- How Do Cobots Work in Manufacturing?

- Top 10 Use Cases of Cobots in Manufacturing With Real-Life Examples

- Assembly Line Support

- Material Handling

- Welding and Soldering

- Inspection and Quality Control

- Packaging

- Product Testing

- Assembly and Kitting

- Painting and Coating

- Picking and Sorting

- Post-Production Handling

- Benefits of Cobots in Modern Manufacturing

- Increased Productivity

- Better Worker Safety

- Flexibility and Adaptability

- Cost Savings

- Better Human Robot Teamwork

- Less Downtime

- Better Ergonomics

- Satisfied Customers

- How to Successfully Bring Cobots into Your Current Manufacturing Setup

- Figure Out What Your Factory Actually Needs

- Pick the Right Cobot As Per Your Needs

- Reprogram and Train Your People

- Connect With Your Existing System

- Implement Safety and Risk Assessment Measures

- Conduct Pilot Testing and Performance Evaluation

- Establish Ongoing Monitoring and Maintenance Protocols

- Challenges and Considerations for Cobot Integration in Manufacturing

- Big Upfront Costs

- Compatibility with Existing Systems

- Workforce Resistance to Change

- Safety and Compliance

- Implement Cobots in Your Existing Manufacturing System With Appinventiv

- FAQs

Key takeaways:

- Cobots work next to human workers, taking care of repetitive jobs like welding and assembly, boosting efficiency and reducing physical strain. This teamwork is changing traditional manufacturing.

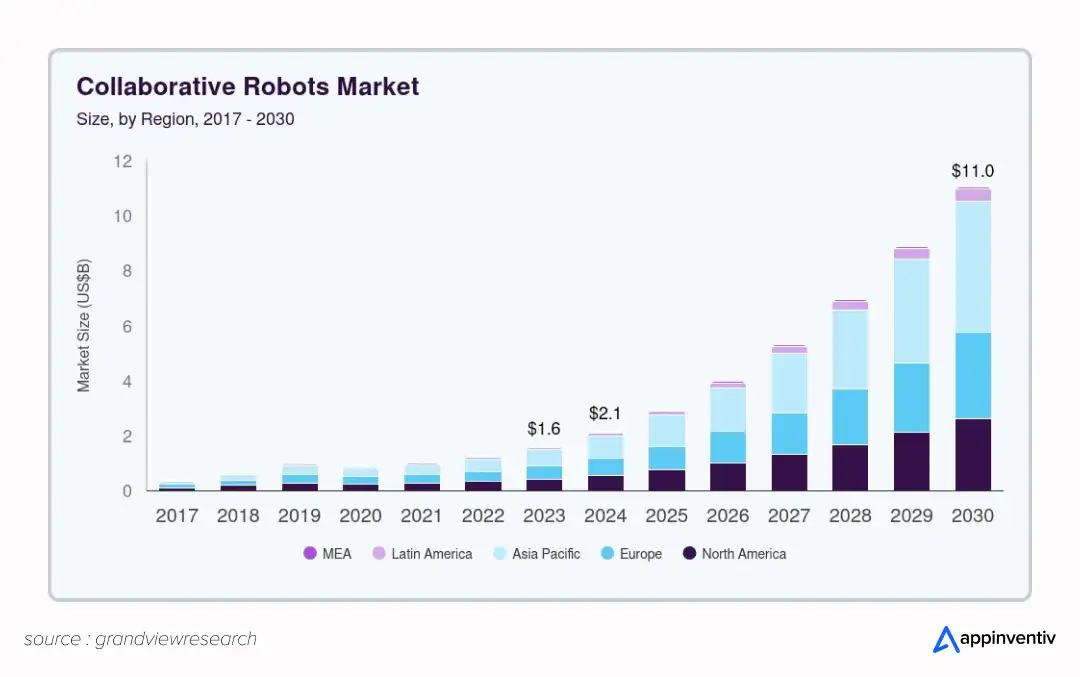

- The cobot market is expected to hit $11.64 billion by 2030, showing the growing move toward automation and the increasing need for flexible, collaborative robots.

- Companies like Ford and BMW are using cobots for assembly line help and precision work, getting higher productivity and safety standards, proving that cobots work well across different sectors.

- From moving materials to checking quality, cobots can be taught new tasks for multiple jobs, letting businesses adjust quickly to changing production needs, cutting downtime, and making processes better.

Collaborative robots, commonly known as cobots, are completely changing manufacturing systems. Gone is the old “robots versus humans” thinking; today, we’re seeing a remarkable shift where robots and humans are working together, not as competitors, but as partners. Cobots are built with this teamwork in mind, designed to work directly alongside human operators rather than replace them. This shift shows up in the growing adoption of cobots across industries.

The numbers tell the whole story. According to the International Federation of Robotics, global installations of industrial robots hit 4 million units, showing the quick integration of automation in manufacturing. As the industry changes, the global cobot market is expected to reach a huge $11.64 billion by 2030, showing just how fast this technology is catching on. (Source: GVR)

This isn’t just some trendy tech fad, either. Companies like Ford are already seeing real results. Their cobots help workers with everything from heavy lifting to bolt tightening, making jobs safer while boosting precision during assembly. It’s exactly what you’d want: better productivity, fewer workplace injuries, and higher quality products.

Again, BMW uses them for precision work, while manufacturers in China rely on cobots for small parts assembly, proving these machines work across different industries and applications.

In this blog, we’re going to look at 10 powerful use cases of cobots in manufacturing, share real examples from companies that are using cobots to drive innovation, improve workplace safety, and reach new levels of efficiency. We will also cover its main benefits, implementation process, challenges and the future it beholds. Let’s take a quick walk through.

Let’s take your manufacturing to the next level!

How Do Cobots Work in Manufacturing?

Collaborative robots are programmed to interact with human workers and introduce a different scope of manufacturing flexibility and efficiency to the manufacturing processes. Cobots in manufacturing, unlike conventional industrial robots, which might be isolated using safety barriers, are designed with sensors, AI, and control measures that enable them to be in the same production line as human beings in a safe manner.

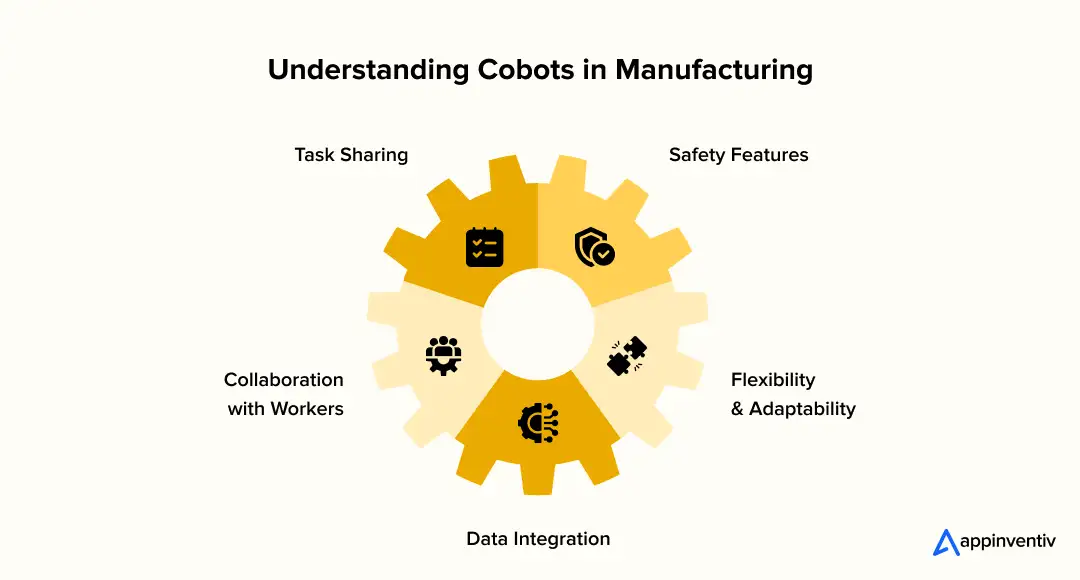

But what is involved in the use of cobots in manufacturing? Here is a bit of a rundown:

Task Sharing: Cobots are assistants who take over repetitive, labor-intensive, or precision work, such as tightening screws, welding, or moving materials. This will leave the human being free to accomplish more complex tasks which will in turn increase productivity in all aspects.

Safety Features: Cobots have superior sensors and artificial intelligence that recognize that the robot is in close proximity to a human. They automatically slow or change directions in response to feelings of resistance or engagement in interaction. This renders them safe to operate in confined spaces with people, which is free of safety barriers.

Flexibility and Adaptability: They are easily reprogrammed to perform new tasks, hence suitable in small and medium-scale businesses where production requirements may change rapidly. This versatility assists the manufacturers in changing tasks that have minimal downtime.

Collaboration with Workers: Cobots do not replace human workers, but instead cooperate with humans. They may help in making processes such as lifting heavy objects easier or make part alignment simpler, relieving workers in a physical way and increasing efficiency and accuracy.

Data Integration: Cases of numerous cobots linked with production management systems or sensors appear, enabling real-time information sharing. It aids manufacturers in regulating workflows and identifying possible maintenance concerns and optimizing their operations.

Top 10 Use Cases of Cobots in Manufacturing With Real-Life Examples

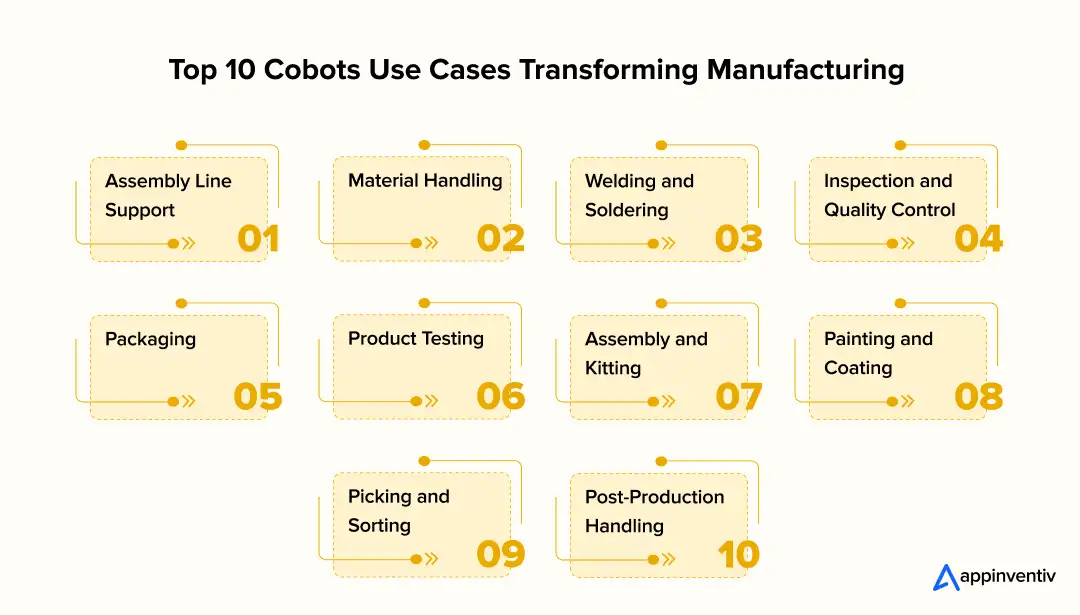

Cobots in manufacturing are revolutionizing industries by enhancing efficiency, improving safety, and enabling more flexible production processes. These collaborative robots are transforming everything from assembly lines to quality control, creating smarter, more agile manufacturing systems. Here are some of the top use cases where cobots are making a significant impact across industries.

Assembly Line Support

Cobots help out on assembly lines by doing the same tasks over and over, like tightening screws, putting parts together, and checking quality, all while working next to people. When you bring cobots in manufacturing, production lines get more efficient and accurate, plus workers don’t get as tired.

At Ford, implementing cobots in manufacturing has cut down on worker exhaustion by taking care of heavy lifting and boring jobs like bolting car parts together, so employees can work on trickier assembly stuff, which makes everything run better.

Material Handling

Cobots are used to move raw materials, load and unload things, and keep components organized, which really cuts down on slowdowns and speeds up how fast things get made. This way of using collaborative robots in manufacturing lets human workers spend time on more important jobs.

BMW puts cobots to work moving materials around their factories. These robots help carry parts smoothly between work areas, so people can focus on putting things together, which makes operations flow much better.

Welding and Soldering

Cobots help out with welding and soldering by doing precise, repetitive work, making sure you get consistent high quality results with hardly any mistakes. Collaborative robots in manufacturing work really well for these jobs that require precise execution.

General Motors has put cobots to work doing welding on its assembly lines. These robots make welds more consistent and of better quality while reducing manual labor, making everything safer and more efficient.

Inspection and Quality Control

Cobots get set up to do careful inspections, finding problems and keeping quality standards high. This way of using cobots for manufacturing gives companies quicker and better checks than human inspectors working alone. These machines can keep going all day and night without getting tired, spotting small flaws that people might miss after hours of work.

Nissan brought cobots into their quality control operations, where the machines check car parts and components visually, cutting defects way down and making products much more consistent. The robots look at hundreds of parts every hour while staying just as precise the whole time.

Packaging

Collaborative robots are showing up more often in packaging work, taking care of jobs like sorting products, putting things in boxes, and sealing packages, while people handle the bigger packaging choices. They work really well with products that need the same placement and careful handling every time.

Coca-Cola put collaborative robots to work improving their packaging operations at manufacturing plants. These machines handle the boring stuff like filling bottles and putting products in boxes, making everything faster and more accurate. The cobots can deal with different bottle sizes and packaging types, switching quickly when production changes to different products.

Product Testing

Cobots get put to work testing products, making sure every single unit meets the right standards before it goes out the door. Their accuracy and reliability really help manufacturers keep their products solid and dependable. These machines can run the same tests over and over without getting bored or making mistakes that tired workers might make.

Siemens puts cobots to work testing products in their electronics factories. The robots take care of checking components repeatedly, keeping quality steady while letting people focus on fixing problems and making processes better. They can test thousands of parts each day while catching issues that might slip through manual testing.

Assembly and Kitting

Cobots help out with tricky assembly jobs and putting together kits before final assembly. Their flexibility makes them great for tasks that need quick changes to build different products when demands shift around. They can learn new assembly patterns much faster than setting up traditional equipment.

Honda uses cobots for assembly and kitting work at their factories. These robots help put together parts for different car models, making it easier to switch between various product setups quickly, which makes operations run much better. The cobots can handle delicate components while maintaining the precise positioning needed for quality assembly work.

Painting and Coating

Cobots take on the exact and repetitive work of painting or coating parts, keeping finishes looking the same and protecting people from harmful chemicals. These machines work great in places where fumes and toxic substances create health problems for workers. They also fit into tight spots where people can’t get smooth coverage.

Tesla puts cobots on painting and coating jobs for car parts, getting precise and even finishes while keeping workers away from fumes and chemicals. The robots handle multiple coats and different paint types while staying consistent across thousands of parts.

Picking and Sorting

Cobots get used for picking and sorting parts in factories, helping with work that needs both speed and accuracy. This improves how things flow and cuts the time needed to organize components. They work all day and night without breaks and handle fragile items that rough treatment might break.

Amazon brings cobots into their shipping centers, helping sort and pick products for delivery. These robots work next to people, making picking faster and reducing mistakes when sorting items. The cobots can find and grab thousands of different products while adjusting to new warehouse layouts.

Post-Production Handling

Once production wraps up, cobots take care of the finished product, doing jobs like packaging, sorting, and getting items ready for shipping. Since they work safely around people, they’re perfect for these kinds of tasks. They can handle different product sizes and packaging requirements without needing major changes to the setup.

Nike puts collaborative robots to work in their post-production facilities to handle and pack finished goods for shipment. This application of collaborative robot in manufacturing makes order fulfillment quicker and more efficient, which improves how the whole supply chain works. The robots can adapt to seasonal changes in product types and shipping volumes without slowing down operations.

Also Read: The Intersection of IoT and Robotics: Transforming Industries and Workforce

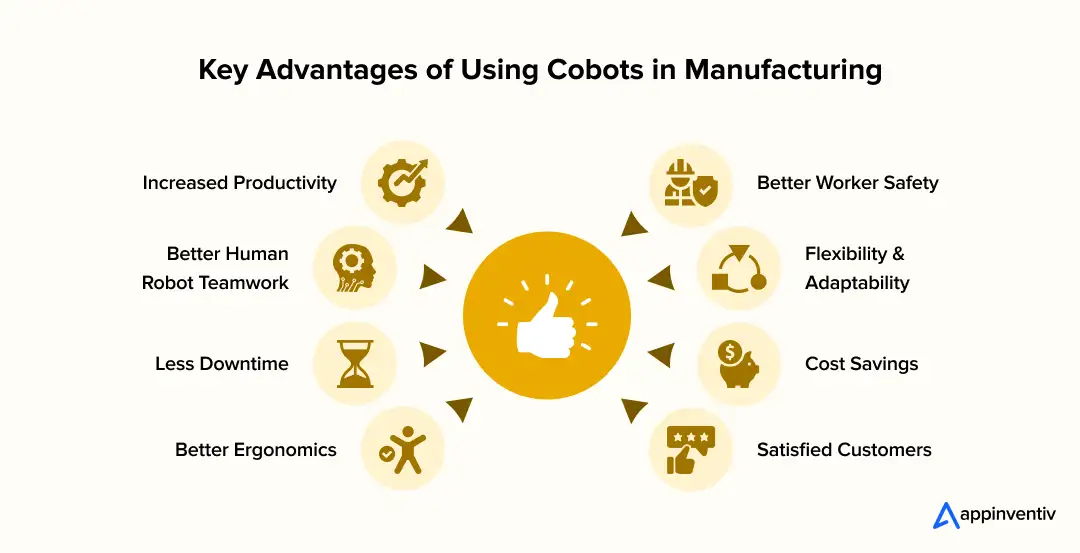

Benefits of Cobots in Modern Manufacturing

Cobots bring a lot of benefits that make them really useful for any manufacturing setup, helping make production more efficient and affordable. Here are some of the main advantages of cobots in manufacturing.

Increased Productivity

Cobots help smooth out boring and physically tough jobs, so human workers can spend time on more valuable work that needs creativity and smart thinking. When integrating cobots in manufacturing, companies get faster production times, better overall output, and can react quickly to changing needs while keeping quality high. These machines don’t get tired or need breaks, so production keeps going longer without quality dropping.

Better Worker Safety

Unlike regular factory robots that work alone, collaborative robots in manufacturing work right next to people, with smart sensors and technology that keep interactions safe. Cobots can tell when someone’s close by and change how they move to stop accidents and injuries from happening.

This makes implementing cobots in manufacturing industry a good way to make shop floors safer. Workers feel better knowing the robots will stop or slow down if they get too close, which creates a much better work environment.

Flexibility and Adaptability

One of the best things about cobots for manufacturing is how flexible they are. You can easily teach them new jobs and change what they do, which works great for smaller businesses that have production needs that go up and down.

Applications of collaborative robots in manufacturing let companies switch between different jobs quickly without stopping everything, making operations run better overall. When market demands shift or new products come in, these machines adapt much faster than traditional equipment.

Cost Savings

While you need to spend money upfront to get cobots, the long-term benefits are way bigger than the costs. Cobots cut labor expenses by taking over boring and physically hard jobs, so people can work on more important stuff.

Plus, cobots work more precisely and make fewer mistakes, which means less fixing things and less waste. Collaborative robots automation in manufacturing industry help companies save a lot of money over time. The payback period is usually much shorter than expected because productivity goes up so much.

Better Human Robot Teamwork

Unlike regular robots, cobots are built to work right alongside people. This teamwork creates a more efficient and helpful work environment. Workers get relief from physically tough jobs, so they can focus on more complicated, creative, and thinking roles.

Industrial collaborative robots make sure both people and machines work together toward the same goals, boosting productivity and making workers satisfied with their jobs. People actually enjoy working with these robots because they feel like helpful teammates rather than threats.

Less Downtime

Cobots work really reliably, and bringing them into manufacturing processes means fewer interruptions. They can keep going without needing breaks, so production lines stay smooth and efficient.

Implementing cobots in manufacturing industry cuts down the time spent fixing things or doing maintenance, making them really valuable for companies that want to avoid stopping production. When something does need attention, cobots can often keep working in a limited way while repairs happen.

Better Ergonomics

Cobots take over jobs that need physical effort, like lifting heavy parts, moving materials, or doing the same motions over and over. This cuts down the physical stress on workers and helps stop injuries like muscle strains and repetitive stress problems.

Cobots for manufacturing make workplace ergonomics better, so employees work in a safer and more comfortable place. Workers can go home each day without the aches and pains that used to come with factory work.

Satisfied Customers

By making production faster, improving product quality, and keeping things consistent, cobots directly help make customers more satisfied. Being able to meet tight deadlines without messing up quality makes companies more competitive in the market.

Collaborative robots automation in the manufacturing industry makes sure companies can get products delivered on time and meet the growing expectations of customers. When orders come in during busy seasons, these robots help maintain the same quality standards even with increased volume.

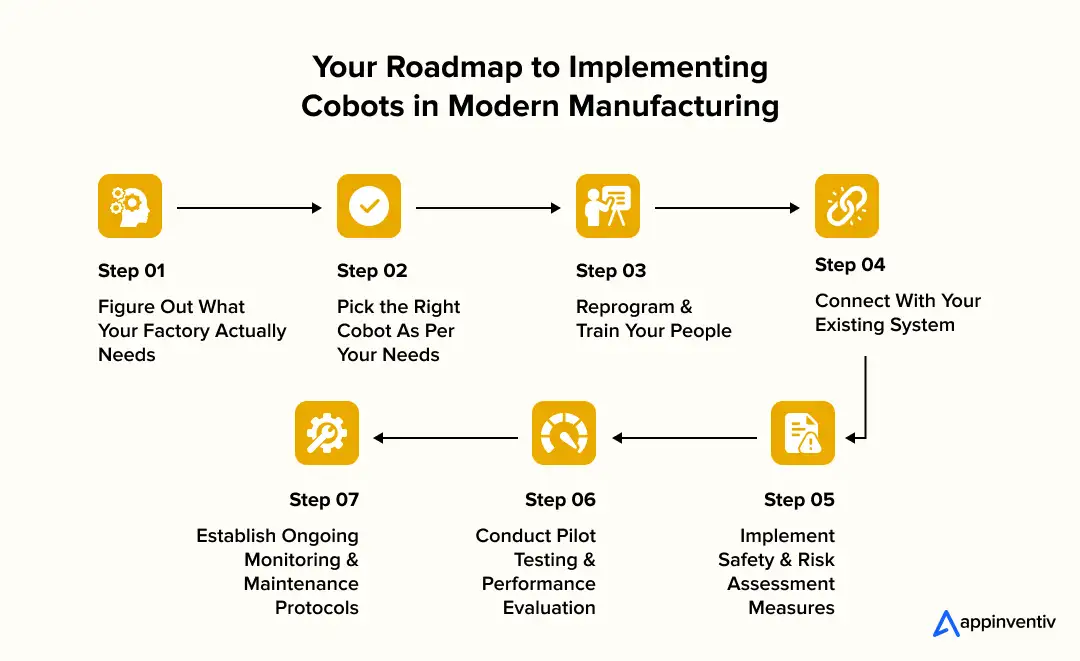

How to Successfully Bring Cobots into Your Current Manufacturing Setup

Getting cobots into your existing factory can really change things for businesses that want to boost their production capacity, make work safer, and improve how everything operates. But implementing cobots in the manufacturing industry takes careful planning, the right setup, and involving key stakeholders to make sure everything works well together. Here are the key steps to help manufacturers successfully add collaborative robots to what they already have.

Figure Out What Your Factory Actually Needs

Before you get cobots, look at the jobs that happen over and over, wear people out physically, or eat up too much time. Find the places where collaborative robots can help the most, such as assembling components, moving materials around, verifying quality, or packing products. This review helps you figure out the best applications of collaborative robots in manufacturing for your specific needs.

Pick the Right Cobot As Per Your Needs

There are different kinds of cobots made for different jobs. Choosing the right one means understanding exactly what tasks the cobot will do, including its size, weight capacity, and reach for your production setup. Cobots for manufacturing come with different features, so picking the best model really matters for getting good results. You also need to think about your workspace layout and whether the robot can fit where you need it.

Reprogram and Train Your People

Collaborative robots in manufacturing are really flexible, but they still need programming to do the specific jobs you want in your system. Reprogramming is pretty easy, but proper training for your team is really important so they know how to work with the cobots the right way. Giving people hands-on training and support helps workers get used to the new technology. Most people pick up the basics pretty quickly once they see how these robots actually work.

Connect With Your Existing System

For things to go smoothly, cobots need to work with your current machines and software. This might mean integrating the cobots with your ERP software, manufacturing CRM, production management system, and sensors. Manufacturing with collaborative robots often requires integrating cobots with existing systems for smooth operation, reducing downtime, and improving overall system performance. You might need some IT help to get all the connections working properly.

Implement Safety and Risk Assessment Measures

Even though cobots get built with safety in mind, you still need to do a careful check to make sure robots and people can work together safely. Set up safety rules, like marking work areas, doing regular upkeep, and monitoring the cobots’ performance. Industrial collaborative robots often come with safety features already built in, but people still need to watch what’s happening. Regular safety meetings help everyone stay aware of how to work around these machines.

Conduct Pilot Testing and Performance Evaluation

Before putting cobots everywhere in your factory, run a test to see how well they work in your manufacturing setup. This step lets you adjust processes, fix any problems, and get feedback from workers on how to make the cobots perform better. The feedback you collect will help guide their placement elsewhere. Most companies find issues during testing that they never would have thought of otherwise.

Establish Ongoing Monitoring and Maintenance Protocols

Cobots work really reliably, but like any machines, they need regular care and checking on how they’re doing. Setting up a system to track cobot productivity, performance, and safety is really important for long-term success. Make sure your team knows how to do routine maintenance and handle any problems that come up. Having someone check on them daily prevents bigger issues from developing later on.

Integrate cobots seamlessly into your manufacturing unit with our expert team and redefine efficiency on your production line!

Challenges and Considerations for Cobot Integration in Manufacturing

While cobots in manufacturing bring lots of benefits, adding them to your operations can create some challenges. These challenges need careful handling to make sure adoption goes smoothly and get the most out of these cobots. Here are some important integration challenges of collbaorative robots for manufacturing and solutions to overcome those.

Big Upfront Costs

The Problem: The initial expenses of buying cobots, software, installation, and training can be really high, making it a big investment for companies.

The Solution: Manufacturers should go into cobot implementation with a clear ROI plan ready. A step-by-step approach, where cobots get slowly brought into high-impact areas, can help spread out costs. Also, some manufacturers might think about leasing options to lower the initial money burden while still getting the benefits from automation.

Compatibility with Existing Systems

The Problem: Cobots in manufacturing need to work with existing machines, production lines, and software systems, which can sometimes be complicated and need system upgrades.

The Solution: A complete check of existing systems before bringing in cobots is really important. Manufacturers should buy cobots that work with existing setups or choose modular cobots that can be easily added and reprogrammed. Getting help from system integration experts can also make the process smoother.

Workforce Resistance to Change

The Problem: Employees might worry about losing their jobs or have trouble adjusting to working next to robots.

The Solution: To get past this resistance, manufacturers should get employees involved in the implementation process. Giving training programs to help workers understand how cobots can make their jobs better, not replace them, is really important. Building a teamwork culture and showing that cobots are there to reduce physical stress, not get rid of jobs, can also calm worries.

Safety and Compliance

The Problem: Even though cobots are designed to be safe, manufacturers need to set up proper safety steps to keep workers protected when working with the robots.

The Solution: Collaborative robots in manufacturing come with safety features already built in, like sensors that spot when people are around and change how the cobot moves. Manufacturers should follow safety standards like ISO 10218 and ISO/TS 15066 and do regular safety training and checks. Making sure workers know how to operate cobots safely is key to keeping the workplace secure.

Implement Cobots in Your Existing Manufacturing System With Appinventiv

The future of manufacturing with cobots looks really promising as technology keeps moving forward. In the next few years, cobots will grow from basic task helpers to really smart, AI-powered partners that can make decisions on their own, improve production lines, and predict when maintenance is needed. With a focus on being flexible, cobots will let manufacturers quickly adjust to market changes, cut down on downtime, and make better quality products. The future will have cobots working smoothly with IoT and AI systems, creating a fully connected and highly efficient manufacturing setup that runs with minimal human intervention.

Appinventiv, as a reputed manufacturing IT services partner, is perfectly positioned to help businesses take advantage of the game-changing power of cobots. With our expertise in AI-driven solutions, we focus on guiding manufacturers through the smooth integration of cobots into existing systems.

We know that adopting new technology needs not just technical knowledge but also strategic thinking. Our experts craft custom solutions to make sure that cobots improve your manufacturing processes, delivering real improvements in productivity, safety, and cost efficiency.

Our work on innovative AI projects like Mudra, JobGet, Americana ALMP, MyExec, and Vyrb shows how Appinventiv is leading the way for future progress. These projects highlight our ability to create meaningful automation and smart decision-making across industries.

With these successes, we bring valuable expertise to manufacturing, helping businesses unlock the full potential of cobots and position themselves for the future of work. Get in touch today to discuss your AI-powered project idea.

FAQs

Q. How do you differentiate between a traditional robot and a cobot?

A. Most of the time, traditional robots operate independently behind safety barriers and perform specific tasks. Cobots for manufacturing work in a different way because they are designed to work together with human workers, sharing workspace and tasks.

These intelligent robots have sensors that make it safe for them to work around people. Cobots, in contrast to conventional robots, are more adaptable, flexible, and actually perform well as a team on factory floors.

Q. How are collaborative robots used in manufacturing?

A. Getting cobots into manufacturing has changed how production lines work by helping with jobs like moving materials, putting things together, and welding. These robots work right next to human workers, improving efficiency without taking anyone’s job. They handle lifting heavy stuff, organizing parts, or making sure everything’s precise.

Manufacturing with collaborative robots makes operations smoother and takes the physical burden off employees, so people can spend time on more important tasks that need human skills.

Q. How do collaborative robots improve productivity in manufacturing?

A. Collaborative robots automation in manufacturing industry makes factories more productive by handling boring or tough physical jobs, so human workers can tackle more complicated stuff. When cobots work next to people, tasks get done quicker with fewer mistakes and better consistency. Since you can easily teach them new jobs, manufacturing with collaborative robots stays efficient and flexible when production requirements change.

Q. How much does it cost to deploy collaborative robots?

A. The cost of getting industrial collaborative robots into your factory depends on things like how complicated the job is, how big the robot needs to be, and what it takes to fit everything together. Most of the time, the cost of cobot implementation runs anywhere from $30,000 to $300,000, plus you’ll need to budget for software, setup, and worker training.

But implementing cobots in the manufacturing industry saves money over time by making operations run smoother, cutting down on labor expenses, and reducing mistakes, which means you’ll see a good return on what you spent.

Q. What safety standards apply to collaborative robots in manufacturing?

A. The safety in the manufacturing industry is key when carrying out cobots. The interaction, design, and operation of industrial collaborative robots are regulated by such standards as ISO 10218-1 or ISO/TS 15066.

The above guidelines enable collaborative robots to be sensor-equipped to perceive the presence of a human and halt or maneuver changes of movements to prevent an injury, hence it is secure to exploit human labour during manufacturing with a collaborative robot and in turn increase safety at the workplace.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.