- Types of Inventory Management Software

- 1. Basic Inventory Management Software

- 2. Advanced Inventory Control System Software

- 3. Inventory Management Software, Cloud-Based

- 4. Custom Inventory Management Systems

- 5. ERP Inventory Management Software

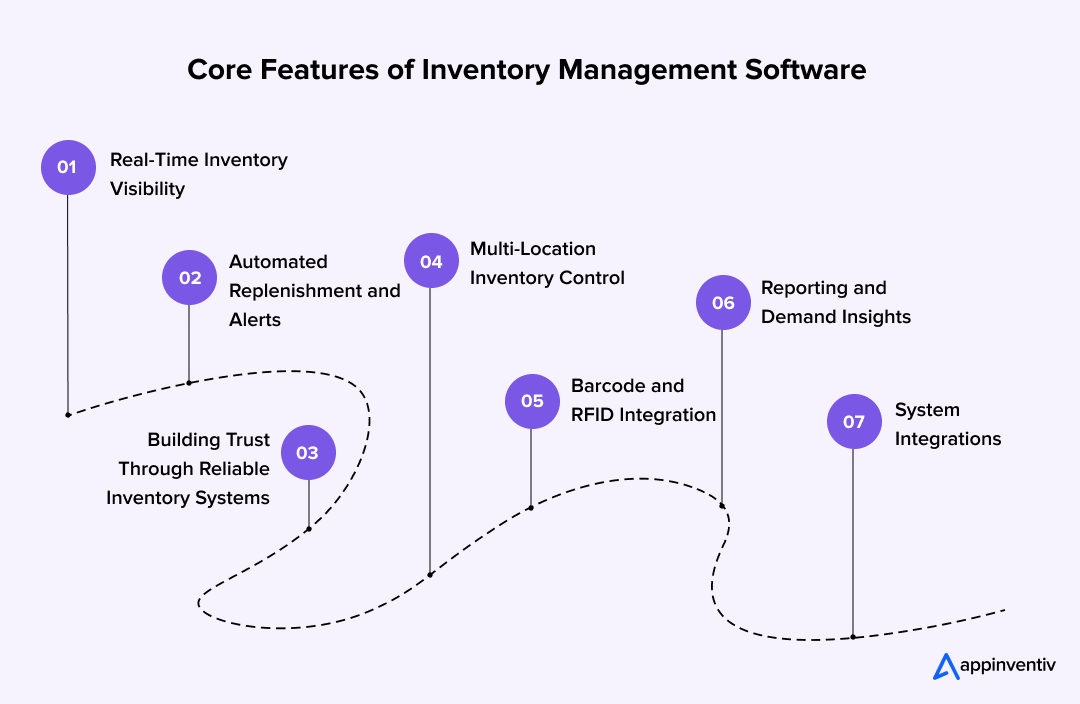

- Core Features of Inventory Management Software

- 1. Real-time inventory visibility

- 2. Automated replenishment and alerts

- 3. Multi-location inventory control

- 4. Barcode and RFID integration

- 5. Reporting and demand insights

- 6. System integrations

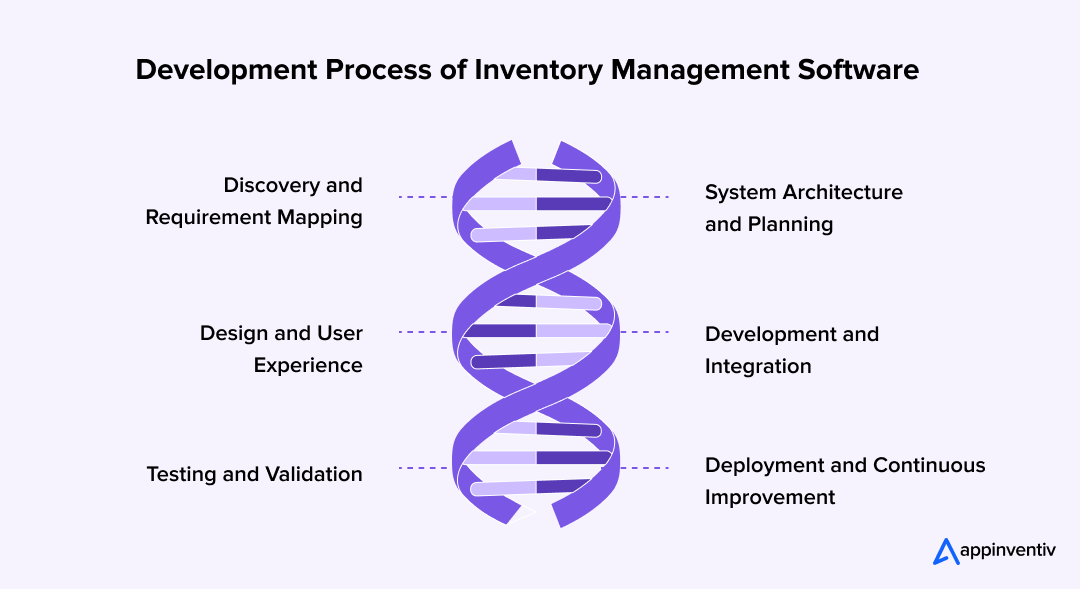

- Development Process of Inventory Management Software

- 1. Discovery and Requirement Mapping

- 2. System Architecture and Planning

- 3. Design and User Experience

- 4. Development and Integration

- 5. Testing and Validation

- 6. Deployment and Continuous Improvement

- Custom Inventory Management Tech Stack

- 1. Backend foundations

- 2. Frontend experience

- 3. Integrations and APIs

- 4. Security and access control

- Inventory Management Software Cost

- Advanced Technologies for Inventory Management

- 1. Predictive Analytics and Machine Learning

- 2. Internet of Things (IoT)

- 3. Blockchain for Traceability

- 4. RFID and Advanced Scanning

- 5. Cloud-native Architecture

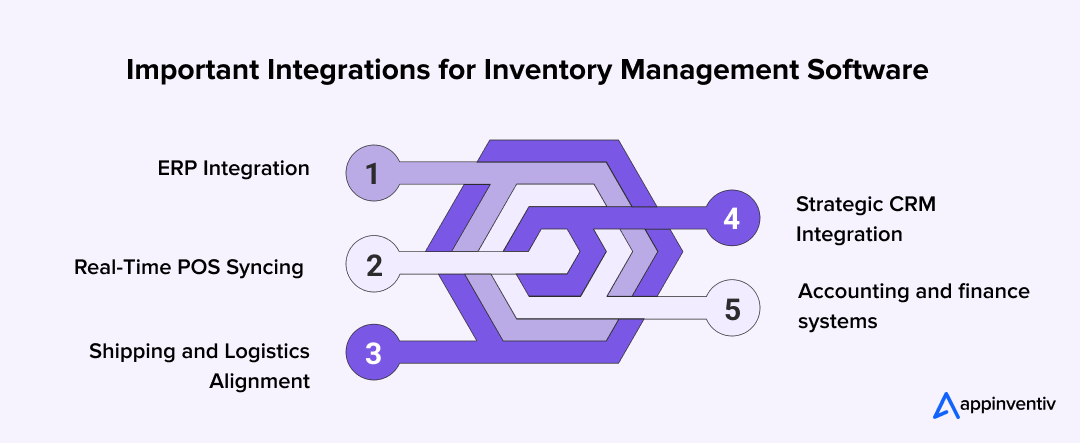

- Important Integrations for Inventory Management Software

- 1. ERP Integration

- 2. Real-Time POS Syncing

- 3. Shipping and Logistics Alignment

- 4. Strategic CRM Integration

- 5. Accounting and finance systems

- Benefits of Inventory Management Software

- 1. Stronger Operational Control

- 2. Lower Operational Costs

- 3. Fewer Errors, Higher Data Confidence

- 4. Improved Customer Reliability

- 5. Smarter Planning and Forecasting

- 6. Built-in Scalability

- Use Cases and Real-World Examples of Inventory Management Software

- 1. Retail: Keeping Products Available Without Guesswork

- 2. Manufacturing: Keeping Production Moving

- 3. E-commerce: Managing Inventory That Never Stops Moving

- 4. Food and Beverage: Reducing Waste While Staying Compliant

- 5. Healthcare: Making Sure Critical Supplies Are Available

- Common Challenges in Inventory Management and How to Tackle Them

- How Appinventiv Can Transform Your Inventory Management with Tailored Solutions

- FAQs

Key Takeaways

- Inventory problems usually come from disconnected systems, not a lack of data. The right software brings everything into one reliable view.

- Custom inventory management software scales with the business, while generic tools often break down as complexity grows.

- Real-time visibility and automation reduce stock errors, manual effort, and costly last-minute decisions.

- Cloud-based inventory systems make it easier to expand across locations without rebuilding infrastructure.

- When implemented correctly, inventory software becomes a quiet infrastructure that supports operations without constant oversight.

Inventory issues rarely announce themselves. They usually surface during a busy week when something small goes wrong. A reorder that didn’t trigger. A product that showed as available but wasn’t. A customer promise that suddenly became uncomfortable to explain. As businesses grow, these moments become more frequent, and they expose the limits of manual tracking and disconnected tools.

That shift is why inventory management software development is now seen as a business decision, not just an IT one. The global market is projected to reach USD 4.79 billion by 2032, growing at 9.6% annually, according to Fortune Business Insights. What’s driving that growth isn’t hype. It’s the reality that modern operations need visibility, accuracy, and real-time systems. More companies are choosing custom inventory management software development because generic platforms struggle to reflect how their supply chains actually operate.

This guide walks through what it takes to develop custom inventory management software that supports real-world complexity. You’ll learn about the types of inventory management software, the features that matter at scale, emerging technologies shaping inventory systems, real examples from global businesses, cost considerations, and the practical steps involved in building a solution that doesn’t break the moment your business expands.

With the global inventory management software market projected to reach USD 4.79 billion by 2032, enterprises that modernize early gain tighter control, lower risk, and better scalability.

Types of Inventory Management Software

Inventory management often feels under control until scale quietly changes the rules. Growth introduces more SKUs, more locations, and far less room for error. What once felt predictable starts demanding accuracy at a level most systems were never designed to handle. That’s usually when businesses start rethinking their tools and looking closely at the different types of inventory management software available.

There isn’t a single “best” option. The right choice depends on how complex your operations are today and how quickly they’re evolving.

1. Basic Inventory Management Software

This is often where businesses begin.

- Focuses on stock visibility and low-stock alerts

- Works well for small teams or single-location operations

- Keeps inventory software management simple without heavy setup

It’s ideal when the goal is control, not sophistication. You know what’s in stock, what’s moving, and when to reorder. Nothing more, nothing less.

2. Advanced Inventory Control System Software

As operations grow, manual checks do not scale.

- Supports multiple warehouses or stores

- Automates replenishment and stock transfers

- Adds reporting to highlight trends and slow-moving items

At this stage, many companies start to develop inventory management software solutions that align better with their supply chain automation instead of forcing teams to work around platform limitations.

3. Inventory Management Software, Cloud-Based

Cloud access changes how teams work together.

- Real-time updates across locations

- Remote access for managers and leadership

- Easier scaling without server maintenance

For distributed teams, cloud-based inventory management solutions remove delays and keep everyone working from the same numbers, regardless of location.

4. Custom Inventory Management Systems

Some businesses outgrow standard platforms altogether.

- Designed around specific workflows

- Handles complex approvals, compliance rules, or product logic

- Integrates deeply with internal systems

This is where companies choose to build customizable inventory management software or create an inventory management system tailored to how inventory actually moves through their organization.

5. ERP Inventory Management Software

For enterprises, inventory rarely operates alone.

- Connects inventory with finance, procurement, and sales

- Reduces data gaps between departments

- Improves forecasting and planning accuracy

When done right, ERP inventory management software becomes the backbone of broader inventory management development, keeping operations aligned as scale increases.

The takeaway is simple. Inventory software should quietly support growth, not slow it down. Choosing the right type early saves teams from constant fixes later and sets the foundation for long-term efficiency.

Also Read: 10 Ways to Unlock the Power of AI in Inventory Management

Core Features of Inventory Management Software

Inventory software should earn its place quietly. You don’t notice it when everything is working, but you feel it immediately when something breaks. The right system doesn’t just track stock. It removes friction from daily operations and gives teams confidence in the numbers they’re working with.

These are the inventory management system software features that actually matter once operations move beyond spreadsheets.

1. Real-time inventory visibility

Decisions fall apart when data lags behind reality.

- Live stock updates across warehouses and stores

- Clear view of what’s available, reserved, or in transit

- Fewer surprises during peak demand

This level of visibility is the backbone of reliable inventory software management, especially when multiple teams rely on the same data.

2. Automated replenishment and alerts

Manual reordering works until it doesn’t.

- Reorder triggers based on minimum stock thresholds

- Automatic alerts for fast-moving or critical SKUs

- Reduced dependence on memory or manual checks

Intelligent Automation is often the first step businesses take when they begin to develop inventory management software solutions that scale with demand.

3. Multi-location inventory control

As soon as inventory spreads across locations, complexity multiplies.

- Unified dashboard for all warehouses or stores

- Stock transfers between locations without guesswork

- Better utilization of existing inventory

This is where a strong inventory control system software prevents overstock in one place and shortages in another.

4. Barcode and RFID integration

Accuracy usually improves the moment humans stop typing.

- Faster stock updates through scanning

- Reduced errors during receiving and dispatch

- Better audit trails for inventory movement

Hardware integration plays a key role in improving data integrity during inventory management development.

5. Reporting and demand insights

Raw data only helps if it leads to action.

- Sales trends and product performance tracking

- Identification of slow-moving or aging stock

- Smarter purchasing decisions

These insights help teams move from reactive restocking to proactive planning.

6. System integrations

Inventory should never sit in isolation.

- Sync with ERP, POS, accounting, and CRM tools

- Real-time updates across systems

- Fewer reconciliation issues at month end

Strong integrations are essential when businesses move toward ERP inventory management software or broader platform consolidation.

The goal of these features isn’t complexity. Its reliability. When inventory systems work as expected, teams stop double-checking numbers and start trusting the data. That trust is what allows businesses to move faster without losing control.

Development Process of Inventory Management Software

Building an inventory system isn’t about writing code quickly. It’s about translating how your business actually works into software that holds up under pressure. A well-planned inventory management software implementation process reduces risk, avoids rework, and ensures the system supports growth instead of slowing it down.

Below is how most enterprises approach inventory management development when the goal is long-term reliability.

1. Discovery and Requirement Mapping

Every successful build starts with clarity.

- Understand current inventory flows and pain points

- Identify gaps in existing tools or manual processes

- Define what success looks like across teams

This phase lays the groundwork to develop custom inventory management software that reflects real operations rather than assumptions.

2. System Architecture and Planning

Once requirements are clear, structure matters.

- Decide between modular or centralized architecture

- Plan integrations with ERP, POS, CRM, and logistics systems

- Define data models and access roles

This step is critical when developing inventory management platforms meant to scale across locations or business units.

Also Read: How to Choose the Right Enterprise Software Architecture

3. Design and User Experience

Software adoption often succeeds or fails here.

- Simple dashboards for daily users

- Clear workflows for approvals and stock movement

- Interfaces that reduce training time

Strong UX ensures the system supports teams instead of becoming another tool they work around.

4. Development and Integration

This is where the system takes shape.

- Core inventory logic and automation rules

- Integration with existing business systems

- Configuration for reporting and alerts

At this stage, teams actively develop inventory management software solutions that align with operational realities.

5. Testing and Validation

Inventory systems don’t get second chances.

- Stress testing with real-world data volumes

- Validation of real-time sync and automation rules

- Edge-case handling for peak demand or failures

Thorough testing protects the integrity of your inventory control system software before it goes live.

6. Deployment and Continuous Improvement

Launch is the beginning, not the end.

- Cloud data migration and team onboarding

- Monitoring performance and adoption

- Iterative improvements as business needs evolve

Enterprises that invest in end-to-end inventory management development services treat inventory software as a living system, not a one-time project.

A thoughtful development process turns inventory software into dependable infrastructure. When done right, it fades into the background while your teams focus on execution, not exceptions.

Custom Inventory Management Tech Stack

The tech stack behind an inventory system rarely gets attention until something breaks or slows down. But when businesses invest in custom inventory management system development, this foundation decides how reliable, scalable, and future-ready the software will be.

A well-chosen stack keeps the system stable as operations grow.

1. Backend foundations

This is where accuracy and performance come from.

- Databases like MySQL or PostgreSQL handle large volumes of inventory data

- Cloud platforms such as AWS or Google Cloud support scaling without infrastructure headaches

- Core logic ensures stock updates and automation work consistently

These choices matter when teams develop inventory management software solutions that need to perform under real operational pressure.

2. Frontend experience

Adoption depends on usability.

- Frameworks like React or Angular keep interfaces fast and intuitive

- Dashboards are designed around daily warehouse and management workflows

- Cleaner layouts reduce training time and resistance

This directly improves how teams interact with inventory software management systems.

3. Integrations and APIs

Inventory doesn’t operate in isolation.

- APIs connect inventory with ERP, CRM, POS, and logistics tools

- Data syncs automatically across systems

- Manual errors and reconciliation effort drop significantly

This flexibility is key when businesses build customizable inventory management software.

4. Security and access control

Inventory data is operational and financial.

- Encryption protects sensitive information

- Multi-factor Authentication reduces access risk

- Role-based permissions keep data exposure controlled

Security becomes essential as inventory management development scales across teams and locations.

A strong custom inventory management tech stack stays out of the spotlight. It supports growth quietly, adapts as operations change, and lets teams focus on execution instead of system reliability.

Inventory Management Software Cost

Cost is usually the first question leaders ask, and rightly so. But with inventory systems, price alone rarely tells the full story. The inventory management software cost depends on how complex your operations are today and how much flexibility you need tomorrow.

A basic setup may solve visibility issues. A more advanced build supports automation, integrations, and scale. The difference shows up not just in the upfront spend, but in how much manual effort and rework the system removes over time.

Here’s a practical view of typical cost ranges:

| Type of Software | Estimated Cost Range | Key Factors |

|---|---|---|

| Basic Inventory Management | $40,000 – $80,000 | Simple features, fewer integrations, ideal for small businesses or startups. |

| Advanced Inventory Management | $80,000 – $150,000 | More complex features, multi-location support, and detailed analytics for growing businesses. |

| Cloud-Based Solutions | $100,000 – $250,000 | Scalable and flexible, ideal for businesses looking for remote access and easy integration. |

| Custom Inventory Software | $150,000 – $300,000 | Tailored to business needs with custom features, integrations, and high flexibility. |

| ERP-Integrated Inventory | $200,000 – $400,000 | Full integration with ERP systems for large enterprises, offering complex workflows and scalability. |

Several factors influence where your project lands within this range:

- Number of warehouses, stores, or fulfillment centers

- Depth of integrations with ERP, CRM, POS, or logistics systems

- Level of automation and reporting required

- Security, compliance, and access control needs

While the inventory management software cost may seem significant upfront, most businesses see returns through reduced stock errors, lower carrying costs, and faster decision-making. When planned correctly, the investment supports long-term efficiency rather than becoming another system teams work around.

Also Read: Manufacturing Inventory Software Development Cost

Advanced Technologies for Inventory Management

Once inventory moves beyond basic tracking, technology starts doing the heavy lifting. Not in flashy ways, but in quiet, practical ones. The goal isn’t to add complexity. It’s to reduce uncertainty, shorten response times, and remove guesswork from everyday decisions.

Here’s how modern technology is reshaping inventory management development in real-world environments.

1. Predictive Analytics and Machine Learning

Demand Forecasting used to rely on gut instinct and last year’s numbers. That no longer holds up.

- Learns from historical sales and demand patterns

- Adjusts reorder points automatically

- Helps avoid overstock and sudden shortages

This is especially valuable when businesses develop inventory management software solutions meant to support seasonal demand or fluctuating supply chains.

2. Internet of Things (IoT)

IoT in the supply chain brings visibility to what was previously invisible.

- Tracks the location and movement of goods in real time

- Monitors conditions like temperature or handling for sensitive items

- Sends alerts when something goes off track

For industries dealing with perishables or high-value items, IoT adds a layer of control that traditional systems can’t provide.

3. Blockchain for Traceability

In regulated or high-trust industries, proof matters.

- Creates an immutable record of inventory movement

- Improves transparency across suppliers and distributors

- Reduces disputes and compliance risks

The blockchain technology is often adopted when companies are developing inventory management platforms for pharmaceuticals, food, or global supply chains.

4. RFID and Advanced Scanning

Speed and accuracy rarely coexist with manual processes.

- Bulk scanning instead of item-by-item updates

- Faster receiving and dispatch

- Cleaner audit trails

RFID strengthens the reliability of any inventory control system software, especially in large warehouses.

5. Cloud-native Architecture

Growth becomes easier when systems aren’t tied to a single location.

- Real-time access across teams and regions

- Easier updates and scalability

- Lower infrastructure overhead

This is why many businesses now prefer cloud-based inventory management software and cloud-based systems as the foundation of their operations.

Advanced technology doesn’t replace good inventory practices. It reinforces them. When implemented thoughtfully, these tools fade into the background and let teams focus on execution instead of constant monitoring.

AI, cloud, and automation don’t fix inventory problems on their own. Value comes from systems built around real workflows, not feature checklists.

Important Integrations for Inventory Management Software

Inventory systems rarely fail on their own. Most problems start when data has to jump between tools manually. Sales numbers live in one system. Stock data sits somewhere else. Finance works off a third view altogether. That disconnect slows teams down and creates errors that compound over time.

Strong integrations are what turn inventory software into a reliable operational layer rather than just another dashboard.

1. ERP Integration

This is often the backbone of enterprise setups.

- Syncs inventory with procurement, finance, and production

- Ensures consistent data across departments

- Reduces reconciliation effort at month end

When paired correctly, ERP inventory management software helps leadership make decisions based on a single source of truth rather than fragmented reports.

2. Real-Time POS Syncing

Sales activity should update inventory instantly.

- Real-time stock deduction after every sale

- Prevents overselling and stock mismatches

- Keeps online and offline channels aligned

This integration becomes critical during the inventory management software implementation process, especially for retail and omnichannel businesses.

3. Shipping and Logistics Alignment

Inventory doesn’t stop moving once it leaves the warehouse.

- Tracks goods in transit

- Improves delivery forecasting

- Helps plan replenishment based on actual lead times

These connections are commonly built into supply chain inventory management software development projects where timing directly impacts customer experience.

4. Strategic CRM Integration

Sales teams work better when they know what’s available.

- Visibility into stock during deal conversations

- Better commitment to delivery timelines

- Fewer last-minute order changes

This allows inventory data to support revenue generation instead of reacting to it.

5. Accounting and finance systems

Stock levels and financials should always agree.

- Automatic Cost of Goods Sold updates

- Accurate valuation of inventory assets

- Cleaner audits and reporting

Tight financial integration strengthens overall inventory management development, especially in regulated or high-volume environments.

When these integrations work together, inventory stops being a bottleneck. Data flows naturally, teams trust the numbers they see, and operations move faster without added oversight. That’s when inventory software starts behaving like infrastructure rather than a tool.

Benefits of Inventory Management Software

Inventory software proves its value in everyday moments. Fewer last-minute calls. Fewer manual checks. Fewer uncomfortable conversations about missed deliveries. When implemented well, it shifts teams from reacting to problems to staying ahead of them. That’s the real benefit of digitizing inventory management.

1. Stronger Operational Control

Visibility changes behavior.

- Real-time stock awareness across locations

- Fewer blind spots during peak demand

- Better coordination between the warehouse and sales teams

This level of control is a direct outcome of mature inventory software management practices.

2. Lower Operational Costs

Waste often hides in plain sight.

- Reduced overstock and emergency reorders

- Less capital tied up in slow-moving items

- Lower labor hours spent on manual audits

Many organizations recover their inventory management software cost faster than expected once inefficiencies are removed.

3. Fewer Errors, Higher Data Confidence

Manual processes break under pressure.

- Automated updates reduce entry mistakes

- Consistent data across systems

- Cleaner reporting and forecasting

This reliability is critical when teams rely on an inventory control system software for decision-making.

4. Improved Customer Reliability

Inventory accuracy protects brand trust.

- Fewer backorders after purchase

- More accurate delivery commitments

- Better fulfillment performance across channels

Integrated systems ensure storefronts, warehouses, and fulfillment teams stay aligned.

5. Smarter Planning and Forecasting

Data becomes actionable when it’s trusted.

- Clear insight into product performance

- Early signals for demand shifts

- Better procurement timing

These insights support long-term inventory management development, not just day-to-day operations.

6. Built-in Scalability

Growth shouldn’t break systems.

- Easy expansion to new locations

- Support for higher SKU counts

- Adaptability to new sales channels

This is why many businesses move toward custom inventory management software development rather than relying on tools they quickly outgrow.

The real value of inventory management software isn’t just efficiency. It’s confidence. Confidence in numbers, in decisions, and in the systems supporting daily operations as the business scales.

Also Read: How Technology in Supply Chain can Surpass Challenges

Use Cases and Real-World Examples of Inventory Management Software

Inventory software usually earns its keep when things are already busy. A shipment is late. Orders are piling up. Someone needs to know, right now, what’s actually available. In moments like these, spreadsheets and disconnected tools fall apart. That’s where inventory management software quietly steps in and keeps operations steady.

Below are common industry scenarios, along with real-world examples of inventory management system usage that show how this plays out in practice.

1. Retail: Keeping Products Available Without Guesswork

Retail inventory is a balancing act. Too little stock means lost sales. Too much means tied-up cash. Retailers depend on inventory software management to keep shelves stocked without overcorrecting.

Starbucks is rolling out an AI-based inventory counting system across more than 11,000 stores in North America to improve real-time stock visibility. The system uses computer vision and AI to automate inventory counts, helping stores replenish faster and reduce out-of-stock situations during peak demand periods.

This is a straightforward use case of inventory management software where accuracy directly affects revenue and customer experience.

Also Read: Boost Retail Inventory Optimization with Data Analytics

2. Manufacturing: Keeping Production Moving

In manufacturing, inventory mistakes don’t stay isolated. A single missing part can delay an entire production run. That’s why manufacturers rely on inventory control system software to track materials across every stage of production.

Toyota’s Toyota Production System (TPS) is built around Just-in-Time production, where parts are supplied only as needed, neither early nor late. This approach relies on tight inventory flow and pull-based replenishment to avoid bottlenecks and keep production moving.

This reflects how inventory management development supports operational discipline, not constant firefighting.

3. E-commerce: Managing Inventory That Never Stops Moving

E-commerce inventory doesn’t slow down. Orders come in around the clock, often across multiple platforms. That’s where cloud-based inventory management software cloud-based systems become essential.

Amazon operates one of the most complex inventory networks in the world, using automation and real-time synchronization to manage stock across fulfillment centers and seller ecosystems.

These systems are examples of developing inventory management platforms built to scale without losing accuracy.

4. Food and Beverage: Reducing Waste While Staying Compliant

Food inventory leaves little room for error. Expiration dates matter. Batch tracking matters. Mistakes lead to waste or compliance risk. Businesses use inventory systems to keep tighter control without slowing operations.

Ocado describes how its AI-enabled inventory management considers stock, shelf-life (quality), and demand together to reduce “purge” risk and keep waste low. The system uses integrated software and AI to make real-time decisions that balance availability with freshness.

This is a practical example of a well-structured inventory management software implementation process tied to daily operations.

5. Healthcare: Making Sure Critical Supplies Are Available

In healthcare, inventory management issues carry real consequences. Shortages affect patient care. Expired supplies create risk. That’s why providers depend on ERP inventory management software for centralized visibility.

CVS Health uses integrated healthcare inventory software development systems to manage pharmaceuticals and medical supplies across thousands of locations while meeting strict regulatory requirements.

This shows how custom inventory management system development supports both efficiency and safety in regulated environments.

Across industries, the pattern is consistent. Businesses don’t adopt inventory systems to add complexity. They do it to remove uncertainty. When implemented well, inventory software stays out of the spotlight, doing its job quietly while teams focus on running the business.

Common Challenges in Inventory Management and How to Tackle Them

Inventory systems usually struggle for simple reasons. Data sits in different tools. Teams follow different processes. Legacy systems don’t integrate cleanly. These gaps create delays, errors, and mistrust in the numbers.

Here are the most common challenges and how businesses address them.

1. Disconnected systems

Inventory data often doesn’t align with sales, finance, or logistics.

- Teams rely on manual reconciliation

- Reports don’t match across systems

How to overcome it: Treat integrations as a core part of inventory management development, connecting inventory with ERP, CRM, POS, and logistics tools through APIs.

2. Low team adoption

Software fails when people avoid using it.

- Interfaces feel complex

- Workflows don’t match daily operations

How to overcome it: When businesses build customizable inventory management software, usability and role-based access help teams adopt the system naturally.

- Inaccurate inventory data

Manual updates introduce errors.

- Stock levels drift from reality

- Forecasting becomes unreliable

How to overcome it: Automation through scanning, real-time updates, and validation rules within the inventory control system software keeps data accurate.

4. Scaling issues

Systems built for small operations break under growth.

- Performance drops with higher volume

- Adding locations becomes painful

How to overcome it: Using inventory management software with cloud-based architectures allows systems to scale without constant rework.

5. Cost concerns

Upfront investment can slow decisions.

- ROI feels unclear

- Budgets get questioned

How to overcome it: Looking at inventory management software cost against long-term savings helps teams see the value beyond the initial spend.

Most inventory challenges are predictable. When addressed early through a structured inventory management software implementation process, systems stay reliable as the business grows.

Most failures come from known gaps. Disconnected data, poor visibility, and systems that no longer scale with the business.

How Appinventiv Can Transform Your Inventory Management with Tailored Solutions

At Appinventiv, work usually starts with a conversation, not a feature list. How inventory moves inside your business matters more than generic workflows. That mindset has helped us master operations across 35+ industries, where inventory challenges look very different from one sector to another. That’s why our approach to customized software solution development is grounded in how teams actually operate day to day, across warehouses, systems, and people. The aim is simple: build software that feels natural to use and practical to scale.

With 3000+ solutions designed and delivered, our experience in supply chain software development services becomes especially valuable once inventory needs to connect with the rest of the business. ERP, CRM, POS, and finance. When these systems stay disconnected, decisions slow down, and errors creep in. We focus on tightening those connections so data flows cleanly, teams stay aligned, and inventory decisions are based on what’s really happening, not delayed reports.

The work does not end at launch. As volumes grow and processes evolve, systems need to keep pace. Having transformed 500+ legacy processes, we stay involved to ensure inventory software continues to support operations as complexity increases. If inventory challenges are starting to slow teams down, it may be time for a solution shaped around your reality, not someone else’s template.

Speak with our team to see how a tailored inventory solution can bring clarity and control back into your supply chain.

FAQs

Q. How much does it cost to build a custom inventory management solution?

A. The cost of building a custom inventory management solution can range from $40,000 to $400,000, depending on factors like the complexity of the system, features required, and integrations with existing tools. The final price will vary based on whether you’re looking for a simple, off-the-shelf solution or a fully customized, scalable system that meets your specific needs.

Q. How long can it take to develop an inventory management solution?

A. The timeline for developing an inventory management solution can vary, but typically, it takes anywhere from 3 to 6 months for a custom solution, depending on the complexity and the features involved. This includes time for planning, design, development, testing, and deployment. For more complex systems with advanced integrations, it could take longer.

Q. How to Create an Inventory Management System?

A. Creating an inventory management system starts with understanding your business needs and identifying key features like real-time tracking, automated reordering, and integrations with existing software. After defining the requirements, you’ll move on to system design, development, and testing before going live. Partnering with experienced software developers, like those at Appinventiv, can help you build a solution tailored to your business and ensure a smooth implementation.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

The ROI of Strategic Insurance Technology Consulting for Legacy Modernization

Key takeaways: Insurance technology consulting delivers ROI only when modernization is tied to real workflows, not system replacement. Most legacy modernization failures stem from weak ROI definition and tracking, not from technology limitations. The strongest returns come from reduced operational friction, faster change cycles, and tighter claims and underwriting control. Delaying modernization incurs hidden costs…

Key Takeaways Use a scorecard-driven RFP and a technical assessment to compare vendors on capability, compliance, and delivery risk. Local partners provide regulatory and cultural alignment; hybrid teams often pair that with offshore cost efficiency. Start with a scoped pilot or MVP, milestone-based contracts, and clear IP/SLAs to reduce procurement risk. Require demonstrable security controls,…

A Strategic Framework for Proof of Concept Software Development

Key takeaways: Most enterprise PoCs fail due to a lack of decision clarity, not technical feasibility or innovation potential. A disciplined PoC framework reduces delivery risk before budgets, teams, and timelines are committed. Enterprise-grade PoCs validate feasibility, compliance, and scale assumptions under realistic operating constraints. Clear success metrics and governance turn PoCs into reliable inputs…