- A Quick Overview of the Role of 3D Printing in Healthcare

- Types of 3D Printing Technologies Used in Healthcare

- Key Steps of Putting Medical 3D Printing into Practice

- Medical 3D Printing Use Cases Transforming the Industry

- Patient-Specific Implants & Prosthetics

- Surgical Planning & Anatomical Models

- Bioprinting & Regenerative Medicine

- Personalized Pharmaceuticals

- Medical Devices & Surgical Instruments

- Real World Examples of Healthcare Organizations Leveraging 3D Printing

- Rady Children

- Mayo Clinic

- Anatomiz3D

- Johns Hopkins

- Game-Changing Benefits of 3D Printing in Healthcare

- Enhanced Personalization and Precision

- Reduced Costs & Faster Prototyping

- Improved Accessibility in Remote or Underserved Areas

- Sustainability Through Reduced Waste

- Faster Innovation Cycles and Agility in Product Development

- Challenges in Medical 3D Printing Implementation & Strategies to Overcome Them

- Regulatory Hurdles & Quality Assurance

- Data Security & Privacy Concerns

- Scalability & Integration

- Future Trends and Technologies to Watch in 2025 and Beyond

- Artificial Intelligence and Machine Learning

- Extended Reality (XR) in 3D Planning

- Sustainable 3D Printing

- 3D Planning and Printing Expansion

- How Appinventiv Can Help You Leverage 3D Printing in Healthcare

- FAQs

- 3D printing enables the rapid production of personalized medical implants and models, thereby improving patient outcomes and recovery.

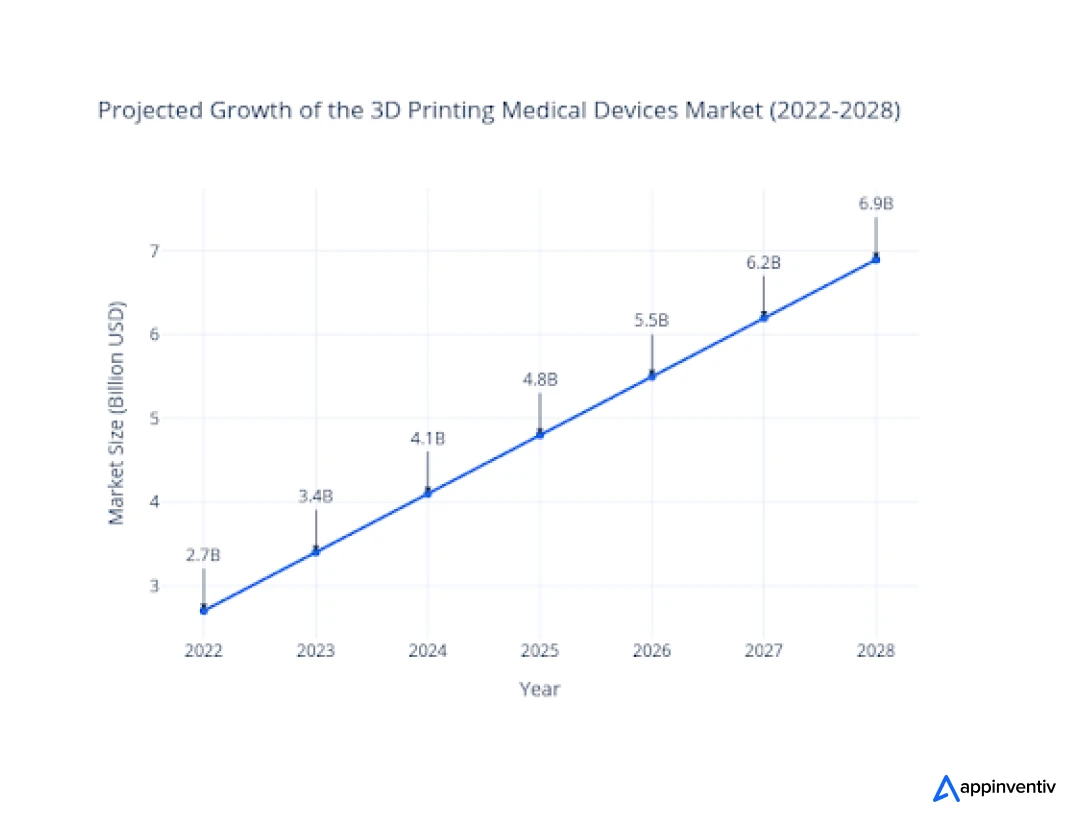

- The medical 3D printing market is experiencing rapid growth, with an expected value of $6 billion by 2028.

- Major applications of 3D printing in healthcare include orthopedics, surgical planning, regenerative medicine, and the production of custom pharmaceuticals.

- Custom 3D printing software development costs vary widely, typically ranging from $40,000 to $ 400,000 or more, depending on the complexity.

When a woman in her 50s became the world’s first recipient of a 3D-printed windpipe transplant at Seoul St Mary’s Hospital in 2023, it marked more than just a medical milestone. It signaled the dawn of a new era in healthcare.

The conventional approach and treatment would have taken months to deliver a perfect windpipe transplant suited to the patient’s anatomy. However, with 3D printing in healthcare, this could be achieved in days, thereby enhancing outcomes and reducing recovery times. This is indeed a revolutionary approach that’s reshaping everything from surgical planning to organ transplantation.

This is the reason that the global medical 3D printing market, valued at $2.7 billion in 2022, is expected to reach $6.09 billion by 2028, growing at a CAGR of over 17.1% from 2022 to 2028 (source: Markets and Markets), reflecting the unprecedented momentum behind this transformative technology.

Critical challenges, including organ shortages, the growing demand for personalized medicine, and cost pressures on hospitals and healthcare providers, drive this significant trend in 3D printing.

But what exactly is 3D printing for healthcare, why is it crucial for medical innovation, and how does it help elevate the digital transformation journey in healthcare? This blog delves into the fascinating world of healthcare 3D printing, exploring its fundamental principles, diverse applications, undeniable benefits, challenges businesses face, and the exciting future it promises.

Let Appinventiv be your tech partner in this transformative journey.

A Quick Overview of the Role of 3D Printing in Healthcare

At its core, 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects layer by layer from a digital design. Unlike traditional subtractive manufacturing methods that remove material from a larger block, 3D printing builds up the object, often with minimal waste.

When applied to medicine, this technology unlocks a realm of possibilities that conventional methods simply cannot match. From developing highly customized medical devices to engineering living tissues, medical 3D printing is revolutionizing patient care and treatment.

3D printing for healthcare offers four core promises that are revolutionizing medical practice:

- Personalization – Every patient’s anatomy is unique, and 3D printing enables mass customization of medical devices, implants, and surgical tools tailored to individual specifications.

- Precision – Digital manufacturing eliminates human error and ensures reproducible accuracy that surpasses traditional methods.

- Efficiency – Rapid prototyping and on-demand manufacturing dramatically reduce lead times from months to days or even hours.

- Accessibility – Point-of-care manufacturing brings advanced medical solutions to remote areas and underserved populations.

Types of 3D Printing Technologies Used in Healthcare

To truly unlock its transformative promise, 3D printing in healthcare leverages several distinct additive manufacturing technologies, each meticulously selected for its suitability to diverse medical applications. Here are some common types of 3D printing technology in healthcare:

- Stereolithography (SLA): Uses ultraviolet lasers to cure resin into solid layers. Known for its high accuracy, this material is ideal for dental models and surgical guides.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered materials, suitable for durable implants and prosthetics.

- Fused Deposition Modeling (FDM): Melts and deposits thermoplastic filaments layer by layer. It’s cost-effective and widely used for prototyping medical equipment.

- Digital Light Processing (DLP): Similar to SLA, but uses a projector to cure an entire layer of resin at once, leading to faster print times. Often used for high-volume, small-part production in dentistry.

These technologies offer a unique blend of customization, speed, and cost efficiency that align perfectly with the demands of healthcare.

Key Steps of Putting Medical 3D Printing into Practice

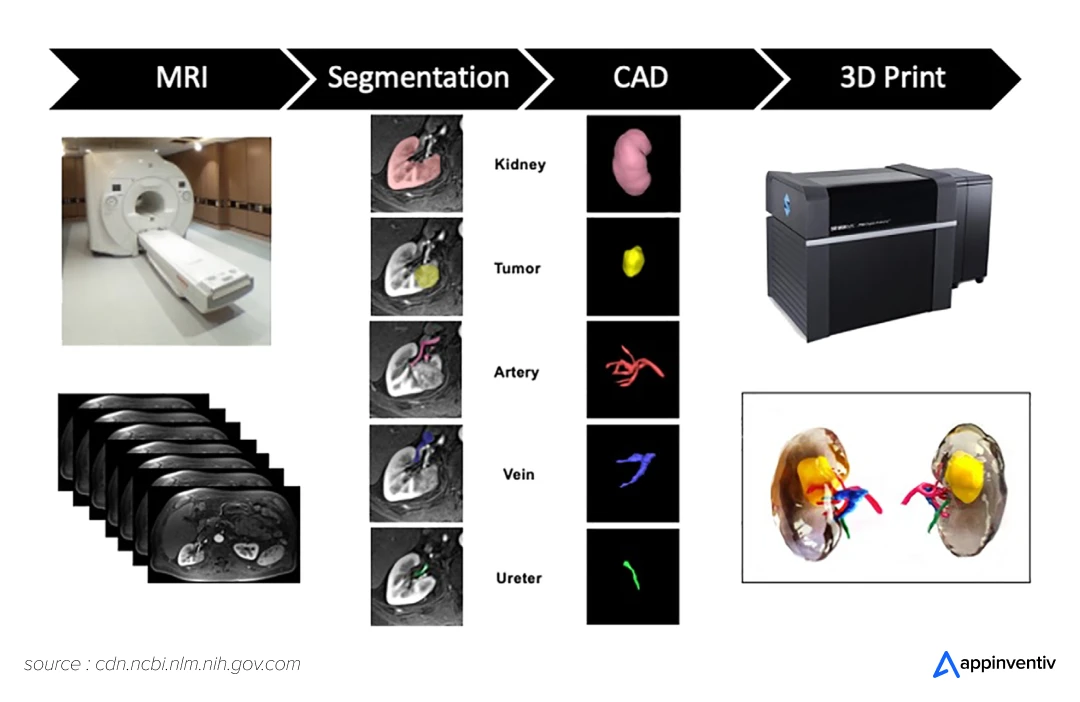

Essentially, it transforms digital blueprints into tangible, physical objects through a meticulous, layer-by-layer deposition of material.

The process typically begins with a digital model, often derived from a patient’s medical scans (like CT or MRI). This digital file is then sliced into thousands of thin, two-dimensional layers. A 3D printer then reads these layers and, using various technologies, deposits or solidifies material precisely, building the object from the ground up.

The steps for putting medical 3D printing into practice generally involve:

- Image Acquisition: Utilizing medical imaging (CT, MRI, ultrasound) to capture detailed anatomical data.

- Segmentation & Design: Medical images are segmented into 3D digital models using advanced software. Clinicians or engineers can then leverage intuitive apps and CAD software to design or customize medical devices, implants, or anatomical models.

- Material Selection: Choosing the appropriate biocompatible material (polymers, metals, ceramics, or bio-inks) based on the application.

- Printing: The digital model is sent to the 3D printers in medicine, which build the object layer by layer according to the precise digital blueprint.

- Post-processing: Cleaning, curing, sterilizing, and finishing the printed object for medical use.

This streamlined process enables rapid iteration and personalization previously impossible with conventional manufacturing.

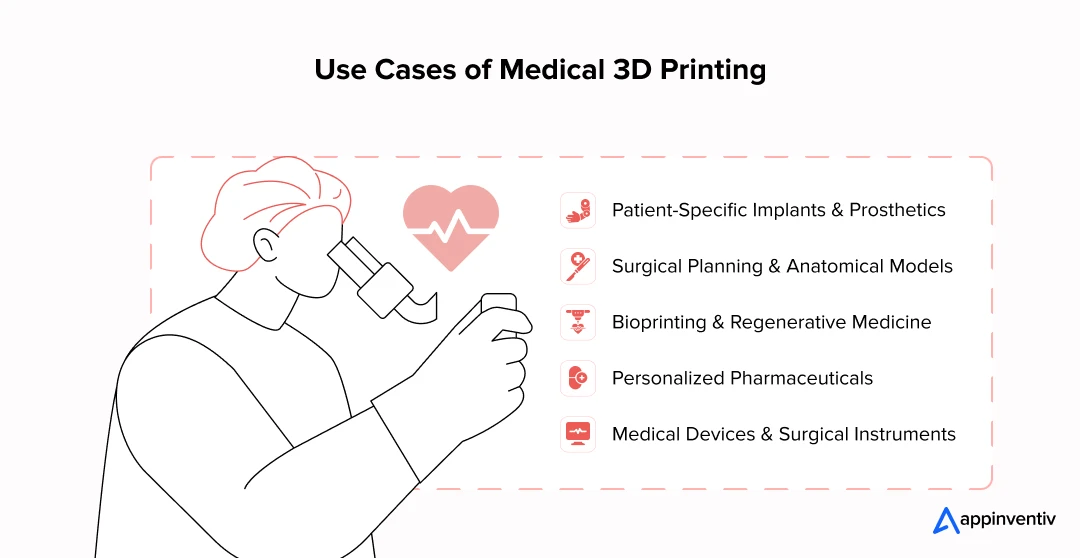

Medical 3D Printing Use Cases Transforming the Industry

The transformative power of medical 3D printing is evident across a spectrum of healthcare applications, each pushing the boundaries of what’s possible in patient care. This technology is fundamentally reshaping how medical devices are designed, how surgeries are planned, and even how biological tissues are engineered. Here are some game-changing applications of 3D printing technology in healthcare that demonstrate the current and future impact of additive manufacturing on global health.

Patient-Specific Implants & Prosthetics

One of the most significant applications of 3d printing for healthcare lies in the creation of patient-specific implants and prosthetics. The human body is incredibly diverse, and traditional, “one-size-fits-all” medical devices often lead to suboptimal fit, discomfort, and extended recovery times. Medical 3D printing overcomes this by producing devices perfectly tailored to an individual’s anatomy.

- Orthopedics: In orthopedics, 3D printing enables the creation of custom hip and knee implants, spinal cages, and bone grafts that precisely match a patient’s bone structure. This precision can lead to better integration, reduced revision surgeries, and enhanced mobility.

- Dental & Maxillofacial: The dental industry has been an early adopter, leveraging healthcare 3D printing for highly accurate crowns, bridges, dentures, and clear aligners.

- Cranio-Maxillofacial (CMF) Reconstruction: For patients suffering from facial trauma or requiring tumor resection, 3d printing can create custom plates and implants for reconstruction, restoring both function and aesthetics with remarkable accuracy.

- Custom Prosthetic Limbs: Traditional prosthetics can be expensive and uncomfortable. 3d printing for healthcare offers the ability to produce lightweight, highly personalized, and more affordable prosthetic limbs, allowing increased mobility for patients worldwide.

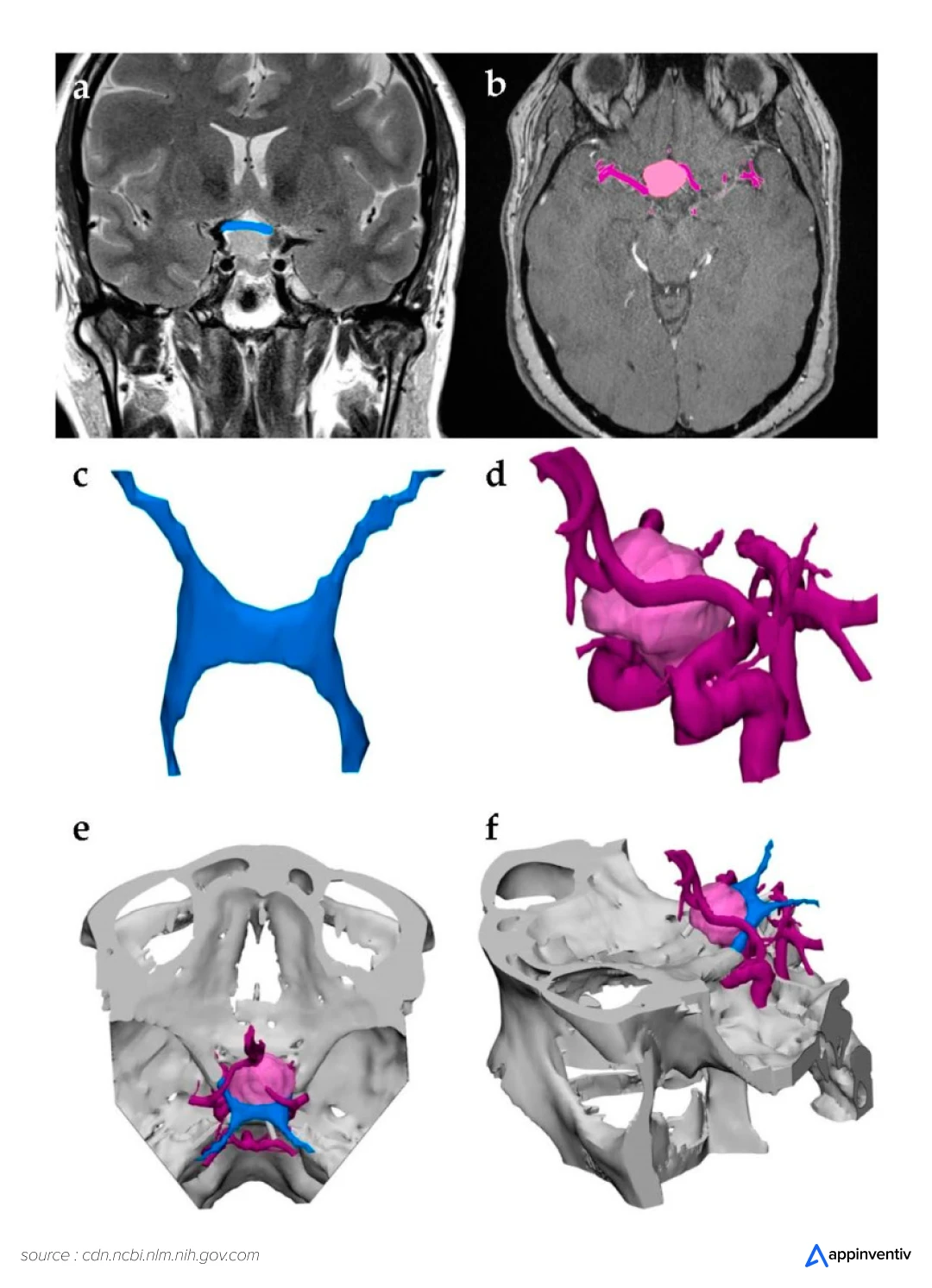

Surgical Planning & Anatomical Models

Beyond direct implantation, 3d printing in hospitals is proving invaluable for pre-surgical planning and creating lifelike anatomical models. These models transform complex 2D scans into tangible, interactive tools.

- Pre-surgical Visualization: Surgeons can now hold exact replicas of a patient’s organs or bones in their hands, allowing them to practice complex procedures multiple times before entering the operating room. This “dry run” enhances precision, reduces surgical time, and minimizes risks.

- Patient Education: 3D-printed models offer a tangible aid in explaining complex medical conditions or upcoming surgeries, enabling patients and their families to understand their condition and the planned intervention better, thereby fostering greater trust and adherence.

- Medical Training: From medical schools to advanced surgical training centers, 3d printing and healthcare models offer realistic, cost-effective alternatives to cadavers, enabling students, surgeons, and caregivers to hone their skills in a safe and repeatable environment.

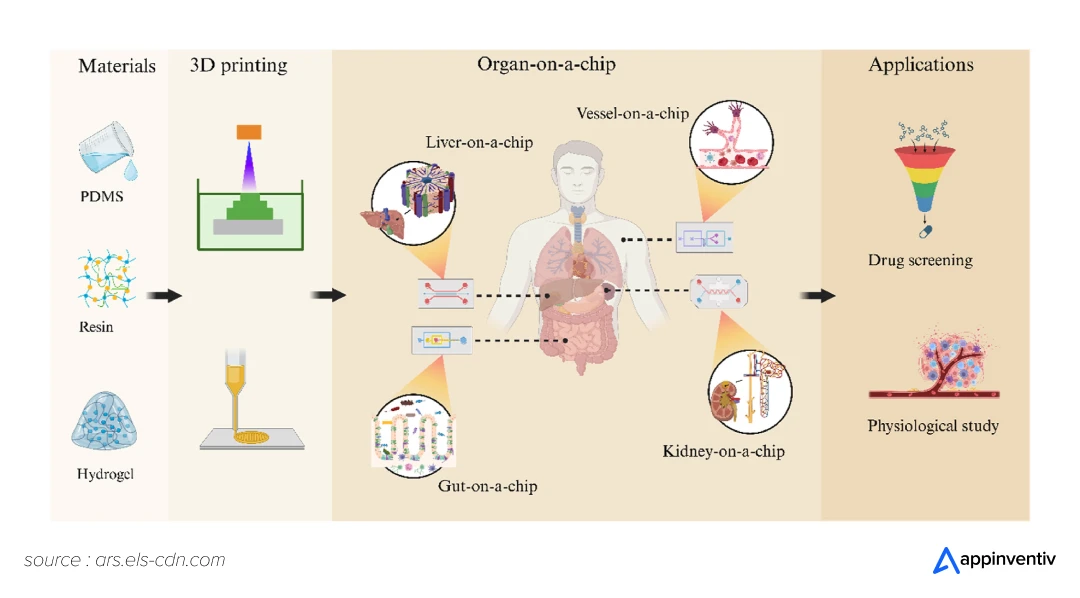

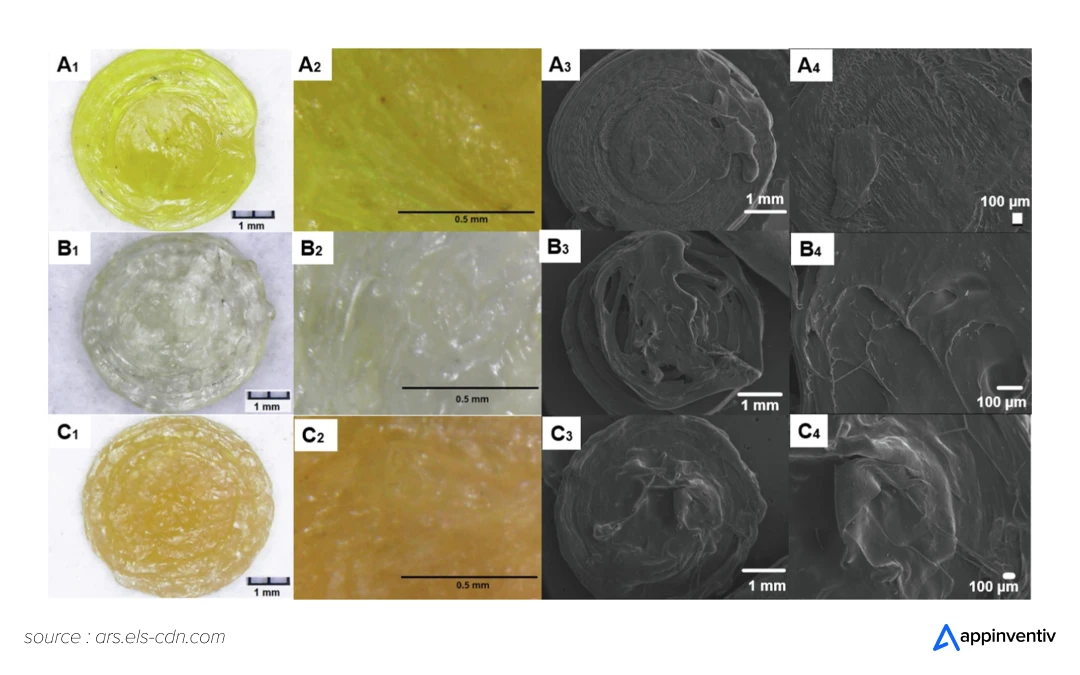

Bioprinting & Regenerative Medicine

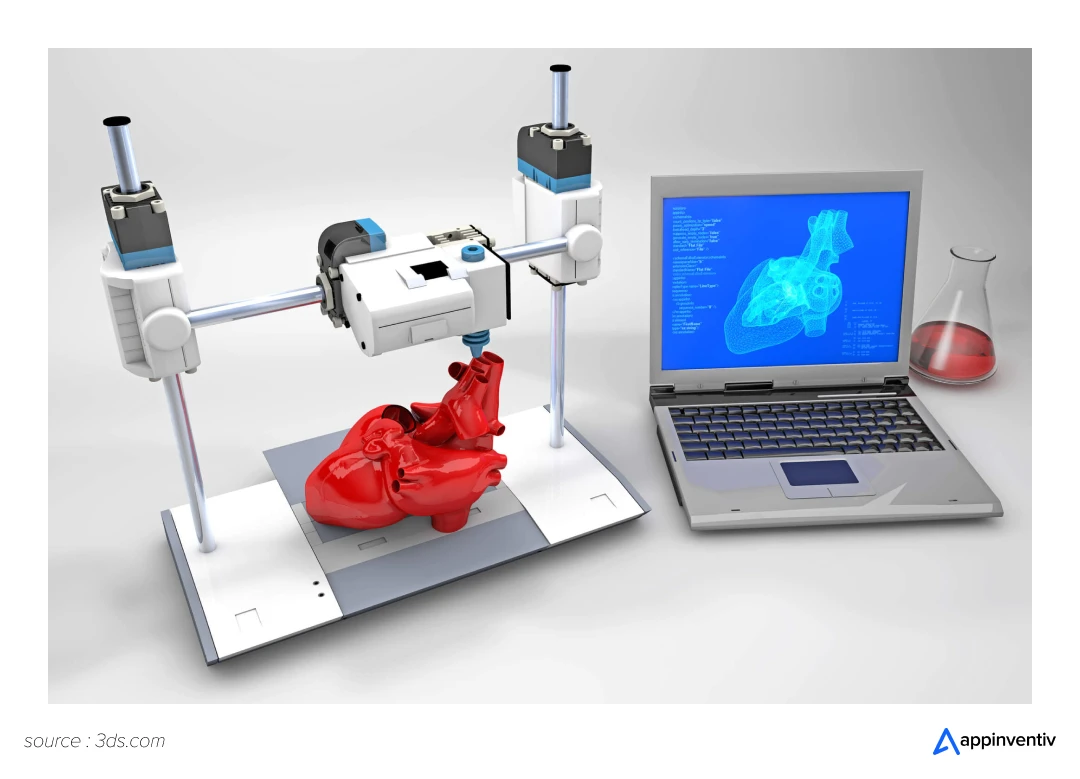

Bioprinting represents the most revolutionary application of 3D printing in healthcare, expanding directly into tissue engineering and regenerative medicine.

- Tissue Engineering: It represents the cutting edge of medical 3D printing with potentially revolutionary implications for organ transplantation and regenerative medicine. While full organ printing remains experimental, significant progress has been made in creating functional tissue constructs for drug testing and therapeutic applications.

“While it’s too soon to say that 3D bioprinting could be the solution for the current shortage of organs for transplantation, it increases the hopes to partially solve the issue for some organs or some specific indications.”

Dr. Paulo Marinho, Head of Scientific Strategy at T&R Biofab.

- Organ-on-a-chip: This 3D technology combines 3D printing with microfluidics to create physiologically relevant tissue models for drug discovery. These miniaturized organ systems enable pharmaceutical companies to test drug efficacy and toxicity more accurately than traditional cell culture methods.

Currently, a significant number of research organizations are intensely focused on 3D bioprinting for drug testing and developing sophisticated cellular models. For instance, the successful printing of stem cell-derived heart patches to assist infarcted rat hearts offers a tangible glimpse into where this technology might lead in the not-so-distant future. The ultimate goal of 3D bioprinting is functional organ printing, a breakthrough recently highlighted in the world’s first 3D-printed windpipe transplant.

Personalized Pharmaceuticals

3D printing in the healthcare industry is also poised to transform the production and administration of medications, leading to highly customized drug therapies.

- Custom Dosages: Traditional pills come in fixed dosages. 3D printing in healthcare enables the tailoring of medication dosages to individual patient needs, which is particularly beneficial for children, the elderly, or patients with specific metabolic rates.

- Polypills: Imagine a single pill containing multiple medications precisely combined and released over time. 3D printers in medicine can create such “polypills,” simplifying complex drug regimens and improving patient adherence.

The innovation of 3d printing in personalized pharmaceuticals ensures higher efficacy, improved compliance, and fewer side effects.

Medical Devices & Surgical Instruments

3D printing in the healthcare industry also accelerates prototyping and production of medical devices and surgical equipment.

- Custom Surgical Guides: 3D printing in surgery can create highly accurate surgical guides used by surgeons to ensure precise cuts and placements during operations, particularly in complex procedures like tumor removal or orthopedic alignments.

- Low-Volume Specialized Tools: 3D printing medical equipment provides a cost-effective method for producing low-volume, specialized tools. This capability is particularly valuable for pediatric instruments where smaller sizes are needed infrequently.

- Rapid Prototyping: 3d printing in healthcare allows medical device manufacturers to rapidly prototype new designs, test their functionality, and iterate quickly, accelerating the development cycle.

Real World Examples of Healthcare Organizations Leveraging 3D Printing

The revolutionary potential of 3D printing in healthcare is not just theoretical; visionary entrepreneurs and forward-thinking healthcare leaders worldwide are actively harnessing it. Their initiatives highlight the diverse commercial opportunities and the profound impact this technology is having on patients’ lives.

Rady Children

Rady Children’s Hospital Innovation exemplifies specialized applications in pediatric care. Rady Children’s Hospital in the US has established a 3D Innovations Lab, where medical engineers 3D print dozens of models per week. Their focus on pediatric applications demonstrates how 3D printing’s customization advantages are particularly valuable for treating children, where standard-sized devices often require modification.

Mayo Clinic

Mayo Clinic’s Advanced Integration showcases how leading healthcare institutions are scaling 3D printing across multiple specialties. The organization’s 3D Anatomic Modeling Laboratory produces hundreds of patient-specific models annually for surgical planning, medical education, and device development.

Anatomiz3D

Anatomiz3D, an Indian med-tech startup, leveraged 3D printing in healthcare to provide customized models of organs, soft tissue, and bones to hospitals across India. Their innovative approach not only enhances surgical precision but also significantly reduces the cost of these essential models, making advanced medical solutions more accessible.

“We have made customised 3D models for nearly 4,000 surgeries so far. Apart from surgical planning, these models assist in procedure simulations and medical education as well.”

By Firoza Kothari, Co-founder at Med-Tech Startup

Johns Hopkins

Johns Hopkins’ Surgical Innovation demonstrates how 3D printing enables previously impossible surgical procedures. Their use of 3D printed guides for complex spinal surgeries has reduced operative time and improved precision in procedures where millimeter accuracy is critical for patient safety.

These are just a few instances. Countless other organizations in the medical world are actively shaping how 3D printing can help humans achieve better health outcomes, demonstrating the immense and diverse potential of 3D printing for the healthcare ecosystem.

Game-Changing Benefits of 3D Printing in Healthcare

The transformative potential of 3D printers in medicine becomes evident when examining the measurable benefits across clinical, operational, and economic dimensions. Healthcare organizations worldwide are reporting significant improvements in patient outcomes, cost reduction, and operational efficiency through strategic applications of medical 3D printing. Here are some of the most tangible benefits of 3d printing in healthcare:

Enhanced Personalization and Precision

The foremost benefits of 3d printing in healthcare are the unparalleled level of personalization. Every human body is unique, and 3d printing in healthcare enables the creation of devices, implants, and even pharmaceuticals that are precisely tailored to an individual’s anatomy, pathology, or metabolic needs. This bespoke approach leads to improved fit, reduced discomfort, and significantly better patient outcomes.

Reduced Costs & Faster Prototyping

While the initial investment in 3D printing medical technology can be substantial, the long-term cost benefits are compelling. By manufacturing devices on demand and to exact specifications, 3D printing in the medical field significantly reduces material waste and the need for large inventories.

Improved Accessibility in Remote or Underserved Areas

3d printing in hospitals and local clinics addresses healthcare equity challenges that traditional manufacturing models cannot solve. Point-of-care manufacturing enables advanced medical devices to be produced in underserved regions without complex supply chain logistics. During the COVID-19 pandemic, this capability proved invaluable for rapidly producing essential supplies, such as personal protective equipment (PPE), underscoring its crucial role in enhancing healthcare resilience.

Sustainability Through Reduced Waste

3D printing is significantly more eco-friendly and minimizes waste. For instance, unlike traditional manufacturing, which often involves significant material removal and waste, 3d printing in healthcare is an additive process. It builds objects layer by layer, using only the necessary material. This inherent efficiency dramatically reduces scrap rates, contributing to a more sustainable and environmentally friendly manufacturing process within the healthcare industry.

Faster Innovation Cycles and Agility in Product Development

The rapid prototyping application of 3D printing in healthcare enables the testing, refinement, and deployment of new ideas with unprecedented speed. This agility fosters continuous innovation, allowing medical device manufacturers and researchers to respond quickly to evolving patient needs and technological advancements.

The quick turnaround time of 3D printing enables rapid design iteration. For instance, surgeons can provide immediate feedback on a custom tool or surgical guide, which can then be quickly applied to the design and reprinted, dramatically accelerating development cycles.

Inspired by the immense applications and advantages of 3D printing in healthcare? Realizing these potentials often requires a robust digital platform. If you are not sure how to do it right and enter into the fascinating world of medicine, here is our comprehensive guide on healthcare app development, which will help you kickstart your journey.

Build Your Next-Gen 3D Printing Medical Platform with Appinventiv in Action

Challenges in Medical 3D Printing Implementation & Strategies to Overcome Them

While the benefits of 3D printing in healthcare are substantial, its successful implementation requires addressing several key challenges that healthcare organizations must navigate carefully. Overcoming these hurdles often involves strategic technological solutions that enhance efficiency, compliance, and scalability. Let’s overcome some of the most critical challenges of 3D printing in healthcare.

Regulatory Hurdles & Quality Assurance

- Challenges: Ensuring the safety and efficacy of 3D-printed medical devices and implants demands stringent regulatory scrutiny. The highly customized nature of 3D printing in the medical field presents complexities for maintaining consistent quality control and ensuring traceability.

- Solutions: Consider partnering with a reputable medical software development services provider that helps ensure adherence to standards such as HIPAA, FDA, and CE regulations, facilitating transparent data sharing and auditing.

Data Security & Privacy Concerns

- Challenges: The creation of patient-specific devices relies heavily on sensitive patient data, making data security and privacy a paramount concern. Transmitting this information between systems carries inherent risks.

- Solutions: Implementing robust cybersecurity measures, including end-to-end encryption and secure cloud storage, can safeguard patient data and design files.

Scalability & Integration

- Challenges: While 3D printing in healthcare excels at customization, integrating it seamlessly into existing hospital IT infrastructure and scaling operations for broader adoption can be complex.

- Solutions: Developing custom API integrations and middleware solutions can bridge the gap between 3D printing software and legacy hospital systems, enabling seamless integration. Additionally, organizations can build modular, scalable digital platforms to expand their 3D printing capabilities without requiring an overhaul of their entire IT infrastructure.

Also Read: 4 Things You Should Know About Healthcare App Development

Future Trends and Technologies to Watch in 2025 and Beyond

The landscape of 3D printing in healthcare is evolving at a remarkable pace, driven by continuous innovation and expanding possibilities. In the coming decade, several emerging trends and technologies are poised to revolutionize patient care further. These advancements promise to enhance precision, personalize treatments, and streamline processes, leading us to a future where cutting-edge digital solutions will be intrinsically linked to medical breakthroughs. Understanding these emerging trends is crucial for healthcare organizations planning strategic technology investments.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning will play an increasingly critical role in redefining the future of 3D printing in healthcare. AI algorithms in healthcare can optimize complex 3D printing medical application designs, predict material performance, and automate parts of the workflow, from image segmentation to quality control.

Materialise’s 2025 trends report highlights that “AI and operational efficiency are driving market expansion” in 3D planning and printing at the point of care.

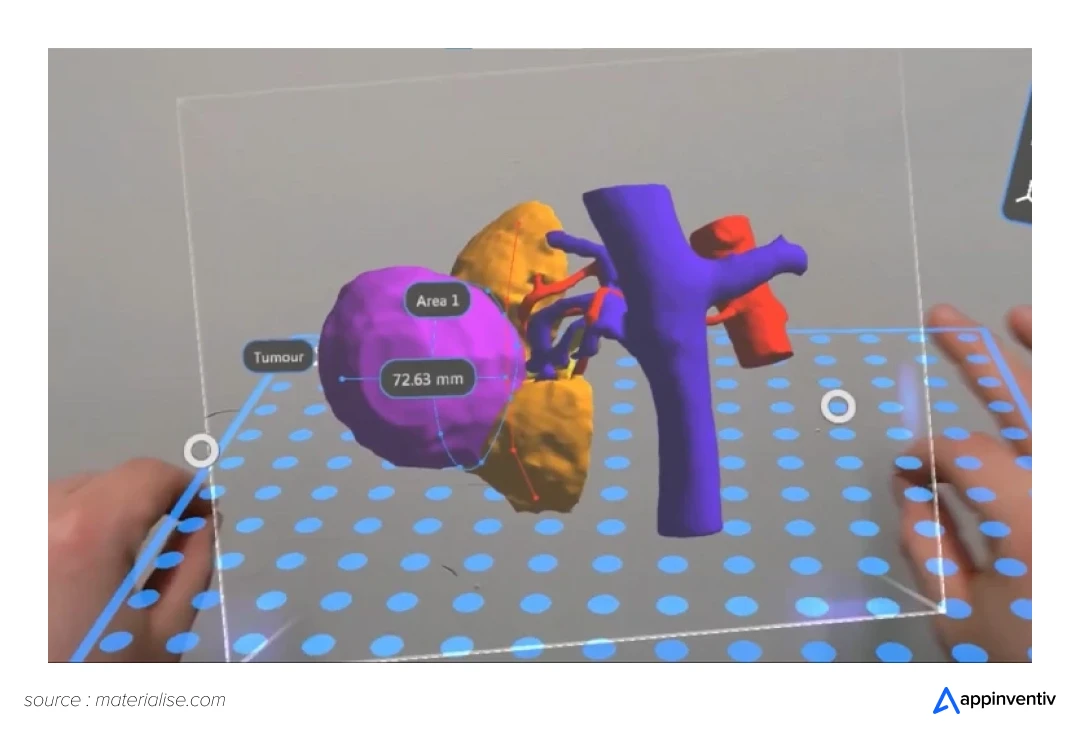

Extended Reality (XR) in 3D Planning

Augmented Reality (AR) and Virtual Reality (VR) in healthcare are transforming how clinicians interact with 3D anatomical models. Surgeons can virtually “walk through” a patient’s anatomy or overlay 3D models onto a real patient during surgery, enhancing planning and execution. Materialise notes that “Extended reality (XR) is making 3D more accessible and efficient” for medical planning.

Also Read: How Extended Reality is Driving Innovation Across Industries

Sustainable 3D Printing

A growing focus on environmentally friendly practices will drive the development of biodegradable and recyclable materials for 3D printing medical equipment, reducing the environmental footprint of healthcare manufacturing.

3D Planning and Printing Expansion

While 3D printing in healthcare initially gained traction in cranio-maxillofacial and orthopedic fields, its reach is rapidly expanding. In 2025, we’re seeing significant momentum in areas like congenital heart disease (CHD) and oncology.

For CHD, patient-specific 3D models are proving crucial for surgical planning, resulting in reduced ICU stays and improved management of post-operative issues. In oncology, personalized surgical guides and radiotherapy devices are enhancing precision in tumor resections and radiation treatments. This trend is set to drive broader adoption across cardiovascular, neurosurgical, and interventional fields throughout the year.

These technological innovations in healthcare collectively point towards a future where 3D printing medical technology is not just an innovative niche but an indispensable, integrated component of healthcare delivery worldwide.

Also Read: Top Healthcare Trends That Will Redefine The Industry in 2025

How Appinventiv Can Help You Leverage 3D Printing in Healthcare

At Appinventiv, we understand the immense potential of 3d printing in healthcare. While we don’t produce the physical prints, our expertise in medical software development services is crucial for enabling the digital ecosystem that powers these advancements.

For instance, imagine a system where a surgeon scans a patient, customizes an implant design via a user-friendly app, and sends it directly to a 3D printer – all facilitated by seamless, secure software.

Don’t just take our word for it; rather, peek into some of the success stories of our healthcare clients that exemplify our excellence in helping them achieve their digital goals:

Soniphi – The First Resonant Frequency Wellness App

While not directly a 3D printing case study, Soniphi showcases Appinventiv’s capability in building advanced health and wellness platforms that leverage data. Our tech experts can apply a similar or tailored approach to manage patient data for 3D printing, track device performance, or even integrate AI for predictive outcomes in personalized treatments.

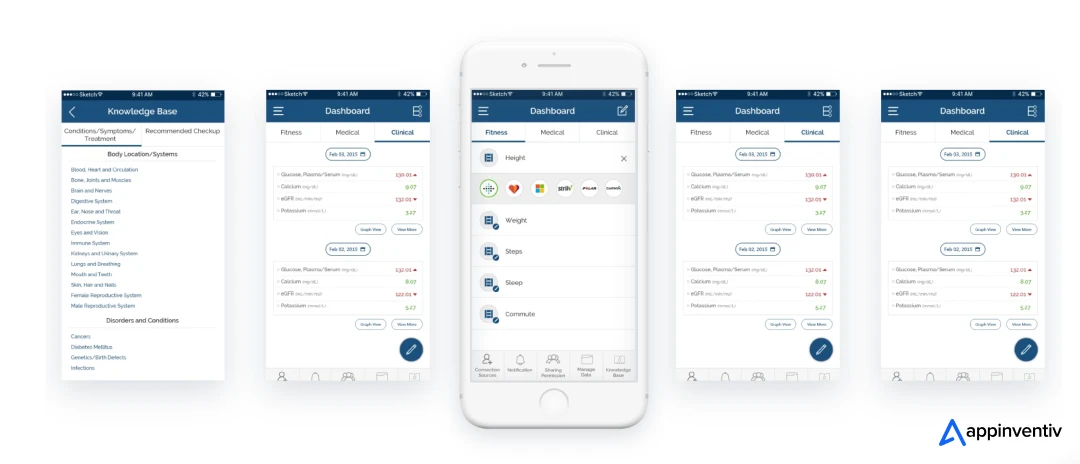

Health-e-People – A Comprehensive Health Ecosystem

Health-e-People showcases Appinventiv’s expertise in developing comprehensive digital health ecosystems. In the context of 3d printing for healthcare, such an ecosystem could serve as a central hub for managing patient-specific design files, facilitate communication between surgeons and 3D printing labs, and even track the entire workflow from diagnosis to post-operative care. This platform could manage the entire digital thread of a 3D-printed device, from diagnosis to post-operative care.

DiabeticU – Personalized Diabetes Management

DiabeticU highlights Appinventiv’s focus on personalized patient care and chronic disease management through intuitive mobile applications. For 3d printing and healthcare, this expertise is invaluable in developing patient-facing apps that provide detailed information about their custom-printed prosthetics or implants, offer interactive rehabilitation exercises, track recovery progress, or even connect them with support groups and their healthcare team.

These examples underscore how Appinventiv’s decade of experience in healthcare technology can build the critical digital backbone for 3d printing and healthcare to thrive.

We combine deep healthcare expertise with cutting-edge software development to empower innovators in 3D printing medical equipment. Whether you aim to leverage 3D printing in healthcare for personalized medical devices or custom surgical guides, we are here to help.

By partnering with Appinventiv, you can transform your innovative 3D printing in healthcare ideas into market-ready, scalable solutions.

So, why wait? This is the time to act fast and grab the opportunity that the medical 3D printing market holds for you. Get in touch with us now.

FAQs

Q. What is 3D printing in healthcare?

A. 3D printing in healthcare, also known as additive manufacturing, is a process that creates three-dimensional medical objects, devices, or even biological tissues layer by layer from a digital design. It leverages various technologies and biocompatible materials to produce patient-specific solutions, customized implants, anatomical models for surgical planning, and more.

Q. How much does 3D printing software development cost in healthcare?

A. Custom software development costs for 3D printing in healthcare vary widely, ranging from $40,000 to $400,000 or more.

The cost is primarily driven by the software’s complexity, features (e.g., advanced imaging integration, AI-driven design, workflow automation), regulatory compliance requirements (like HIPAA, FDA), and the expertise of the development team. User experience design, scalability, tech stack, and integration with existing hospital systems also play a crucial role in determining the overall cost of developing 3D printing software for healthcare.

Contact us to get a more precise estimate for the 3D printing software development costs.

Q. How is 3D printing used in the medical field?

A. 3D printing in the medical field is used to create patient-specific implants, prosthetics, surgical models, dental devices, and even bioprinted tissues. It allows precise customization based on individual anatomy, improves surgical planning through anatomical replicas, accelerates prototyping of medical devices, and supports regenerative medicine research by printing tissues for drug testing and future organ transplants.

Q. What are the regulatory considerations (FDA/CE) for 3D-printed medical devices and implants?

A. 3D-printed medical devices and implants must comply with strict regulatory standards to ensure safety and efficacy. The FDA and CE authorities require thorough testing, validation, and documentation, including design controls, material biocompatibility, and manufacturing process consistency. Patient-specific devices often need customized approval pathways. Manufacturers must also ensure traceability, post-market surveillance, and adherence to quality management systems.

Q. Are 3D-printed organs FDA-approved?

A. Yes, many 3D-printed medical devices are FDA approved. The FDA regulates these devices based on their intended use and risk, classifying them into Class I, II, or III. High-risk devices like implants require a stringent premarket review, while over 100 3D-printed medical devices have been reviewed and cleared by the FDA. However, certain 3D-printed tissues and scaffolds are under clinical trials and show promising potential for future approval and use.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How to Build a Custom Pediatric EMR and EHR System?

Key takeaways: Clinical Precision: Custom systems accommodate pediatric-specific data points like percentile curves and weight-based longitudinal dosing. Interoperability: Seamless data exchange via HL7 FHIR ensures your practice stays connected to pharmacies, labs, and state registries. Regulatory Resilience: Built-in compliance with HIPAA, HITECH, and MACRA/MIPS reduces legal friction. Enhanced Engagement: Parent portals reduce administrative overhead by…

Change Management in Healthcare: Principles, Processes, and Models

Key Takeaways Change in healthcare fails quietly when ownership, workflow alignment, and follow-through are missing. Successful change management in healthcare focuses on adoption, not just system implementation. Clinical workflows and workforce capacity determine whether transformation sticks or stalls. Governance, clear accountability, and post-go-live support matter more than the model used. Sustainable healthcare transformation depends on…

A Practical Guide to Building Your Mental Health Chatbot - Use Cases, Cost, & ROI

Key takeaways: Mental health chatbots work when they know their limits. They’re most useful as a gentle first step, not as a stand-in for real care. Good chatbot design is more about judgment than AI. Clear boundaries, calm responses, and safety matter more than smart language models. Enterprises invest in chatbots to make support easier…