactive IT management, we help manufacturers minimize downtime, optimize costs, and maintain a competitive edge in the rapidly transforming landscape of smart manufacturing.

From predictive maintenance solutions to enabling smart factory capabilities and securing critical data, our goal is to empower manufacturing businesses with IT services that are not only robust but future-ready.

If you’re ready to optimize your manufacturing operations with managed IT services, get in touch with us. Let’s collaborate to build a secure, efficient, and future-ready IT infrastructure for your business.

FAQs

Q. How do managed IT services improve manufacturing efficiency?

A. Managed IT services streamline manufacturing processes by integrating advanced technologies like IoT, cloud computing, and automation tools. They optimize workflow management, reduce system downtime through proactive monitoring, and enhance communication across teams with reliable IT infrastructure.

Additionally, MSPs provide data-driven insights, enabling manufacturers to make smarter decisions, improve production schedules, and address inefficiencies in real time.

Q. Exactly what services do managed service providers provide?

A. Managed service providers offer a wide range of services tailored to meet manufacturing needs, including:

- Network Management: Monitoring and maintaining IT networks to ensure reliability and security.

- Cybersecurity Solutions: Protecting systems from threats with firewalls, encryption, and regular vulnerability assessments.

- Cloud Services: Providing scalable storage, backup solutions, and cloud-based applications.

- IT Support: Offering 24/7 technical assistance and troubleshooting.

- Data Analytics: Delivering insights to improve production efficiency and reduce waste.

- Compliance Management: Ensuring IT systems meet industry standards and regulations.

- IoT Integration: Connecting devices and equipment for real-time monitoring and automation.

Q. How can you achieve cost savings with IT services in manufacturing?

A. Cost savings are achieved through optimized operations, minimized downtime, and better resource management. Managed IT services enhance equipment efficiency by enabling predictive maintenance, reducing the likelihood of costly breakdowns. They also automate routine tasks, lowering manual labor costs.

By utilizing cloud solutions, manufacturers can cut expenses on physical servers and maintenance. Additionally, MSPs implement robust cybersecurity measures, reducing the financial risks associated with data breaches or system disruptions.

Q. How are managed IT services transforming the manufacturing sector?

A. Managed IT services make operations easier, provide better cybersecurity and lead to real-time data analytics, which increases manufacturing efficiency, minimizes downtime, and enhances scalability.

Q. How do managed IT services support digital transformation in manufacturing?

A. Their offerings in cloud-based solutions, IoT, and automation tools allow them to create smart factories, enhance decision-making on the basis of data, and achieve effortless connectivity by linking the systems of production.

Q. How can managed services help manufacturers achieve Industry 4.0 goals?

A. Industry 4.0 can be facilitated through managed services by the use of artificial intelligence (AI), machine learning, and predictive maintenance, supply chain optimization, and interrelated, smart manufacturing environments.

Q. How do leading manufacturers choose their managed IT partners?

A. They choose their IT partners by focusing on their specialties in the industry, track records, well-developed cybersecurity strategies and measurements, and discordance with their strategic goals in digital transformation and Industry 4.0.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Why Choose Managed IT Services in Dubai - Benefits, Cost, & ROI

Key Takeaways Managed IT services in Dubai replace reactive support with structured, SLA-driven IT operations, improving uptime, response times, and governance. The cost benefit of managed IT services is clearer when measured through TCO, helping reduce IT operational costs in the UAE without adding long-term staffing risk. Compliance-ready services in the UAE are essential, as…

Capital Structuring and Tech Investments: What Enterprises Must Consider in 2026?

Key takeaways: Strategic capital structuring is essential to fund innovation without sacrificing financial stability. Each tech investment, like AI, cloud, cybersecurity, and sustainability, requires a tailored financing approach. Misalignment between capital structure and tech strategy can stall growth or strain margins. Hybrid and structured financing models help enterprises balance risk, control, and agility in 2026.…

Why Appinventiv Stands Out as the Leading Tech Consulting Provider for Digital-First Enterprises

Key takeaways: Appinventiv operates as a strategic partner, not just a service provider, focusing on business outcomes and ROI before technology. Success stories with global brands like KFC, IKEA, Adidas, etc., prove we tackle complex, enterprise-grade projects and deliver real results. Our capabilities span from AI-powered product building and cloud upgrades to custom software creation,…