- Evolution of Physical AI and How It Is Changing Industries?

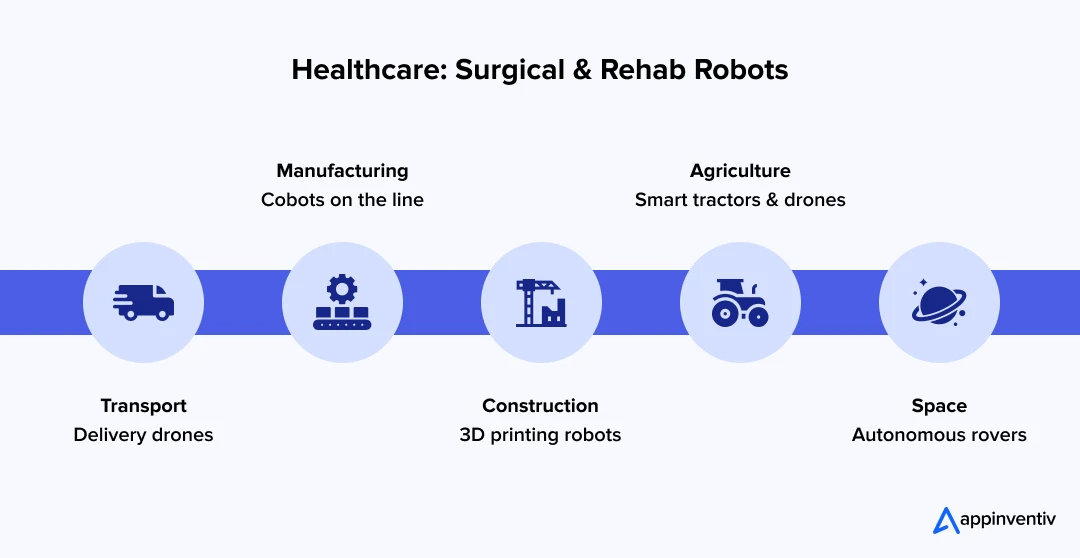

- Manufacturing

- Healthcare

- Logistics and Warehousing

- Transportation

- Agriculture

- Construction

- Space Exploration

- How Does Physical AI Work?

- Perception

- Handling

- Making Choices

- Take Action

- Key Benefits of Physical AI Across Industries

- Tangible Efficiency Improvements

- Enhanced Safety Protocols

- Continuous Operational Capacity

- Precision and Quality Assurance

- Intelligent Data Analysis and Decision Support

- Scalable Implementation and Consistent Performance

- How to Leverage Physical AI for Competitive Advantage?

- Start with High-ROI Use Cases

- Integrate with Existing Systems

- Enable Real-Time Decision-Making

- Invest in Workforce Readiness

- Scale Across Locations

- Track ROI and Optimize

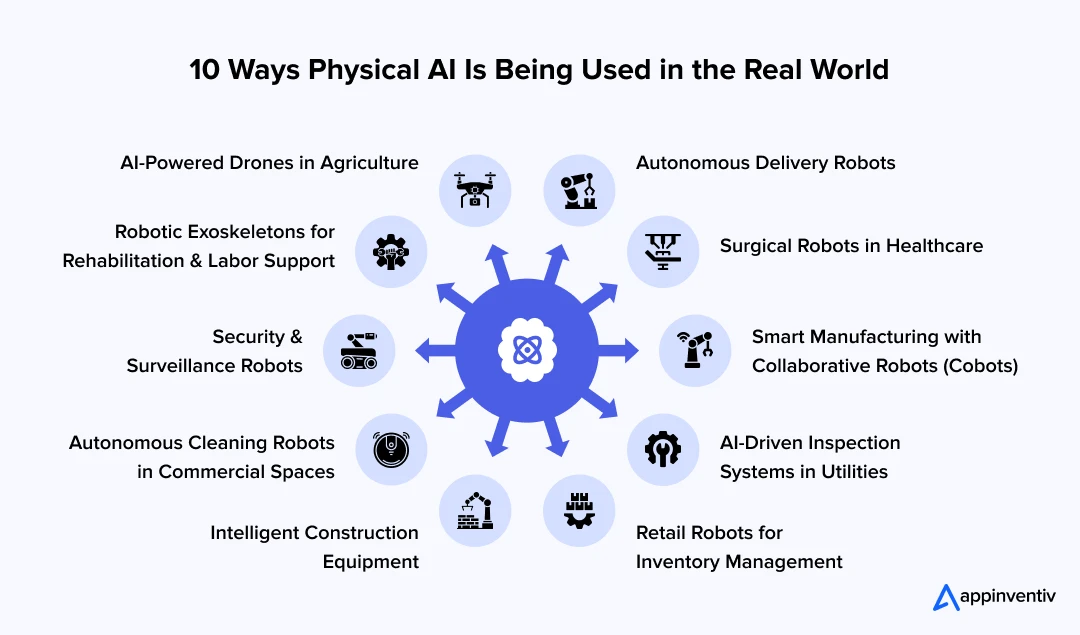

- 10 Real-World Use Cases of Physical AI With Real-Life Examples

- 1. Autonomous Delivery Robots

- 2. Surgical Robots in Healthcare

- 3. Smart Manufacturing with Collaborative Robots (Cobots)

- 4. AI-Driven Inspection Systems in Utilities

- 5. Retail Robots for Inventory Management

- 6. Intelligent Construction Equipment

- 7. Autonomous Cleaning Robots in Commercial Spaces

- 8. Security and Surveillance Robots

- 9. Robotic Exoskeletons for Rehabilitation and Labor Support

- 10. AI-Powered Drones in Agriculture

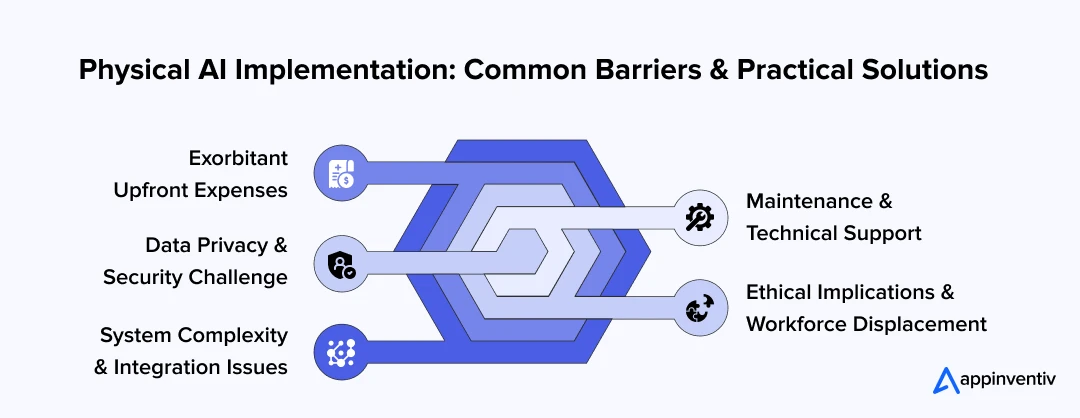

- Challenges in Implementing Physical AI and Solutions and How to Overcome Them

- Exorbitant Upfront Expenses

- Data Privacy & Security Challenge

- System Complexity and Integration Issues

- Maintenance and Technical Support

- Ethical Implications and Workforce Displacement

- Step Into the Future of Physical AI With Appinventiv

- FAQs

Ever wondered what factory work will look like in the next 10 years? Just visit a Tesla facility. Most people know Tesla uses industrial robots for assembly, painting, and welding. What’s different now is their Optimus project: humanoid robots designed to handle physical tasks throughout their manufacturing facilities. This technology has moved well beyond concept phases.

Amazon’s warehouse operations tell a similar story, though on a much larger scale. The company runs over 750,000 robots across their fulfillment network. These machines work directly with human employees on tasks like picking, sorting, lifting, and package movement. Anyone who’s seen holiday shipping volumes knows how critical this automation has become for handling demand spikes.

These examples highlight Physical AI implementation embedded in physical machines that observe, decide, and act independently. The technology applications extend far beyond basic automation. Companies use these systems for workplace safety improvements, continuous operation capabilities, and faster response to market changes.

In this blog, we will cover Physical AI in depth, encircling the top Physical AI use cases, benefits, real-life examples, and most importantly, how it has changed industries and brought a positive impact. Let’s take a quick walk through.

If you haven’t started exploring its potential, now is the time to act.

Evolution of Physical AI and How It Is Changing Industries?

Physical AI has undergone a remarkable transformation since those early industrial robots from the 1980s. Back then, factory robots did the same repetitive motions over and over. They worked, but couldn’t adapt when something unexpected happened.

Today’s situation is completely different. These systems can observe their environment, process what’s happening, and adjust their behavior accordingly. The technology combines sophisticated sensors, machine learning algorithms, and processing power that handles massive amounts of data in milliseconds.

Manufacturing

Physical AI use cases in manufacturing have caught everyone off guard with how fast things have changed. Just a few years ago, switching an automotive assembly line from sedans to SUVs meant shutting down production for at least a week. Now these systems figure out the new specifications and reconfigure welding patterns, assembly sequences, and quality checks automatically.

Healthcare

Physical AI in healthcare keeps pushing boundaries that seemed impossible not long ago. Surgeons are performing operations they wouldn’t have attempted before because the robotic systems eliminate hand tremors and provide better visualization. Physical therapy has changed dramatically too. Stroke patients work with robotic systems that adjust difficulty based on their daily progress rather than following generic exercise routines. Hospital pharmacies have practically eliminated medication errors through automated preparation systems. With the utilization of AI in healthcare, the entire medical care process has been completely changed.

Logistics and Warehousing

Warehouse operations look completely different now. Places that used to employ hundreds of workers for order picking now run with maybe a dozen people overseeing robot fleets. These machines coordinate picking routes and reorganize inventory placement constantly based on demand patterns. The speed and accuracy improvements are significant—error rates have dropped while processing times got cut in half.

Transportation

Long-haul trucking is shifting faster than most people realize. Autonomous freight trucks handle interstate routes while calculating optimal fuel usage and delivery timing. City transit systems predict when buses or trains need maintenance before breakdowns happen. Port operations coordinate container movements that would take human teams hours to plan—the logistics complexity these systems handle is remarkable.

Agriculture

Farming has gone high-tech in ways that surprise people outside the industry. Autonomous tractors and combines analyze soil conditions field by field, adjusting seed placement and fertilizer application accordingly. Through AI in agricultural operations, ranchers monitor thousands of cattle through sensor networks that track health indicators and grazing patterns. Weather data integration helps optimize irrigation timing down to specific field sections.

Construction

Construction sites now feature heavy equipment that operates with surveyor-level precision through the use of Physical AI. Excavators grade terrain to millimeter tolerances while adjusting for underground utilities or rock formations they encounter. Building inspections happen through drone surveys that spot structural issues human inspectors often miss. Project coordination between multiple machines happens automatically without constant radio chatter.

Also Read: AI in Construction: Use cases, Benefits & Future Growth

Space Exploration

Space missions depend entirely on systems that work independently for months at a time. Mars rovers navigate terrain and conduct experiments while dealing with communication delays that make real-time control impossible. Satellite servicing robots perform repairs in orbit that would require complex spacewalks if humans attempted them. The autonomy levels required for space operations pushed technology development in directions that benefit earthbound applications.

The benefits of Physical AI extend well beyond operational improvements. This transformation is happening faster than most people anticipated. Technologies that seemed experimental five years ago are now becoming standard equipment in competitive industries. Companies that understand this shift early will likely maintain significant advantages over those that approach it as just another operational upgrade.

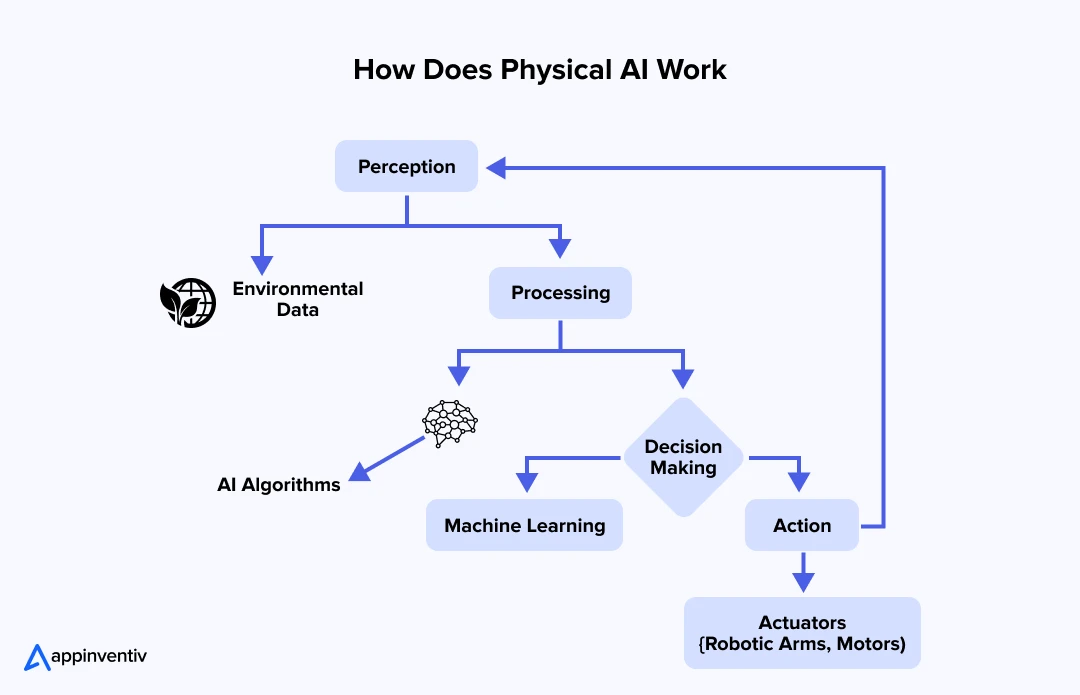

How Does Physical AI Work?

Physical AI allows machines to act intelligently in the real world by means of an ongoing cycle of perception, processing, decision-making, and action. This continuous feedback loop enables machines to respond dynamically to real-world situations with increasing accuracy and autonomy. Here’s how Physical AI works:

Perception

Using a range of sensors, including cameras, LiDAR, temperature gauges, and motion detectors, the system first gathers real-time data from its surroundings. It is able to “see” and “sense” what is going on around it thanks to this sensory input.

Handling

Advanced AI models are then fed the collected data. In essence, these models convert raw data into useful intelligence by analyzing the input to find patterns, draw conclusions, and comprehend context.

Making Choices

Based on its analysis, the system assesses potential courses of action using machine learning and deep learning techniques. It chooses the best course of action to accomplish goals or adjust to shifting circumstances.

Take Action

After that, the AI commands physical parts, like wheels, robotic arms, or drones, to perform the selected action. Additionally, it has the ability to track results, reevaluate in real time, and modify behavior as necessary.

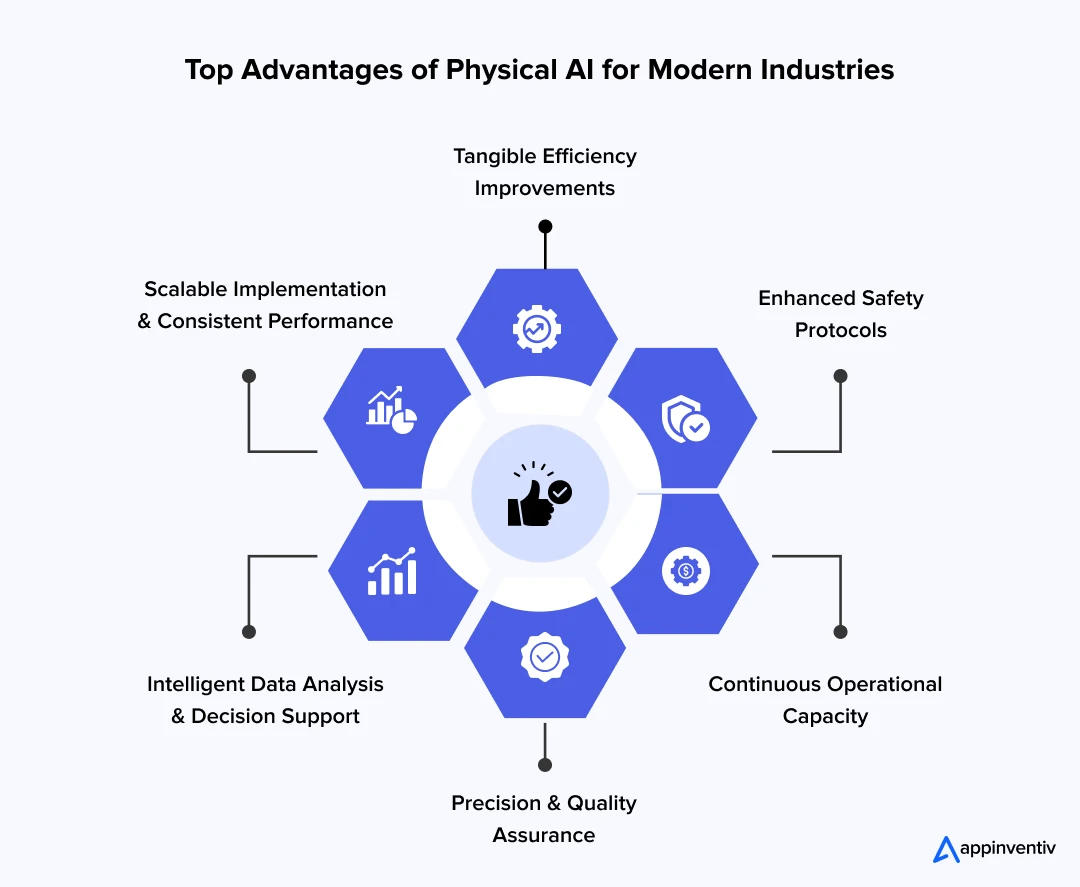

Key Benefits of Physical AI Across Industries

The benefits of Physical AI have emerged as a transformative force across multiple sectors. Industry leaders recognize that this technology represents more than incremental improvement—it constitutes a fundamental shift in operational capabilities.

Tangible Efficiency Improvements

Manufacturing facilities implementing Physical AI systems report productivity increases ranging from 20-40%. These improvements stem from the technology’s ability to optimize multiple operational variables simultaneously.

Physical AI for industrial automation demonstrates its value through dynamic workflow management. When production demands shift unexpectedly, these systems automatically adjust material flows and reallocate resources across production lines.

Enhanced Safety Protocols

Physical AI has revolutionized workplace safety across high-risk industries. Mining operations now deploy autonomous systems for equipment inspections in unstable underground areas.

These robotic systems eliminate human exposure to cave-in risks and toxic gas concentrations. They navigate hazardous environments while transmitting real-time data to surface control centers.

Continuous Operational Capacity

Physical AI use cases across various industries demonstrate the competitive advantages of round-the-clock operations. Distribution centers have experienced significant improvements in order processing capabilities.

AI systems maintain peak performance during overnight hours when human supervision is minimal. The technology eliminates productivity dips typically associated with shift changes and human fatigue. Organizations with high capital equipment costs find this particularly valuable for maximizing asset utilization.

Precision and Quality Assurance

Physical AI in Robotics has established new benchmarks for precision across numerous applications. Surgical robotics enables procedures requiring microscopic accuracy while eliminating human hand tremors.

Quality control processes have been transformed through RPA that detects errors invisible to human inspectors. Electronics manufacturers utilize these systems to identify component placement errors and surface defects.

Intelligent Data Analysis and Decision Support

The integration of generative Physical AI capabilities enables systems to move beyond reactive responses toward predictive problem-solving. These systems analyze operational patterns and generate strategic recommendations.

Supply chain management has been enhanced through AI systems that identify potential disruptions before they impact operations. These systems monitor supplier performance and market conditions continuously.

Scalable Implementation and Consistent Performance

Physical AI technology offers unprecedented scalability advantages. Companies expanding to new locations can deploy proven systems that perform consistently from day one. This eliminates the traditional months-long training periods and gradual improvement curves associated with new facility launches. Operational knowledge transfers instantly across all locations.

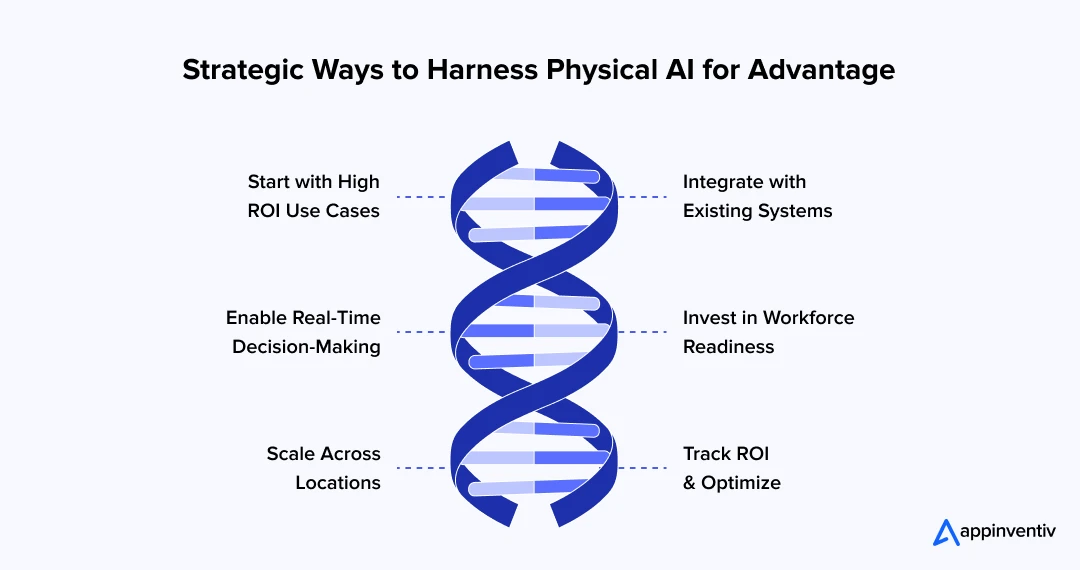

How to Leverage Physical AI for Competitive Advantage?

Most executives are wrestling with the same question: how to actually implement Physical AI without it becoming another expensive experiment that sits unused. The companies getting this right have learned some hard lessons about what works and what doesn’t.

Start with High-ROI Use Cases

Smart organizations focus on problems that already keep operations managers awake at night. Quality control makes sense as a starting point because success can be measured immediately—either the system catches defects or it doesn’t. Manufacturing companies often recoup their entire investment within six months just from reducing warranty claims.

Predictive maintenance offers another compelling entry point, especially for companies that have experienced costly unplanned downtime. Logistics optimization has proven particularly valuable for companies with complex supply chains. Rather than trying to transform everything at once, successful organizations focus on the bottlenecks that cost the most money or cause the biggest operational disruptions.

Integrate with Existing Systems

Physical AI works best when it connects seamlessly with systems already in place. The biggest implementation failures happen when companies try to replace everything at once instead of building bridges between new AI capabilities and existing infrastructure.

Manufacturing execution systems, inventory management platforms, and quality management software need to communicate effectively with new AI tools. This integration challenge often determines success or failure more than the AI technology itself. Companies that invest time upfront in proper system integration see faster adoption and better long-term results.

Enable Real-Time Decision-Making

The real competitive advantage comes from speed—using AI insights to respond quickly when operational conditions change or market demands shift. Traditional reporting cycles that take hours or days become obsolete when AI systems can identify problems and suggest solutions in real-time.

Manufacturing facilities using this approach can adjust production parameters within minutes of detecting quality issues. Logistics operations can reroute shipments automatically when weather or traffic conditions change. Organizations that master real-time responsiveness gain significant advantages over competitors still relying on traditional decision-making cycles.

Invest in Workforce Readiness

The human element often determines whether Physical AI implementations succeed or fail. Workers who understand how to collaborate effectively with AI systems become force multipliers rather than competitors with the technology. This requires thoughtful training programs that go beyond basic technical skills.

Successful companies focus on developing AI literacy across their workforce, teaching employees how to interpret AI recommendations, when to override system decisions, and how to provide feedback that improves AI performance over time. The goal isn’t replacing human judgment but augmenting it with AI capabilities.

Scale Across Locations

Once Physical AI systems prove their value at one location, scaling becomes the next competitive advantage. Companies that can rapidly deploy proven AI models across multiple facilities achieve consistent performance standards and faster ramp-up times than competitors building from scratch at each location.

This scaling advantage becomes particularly valuable for organizations with multiple manufacturing sites, distribution centers, or service locations. Instead of lengthy implementation periods at each new facility, proven AI systems can deliver immediate operational improvements while maintaining performance standards.

Track ROI and Optimize

Continuous monitoring and refinement separate successful Physical AI implementations from those that plateau after initial deployment. The technology landscape evolves rapidly, and systems that performed well six months ago may need adjustments to maintain competitive advantages.

Organizations establish clear metrics from day one and track performance consistently across all AI implementations. This data-driven approach enables continuous optimization while providing the justification needed for expanding Physical AI investments into new areas or additional locations.

10 Real-World Use Cases of Physical AI With Real-Life Examples

The landscape of Physical AI use cases has shifted dramatically over the past few years. Fortune 500 companies aren’t just experimenting anymore—they’re deploying these systems at scale and seeing real results that transform their operations.

1. Autonomous Delivery Robots

These compact machines navigate urban environments, avoiding obstacles while delivering packages directly to customers. They handle routine deliveries that traditionally require full-sized trucks, operating in various weather conditions. The technology represents a fundamental shift in last-mile logistics, offering cost-effective solutions for suburban areas where parking and package theft present ongoing challenges.

Amazon’s Amazon Scout robots now operate in select neighborhoods, carrying packages up to 30 pounds. The six-wheeled machines have proven particularly effective in suburban areas where traditional delivery trucks face access difficulties.

2. Surgical Robots in Healthcare

Robotic surgical systems enhance procedural precision while reducing patient recovery times across various medical specialties. These machines provide surgeons with tremor elimination, enhanced visualization, and access to difficult anatomical areas. The benefits of Physical AI in operating rooms include improved outcomes for complex procedures that previously carried higher risk profiles.

Johnson & Johnson’s Ottava system enables procedures through keyhole openings that once required large incisions. Recovery times have improved dramatically, with many procedures now involving same-day discharge rather than extended hospitalization.

Also Read: Agentic AI in Healthcare: Use Cases, Cost & Challenges

3. Smart Manufacturing with Collaborative Robots (Cobots)

Collaborative robots work safely alongside human workers without requiring safety barriers, handling repetitive tasks while adapting to individual working styles. These systems enhance human capabilities rather than replacing workers, learning from each interaction to improve coordination. Factory deployment has reduced workplace injuries while improving production quality and efficiency.

General Motors uses cobots for adhesive application and precision assembly across their facilities. Physical AI examples from GM show how these robots adapt to individual worker patterns, reducing injuries while maintaining production quality.

4. AI-Driven Inspection Systems in Utilities

Autonomous drones and robotic crawlers inspect infrastructure, including power lines, pipelines, and wind turbines, with greater consistency than manual methods. These systems operate in dangerous environments where human inspection would be costly or hazardous. The technology detects equipment degradation and potential failure points that ground-based inspections often miss.

Exelon’s AI-powered drone program inspects transmission lines and substations, reducing timeframes from weeks to days. The system detects equipment problems that human inspectors typically miss during routine maintenance checks.

5. Retail Robots for Inventory Management

Inventory robots scan shelves continuously, monitoring stock levels and identifying pricing discrepancies without disrupting shopping activities. These autonomous systems process inventory data significantly faster than manual counting methods while providing real-time visibility into product placement. The technology enables store associates to focus on customer service rather than routine inventory tasks.

Walmart’s Bossa Nova robots patrol aisles during off-peak hours, providing instant inventory updates. The system identifies out-of-stock items, misplaced products, and pricing errors faster than traditional manual processes.

6. Intelligent Construction Equipment

AI-powered heavy machinery analyzes terrain conditions and adjusts operations automatically, optimizing fuel consumption and operational efficiency. These systems coordinate with other equipment on construction sites while enabling remote operation capabilities. Use cases of Physical AI in business include predictive maintenance and automated project coordination that reduce operational conflicts.

Caterpillar’s smart bulldozers and excavators reduce fuel consumption by 15-20% through intelligent terrain analysis. The machines can operate remotely from thousands of miles away while coordinating complex excavation projects.

7. Autonomous Cleaning Robots in Commercial Spaces

Commercial cleaning robots operate independently in large facilities, mapping layouts and adjusting cleaning intensity based on usage patterns. These systems maintain consistent hygiene standards across airports, hospitals, and shopping centers without human supervision. The technology proves particularly valuable in healthcare environments where cleanliness directly impacts patient safety outcomes.

Procter & Gamble’s cleaning robots utilize Swiffer and Mr. Clean solutions in healthcare facilities. Hospital administrators report decreased infection rates in areas where these robots maintain regular cleaning schedules.

8. Security and Surveillance Robots

Autonomous patrol robots use facial recognition and behavioral analysis to monitor large facilities continuously without human fatigue limitations. These systems distinguish between authorized personnel and potential security threats while coordinating with human security teams. The technology operates effectively in conditions where human guards would face safety risks.

Alphabet’s X Moonshot Factory has developed patrol robots with advanced perception systems for facility monitoring. Examples of Physical AI applications include threat detection and automated alerting that enhance comprehensive security coverage.

9. Robotic Exoskeletons for Rehabilitation and Labor Support

Exoskeleton technology assists workers performing physically demanding tasks while helping patients recover from injuries through movement assistance. These systems use AI to predict user movements and provide support precisely when needed. The technology adapts to individual patterns and requirements, reducing fatigue while improving safety conditions.

Ford’s EksoVest system supports assembly-line workers during overhead tasks, reducing fatigue by 60%. Workers wearing these exoskeletons can perform demanding tasks significantly longer without experiencing strain or injury.

10. AI-Powered Drones in Agriculture

Agricultural drones monitor crop health across thousands of acres, identifying pest infestations and irrigation problems weeks before human detection becomes possible. These AI-powered drones analyze soil conditions and assess irrigation requirements with precision that surpasses traditional farming methods. Modern precision agriculture reduces chemical usage while improving yields through targeted interventions based on real-time field analysis.

John Deere’s drone integration enables farmers to reduce chemical usage by 30-40% while improving crop yields. The technology identifies problems across vast acreage in hours rather than days of manual inspection.

Make your business a game-changer and be the next use case in Physical AI implementation

Challenges in Implementing Physical AI and Solutions and How to Overcome Them

Physical AI has the potential to revolutionize business, but there are ethical, financial, and technical challenges in putting it into practice. Businesses can implement AI-powered systems that are more intelligent, secure, and scalable by comprehending these issues and how to resolve them.

Exorbitant Upfront Expenses

Challenge: Robotics, edge devices, AI software, and related infrastructure frequently require large capital expenditures for the deployment of Physical AI systems. This could be a problem, especially for small businesses.

Solution:

- Begin with focused pilot projects in fields with high return on investment (e.g., quality inspection or warehouse automation).

- Make use of government innovation grants, robotics-as-a-service (RaaS) models, or leasing.

- Scale gradually after performance and cost-effectiveness have been confirmed.

Data Privacy & Security Challenge

Visual, biometric, and location-based inputs are just a few of the enormous volumes of real-world data that Physical AI systems gather. This raises issues with privacy and compliance, particularly in light of regulations like GDPR and HIPAA.

Solution:

- Utilize edge AI and on-device processing to minimize data exposure and lessen dependency on cloud storage.

- Put in place access controls, end-to-end encryption, and real-time AI device monitoring.

- Create a data governance plan that complies with legal and moral requirements.

System Complexity and Integration Issues

It can be technically challenging to integrate AI-powered devices with legacy IoT platforms, ERP, or MES. Add to this the difficulty of educating staff members who are not familiar with robotics or AI.

Solution:

- Select systems that are proven to be interoperable, modular, and API-friendly.

- Collaborate with suppliers who provide thorough documentation, training, and support.

- Form cross-functional teams (HR, operations, and IT) to oversee adoption and implementation.

Maintenance and Technical Support

Physical AI systems, in contrast to traditional software, frequently have mechanical components and moving parts that need constant calibration and maintenance. As conditions or variables change, AI models might also require frequent retraining.

Solution:

- Schedule preventive maintenance and collaborate with suppliers of predictive diagnostics.

- Invest in internal teams that can troubleshoot at the software and mechanical levels.

- To model performance problems before they arise in the real world, use digital twins.

Ethical Implications and Workforce Displacement

There are justifiable worries about social justice and job displacement when physical tasks are automated. Employees may lack the skills needed to work with intelligent systems, or they may be afraid of being replaced.

Solution:

- Combine automation with human augmentation and reskilling techniques, like teaching staff members how to operate and maintain robotic equipment.

- AI should be used to supplement human labor, not to replace it. For example, in manufacturing, robotic exoskeletons can lessen worker fatigue without taking away their function.

- Engage teams in conversations about innovation and communicate openly with them.

Step Into the Future of Physical AI With Appinventiv

Physical AI has reached a turning point. Companies are building robots powered by actual biological muscle tissue. Others are developing machines that recognize human emotions and respond accordingly. Meanwhile, autonomous systems are already being deployed for deep-sea research and space missions that would be impossible for human crews.

What makes this particularly interesting is the convergence of several breakthrough technologies. Self-repairing materials can now fix damage automatically. Swarm robotics allows hundreds of small robots to coordinate complex tasks. Edge AI processes data locally instead of relying on remote servers, which dramatically improves response times.

As a reputed AI development services company, Appinventiv integrates this transformative technology shift into every project—shaping smarter, more future-ready solutions. Our experts worked on a budget management application, Mudra, an innovative budget management tool with chatbot feature, formulated to simplify personal finance problems.

Following the intensive six-month work on the design and development, the platform was launched in 12+ countries. Being interactive and easy to use, Mudra is reconstructing the concept of user engagement in the FinTech world and establishing a new standard of digital budgeting.

Another project we worked on is JobGet which uses real-time algorithms to connect employers with candidates faster than traditional methods. Both projects required us to move beyond theoretical concepts and focus on measurable business outcomes.

The applications of advanced AI extend well beyond these examples. Throughout the last decade, we worked with organizations ready to implement these advanced AI solutions now rather than waiting for some distant future. The infrastructure exists today, and early adopters are already seeing competitive advantages.

The question isn’t whether Physical AI will transform industries—it’s happening. The question is whether your organization will lead this transformation or follow others who acted sooner. Get in touch with our AI consulting services experts to discuss your project idea!

FAQs

Q. How is Physical AI transforming industries?

A. By combining intelligent algorithms with physical systems like robots, drones, and sensors, physical artificial intelligence is revolutionizing a number of industries. It increases efficiency, safety, and innovation across industries by automating tasks, improving real-time decision-making, lowering operational risks, and improving precision.

Q. What are the key benefits of Physical AI?

A. Some of the key advantages of using Physical AI in business include:

- Enhanced effectiveness of operations

- Increased accuracy and safety

- 24/7 self-sufficient operations

- Analyzing data in real time

- Scalability between sites

- Decreased human error

Q. How is Physical AI applied in real-world scenarios?

A. Applications such as AI-powered drones in agriculture, autonomous warehouse robots, surgical robots in healthcare, and utility inspection bots are Physical AI examples. These systems perform complex tasks with little assistance from humans by combining perception, learning, and action.

Q. What industries benefit from Physical AI use cases?

A. Physical AI benefits a plethora of industries, streamlining their processes and ensuring high-quality production outputs. Here are some of the top use cases:

Manufacturing: Smart robotics, predictive maintenance, and high-precision quality control are some of the ways that Physical AI in manufacturing and automation streamlines output.

Healthcare: Through intelligent assistance, surgical robotics, remote diagnostics, and better patient outcomes are made possible by Physical AI for healthcare and medical applications.

Agriculture: Precision farming methods increase yields, automate irrigation, and monitor crop health with AI-powered drones and equipment.

Retail: To increase in-store productivity, autonomous robots manage customer service, inventory checks, and checkout automation.

Construction: AI-enabled equipment speeds up project timelines, increases operational precision, and improves site safety.

Logistics and Supply Chain: Using autonomous systems, Physical AI for logistics and supply chain maximizes last-mile delivery, real-time inventory tracking, and warehouse automation.

Energy and Utilities: Predictive analytics and robotic inspection systems reduce operational risks and improve infrastructure dependability.

Aerospace and Defense: In remote and high-risk settings, Physical AI facilitates automated maintenance, mission-critical inspections, and decision support.

Q. How does Physical AI revolutionize manufacturing?

A. Physical AI makes smart automation in manufacturing possible with AI vision systems, collaborative robots, and predictive maintenance. It makes production lines more flexible, lowers downtime, and improves quality control, which results in quicker and more economical operations.

Q. How does Physical AI enhance customer experiences?

A. By facilitating quicker service, more individualized interactions, and error-free operations, Physical AI improves customer experiences. It drives automated checkout processes that expedite the customer journey, precise deliveries, and intelligent inventory in retail and logistics.

Q. What are the best examples of Physical AI in action?

A. Here are some of the top real-life applications of Physical AI in action:

- Amazon’s autonomous delivery robots

- John Deere’s AI-enabled tractors

- Tesla’s AI-powered manufacturing robots

- Ford’s use of robotic exoskeletons

- Walmart’s inventory-scanning robots

- GE’s AI drones for infrastructure inspection

Q. What is the difference between agentic AI and Physical AI?

A. The major distinction between agentic AI vs Physical AI is their perception-agentic AI is used to make independent decisions in virtual worlds, whereas Physical AI engages the physical world to reach the actual world through intelligent robotic and smart machines.

Q. How does Physical AI drive RoI across industries?

A. The ROI gained through Physical AI is attributed to automation of manual operations, lowered operational expenses, enhanced output, and fewer mistakes. Faster throughput, predictive maintenance, and improvement of efficiencies are beneficial to industries such as manufacturing, logistics, and healthcare.

Physical AI also reduces the production cycle, enhances quality, and maximizes asset utilization by enabling 24/7 operations and being able to make decisions in real-time, resulting in financial returns that can be measured across the spectrum.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How to Build an AI Copilot for Enterprises? Process, Costs, and Features

Key takeaways: Strategic Planning: Define target use cases, user personas, and pain points to align Enterprise AI Copilot development with business goals. Feature Design: Incorporate context-awareness, anticipatory help, and actionable interfaces for intuitive, high-value AI Copilot functionality. Technical Foundation: Select robust LLMs, implement RAG, and build a secure, scalable AI stack for seamless enterprise integration.…

How AI Agents Are Revolutionizing Fraud Detection in Financial Services

Key takeaways: AI agents are shaking up fraud detection, moving past old rule systems to offer smart, self-learning capabilities. The U.S. Treasury's proven success in preventing significant fraud shows what AI agents in fraud detection can do. AI agents in financial fraud detection are super fast, accurate, and always getting better. This makes them vital…

How Agentic AI is Revolutionizing the Financial Sector: A Deep Dive for the C-Suite

Key takeaways: Enhanced Efficiency: Agentic AI automates complex tasks, saving up to 90% time. Real-Time Decisions: Adapts instantly to market changes and fraud threats. Hyper-Personalization: Delivers tailored customer experiences 24/7. Proactive Compliance: Reduces risks with automated regulatory tracking. New Revenue Streams: Unlocks innovative business models for growth. The financial services industry has been under pressure…