- Understanding How Manufacturing ERP Works

- Key Types of ERP Manufacturing Software

- Choosing the Right ERP Deployment Strategy

- Cloud ERP

- On-Premise ERP

- Hybrid ERP

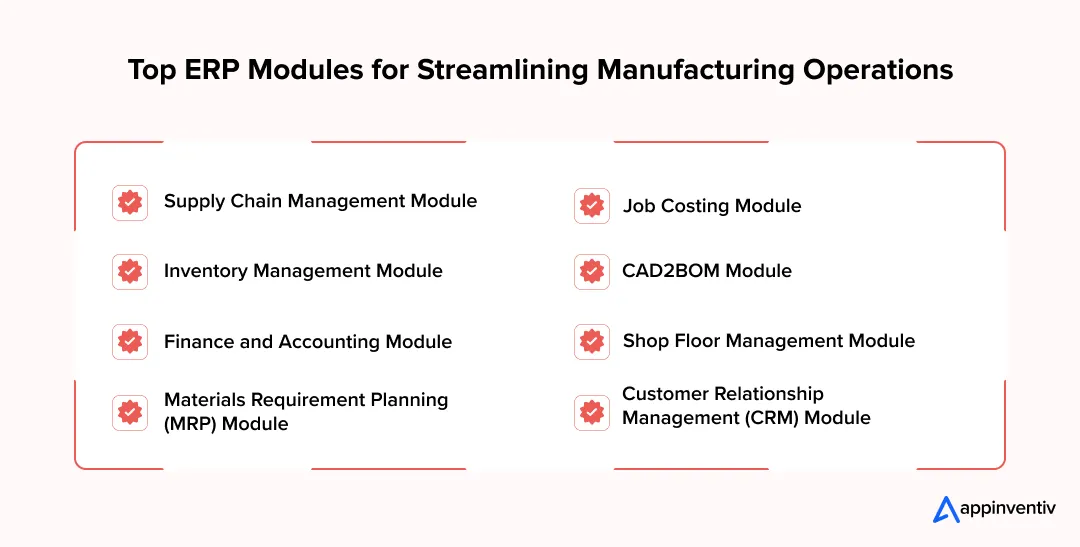

- Key ERP Modules to Optimize Manufacturing Operations

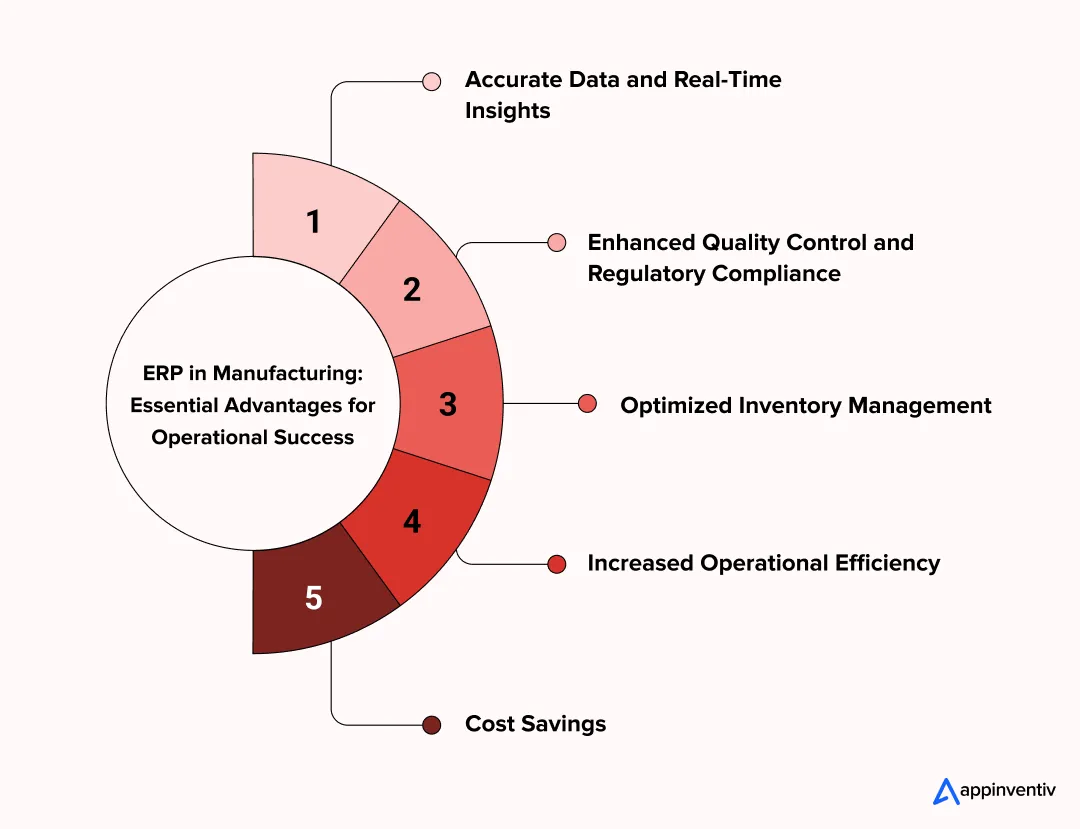

- Benefits of Implementing ERP in Manufacturing Processes

- Accurate Data and Real-Time Insights

- Enhanced Quality Control and Regulatory Compliance

- Optimized Inventory Management

- Increased Operational Efficiency

- Cost Savings

- Key Features of Manufacturing ERP Systems

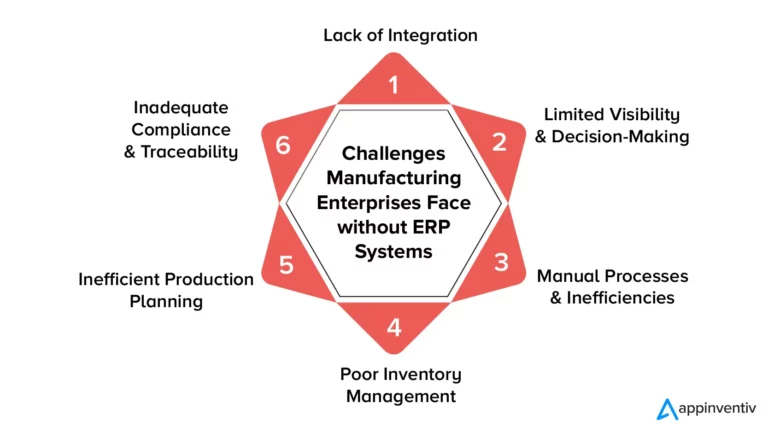

- The Challenges Manufacturing Enterprises Face without ERP Systems

- Lack of Integration

- Limited Visibility and Decision-Making

- Manual Processes and Inefficiencies

- Poor Inventory Management

- Inefficient Production Planning

- Inadequate Compliance and Traceability

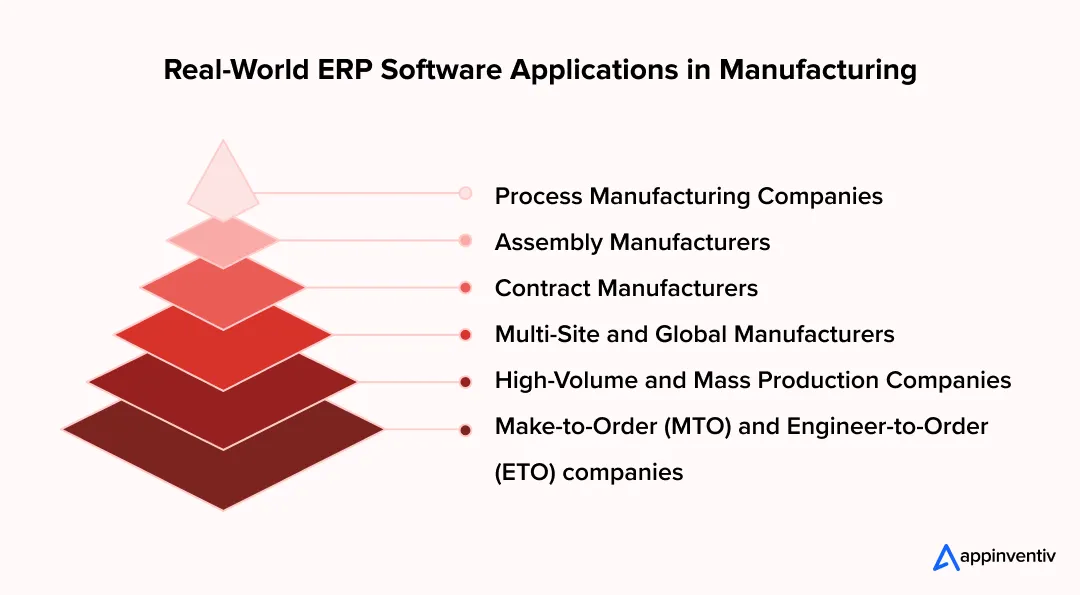

- ERP Software in Manufacturing: Real-World Applications Across Key Sectors

- Process Manufacturing Companies

- Assembly Manufacturers

- Make-to-Order (MTO) and Engineer-to-Order (ETO) companies

- High-Volume and Mass Production Companies

- Multi-Site and Global Manufacturers

- Contract Manufacturers

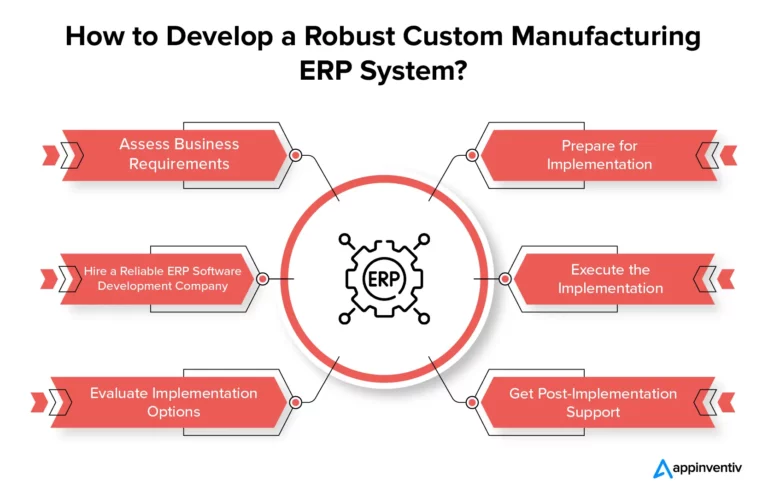

- How Can Businesses Develop a Robust Custom Manufacturing ERP System?

- Assess Business Requirements

- Hire a Reliable ERP Software Development Firm

- Evaluate Implementation Options

- Prepare for Implementation

- Execute the Implementation

- Get Post-Implementation Support

- Manufacturing ERP Software Development Cost

- Factors Affecting the Cost of ERP Software Manufacturing

- How Can Appinventiv Help to Mitigate These Challenges?

- Data Migration Excellence

- Development and Integration Proficiency

- Process Customization

- Initiate Your ERP Manufacturing Software Development Journey Today

- FAQs

Key Takeaways

- The ERP software manufacturing centralizes and integrates the key business operations, resulting in increased operational efficiency and simplified working processes.

- Tailored ERP systems provide manufacturers with real-time data visibility, routinely automate processes, and achieve significant savings in manual performance and costs.

- A proper combination of ERP modules and the correct deployment strategy: cloud, on-premise, or hybrid-based will be the key to making sure that the system fits your business needs and allows the business to grow in the future.

- A powerful ERP system can improve regulation standards, product control, and decision-making, ultimately bringing more profitability and success to manufacturing companies in the long term.

Modern manufacturing operates within an intricate and highly dynamic environment. Think about it: you’ve got this vast web of production lines, plus all the suppliers, and huge inventory systems. To oversee intricate workflows effectively, you need a solution that unifies operations and delivers immediate insights.

This is exactly what ERP systems do. They take production, the supply chain, inventory, finance, and logistics, everything, and integrate it all into one connected platform.

Take Toyota, for instance. Their ERP system monitors every component across a vast global network, ensuring that each part, from large engines to the smallest fasteners, is available precisely when needed. This level of operational control underscores why ERP systems are indispensable in modern manufacturing.

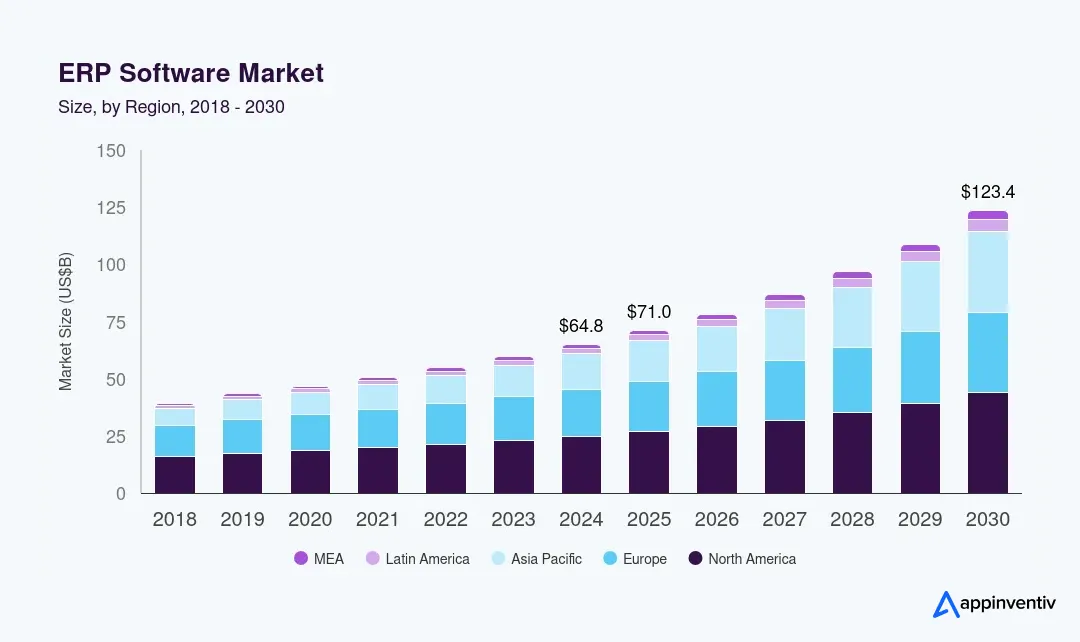

The global ERP software market has witnessed significant growth in recent years. By 2032, its market size will reach an impressive valuation of $123.41 billion, growing at a CAGR of 11.7% from 2025 to 2030 (Source: GVR). This data highlights the increasing recognition and adoption of ERP systems, particularly within the manufacturing industry.

This is enhanced by the fact that there is a growing demand for data-driven decision-making and streamlined operations in different industries. The ERP system makes the intricate processes come together into one system, allowing the real-time sharing and analysis of data, which makes the process more efficient and effective in decision-making.

ERP systems especially come in handy in manufacturing. They enable the combination of production, inventory, and supply management, which contributes to the rise in operational efficiency and responsiveness. The emergence of Industry 4.0, which involves intelligent production and computerization, has only increased the pace of using ERP in this industry.

So, here in this blog, we will explore how ERP for manufacturing enterprises enhances operations and boosts efficiency. It delves into the key manufacturing ERP software features and functionalities designed specifically for the manufacturing sector.

But first, let’s start with the basics!

Step into the future of manufacturing with ERP software that provides complete operational oversight and boosts productivity

Understanding How Manufacturing ERP Works

Manufacturing ERP (Enterprise Resource Planning) constitutes a specialized software system devised exclusively to cater to the requirements and complexities of the manufacturing industry. It encompasses an all-inclusive suite of integrated applications and modules that empower manufacturers with efficient management and optimization of their operations. Manufacturing resource planning software development encompasses a range of functionalities and features designed to meet the unique requirements of manufacturing processes.

ERP solutions for manufacturing seamlessly integrates diverse aspects of a manufacturing enterprise, including production planning, inventory management, supply chain management, shop floor control, quality control, financial management, and more. By consolidating these functions within a centralized system, manufacturing ERP software solutions facilitate smooth data flow and efficient coordination across departments.

Key Types of ERP Manufacturing Software

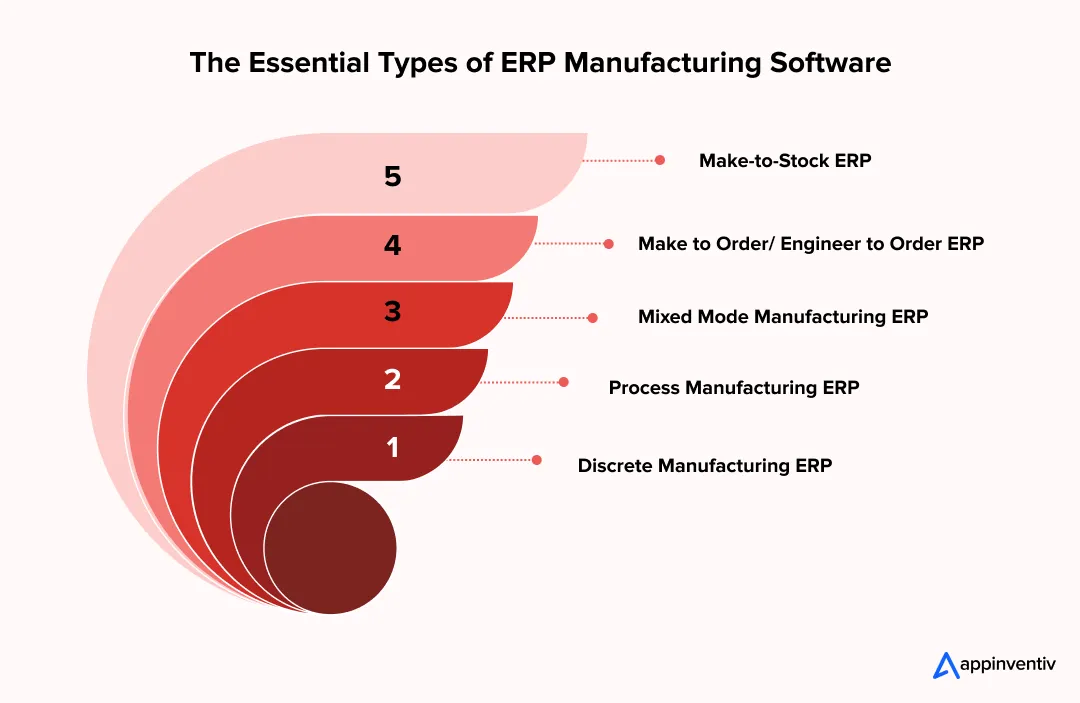

ERP systems are manufactured in a variety of types that are meant to cover particular workflows and the needs of production. For discrete to process manufacturing, the appropriate system to choose can be used to simplify operations and improve the overall efficiency. Here are some of its key types:

- Discrete Manufacturing ERP: Discrete manufacturing ERP is customized to the needs of industries that make discrete products, such as electronics, vehicle parts, or equipment. Such systems are involved in work orders, assembly lines, and elaborate Bills of Materials (BOMs).

- Process Manufacturing ERP: These ERPs are ideal in the industries where recipes and formulas are required (food, chemicals, pharmaceuticals), with the primary emphasis on batch production, compliance, and quality control.

- Mixed Mode Manufacturing ERP: Theoretical to manufacturers who employ discrete and process approaches, it is ideal for those companies that have varying production requirements or hybrid workflows.

- Make to Order/ Engineer to Order ERP: Designed as custom and project-oriented manufacturing systems, they facilitate personalized products and complex specifications and an engineering-oriented production cycle.

- Make-to-Stock ERP: Most suited to manufacturers that make products depending on demand predictions, this form of ERP is aimed at planning inventory, scheduling, and optimizing production efficiency.

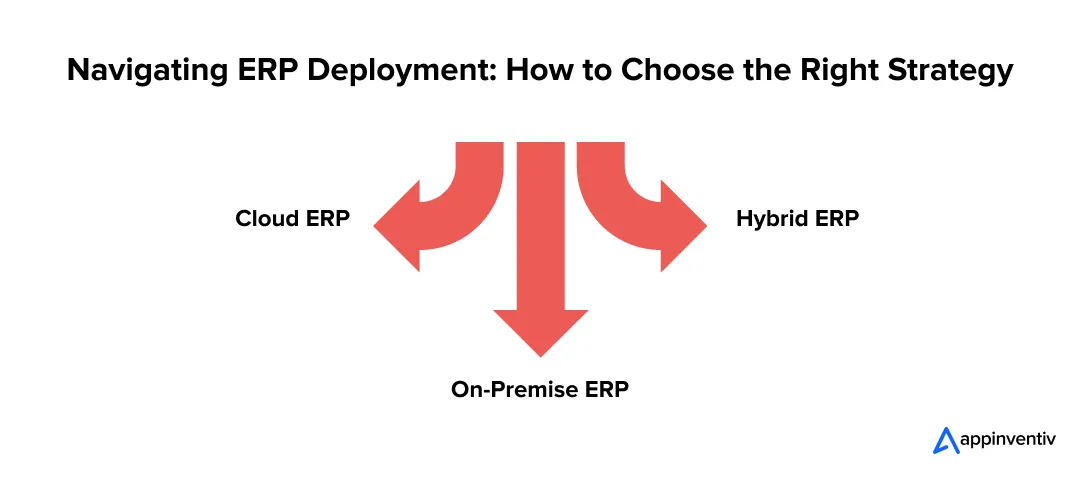

Choosing the Right ERP Deployment Strategy

The correct ERP deployment method is a significant step in the success of the implementation. They have their own advantages and factors to be considered, based on the size, objectives, and technology of your organization. Let’s have a look at those.

Cloud ERP

ERP solutions are integrated in the cloud, hence are flexible and scalable, and businesses can access their systems remotely. This cloud ERP implementation approach will save the expense of on-premise architecture and give businesses real-time data, automatic updates, and increased collaboration among teams.

On-Premise ERP

On-premise ERP deployment provides full power of control over data and system customization, which makes it optimal for businesses that need a custom approach. Through this approach, organizations will be able to control their server and security and adhere to the rigid rules and individual business requirements.

Hybrid ERP

The hybrid ERP integration offers the benefits of both cloud and on-premise solutions, allowing businesses to store important information and functionality locally while leveraging cloud capabilities for scalability and cost-effectiveness. This model offers a flexible approach and is very suitable for organizations that want to have balanced data management and performance of the system.

Key ERP Modules to Optimize Manufacturing Operations

ERP systems assist manufacturers in simplifying operations and streamlining resources and real-time visibility throughout the chain of production processes. Based on the manufacturing ERP software development, the business will be able to deploy solutions that suit its operational requirements. Significant modules that provide optimal impact are:

Materials Requirement Planning (MRP) Module: This module is used to manage the manufacturing software systems; to calculate the exact required materials needed, schedule production, bill of materials, stock, machine capacity, AI-based demand forecasting, and quality assurance, increasing efficiency and minimizing costs.

Inventory Management Module: It is one of the basic modules of any ERP system of manufacturing, which allows monitoring of stock in more than one location, tracking of inventory up to their serial numbers, and making sure they are at the right time and place required. This will avoid any interruptions in production and enhance general inventory management.

Finance and Accounting Module: It is a component of ERP solutions that deals with multi-company, multi-currency accounting and operations that are integrated with manufacturing. Real-time dashboards minimize reconciliation activities, simplify reporting, and give complete financial visibility.

Shop Floor Management Module: This is a crucial aspect of manufacturing ERP software development because it integrates the shop floor with the operations, tracks real-time production, and allows improved coordination, task control, and paperless operations.

Supply Chain Management Module: This module is developed in conjunction with the manufacturing ERP software development. It will handle the relationship with suppliers, purchase orders, and performance of the vendor within one system. The efficiency of purchasing and procurement methods will guarantee that materials are available at the right time, thereby minimizing the time and expenses.

Job Costing Module: ERP solutions are used in manufacturing; therefore, this module saves real-time operation, project, and job costs, analyzing them to obtain accurate job cost calculations for budgeting, pricing, and profitability analysis.

CAD2BOM Module: Automates the process of transferring Bills of Materials (BOMs) in CAD systems to manufacturing software systems and removes manual entry and errors. CAD modification in ERP automatically changes, which saves time on the engineering side and enhances accuracy.

Customer Relationship Management (CRM) Module: Manufacturing CRM integration is a part of manufacturing software systems that deals with customer data, leads, opportunities, and marketing campaigns, enhancing communication and reinforcement of client relationships.

Benefits of Implementing ERP in Manufacturing Processes

Implementing ERP systems in manufacturing streamlines operations, enhances data accuracy, and improves overall efficiency. Implementation of ERP in manufacturing processes offers a series of benefits, including:

Accurate Data and Real-Time Insights

Centralizing data within an ERP system ensures consistent and precise information across the organization. This provides real-time access to critical data, enhancing decision-making, improving forecasts, and allowing for better monitoring of production performance.

Enhanced Quality Control and Regulatory Compliance

ERP systems include comprehensive quality management features that monitor and control production processes. They ensure compliance with industry standards and regulations, support traceability, and help maintain high quality and regulatory adherence.

Optimized Inventory Management

ERP solutions offer advanced inventory management capabilities, including real-time stock tracking, automatic reorder points, and demand forecasting. This helps balance inventory levels, minimize overstock and shortages, and enhance the efficiency of the supply chain.

Increased Operational Efficiency

ERP systems automate and integrate key manufacturing functions such as order processing, production planning, and supply chain management. This reduces manual tasks, speeds up workflows, and reduces errors, ultimately boosting overall productivity and operational efficiency.

Cost Savings

ERP systems contribute to significant cost reductions by streamlining processes and managing resources more effectively. They reduce redundancies, decrease manual effort, and optimize resource use, leading to lower operational costs and improved profitability.

Key Features of Manufacturing ERP Systems

Manufacturing ERP systems are aimed at simplifying operations, enhancing productivity, and giving real-time visibility of the whole production process. Key features include:

Production Planning and Scheduling: Optimization of resources, production schedule, and product delivery on time.

Inventory and Warehouse Management: Trace raw materials, work-in-progress, and finished goods at several locations to minimize stockouts and stock.

Supply Chain Management: Manage the procurement, vendor performance, and logistics to ensure that the operations run smoothly and reduce delays.

Quality Control: Keep an eye on the quality of the production, trace defects, and adhere to the industry standards.

Finance and Accounting Integration: Budgets, costs, and financial reporting can be managed in real time to provide full operational management.

Shop Floor Management: Link the production floor with the management systems, monitor the progress, and enhance the productivity of the workforce.

CRM Customer Relationship Management: Control the leads, customers, and marketing campaigns to enhance client relationships.

Job Costing and Analytics: Monitor operations and project costs, performance, and aid in decision-making.

The Challenges Manufacturing Enterprises Face without ERP Systems

Manufacturing without the use of ERP solutions can create various difficulties that hinder operational efficiency and overall business success. Some of the significant challenges worth noting include:

Lack of Integration

Manufacturers often face difficulties due to a lack of integration in their operations. Without an ERP system, they resort to using separate systems for different functions like production planning, inventory management, and financials.

As a consequence, data silos are formed, leading to manual data entry and ineffective communication between departments. The use of ERP for manufacturing industry results in errors, delays, and reduced visibility into overall operations.

Limited Visibility and Decision-Making

In manufacturing operations, a significant amount of data is generated from various sources. However, without an ERP solution, accessing and analyzing this data can be time-consuming and challenging.

Manufacturers often face difficulties obtaining real-time visibility into crucial information like inventory levels, production status, and financial performance. As a result, making informed decisions becomes hindered and responding promptly to changing customer demands or market conditions becomes difficult.

Manual Processes and Inefficiencies

In manufacturing environments where ERP solutions are absent, manual processes and paper-based systems prevail. These outdated methods are prone to errors, consume a significant amount of time, and rely heavily on paperwork.

Consequently, they give rise to inefficiencies, delays, and increased administrative costs. Moreover, the reliance on manual processes obstructs opportunities for automation and hampers the effective scaling of operations.

Poor Inventory Management

When manufacturers don’t have an integrated ERP system, they encounter difficulties in effectively managing their manufacturing inventory. This leads to inaccurately tracked inventory levels, resulting in either stockouts or excess inventory. Moreover, the absence of real-time visibility into inventory can cause production delays, increased carrying costs, and missed sales opportunities.

Inefficient Production Planning

Manufacturing companies that do not employ ERP solutions for operations often face challenges with inefficient production planning and scheduling. In the absence of a centralized system, coordinating production activities becomes arduous, leading to suboptimal resource allocation, extended lead times, and increased costs.

Inadequate Compliance and Traceability

Inadequate compliance and traceability pose significant challenges for businesses that do not utilize an ERP system. Without this system in place, the task of tracking and documenting quality control measures, managing regulatory requirements, and ensuring product traceability becomes manual and prone to errors. This raises concerns about potential non-compliance issues and customer dissatisfaction for manufacturers.

ERP Software in Manufacturing: Real-World Applications Across Key Sectors

ERP software for manufacturing enterprises plays a crucial role in supporting companies across diverse sectors involved in manufacturing operations. There are several types of companies that can experience significant advantages of ERP-based manufacturing software development. These include:

Process Manufacturing Companies

Manufacturing ERP software simplifies the management for process manufacturers. Process manufacturing ERP software helps them handle complex recipes/formulations, track batch production, maintain quality control standards, ensure compliance with regulations, manage ingredient traceability, and optimize production schedules. Additionally, it offers assistance with inventory management, supplier management, and financial control.

For example, the COFCO Coca-Cola company, a prominent player in the beverage industry, relies on SAP ERP Central Component (ECC) for its manufacturing operations. This comprehensive suite of core components enables Coca-Cola to manage various aspects of its business efficiently.

From financial management and sales, to production planning and human resources, these components ensure seamless coordination across departments and enhance productivity. By leveraging the capabilities of ERP, Coca-Cola streamlines operations and ensures the delivery of high-quality products and services to its customers.

Assembly Manufacturers

Manufacturing ERP systems offer a multitude of benefits to assembly manufacturers. One notable example is Boeing, a renowned aerospace company, which harnessed the power of manufacturing ERP software to streamline their intricate production processes.

Given the complex nature of their assembly lines and the vast number of components involved, Boeing recognized the need for a robust ERP system to optimize inventory management, track production schedules with precision, and ensure timely deliveries of their aircraft.

Boeing uses SAP ERP to manage its complicated aircraft assembly lines. The system helps manage the inventory, handle production schedules, and coordinate all the sub-assemblies. All that is crucial for hitting delivery deadlines and maintaining their high-quality standards. Look, even with the occasional issue, Boeing’s ERP is vital for handling parts and inventory for planes like the 737 and the 787.

Make-to-Order (MTO) and Engineer-to-Order (ETO) companies

Manufacturing ERP software development provides comprehensive support to MTO and ETO companies. It effectively manages customer orders, tracks project timelines, coordinates production activities, handles engineering changes, and facilitates seamless communication across departments. By optimizing production resources and handling supply chain complexities, this software ensures the on-time delivery of customized products.

Siemens offers powerful ERP and PLM-integrated solutions specifically for Engineer-to-Order (ETO) manufacturing. This whole system helps companies design and build products that are perfectly tailored to whatever the customer asks for.

Their platform essentially makes production planning much smoother. It efficiently handles engineering changes (which always happen in ETO!) and ensures every department is coordinated perfectly. By tracking those complex workflows and optimizing resources, Siemens helps ETO manufacturers do two things: deliver customized products on time and keep that quality high.

High-Volume and Mass Production Companies

Manufacturing ERP software supports high-volume and mass-production companies by assisting in various essential functions. These include production scheduling, capacity planning, demand forecasting, material requirements planning, quality control, and lean manufacturing practices.

By leveraging these capabilities, the software enables businesses to reduce production costs, enhance productivity levels, maintain consistent product quality standards, and achieve economies of scale.

Toyota recently implemented SAP S/4HANA to make its massive global supply chain work better. The system allows them to track logistics in real time. It also centralizes the management of master data and gives them much better reporting. This has made operations across their European sites a lot more efficient. Plus, this entire setup is now being used as a model for their operations worldwide.

Multi-Site and Global Manufacturers

Manufacturing companies operating across multiple locations or on a global scale encounter various challenges in their operations, including managing facilities, coordinating activities, and ensuring data consistency. To tackle these complexities, the implementation of manufacturing ERP systems offers centralized control and real-time visibility throughout different locations, ultimately enhancing coordination and efficiency.

Nestlé decided to adopt SAP’s RISE cloud transformation to modernize their whole IT setup. This paid off big time. Their system availability jumped to an amazing 99.97%. They also cut IT downtime from six hours all the way down to just seven minutes, which obviously improved their business agility.

They moved from six data centers on-site to a unified, cloud-first SAP environment, which runs on Microsoft Azure. This simple move boosted scalability and overall resilience throughout their supply chain.

Contract Manufacturers

Manufacturing ERP software development helps contract manufacturers enhance operational efficiency. One notable example is Foxconn, a leading contract manufacturer in the electronic devices industry. They relied on robust manufacturing ERP solutions to effectively manage their contract manufacturing activities across various electronic devices.

These solutions offered comprehensive features such as handling multiple customers, tracking specific requirements for each customer, managing production orders, overseeing subcontracting activities, and providing valuable insights into cost analysis and profitability for individual contracts.

Foxconn, the electronics maker, brought in SAP S/4HANA to streamline its new electric vehicle (EV) manufacturing processes. The system made sure their business processes were consistent and really helped employees adopt the new methods. It basically supports the company’s expansion into the new EV sector. By bringing all their key operations together, Foxconn saw a solid 20% improvement in how they use resources. It also helped them clean up issues related to data quality, accuracy, and carrying too much inventory.

Leverage ERP software to streamline operations, boost efficiency, and set a new standard in your industry

How Can Businesses Develop a Robust Custom Manufacturing ERP System?

Building a custom manufacturing ERP system involves various critical steps. From assessing precise requirements to planning and executing the implementation, companies must pay heed to every step to build a successful ERP system.

Assess Business Requirements

To start, it is important to carefully assess your company’s specific needs and expectations in relation to a manufacturing ERP system. This evaluation should consider factors such as the size of operations, required functionalities, integration needs, and budget constraints.

Hire a Reliable ERP Software Development Firm

Before hiring an ERP development company for manufacturing, businesses should conduct a thorough investigation. This involves considering factors like the company’s track record, previous projects, industry experience, features, scalability options, customization opportunities, and support services.

Evaluate Implementation Options

When evaluating implementation options, one should consider different ERP deployment methods. These options comprise on-premises, cloud-based, or hybrid solutions. The choice depends on control, costs, scalability, and data security.

Prepare for Implementation

To ensure effective implementation, a collaborative effort between the business and the hired development firm is essential. The first step involves working together to develop a comprehensive plan that encompasses stakeholder engagement, project milestones, data migration, training initiatives, and change management processes.

Execute the Implementation

The implementation needs to be executed by following the detailed plan. It is essential to work closely with the ERP development company throughout the process, ensuring system configuration, data migration, training, testing, and integration with other systems are properly handled.

Get Post-Implementation Support

The process of executing the system and providing support after its implementation involves various stages. These include conducting final testing, launching the system, monitoring performance, getting ongoing support and training, addressing any arising issues, and establishing mechanisms for continuous improvement.

Also Read: ERP Software Integration: A Complete Guide

Manufacturing ERP Software Development Cost

The cost of developing an ERP software for manufacturing typically ranges from $50,000 to $500,000 and beyond, depending on the size, complexity, and degree of customization. To get a clearer estimate, analyze the table below that lists the costs, broken down by implementation complexity:

| Complexity Level | Features & Modules | Estimated Cost |

|---|---|---|

| Basic | Core modules like inventory management, finance, and production tracking | $50,000 – $100,000 |

| Medium | Adds MRP, supply chain management, CRM, and shop floor management | $100,000 – $250,000 |

| Advanced | Fully customized ERP software manufacturing solution with CAD2BOM integration, analytics, multi-location support, and extensive automation | $250,000 – $500,000+ |

Factors Affecting the Cost of ERP Software Manufacturing

Let’s have a detailed look at the factors that influence the cost of manufacturing ERP software development:

Number of Modules: More modules can be added, like MRP or CRM, which increases development and integration.

Customization: Adapting ERP to manufacturing industry processes and compliance requirements or workflows will increase the total investment.

System Integration: ERP integration with existing systems, such as CAD systems, IoT devices, or even third-party software, makes the process more complex.

Type of Deployment: On-premise solutions are more costly to deploy, but cloud-based ERP can be less expensive to deploy, although they require recurring subscription charges.

Implementation and Training: Training employees, migrating data, and managing changes will facilitate a smooth adoption and may affect the overall cost.

IT Advanced Capabilities: The use of AI in creating ERP software can increase predictive maintenance, demand forecasting, and operational efficiency, which influences the cost of development.

The initial cost invested in the appropriate ERP system is a strategic business choice as it guarantees long-term efficiency, improved decision-making, and calculable ROI.

Receive a personalized quote and align your budget with your operational goals.

How Can Appinventiv Help to Mitigate These Challenges?

Appinventiv, a leading custom manufacturing ERP software development services company, possesses the necessary expertise to address the challenges associated with building and implementing manufacturing ERP. Let’s explore how Appinventiv can assist in overcoming these hurdles:

Data Migration Excellence

Data migration expertise is a specialty of Appinventiv. We have proven proficiency in managing intricate data migration processes. With the utilization of robust methodologies and cutting-edge tools, we ensure a seamless and precise transfer of data from legacy systems to the new Manufacturing ERP. This approach minimizes disruptions and mitigates any potential issues with data integrity.

Development and Integration Proficiency

Appinventiv specializes in designing and developing ERP systems that seamlessly integrate with existing systems. With our extensive experience in developing interfaces and data exchange protocols, we ensure efficient integration with accounting software, inventory management systems, and CRM systems. This enables smooth data flow and seamless system interoperability.

Process Customization

Appinventiv recognizes the significance of aligning the ERP system with unique business processes. We demonstrate expertise in custom manufacturing ERP software to meet specific business requirements, effectively balancing standardization and flexibility.

For instance, one success story highlighting our capability is the ERP solution we built for IKEA. This ERP solution enables walk-in customers to access the store’s product catalogs right from store-erected tablet panels.

This two-fold solution not only offers customers an in-store catalog solution but also uses their information as a marketing asset. This level of customization helps businesses like IKEA streamline their operations and deliver a personalized experience to customers.

Initiate Your ERP Manufacturing Software Development Journey Today

Manufacturing ERP software development is crucial in the manufacturing industry. It helps streamline operations, maximize efficiency, and tackle challenges like resistance to change, data migration, integration issues, and more.

By hiring Appinventiv’s manufacturing IT services, businesses can optimize production planning, improve inventory management, enhance supply chain coordination, and boost operational efficiency. Ultimately, adopting ERP manufacturing software is vital for companies striving to remain competitive and achieve sustainable growth in today’s dynamic market.

Connect with our experts to develop a custom ERP solution now.

FAQs

Q. What is an ERP system in manufacturing?

A. In manufacturing, ERP software serves multiple purposes. It aids in production planning, inventory management, supply chain coordination, quality control, financial management, and overall operational streamlining. Its implementation leads to enhanced efficiency and productivity.

Q. How does ERP work in manufacturing?

A. ERP software in manufacturing operates by integrating different business functions into a centralized system. This centralization allows for real-time data sharing and analysis, streamlining processes, and facilitating efficient coordination across departments. The end result is improved productivity and better decision-making capabilities.

Q. How much does it cost to develop ERP for manufacturing?

A. The cost of developing an ERP software for manufacturing enterprises can vary significantly. Typically, it ranges from $20,000 to $350,000 or even more. It is crucial to note that the final price depends on various factors, including project complexity, required modules, and the location of the enterprise software development company. Connect with our experts to get precise cost estimates for your project.

Q. What is the difference between a manufacturing ERP and standard ERP?

A. A manufacturing ERP is tailored to the specific demands of production environments, focusing on areas like inventory control, production scheduling, and quality management. It integrates directly with manufacturing processes to enhance efficiency and resource use. Conversely, a standard ERP system provides general functionalities for diverse industries, including finance, HR, and sales, but may not include the specialized tools required for effective manufacturing management.

Q. How to develop ERP software for manufacturing?

A. ERP software development in manufacturing entails a number of steps that guarantee efficiency and scalability in the long run. Here’s how it’s done:

Define Objectives: Determine your production objectives, workflows, and special needs that are peculiar to your production.

Select Essential Modules: Select the core modules that are important to your business, like inventory management, production planning, finance, and supply chain management.

Develop Architecture: Develop an architecture that will facilitate scaling, security, and easy integration with other enterprise tools.

Adopt Technologies: Adopt modern ERP solutions for manufacturing with IoT connectivity, data analytics, and AI predictive tools, and real-time visibility.

Develop and Test: Create the ERP system, do performance and security testing, and make sure that all modules are functional within all departments.

Train and Deploy: Train the employees and implement the system in stages to create less disruption and facilitate an easy transition.

Monitor and Optimize: Keep on reviewing performance, collecting feedback, and testing module improvements to drive productivity and ROI.

Q. What is the ROI of ERP in manufacturing?

A. The ROI of implementing ERP for the manufacturing industry largely depends on how effectively it optimizes processes, improves data accuracy, and reduces manual effort. On average, manufacturers experience a reduction in operational costs by 10-25% and a reduction in production cycles, and an increase in inventory turnover within the initial year.

The system remains value-creating, over the years, with smarter resource utilization, data-driven decision-making, and more robust customer relationships, which is a primary pillar of sustainable growth and profitability.

Q. What are some of the top examples of ERP software?

A. Here are some of the best ERP software for manufacturing industry that streamlines processes and enhances efficiency and productivity:

- SAP S/4HANA: A robust, enterprise-grade ERP widely used in large-scale manufacturing.

- Oracle NetSuite: A flexible, cloud-based ERP suited for growing manufacturers.

- Microsoft Dynamics 365: Offers modular solutions for manufacturing, operations, and finance.

- Infor CloudSuite Industrial (SyteLine): Designed specifically for complex manufacturing needs.

- Epicor ERP: A strong choice for mid-sized manufacturers with industry-specific capabilities.

- Odoo: Odoo is an open-source ERP with customizable modules for manufacturing and inventory.

Q. What are some of the top uses of ERP for custom manufacturing?

A. Modern ERP solutions are critically important for custom manufacturers. Here are the key uses of ERP solutions for manufacturing businesses:

- Centralized Operations

- Tracking Materials and Resources

- Automated Scheduling

- Real-Time Visibility

- Customization Management

- Profitability Optimization

Q. How is AI transforming modern manufacturing ERP software?

A. Employing AI in manufacturing ERP software is transforming the way factories are operated by implementing predictive intelligence and automation in everyday activities. It facilitates proper demand forecast, simplified quality control in anomaly detection, and predictive maintenance that reduces downtime.

Resource allocation, equipment performance monitoring, and the identification of inefficiencies can be optimized with the help of AI-based analytics, making ERP systems more dynamic and promoting more intelligent, quicker, and more informed choices.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Oil and Gas ERP Software Development: Features, Benefits, Process, Integration and more

The oil and gas industry operates in a complex and volatile environment. It involves oil and gas exploration, extraction, drilling, production, and transportation. Consequently, the industry faces several challenges, such as fluctuating market demands, stringent regulatory requirements, and the constant pressure to reduce greenhouse gas emissions. Notably, oil and gas production, transport, and processing contribute…

Odoo Implementation Cost in 2026: Complete ERP Budget Breakdown

Key Takeaways Enterprise Odoo implementation typically ranges from $50K to $500K+, depending on scope. Integration and customization typically account for 45%–70% of the total implementation budget. Licensing scales per user, while complexity drives configuration and integration costs. Annual ownership averages 15%–25% of the initial implementation investment. Phased rollout and disciplined governance significantly reduce budget overruns.…

How ERP AI Chatbots Are Reshaping Enterprise Workflows

Key takeaways: ERP AI chatbots turn slow, manual ERP tasks into instant, automated actions. Real-time data, voice commands, and multi-system access make ERP chatbots a game changer. Leading brands like H&M, Unilever, and PepsiCo are already leveraging ERP AI chatbots. AI chatbots improve user adoption by simplifying complex ERP navigation. Challenges like integration, scalability, and…