- Understanding AI in Robotics and How Does It Fit Into the Enterprise Stack

- What Makes Robotics “Intelligent”?

- So, how AI-driven robotics differ from traditional automation?

- How Intelligent Robotics Fits Into the Enterprise?

- The Strategic Edge: Why Intelligent Robotics Matters Now

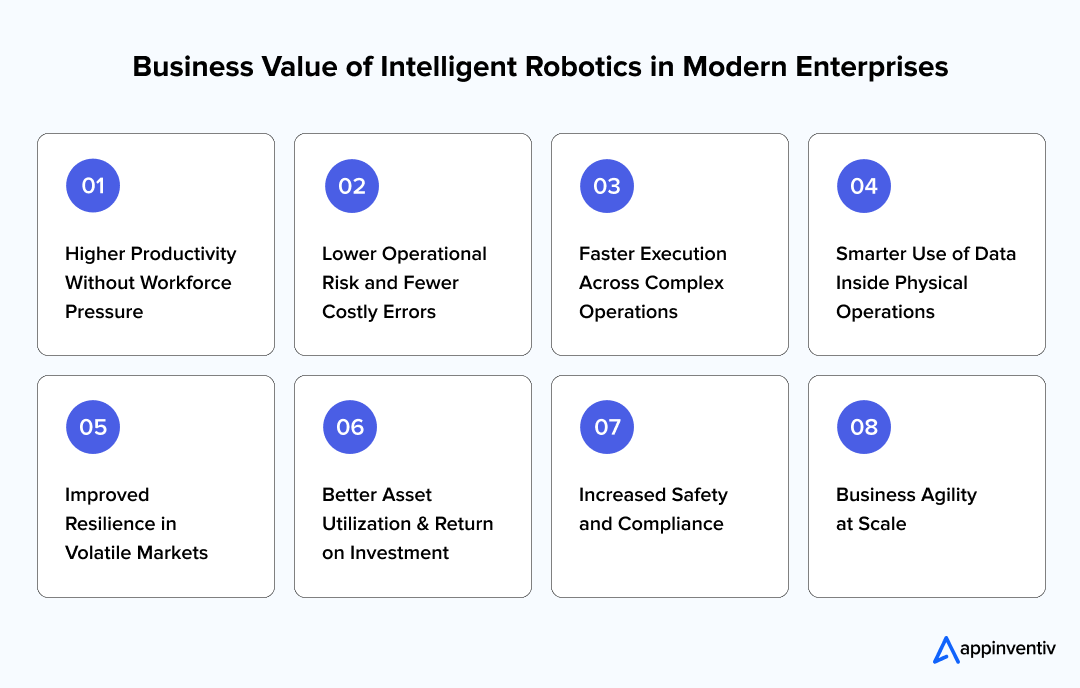

- Benefits of AI-Driven Robotics for Businesses

- Higher Productivity Without Workforce Pressure

- Lower Operational Risk and Fewer Costly Errors

- Faster Execution Across Complex Operations

- Smarter Use of Data Inside Physical Operations

- Improved Resilience in Volatile Markets

- Better Asset Utilization and Return on Investment

- Increased Safety and Compliance

- Business Agility at Scale

- 14 Transformative Use Cases and Examples of AI-Powered Robotics in Business Operations

- Intelligent Warehouse Orchestration

- Autonomous Quality Inspection

- Surgical Robotics and Clinical Augmentation

- Smart Logistics Sorting and Routing

- Retail Shelf Intelligence

- Infrastructure Inspection Robotics

- Customer Interaction Robotics

- Autonomous Construction Machinery

- Precision Agriculture

- Airport Operations and Passenger Robotics

- Autonomous Mining Operations

- Banking Service Automation

- Restaurant Automation

- Hazardous Zone Robotics

- The Unseen Hurdles: Navigating the Complexities of Intelligent Robotics Adoption

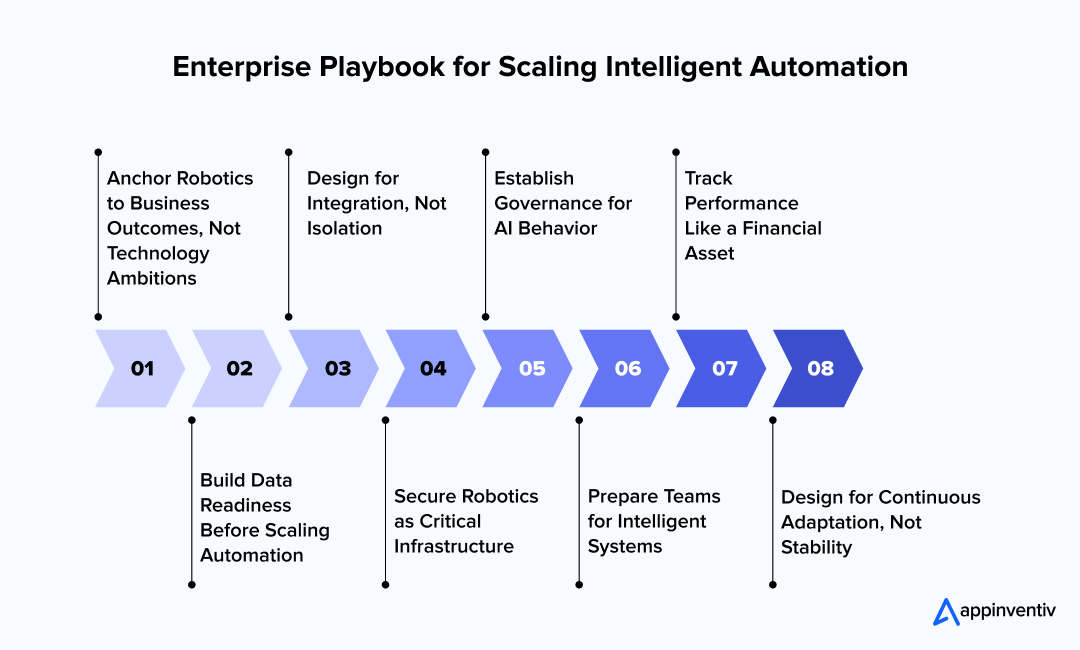

- A Strategic Blueprint for Intelligent Automation Success

- Step 1: Anchor Robotics to Business Outcomes, Not Technology Ambitions

- Step 2: Build Data Readiness Before Scaling Automation

- Step 3: Design for Integration, Not Isolation

- Step 4: Secure Robotics as Critical Infrastructure

- Step 5: Establish Governance for AI Behavior

- Step 6: Prepare Teams for Intelligent Systems

- Step 7: Track Performance Like a Financial Asset

- Step 8: Design for Continuous Adaptation, Not Stability

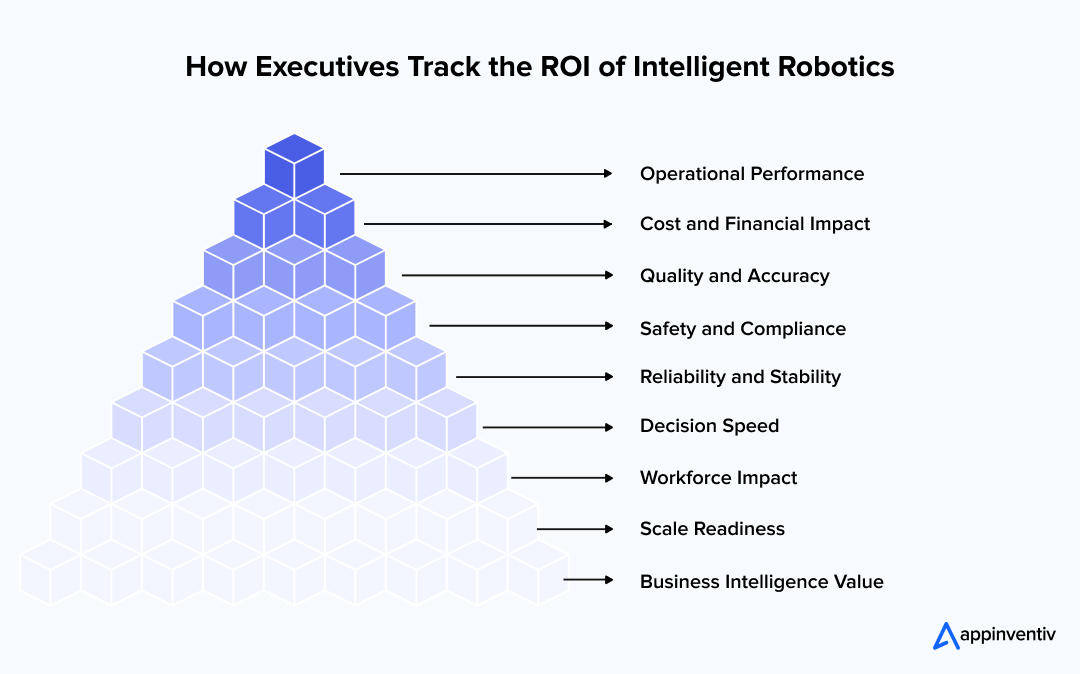

- Measuring the Impact of AI in Robotics: KPIs That Matter to Enterprises

- Operational Performance

- Cost and Financial Impact

- Quality and Accuracy

- Safety and Compliance

- Reliability and Stability

- Decision Speed

- Workforce Impact

- Scale Readiness

- Business Intelligence Value

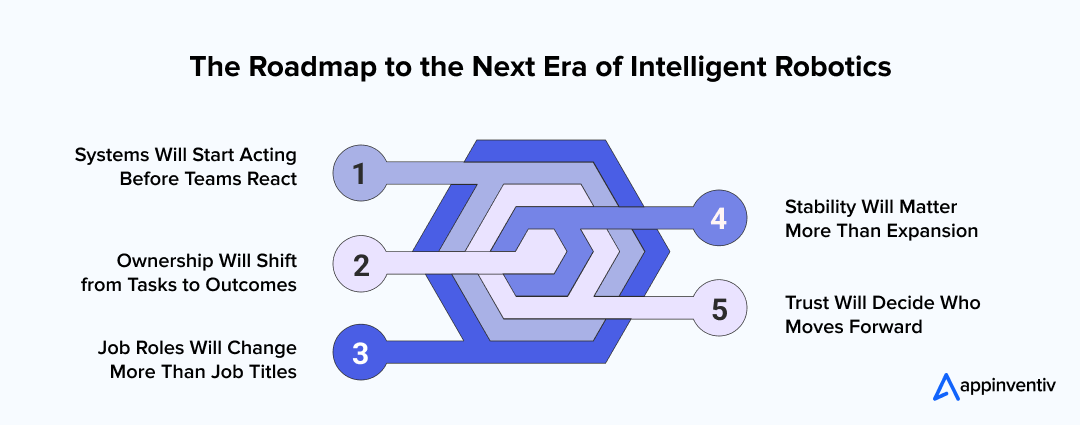

- The Horizon Ahead: Preparing for the Next Wave of AI-Driven Robotics

- Systems Will Start Acting Before Teams React

- Ownership Will Shift from Tasks to Outcomes

- Job Roles Will Change More Than Job Titles

- Stability Will Matter More Than Expansion

- Trust Will Decide Who Moves Forward

- Partnering for the Robotic Revolution: How Appinventiv Can Lead Your Journey

- FAQs

Key takeaways:

- AI-driven robotics has shifted from automation tools to core operating infrastructure for enterprises.

- Intelligent robots now make decisions, not just execute instructions.

- Enterprises are adopting AI robotics at scale, not as pilots.

- Business impact shows up first in productivity, quality, and operational resilience.

- Integration and governance matter more than hardware.

- Companies that delay adoption will face structural disadvantage, not just slower growth

Enterprises across industries like manufacturing, logistics, healthcare, infrastructure and more are facing a common pressure point. Skilled labor is harder to retain, operational precision is no longer optional, and the cost of even minor errors is rising faster than most businesses can absorb. At the same time, customer expectations, regulatory demands, and delivery timelines continue to compress. In this environment, robotics is no longer viewed as an efficiency upgrade. It is emerging as a foundational business system that determines whether operations can scale at all.

This shift is being driven by AI in robotics, which is fundamentally changing what machines are capable of doing. Traditional industrial robots executed fixed instructions. Today’s systems interpret surroundings, adjust to change, and improve through experience. The role of AI in robotics is not limited to automation. It enables perception, reasoning, and decision-making on the operating floor itself. Where robotics once replaced repetition, artificial intelligence in robotics now replaces uncertainty.

What makes this moment different is that the technology has matured at every layer. Hardware is faster and more reliable. Data environments are richer. Models adapt in real time. The result is that artificial intelligence in the robotics industry has moved from experimentation into large-scale deployment. Enterprises are not just installing machines that move parts. They are deploying systems that make operational decisions, collaborate with human teams, and anticipate failure before it halts production. This convergence of robotics and artificial intelligence is reshaping how work gets done in ways that were not achievable even a few years ago.

In this article, we explore how AI robotics is being applied across enterprises through real-world use cases, not theory. You will see where organizations are deploying intelligent systems, how the benefits of AI in robotics translate into business outcomes, and what leaders must understand about the future of AI in robotics to stay competitive.

Discover how AI-powered robotics changes how enterprises operate.

Understanding AI in Robotics and How Does It Fit Into the Enterprise Stack

AI-driven robotics is not about making robots “smarter” in a lab. It is about putting decision-making inside machines that already run real operations. Instead of following only pre-written instructions, these systems react to what they see, adjust when things change, and make choices based on live information.

When companies adopt intelligent robotics, they are not just upgrading equipment. They are introducing judgment into workflows that were once rigid and predictable. That is the real shift.

What Makes Robotics “Intelligent”?

Intelligent robotics is not defined by one feature. It is defined by how machines observe, decide, and act in real situations:

Perception (What the Robot Notices)

Traditional robots move blindly along fixed paths. Intelligent systems do not. They “see” what is happening around them through cameras, sensors, and signals from other systems. A robot in a warehouse does not just go from point A to point B. It notices congestion, detects misplaced items, and understands when something is out of order.

Decision-Making (What the Robot Chooses)

This is where most misunderstandings happen. A robot does not become “intelligent” just because it has software. Intelligence comes from the system’s ability to decide what to do next based on changing conditions. When workloads spike, routing changes, or an error is detected, the system adjusts instead of waiting for an engineer to intervene.

Execution (What the Robot Does)

Once a decision is made, motion follows. Arms move, wheels turn, machines reposition. But unlike traditional automation, those actions are not fixed in advance. They change depending on what the system learns at the moment.

So, how AI-driven robotics differ from traditional automation?

Below is the simplest way to understand the gap between old automation and intelligent robotics.

| Area | Traditional Robots | AI-Driven Robots |

|---|---|---|

| Instructions | Follow pre-set commands | Act based on real-time conditions |

| Response to change | Stop or fail when the environment shifts | Adjust automatically |

| Use of data | Limited and mostly offline | Continuous and live |

| Scalability | Requires reprogramming | Learns and evolves |

| Business role | Performs tasks | Influences outcomes |

In short: older robots execute orders. Newer ones make judgments within boundaries that leadership defines.

How Intelligent Robotics Fits Into the Enterprise?

Robots do not work alone. In a real enterprise, intelligent systems plug into an ecosystem of data, software, and workflows.

Data Layer: Where Reality Enters the System

This is where the robot gets its understanding of the world.

Cameras, sensors, machines, and business systems continuously feed information into the environment. If data is unreliable, decisions will be too. Most failures in robotics do not come from hardware. They come from bad data flowing into good systems.

Intelligence Layer: Where Meaning Is Built

This layer decides what the robot should do. It compares current input with historical patterns, production targets, and safety boundaries. This is not about “thinking” like a human. It is about recognizing patterns faster and more consistently than a human can during peak operations.

Execution Layer: Where Work Happens

Here is the physical side. Machines move, lift, assemble, inspect, or transport. What changes is that those actions are no longer mechanical routines. They respond to the situation rather than repeating the past.

Integration Layer: Where Robotics Meets the Business

This is the part many organizations ignore and later regret.

Robots must connect to planning systems, inventory records, order platforms, and service workflows. Without that connection, robots become isolated machines doing clever things without business impact. When linked properly, robotics becomes part of how decisions flow across the organization.

When all four layers work together, robotics is no longer equipment. It becomes part of how the enterprise thinks and operates.

The Strategic Edge: Why Intelligent Robotics Matters Now

At its core, intelligent robotics is not about replacing people or automating a few tasks. It is about changing how work itself gets done. Enterprises are moving away from linear operations and toward systems that sense, decide, and act in real time. That shift is what separates basic automation from intelligent robotics. Traditional robots execute instructions. AI-powered robotics interprets environments, adjusts behavior on the fly, and improves performance over time. The difference is not technological. It is strategic.

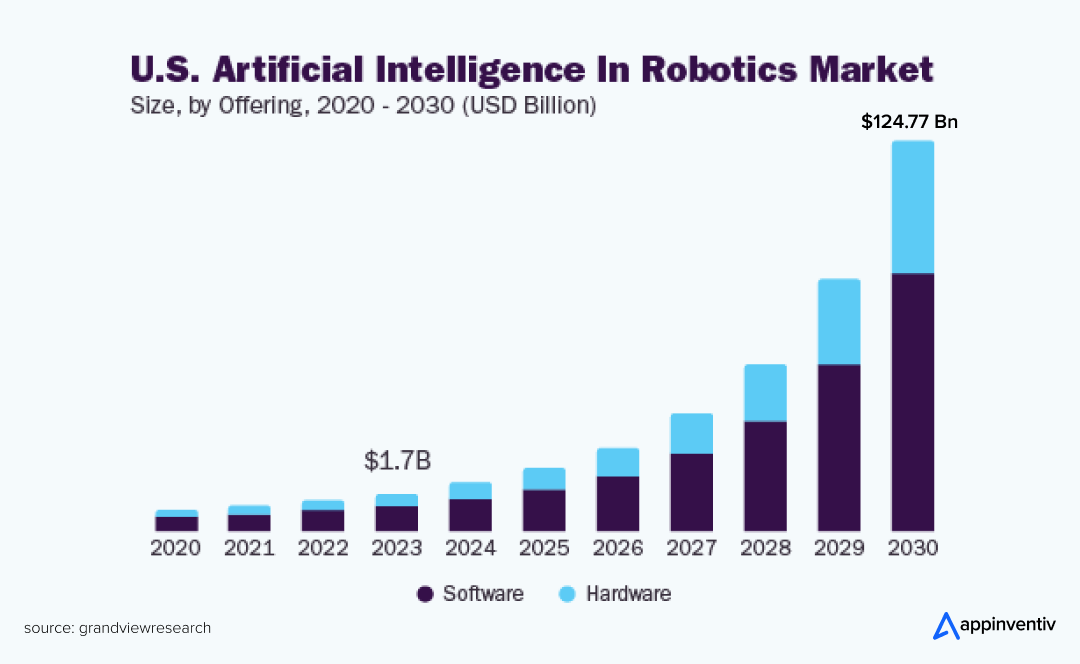

This change is already showing up in economic impact at a scale that cannot be ignored. The global AI-powered robotics market was valued at $12.77 billion in 2023 and is expected to expand to $124.77 billion by 2030, reflecting a compound annual growth rate of 38.5% between 2024 and 2030.

Furthermore, according to an analysis by McKinsey & Company, AI-powered agents and robots could generate approximately $2.9 trillion in economic value every year in the United States alone by 2030. That is not driven by gadget manufacturing or experimental labs. It comes from productivity gains, faster operations, better asset utilization, and lower error rates across manufacturing, logistics, healthcare, and service industries. In simple terms, intelligent robotics is becoming a profit engine, not a technical upgrade.

At the same time, adoption is accelerating faster than many leaders expect. The International Federation of Robotics reports that global factory-robot installations are projected to rise 6% in 2025 and could exceed 700,000 new units annually by 2028. This tells a different story than “emerging technology.” Enterprises are not testing robotics anymore. They are building with it. The volume of deployment shows that robotics and artificial intelligence are already being treated as operational infrastructure, not discretionary spending.

What makes this moment different from earlier waves of automation is not hardware. It is intelligence. Robots are no longer locked into fixed scripts. With artificial intelligence in robotics, machines learn from data, adapt to unpredictable conditions, and coordinate across systems. That is why robots are now being deployed in environments that once required human judgment: warehouses that reroute in real time, hospitals that automate precision work, factories that self-correct defects as they happen. The role of AI in robotics today is not efficiency alone. It is independence at scale.

For leadership teams, the implication is simple and uncomfortable. Robotics is no longer coming “someday.” It is already reshaping cost structures, operating speed, and competitive advantage. The companies that treat intelligent robotics as a business capability instead of a technology experiment will define their industries over the next decade. Those who delay will not just be slower. They will be structurally disadvantaged.

AI-powered robotics is not a trend. It is the new operating layer. And the market has already voted with capital.

Benefits of AI-Driven Robotics for Businesses

AI-driven robotics is not about deploying machines. It is about redesigning how value flows through your organization. When artificial intelligence in robotics is applied strategically, robotics shifts from being an operations tool to a growth engine. Businesses stop using robots only to reduce labour and start using them to increase speed, accuracy, and decision power across the enterprise.

Below are the business benefits leaders actually see once AI robotics moves beyond pilots and into operations.

Higher Productivity Without Workforce Pressure

AI robotics allows operations to scale without requiring constant headcount expansion. Systems work around the clock, adapt to new conditions, and absorb workload spikes without slowing performance. This is where AI applications in robotics deliver value that human effort alone cannot replicate. Businesses gain output without burnout and capacity without disruption.

Lower Operational Risk and Fewer Costly Errors

Traditional robotics follows scripts. AI-powered robotics understands context. This significantly reduces quality failures, operational mistakes, and production defects. Through artificial intelligence in the robotics industry, systems learn from past errors and avoid repeating them. Risk becomes predictable instead of reactive.

Faster Execution Across Complex Operations

From manufacturing to logistics, robotics and artificial intelligence speed up workflows that once stalled due to coordination problems and communication gaps. Predictive logic allows robots to make decisions on the move. Businesses experience faster throughput, fewer delays, and smoother transitions between processes.

Also Read: 10 Use Cases, Benefits, and Examples of How Cobots are Transforming the Manufacturing Industry

Smarter Use of Data Inside Physical Operations

Data is no longer trapped inside reports and dashboards. The deployment examples of AI in robotics show systems that use live data directly inside operational workflows. Inventory movement, equipment performance, and output quality are optimized in real time. Decisions no longer wait for reviews. They happen in motion.

Improved Resilience in Volatile Markets

Uncertainty disrupts traditional planning. AI-powered robotics responds to change as it happens, not after it happens. When demand patterns shift or supply chains tighten, robotics systems adjust automatically. This is one of the most undervalued advantages of AI in robotics. Stability becomes part of the operating model.

Better Asset Utilization and Return on Investment

Idle machines, underused fleets, and inefficient facilities drain capital. AI for robotics enables continuous monitoring and self-optimization. Equipment performs longer. Maintenance becomes predictive. Downtime becomes avoidable. That is how artificial intelligence in robotics quietly improves financial performance without major reinvestment.

Increased Safety and Compliance

Robots already operate in hazardous environments. AI makes them smarter about it. By sensing risk patterns and responding dynamically, AI-powered robots reduce accidents and enforce safety protocols automatically. For industries where compliance and worker protection matter deeply, robots powered by AI helps in risk management and this has become a standard practice.

Business Agility at Scale

Markets change quickly. Workflows rarely do. AI robotics breaks that pattern. Enterprises can reconfigure operations without rebuilding systems. What used to require months of planning now takes days. This is where companies begin to see the future of AI-powered robotics, not as innovation but as operational muscle.

14 Transformative Use Cases and Examples of AI-Powered Robotics in Business Operations

Enterprises are not investing in AI robotics because of novelty. They are investing because operational models built on manual processes and linear automation can no longer keep up with rising complexity, rising costs, and shrinking labour availability. Robotics integrated with artificial intelligence is becoming a foundational capability across modern enterprises. It is being used not only for motion and automation but for real-time judgement, adaptive decision-making, and continuous optimisation across core functions.

Below are fourteen real use cases already redefining how organisations operate, scale, and compete.

| Use Case | Primary Industry | Primary Business Outcome |

|---|---|---|

| Intelligent Warehouse Orchestration | Logistics, eCommerce, Retail | Faster order fulfillment, improved inventory accuracy |

| Autonomous Quality Inspection | Manufacturing, Automotive, Electronics | Lower defect rates, reduced recalls |

| Surgical Robotics and Clinical Augmentation | Healthcare, MedTech | Higher clinical precision, improved outcomes |

| Smart Logistics Sorting and Routing | Logistics, Supply Chain | Faster delivery, reduced operational delays |

| Retail Shelf Intelligence | Retail | Fewer stockouts, improved sales velocity |

| Infrastructure Inspection Robotics | Energy, Utilities, Construction | Improved asset safety, lower inspection costs |

| Customer Interaction Robots | Banking, Retail, Hospitality | Better service consistency, reduced wait times |

| Autonomous Construction Machinery | Construction, Real Estate | Faster project completion, lower labor dependency |

| Precision Agriculture | Agriculture, AgriTech | Higher yield, reduced chemical usage |

| Airport Operations and Passenger Robotics | Aviation, Transport | Smoother passenger flow, better on-time performance |

| Autonomous Mining Operations | Mining, Natural Resources | Increased safety, continuous production |

| Banking Service Automation | Financial Services, Banking | Reduced branch workload, improved customer flow |

| Robotic Kitchen Automation | Food & Beverage, QSR | Consistent output, labor stabilization |

| Hazardous Environment Robotics | Energy, Nuclear, Emergency Services | Risk reduction, |

Intelligent Warehouse Orchestration

In modern fulfillment environments, speed is not driven by how fast goods move. It is driven by how smart movement decisions are. AI-driven robotics enables warehouses to rearrange stock continuously based on predicted demand shifts, transportation constraints, and fulfilment priority rather than manual instruction. Inventory no longer waits for orders. It anticipates them.

Amazon operates over 750,000 robots globally. These machines work as part of an AI layer that decides where products should be stored before orders occur based on live demand trends, reducing delivery time and inventory congestion at scale. This is artificial intelligence in robotics acting as spatial intelligence across physical operations.

Also Read: AI in Warehouse Management: Benefits, Use Cases, and Real World Examples

Autonomous Quality Inspection

Instead of sampling-based quality checks or final-stage inspections, AI-powered robotics performs continuous inspection during manufacturing. Visual analysis systems identify microscopic defects, alignment errors, inconsistencies, and structural anomalies while components are being built, not after assembly completes.

BMW deploys intelligent vision robots inline across production plants to detect micro-level paint flaws, misaligned body panels, and welding defects. This allows defects to be corrected before they propagate through production, reducing recalls and improving yield control at enterprise scale.

Surgical Robotics and Clinical Augmentation

In healthcare, robotics does more than assist motion. AI systems support decision-making by enhancing visual interpretation, stability, and procedural forecasting. Robots help clinicians operate with higher precision under constrained conditions where human hands alone are insufficient. Simply put, the use of robots that provide automation in healthcare is no longer about convenience. It is about achieving consistency, reducing clinical risk, and improving surgical outcomes at scale.

Intuitive Surgical’s Da Vinci system is used globally in millions of procedures, enabling enhanced dexterity in oncology, urology, and cardiac surgery. This is robotics and artificial intelligence extending the surgeon’s skill rather than replacing it.

Smart Logistics Sorting and Routing

Logistics operations no longer follow static routes or batch schedules. AI-driven robotics continuously re-evaluates delivery pathways based on traffic data, package urgency, hub congestion, and carrier performance.

DHL uses robotics and artificial intelligence to dynamically prioritize and reposition packages within sorting centres. Instead of rigid routing, parcels are constantly re-ranked and redirected in real time, increasing on-time delivery performance without expanding physical footprint.

Retail Shelf Intelligence

In physical retail, stock loses value every hour it remains unavailable or incorrectly priced. AI robotics performs continuous visual audits of shelves to detect empty spaces, inaccurate labels, and misplaced goods.

Walmart uses autonomous robots to monitor shelf health in real time across stores, driving dynamic replenishment workflows that prevent stockouts before sales loss occurs. This use of AI in robotics converts merchandising into real-time operational intelligence.

Infrastructure Inspection Robotics

AI robotics in infrastructure replaces high-risk manual inspections with intelligent machines that assess conditions continuously rather than episodically. Cracks, corrosion, pressure imbalances, and heat anomalies are detected automatically instead of waiting for failure.

BP and Shell deploy inspection robots across offshore rigs and refineries to monitor structural health while environments remain operational. Inspection becomes embedded rather than interruptive.

Customer Interaction Robotics

In service environments, robots act as intelligent interaction hubs rather than static kiosks. AI enables robots to respond contextually, recognise repeat visitors, and deliver natural conversation within physical spaces.

SoftBank’s Pepper robot is deployed by retail chains and banks including HSBC and Carrefour to manage customer engagement and in-store guidance using speech recognition and emotional detection.

Autonomous Construction Machinery

AI robotics removes the requirement for manual control of heavy machinery. Operations are programmed through computer vision, mapping intelligence, and motion optimization.

Built Robotics deploys AI autonomy on Caterpillar equipment, enabling construction grading and excavation to operate without human drivers. Entire construction zones now function through robotics and artificial intelligence as supervisory systems.

Precision Agriculture

Agricultural robotics replaces mass application with micro-precision. AI enables every plant to be identified, evaluated, and treated individually.

John Deere’s AI tractors use image recognition to spray herbicide directly onto weeds instead of open-field application. This dramatically reduces chemical consumption while increasing crop health.

Airport Operations and Passenger Robotics

Airports use robotics not only for assistance but for operational load balancing across passenger movement and security.

Seoul Incheon International Airport uses AI robots for passenger guidance, security patrol, and real-time facilities management, improving traveller flow during peak congestion windows.

Autonomous Mining Operations

In modern mining operations, the real challenge is not extraction. It is safety, continuity, and output stability across massive, hazardous environments that do not tolerate human error. AI-driven robotics allows mining firms to operate fleets across unpredictable terrain, extreme weather conditions, and remote locations where manual oversight is impractical or unsafe.

Rio Tinto operates the world’s largest autonomous mining network in Western Australia, where AI robotics controls haul trucks, drills, and rail systems without drivers. Entire value chains operate remotely through central control rooms, allowing production to continue 24 hours a day with higher safety standards and operational efficiency than human-led mining could achieve.

Banking Service Automation

In financial institutions, robotics is no longer cosmetic customer service. It is becoming a functional layer of frontline operations designed to reduce manual workload, improve service consistency, and increase branch availability under labour constraints. AI-enabled robots support customer onboarding, routine inquiries, and navigation while integrating continuously with core banking systems. This enables human teams to shift away from transactional interactions toward advisory work that generates value.

Mizuho Bank in Japan deploys humanoid service robots across bank branches to assist customers with information access and service routing. The result is reduced congestion, faster resolution, and improved customer flow management without increasing staffing costs.

Restaurant Automation

Food service operations struggle with rising labour shortages, inconsistent preparation quality, and operational downtime during peak hours. Autonomous robots allow restaurants to move critical processes into systems that operate with machine precision under continuous demand conditions. These robots manage heat, timing, cooking cycles, and output standardisation while reducing operational volatility caused by staff turnover. Furthermore, businesses are also using autonomous robots for quick food delivery.

White Castle uses Flippy, an AI kitchen robot developed by Miso Robotics, to manage frying operations across locations in the United States. The system maintains consistent output quality, reduces food waste, and allows restaurants to operate reliably even during staff shortages.

Hazardous Zone Robotics

Some environments simply cannot be entered safely by humans. Nuclear sites, chemical plants, disaster zones, and structurally compromised facilities require inspection and intervention without physical presence. AI-driven robotics enables organisations to restore operations, assess risk, and plan remediation without exposing employees to life-threatening hazards.

Boston Dynamics deployed the Spot robot during the Fukushima nuclear recovery effort to inspect radiation-affected areas. The robot gathered environmental data, surveyed damage, and supported cleanup planning while eliminating the need for human exposure in unstable zones.

Let’s build intelligent systems that work for your business, not just your technology stack.

The Unseen Hurdles: Navigating the Complexities of Intelligent Robotics Adoption

Enterprises struggle with AI in robotics not because machines fail, but because intelligence reshapes accountability, risk, and decision-making across the business. As companies move into AI robotics, robotics and artificial intelligence stop being technical upgrades and start becoming enterprise-wide transformations. Without strong governance and integration planning, even systems promising the benefits of AI in robotics introduce hidden complexity instead of strategic advantage.

| Challenge | How It Impacts The Business | How Enterprises Resolve It |

|---|---|---|

| Data instability and poor data pipelines | AI systems fail silently when training data is inaccurate or outdated. Robots behave inconsistently, causing production delays, safety risks, and audit failures. The issue worsens as enterprises scale AI applications without standard data governance. | Establish centralized data governance, introduce real-time validation, and design robotics deployments around live data health monitoring instead of static feeds. |

| Integration AI with legacy systems | Most robots must interact with ERP, SCM, and MES platforms never built for intelligence-driven decision-making. This creates operational deadlocks where robots generate insights that systems cannot process. | Enterprises modernize integration layers using APIs, middleware, and data orchestration tools to bridge robotics workflows with enterprise platforms. |

| Model unpredictability in live operations | As robots learn, outcomes shift. Leaders lose confidence when behavior changes without visibility. Errors are harder to trace compared to rule-based automation. | Implement explainability layers and operational dashboards so teams can inspect model decisions across AI use cases in robotics. |

| Security vulnerabilities from intelligent systems | Robotics introduces new cyber entry points via sensors, networks, and control APIs. Without proper protection, an attack can disrupt physical operations. | Apply Zero Trust security models, isolate robot networks, and perform continuous risk scanning for AI-enabled systems. |

| Compliance and decision accountability | When a robot makes a faulty decision, teams struggle to assign responsibility. Regulators increasingly demand proof of oversight in systems using artificial intelligence in the robotics industry. | Introduce AI governance frameworks defining responsibility, escalation protocols, and audit trails for intelligent systems. |

| High dependence on vendor ecosystems | Proprietary robotics platforms limit flexibility. Enterprises face lock-in and rising costs when scaling AI robotics across locations. | Prioritize modular architectures, open standards, and cross-vendor interoperability during solution selection. |

| Skill gaps within operations teams | Teams trained in machinery maintenance are unprepared for managing AI behavior, models, and system drift. Performance declines, and downtime increases. | Upskill engineers with AI literacy programs and embed analytics roles inside robotics teams. |

| Uncontrolled model collapse | Over time, robotics models diverge from real-world patterns, leading to flawed decisions and rising exception rates. | Implement continuous monitoring, retraining schedules, and environment simulation testing across critical applications of AI in robotics. |

| Unclear ROI and performance ownership | Robotics investments fail when financial accountability is not assigned to business leaders. AI pilots remain stuck in experimentation. | Tie robotics programs to operational KPIs, not IT success metrics. |

| Over-automation leading to human displacement anxiety | Workers resist systems that appear to replace judgment. Productivity drops when trust fades. | Combine automation with job redesign, training, and role expansion. Emphasize the advantages of AI in robotics as augmentation, not elimination. |

| Ethical and societal risk exposure | Poorly governed systems cause bias, safety hazards, and public distrust when robots operate in human environments. | Establish ethical review boards, deploy incident response protocols, and audit critical AI in robotics example workflows. |

| Scalability limitations | Pilot deployments work, enterprise rollout fails. Performance drops as robots increase in volume and complexity. | Shift from local deployments to cloud-native infrastructure capable of supporting enterprise-scale AI workloads. |

A Strategic Blueprint for Intelligent Automation Success

Enterprises adopting AI in robotics are not chasing technology upgrades. They are redesigning how work gets done. As AI robotics moves into daily operations, success depends less on tools and more on how well intelligence is embedded into business design.

This shift places robotics and artificial intelligence at the center of operational strategy. Organizations that understand this treat automation as infrastructure, not experimentation.

Step 1: Anchor Robotics to Business Outcomes, Not Technology Ambitions

Intelligent robotics must solve business problems before it solves technical ones. Many enterprises adopt AI for robotics with vague goals like “improve efficiency” or “reduce labor dependency.” This leads to disconnected deployments that look impressive but fail to move performance metrics.

Successful leaders map AI applications in robotics directly to revenue growth, cost leakage, safety exposure, or delivery performance. When AI is introduced as a tool to protect margin or improve service quality, robotics investments become strategic rather than experimental.

Step 2: Build Data Readiness Before Scaling Automation

Data is the backbone of artificial intelligence in robotics. Without reliable data pipelines, robots simply repeat mistakes faster. Most failures in AI robotics adoption happen not on the factory floor, but inside unstable data systems.

Enterprises that scale successfully design centralized data governance models. Real-time validation, structured data ownership, and consistent data formats allow robots to learn safely from live environments.

Step 3: Design for Integration, Not Isolation

Deploying robots without enterprise connection traps intelligence inside machines. For robotics and artificial intelligence to drive impact, robots must communicate with ERP, production planning, customer systems, and workforce platforms.

This is why leaders treat integration as a foundation layer. Modern enterprises architect robotics around APIs, process orchestration platforms, and event-driven workflows so robotics becomes a digital worker inside core operations.

Step 4: Secure Robotics as Critical Infrastructure

As robots become intelligent, they also become attack surfaces. Every robot running on AI becomes a networked device capable of exposing systems, processes, and physical environments.

Security today is inseparable from artificial intelligence in the robotics industry. Enterprises embed Zero Trust frameworks, isolate robotics networks, and audit decision paths to ensure AI-driven systems cannot be exploited or manipulated.

Step 5: Establish Governance for AI Behavior

When AI makes operational decisions, responsibility shifts. Leaders must know who owns compliance when automation acts incorrectly. The role of AI in robotics extends beyond action into accountability.

High-performing organizations define ethical boundaries, failure escalation paths, and audit standards early. Governance is not an afterthought; it is infrastructure for trust.

Step 6: Prepare Teams for Intelligent Systems

Machines may automate motion, but people manage meaning. Organizations underestimate the skill shift required to operate AI-driven systems.

Enterprises investing in generative AI in robotics train teams not just to maintain hardware, but to understand model behavior, decision logic, and exception patterns. Robotics no longer belongs solely to engineering teams; it becomes part of operations leadership.

Step 7: Track Performance Like a Financial Asset

Robotics initiatives often fail because success is measured technically instead of financially. Runtime, throughput, and uptime do not reveal business return.

Leaders measure robotics the same way they measure plants or platforms. Cost per unit, service resolution time, safety incidents, and capacity growth determine whether AI use cases in robotics justify expansion.

Step 8: Design for Continuous Adaptation, Not Stability

Robotics powered by AI must evolve. Models age. Environments change. Human behavior shifts.

Organizations that understand the future of AI in robotics design feedback loops into operations. Monitoring, retraining, and scenario validation allow robotics systems to stay relevant, not brittle.

Measuring the Impact of AI in Robotics: KPIs That Matter to Enterprises

Adopting AI in robotics only makes sense when leaders can see exactly where performance improves and where it does not. Intelligent automation must be treated like a business system, not a technical experiment. The right KPIs turn AI robotics into something measurable, manageable, and scalable.

Operational Performance

Track throughput per hour, order or task cycle time, system utilization rate, and unplanned downtime. These show whether the use of AI in robotics is removing bottlenecks or just creating new ones in different places.

Cost and Financial Impact

Watch cost per unit, energy consumption, maintenance spend, and waste or rework cost. These numbers tell you if the benefits of AI in robotics are translating into real savings instead of staying on paper.

Quality and Accuracy

Measure defect rate, inspection pass percentage, return rate, and rework frequency. This is where artificial intelligence in robotics proves its value quickly by improving consistency and reducing silent failures.

Safety and Compliance

Monitor incident rate, near-miss reports, safety downtime, and audit exceptions. A decline in these proves that artificial intelligence in the robotics industry is strengthening operational discipline, not just speed.

Reliability and Stability

Follow uptime percentage, recovery time after failure, repeat fault frequency, and system availability across locations. These KPIs reflect whether robotics and artificial intelligence are ready for scale or still fragile.

Decision Speed

Track exception resolution time, average response time to disruptions, and backlog reduction rate. Faster execution confirms the role of AI in robotics goes beyond automation into real operational control.

Workforce Impact

Compare overtime hours, training time, error rates, and staff retention after automation. Healthy trends here signal that AI use cases in robotics are supporting teams instead of straining them.

Scale Readiness

Measure rollout time per site, infrastructure load growth, and performance consistency as deployments expand. This shows whether the future of AI in robotics is being built deliberately or drifted into.

Business Intelligence Value

Watch alert accuracy, forecast reliability, override frequency, and data usage by operations managers. Strong results indicate that the application of AI in robotics is improving clarity, not noise.

The Horizon Ahead: Preparing for the Next Wave of AI-Driven Robotics

The next stage of robotics adoption will not feel dramatic. It will show up quietly inside daily operations through faster decisions, fewer handoffs, and systems that start “thinking” for themselves. Companies that prepare now will not be the ones chasing tools later, but the ones reshaping how work actually happens.

Systems Will Start Acting Before Teams React

Robotics platforms will move from assisting teams to working ahead of them. Tasks that once waited on approvals will begin to resolve automatically. Businesses that still rely on layered sign-offs and human queue management will find themselves constantly catching up.

Ownership Will Shift from Tasks to Outcomes

Managers will spend less time directing activity and more time governing results. Responsibility will no longer live in job titles but in how rules and workflows are designed. Organizations that do not adapt will struggle when mistakes occur, because no one will clearly own them.

Job Roles Will Change More Than Job Titles

Automation will not eliminate roles overnight, but it will reshape them quietly. Work will move away from checking and approving toward monitoring and improving. Companies that treat training as optional will feel the impact first when performance dips without warning.

Stability Will Matter More Than Expansion

Fast growth will expose weak systems. As robotics deployments spread across teams and locations, cracks in design will show. Enterprises that invest in consistency early will avoid the chaos that follows rushed rollouts.

Trust Will Decide Who Moves Forward

People will not adopt systems they do not believe in. Whether it is customers or internal teams, confidence will matter more than features. Businesses that build transparency into their systems will move faster with far less resistance.

Partnering for the Robotic Revolution: How Appinventiv Can Lead Your Journey

Navigating the complexities and seizing the opportunities of AI-powered robotics demands more than just vision; it calls for deep expertise and a proven track record in robotics and artificial intelligence. This is precisely where our Artificial Intelligence development services can become a strategic ally.

Our teams work closely with business and operations leaders to identify practical opportunities where intelligent automation can improve performance, reduce cost, or increase resilience. Instead of starting with technology, we start with your business goals and design solutions that fit into your operations naturally.

We build systems that work in the real world, not just in controlled environments. Our engineering approach focuses on creating stable, scalable deployments that integrate with your existing platforms and workflows. Whether you are modernising a factory, optimising logistics, or improving service delivery, we ensure robotics becomes part of your core operations rather than sitting on the side as a pilot project.

We also support you beyond deployment. Intelligent systems need oversight, tuning, and continuous improvement. We help you monitor performance, refine models, and adapt systems as your business changes. This allows your robotics investments to keep delivering value instead of becoming outdated after the initial rollout.

Most importantly, we work as long-term partners, not just implementation teams. From strategy and design through to development and optimisation, we stay involved to ensure your transformation delivers measurable results. Our goal is not just to launch robotics solutions, but to help you build operational strength that lasts.

Get in touch with us to make intelligent automation part of how your business runs every day.

FAQs

Q. What are the benefits of AI in robotics?

A. The benefits of AI in robotics are vast, enhancing efficiency, precision, and adaptability, and driving innovation across industries. By enabling robots to learn autonomously, AI improves performance over time, reducing errors and optimizing operations. This results in increased productivity, cost reduction, and better safety. AI-powered robotics is revolutionizing manufacturing, logistics, and warehouse management, making them smarter, scalable, and more efficient.

Q. What are the best AI robotics solutions for businesses?

A. The best AI robotics solutions for businesses include:

- Autonomous Mobile Robots (AMRs): Automating actions of the logistics and inventory control in warehouses.

- Collaborative Robots (Cobots): Robots to work side by side with humans in the manufacturing industry in order to achieve precision and productivity.

- Predictive Maintenance Robots: Predictive maintenance of equipment with the help of AI to avoid surprises and minimize downtimes.

- AI Customer Service Robots: The customer experiences will improve as a result of automating assistance and fulfillment.

- Autonomous Delivery Robots: AI navigation that will minimize delivery prices and delivery times.

Q. How is AI used in robotics?

A. AI for robotics is used to enhance the capabilities of robots, making them smarter, more efficient, and autonomous. It enables robots to navigate complex environments, recognize objects, and manipulate them with high precision. Through AI, robots can also predict maintenance needs by analyzing their performance, preventing downtime. AI allows robots to learn from their surroundings, improving their problem-solving and decision-making skills over time. Additionally, AI-powered robots can work safely alongside humans in collaborative environments, increasing productivity and reducing operational costs.

Q. Which industries are leading in AI-robotics adoption?

A. Manufacturing industry is the most prominent one in which AI-powered robots are already used in order to fulfill processes such as assembly, material handling, and quality control processes, which contribute to the productivity and accuracy to the greatest extent, and the companies considered to be such ones may be viewed as BMW and Tesla.

AI robots such as autonomous mobile robots could help optimize warehouse and logistic management, stocked items, and order processing, like Amazon and FedEx have done through these robots. Robotics is also infiltrating the medical field, more specifically, surgery and diagnostics, where companies like Intuitive Surgical are changing the way patients are handled. Retail is another leading sector adopter, with AI robotics shaping up to organize customer services, stock level management, and delivery of these, and Walmart and Carrefour are among the pioneers.

Lastly, the agricultural sector is already reaping the benefits of artificial intelligence-powered robots that are deployed to monitor crops and reap harvests, as exhibited by companies like John Deere and FFRobotics. They are setting the future of the area of AI robotics, where these industries alter their ways and push the boundaries on innovation.

Q. How to integrate AI in robotics systems?

A. The inclusion of AI into robotic systems occurs in a few steps. A. First, identify the AI model, e.g., machine learning, computer vision, depending on the point of use. Install sensors and cameras on the robot to collect environment data and engineer real-time decision algorithms. Feed the AI with huge amounts of data and implant self-control mechanisms of mobility and action. Lastly, introduce a feedback loop into continuous learning and adjusting to new tasks. This partnership maximizes efficiency and independence.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

From Chatbots to AI Agents: Why Kuwaiti Enterprises are Investing in AI-Powered App Development

Key Takeaways Kuwaiti organizations are moving beyond basic chatbots to deploy AI agents that handle tasks, analyze data, and support operations intelligently. National initiatives such as Vision 2035 and CITRA regulations are creating a structured environment for AI-powered app development in Kuwait. Businesses in key sectors like banking, oil and gas, retail, and public services…

Beyond the Hype: Practical Generative AI Use Cases for Australian Enterprises

Key takeaways: Enterprises in Australia are adopting Gen AI to address real productivity gaps, particularly in reporting, analysis, and service delivery. From banking and pharmaceutical to mining and agriculture, Gen AI is applied across industries to modernise legacy systems and automate knowledge-intensive and documentation-heavy workflows. The strongest outcomes appear where Gen AI is embedded into…

The ROI of Accuracy: How RAG Models Solve the "Trust Problem" in Generative AI

Key takeaways: RAG models in generative AI attach real, verifiable sources to model outputs, which sharply cuts hallucinations and raises user confidence. Accuracy directly impacts ROI, driving fewer escalations, faster decision cycles, and lower support costs. RAG vs fine-tuning: RAG allows real-time updates without retraining, offering faster deployment and lower maintenance. Vector databases for RAG…