- Why Warehouse Management Systems Development in Australia Matters

- Building a Warehouse Management System in Australia

- Step 1: Discovery and Needs Assessment

- Step 2: Architecture and Technology Selection

- Step 3: Design and Prototyping

- Step 4: Integration with Other Systems

- Step 5: Pilot Implementation

- Step 6: Phased Rollout and Change Management

- Step 7: Optimization and Automation

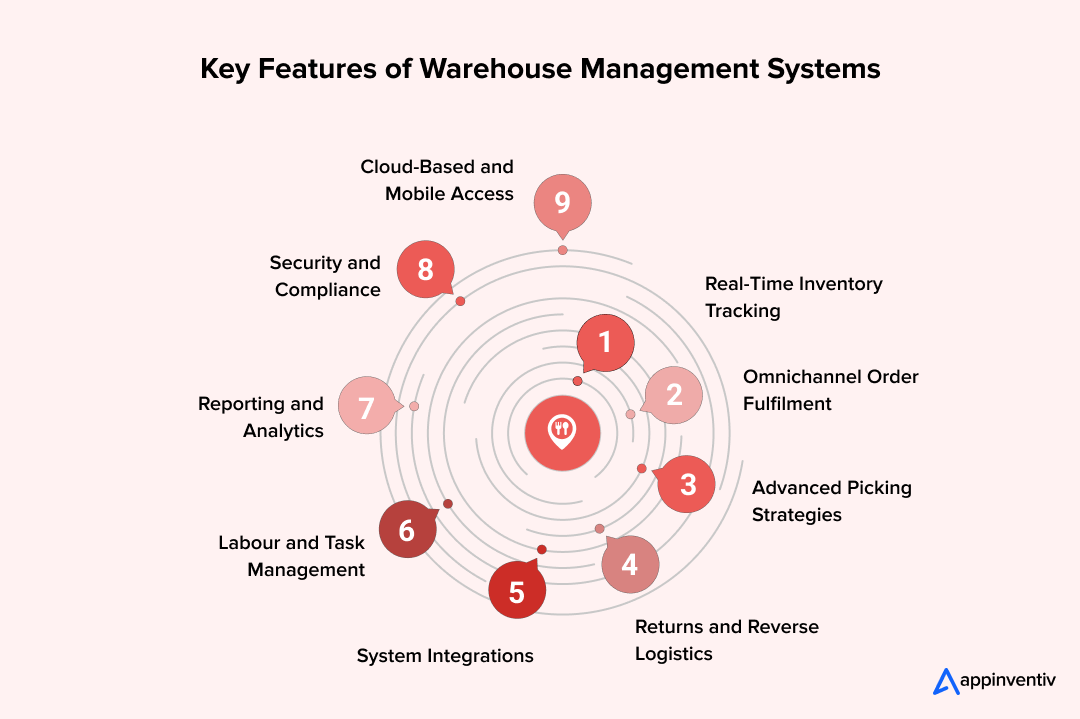

- Key Features of Warehouse Management Systems

- 1. Real-Time Inventory Tracking

- 2. Omnichannel Order Fulfilment

- 3. Advanced Picking Strategies

- 4. Returns and Reverse Logistics

- 5. System Integrations

- 6. Labour and Task Management

- 7. Reporting and Analytics

- 8. Security and Compliance

- 9. Cloud-Based and Mobile Access

- Which WMS Features Do You Really Need?

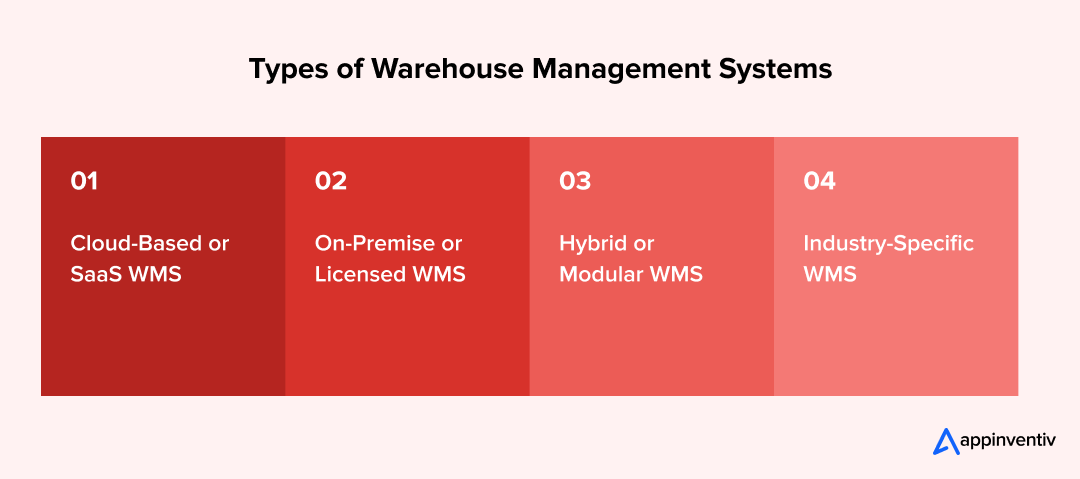

- Types of Warehouse Management Systems for Australia

- 1. Cloud-Based or SaaS WMS

- 2. On-Premise or Licensed WMS

- 3. Hybrid or Modular WMS

- 4. Industry-Specific WMS

- Common Challenges When Implementing a WMS (and How to Avoid Them)

- 1. Over-Customisation

- 2. Skipping the Pilot Phase

- 3. Weak Change Management

- 4. Poor Data Quality

- 5. Ignoring Mobile and User Experience

- Cost Considerations and the Build vs Buy Decision

- Cost Range Overview

- Build vs Buy — Making the Right Choice

- Why Choose Appinventiv for Your Warehouse Management Software Development

- Frequently Asked Questions

Key takeaways:

- Before you build a Warehouse Management System (WMS) in Australia, check how things work in your warehouse right now. Find the problems that slow you down.

- You’ll need to create the system design. Then choose what technology to use. Connect it to the tools you already have. Train your team so they know how to use it properly.

- A warehouse management system development in Australia keeps track of your stock, speeds up how you process orders, and cuts down on mistakes people make.

- Cloud-based WMS options work well for small and medium businesses, and plenty of larger companies use them too.

- What you’ll spend usually sits somewhere between $35,000 and $400,000 or more, depending on how big your business is and what you’re after.

- Working with a WMS provider who knows what they’re doing means smoother day-to-day operations and better chances your business keeps growing.

Running a warehouse in Australia today is tougher than ever. Rising logistics costs, growing online orders, and labour shortages are putting immense pressure on operations. The Australian Logistics Council states that the freight and logistics sector contributes 8.6% of Australia’s GDP.

Still, many businesses use old systems to track inventory, watch orders, and handle shipments. The consequences include excess stock, delayed deliveries, and financial losses.

A Warehouse Management System (WMS) helps fix these issues. It shows you what’s happening right now in your warehouse. It cuts down on manual tasks. It makes sure orders go out correctly.

This post explains how to build a warehouse management system in Australia that can grow with your business and follow Australian rules. We’ll show you the main features you need, what different industries require, how to set it up step by step, and what benefits your business gets.

Join hands with us to build your WMS now.

Why Warehouse Management Systems Development in Australia Matters

Australia’s logistics landscape is changing fast. Online shopping continues to grow each year, driven by new trends. Especially, with social commerce pushing things along, customers expect a quick response. They expect orders to be fast, want returns to be painless, and like knowing exactly where their package is. If your WMS in Australia isn’t up to scratch, keeping up with all this gets really hard.

Many Australian warehouses are still running on spreadsheets or using different tools. These don’t interact with each other. This leads to incorrect inventory counts, late shipments, and excessive labor costs. When you factor in how far apart Australian cities and regional areas are, these problems cost you time and money fast.

Warehouse management software development in Australia can tackle these challenges. You can see all your inventory in one place, cut down on manual work, and run everything from one system. Managers know where products are, how quickly orders are moving, and can spot holdups the moment they happen.

For Australian businesses, benefits of implementing warehouse management system offer clear benefits, like:

- Fewer picking and packing errors

- Faster order fulfilment

- Lower operating and labour costs

- Better customer satisfaction

The Australian WMS market is picking up speed as businesses hunt for supply chains that work smarter and connect better. Companies jumping on WMS technology now get ahead of their competition—they control operations better, get more done, and have warehouses that can handle whatever growth comes next.

Building a Warehouse Management System in Australia

Building a Warehouse Management System (WMS) isn’t just about coding software. Then? How to build a warehouse management system in Australia?

You need to make something that fits your warehouse the way it actually works. It needs to match what your team can do and what your customers want. In Australia, supply chains often go across states and cover really long distances. That’s why planning and doing it right matters so much.

Here’s a step-by-step guide for Australian businesses that want to build a WMS that works well and grows with them.

Step 1: Discovery and Needs Assessment

Begin by understanding how your warehouse runs today. Document each process from receiving goods through to dispatch. Talk to your warehouse managers, floor workers, and the people who handle your logistics. Find what’s broken—maybe your picking routes take too long or your stock counts are always wrong.

Set clear goals. How accurate your inventory should be? How fast orders should process? What your fulfillment rate needs to be? Australian companies also need to think about regional stuff. How long trucks take to get places? How weather messes things up? And, how to keep multiple warehouses in sync?

Step 2: Architecture and Technology Selection

Choose the right tech foundation for your WMS. Decide if on-premise, hybrid, or cloud-based warehouse software in Australia works best for you.

Most Australian retailers and logistics companies prefer cloud-based systems. You can access them from anywhere. Warehouses in different spots can share data without problems.

Pick your technology stack early—your backend setup, database, and how it connects to other systems. Make sure it can grow when you add automation equipment or robots later.

Step 3: Design and Prototyping

Before you create the full system, build a working model (prototype). This should have your main warehouse features. Focus on tracking inventory, picking, packing, and shipping. Make screens that warehouse workers can use easily on their phones or tablets, all day.

Test the prototype in just one small area first. You’ll find user issues and workflow problems early. In Australia’s fast eCommerce market, even tiny design changes can speed things up and make them more accurate.

Step 4: Integration with Other Systems

Your WMS needs to integrate with other systems. It could be ERP, eCommerce platform, transportation management system, and barcode or RFID hardware. Without these connections, it won’t work properly.

These links help with real-time warehouse tracking systems in Australia. It lets the information flow in between sales, inventory, and delivery. A customer orders something online, and your WMS instantly updates stock and creates a picking task.

Plan your integrations carefully. They’re what make a coordinated, accurate supply chain actually work.

Step 5: Pilot Implementation

Run the WMS in one warehouse or department first. Set measurable goals — such as a 10% increase in picking speed or zero stock errors during the pilot period.

Use this phase to train staff and collect feedback. In Australia, where teams frequently work different shifts or across regions, proper training ensures uniform performance at all locations.

Expand to additional sites once the pilot demonstrates success.

Step 6: Phased Rollout and Change Management

Roll out the system slowly instead of doing everything at once. Start with basic parts like inventory and order tracking. Add more features after that.

Help your team get used to it with hands-on training and simple guides they can really use. Listen to what they tell you and fix problems fast. When you handle the change well, your warehouse keeps working smoothly while you put everything in place.

Step 7: Optimization and Automation

Track the performance of warehouse management systems for Australian businesses after going live. Check the numbers for order accuracy, how long picking takes, and how well you use your warehouse space.

When your business grows, consider adding automation—robots that pick items, AI tools that forecast demand about what customers will order, or better storage layouts.

Australian warehouses pay high wages and deal with long shipping distances. These technologies can really help you work faster and spend less.

Implementation Timeline

A question may pop up in your mind; how long does warehouse management system development take? Have a look at the standard timeframes for building and launching a WMS in Australia:

- Small to mid-sized business: 3–6 months

- Mid-market enterprise: 6–12 months

- Large, multi-location network: 9–18 months

Your actual timeline depends on how complex the system is, getting your data ready, and what integrations you need.

Warehouse management system development in Australia is a long-term investment. When you do it right, you get better visibility, faster order fulfillment, and lower costs across your supply chain. For Australian businesses, it means staying competitive in a market where speed, accuracy, and reliability aren’t optional.

Key Features of Warehouse Management Systems

Good warehouse management software development in Australia gives you complete control over warehouse operations—from when stock arrives to when orders ship out. Here are the core features of Warehouse Management Systems for Australian businesses.

1. Real-Time Inventory Tracking

A WMS keeps watching your stock levels using barcodes, RFID tags, or scanners. Every move—receiving stuff, picking it, or shipping it out—updates the system straight away. This cuts down on mistakes, stops you from running out of stock, and keeps you informed across multiple locations.

Your inventory might be spread across warehouses that are hundreds of kilometers apart. You may also create an inventory management software to handle them with ease. This real-time warehouse tracking system in Australia makes sure you’ve got accurate information for every single site.

2. Omnichannel Order Fulfilment

Customers buy from all sorts of places now—online stores, marketplaces, physical shops. A WMS pulls all these channels into one platform. It handles Buy Online, Pick Up In Store (BOPIS), ship-from-store, and dropshipping without making a mess of things.

This unified setup gets orders out faster and keeps inventory tighter, which really matters for Australian retailers covering huge geographic areas.

3. Advanced Picking Strategies

Efficient picking methods reduce both time and labor costs. A WMS supports different approaches like wave, batch, or zone picking. These methods optimize travel routes and help staff collect orders more quickly. Some systems include voice or vision picking for hands-free work, which decreases errors and increases speed during peak periods.

4. Returns and Reverse Logistics

Returns are just part of retail now, especially for fashion and eCommerce. Warehouse management solutions make this easier by tracking what comes back and marking items for inspection, quarantine, or putting back on shelves. It stops damaged or expired products from getting back into circulation. Your inventory records stay cleaner and customers have a better experience.

5. System Integrations

A WMS that works well connects smoothly with your other platforms—ERP, POS, TMS, and eCommerce systems. Data flows constantly between them, keeping inventory, orders, and shipping information in sync. These integrations get rid of manual data entry mistakes and make orders more accurate.

For growing Australian companies, these connections mean your warehouse, sales, and finance teams all stay on the same page.

6. Labour and Task Management

Labor costs keep climbing across Australia, so getting more out of your workforce matters more than ever. If you develop a WMS software in Australia, it hands out tasks based on who’s good at what, where they are, and what they’re already doing.

It tracks how productive people are, finds bottlenecks, and spreads work evenly across shifts. This means less time wasted and everyone working productively.

7. Reporting and Analytics

Modern warehouse management software development in Australia collects detailed data on inventory accuracy, how fast picking happens, and fulfillment times. Managers can pull up performance dashboards, spot where things are slowing down, and plan how to do things better.

Predictive analytics can also forecast demand, helping prevent overstocking or shortages — both common issues in Australia’s seasonal retail market.

8. Security and Compliance

A WMS keeps detailed records for every item. This helps you track products and follow the rules in sectors like food, healthcare, and logistics.

In Australia, businesses need to follow specific regulations based on what they store and ship. Like:

- Food and beverage warehouses must follow Food Standards Australia New Zealand (FSANZ)) codes. They also must keep cold chain records.

- Healthcare and pharmaceutical operations need to meet Therapeutic Goods Administration (TGA) requirements. It includes how they store items and track products.

- If you handle hazardous materials, you must follow dangerous goods regulations under the Australian Dangerous Goods Code.

- There’s also the Privacy Act 1988. It controls how customer and employee data are handled.

A WMS with secure access controls, role-based permissions, and encrypted data storage helps you follow these rules. Digital records mean you can find documents fast during audits. This saves time and keeps regulators satisfied.

9. Cloud-Based and Mobile Access

Cloud WMS platforms offer remote access, rapid updates, and straightforward scaling as operations grow. They work really well for companies running warehouses in different states or regions. Mobile features mean warehouse staff can scan, update, and track items right from their handheld devices, even when internet coverage gets patchy.

These features together help warehouse management systems for Australian businesses run more accurately, efficiently, and smoothly. They make daily work better while getting businesses ready for growth, automation, and selling internationally.

Which WMS Features Do You Really Need?

Not every business needs the same level of warehouse automation. The right WMS depends on your business needs.

Below is a simple comparison. It will help Australian businesses decide which features are essential and which can be added later as they scale.

| Features | For SMEs | For Enterprises |

|---|---|---|

| Real-Time Inventory Tracking | ✅ Essential for visibility and error reduction | ✅ Core requirement, often with RFID or IoT integration |

| Order Management & Fulfilment | ✅ Basic order routing and picking | ✅ Advanced omnichannel routing, dynamic slotting |

| Barcode Scanning / Mobile Access | ✅ Key for fast data capture | ✅ Expanded to voice or vision picking |

| Returns & Reverse Logistics | ✅ Simple return tracking | ✅ Automated workflows, restock and refund integration |

| System Integrations (ERP, POS, eCommerce) | ✅ Basic API or CSV integration | ✅ Real-time multi-system data sync, middleware-based |

| Reporting & Dashboards | ✅ Standard operational reports | ✅ Custom analytics, predictive insights, AI forecasting |

| Labour & Task Management | ✅ Optional for small teams | ✅ Advanced workforce planning and productivity analytics |

| Cloud Access & Scalability | ✅ Cloud-based or hybrid for flexibility | ✅ Enterprise-grade scalability across multiple sites |

| Security & Compliance | ✅ Role-based access control | ✅ Full audit trails and regulatory compliance features |

| Automation & Robotics Support | ❌ Not required initially | ✅ Integration with AMRs, conveyors, and IoT devices |

Types of Warehouse Management Systems for Australia

Different businesses have distinct warehouse requirements. Some need quick deployment and adaptability, while others require extensive control and customized workflows. Selecting the appropriate custom warehouse management system depends on your company’s size, budget, and sector.

1. Cloud-Based or SaaS WMS

Cloud-based warehouse management solutions operate on remote servers and users access it through a web browser. It can be deployed quickly without significant IT infrastructure.

- Suitable for SMEs and rapidly expanding retailers

- Lower initial costs and straightforward scaling

- Vendor handles regular updates and data backups

- Effective for businesses operating multiple locations across Australia

This option appeals to eCommerce brands because it provides real-time visibility and remote access from any device.

2. On-Premise or Licensed WMS

An on-premise WMS is installed on a company’s own servers. The business maintains complete control over data, security, and system configuration.

- Appropriate for large enterprises or regulated sectors like healthcare, food, and cold storage

- Enables extensive customization for specialized workflows or compliance requirements

- Demands higher initial investment and continuous maintenance

This approach suits businesses needing strict oversight of sensitive data or managing complex warehouse operations.

3. Hybrid or Modular WMS

A hybrid WMS blends on-premise and cloud capabilities. Businesses can store critical data on local servers while using cloud resources for analytics or system integrations.

- Works well for companies scaling operations or running in phases

- Provides flexibility to incorporate modules like automation or reporting as needed

- Minimizes operational disruption during upgrades or expansion

Hybrid models are common among large Australian supply chains requiring both control and adaptability.

4. Industry-Specific WMS

Some WMS solutions are designed for particular industries.

- Cold chain and food businesses: focus on expiry, temperature, and batch tracking

- Pharma and healthcare: ensure full traceability and compliance

- Fashion and retail: support fast returns and size-based inventory

- 3PL providers: handle multiple clients and billing structures

These warehouse management system developments in Australia come with built-in templates, saving time and reducing setup costs.

Which One Should You Choose?

- Small to mid-sized retailers or eCommerce brands: Cloud-based WMS

- Large or regulated organisations: On-premise WMS

- Growing businesses with mixed needs: Hybrid or modular WMS

- Specialised sectors (FMCG, pharma, logistics): Industry-specific WMS

Selecting the right WMS ensures your warehouse stays efficient, compliant, and ready for future growth — no matter where your customers are in Australia.

Scale with a Custom Logistics Solution Built for You.

Common Challenges When Implementing a WMS (and How to Avoid Them)

Warehouse management system development in Australia can really improve operations, but the process comes with several challenges. Many Australian businesses run into similar problems during setup.

1. Over-Customisation

Adding every possible feature sounds good, but too much customization slows down setup and makes future upgrades harder.

Solution: Focus on features that fix your main warehouse problems first. Add advanced modules only after the core system works reliably.

2. Skipping the Pilot Phase

Some companies deploy the full system immediately. This creates more workflow problems and confuses staff.

Solution: Start with a pilot project in one location or process area. Test the system, make needed changes, and train your team before rolling it out to all warehouses.

3. Weak Change Management

A new system alters how employees work. Without good communication and training, even a great WMS can fail.

Solution: Get warehouse teams involved from the start. Explain the benefits clearly and run practical training sessions. Keep communication open during the entire rollout.

4. Poor Data Quality

Old or wrong stock data causes bad inventory counts and delayed orders.

Solution: Clean and check all data before moving it to the new system. Set clear rules for ongoing data entry and barcode scanning.

5. Ignoring Mobile and User Experience

When a system is hard to use, staff will either avoid it or make lots of mistakes.

Solution: Pick a WMS with an easy-to-use, mobile-friendly interface that works well on handheld devices and tablets.

With careful planning and fixing these common challenges, Australian businesses can make sure their WMS project brings real, lasting benefits—more efficient operations, quicker fulfillment, and better visibility throughout the supply chain.

Cost Considerations and the Build vs Buy Decision

The building or implementing a warehouse management system cost in Australia varies considerably. Final expenses depend on your business size, system complexity, integrated features, and required tech stack for backend, database, integration, and more.

Cost Range Overview

A small business seeking a straightforward, cloud-based WMS typically invests around $35,000–$40,000. This generally includes system design, basic integrations, and staff training.

Costs can reach $150,000–$400,000 or higher for mid-sized and enterprise operations. This happens especially when you add advanced AI-powered warehouse management systems in Australia for automation, analytics, and connections to many other systems.

Here’s what affects the final investment:

- Licensing & Subscriptions – Regular payments for SaaS or on-premise licenses

- Hardware Costs – Barcode scanners, RFID systems, and mobile devices

- Integration Effort – Connecting with ERP, CRM, and eCommerce platforms

- Customization – Changing workflows and reports to match how your warehouse works

- Features Complexity – Getting the specific features your business needs

- Training & Support – Ongoing staff training, system updates, and maintenance

These parts add up to form the Total Cost of Ownership (TCO)—a mix of upfront setup costs (CAPEX) and regular operational costs (OPEX).

Build vs Buy — Making the Right Choice

| Factor | Build Custom WMS | Buy Pre-Built WMS |

|---|---|---|

| Cost | Higher upfront cost ($150k–$400k+) | Lower initial cost ($35k–$120k) |

| Time to Market | 6–18 months | 1–3 months |

| Scalability | Fully scalable and flexible | Limited by vendor options |

| Control | Full ownership of features and data | Dependent on vendor updates |

| Best For | Businesses with complex, unique processes | SMEs or fast-growing businesses |

Picking the right WMS means more than just looking at cost—it’s a choice that affects your long-term growth. Ready-made systems work well for some businesses. A custom-built WMS gives you more control and flexibility to grow and change as your business expands. This means better efficiency and accuracy over time.

Let Us Guide You to the Right Solution Within Your Budget.

Why Choose Appinventiv for Your Warehouse Management Software Development

At Appinventiv, we specialize in building warehouse management systems for businesses across Australia. Our team knows the ins and outs of supply chains and logistics software development services in Australia.

Over 1,600 tech experts have developed more than 3,000 solutions across industries such as retail, manufacturing, and logistics. We understand how important it is for your warehouse system to be reliable and easy to use.

- We have deep experience develop a WMS software in Australia that can grow with your business.

- Our experts use the latest technology. It makes sure your system runs fast, stays secure, and grows easily as your needs change.

We can help you with real-time inventory tracking, automation, or connections to other tools. Our team works closely with you to understand your business needs and builds a custom solution that just fits right.

We don’t just make software. We build systems that make your warehouse run smoother, cut down on errors, and give you better visibility. We also make sure your WMS can be updated or expanded easily as your business grows.

As a Deloitte Technology Fast 50 company and a Clutch Global Award winner, we’re known for creating high-quality software that helps businesses succeed.

Our technical skills and years of experience help us build the right WMS so your business runs well now and in the future. Contact us to get started!.

Frequently Asked Questions

Q. What is a warehouse management system, and how does it work?

A. A warehouse management system (WMS) is software that runs your warehouse better. It counts stock, handles orders on its own, manages picking and packing, and updates inventory instantly.

With WMS software, you see all your stock at any time. You make fewer errors, spend less money, and send correct orders to customers.

Q. How much does a warehouse management system cost in Australia?

A. The cost for warehouse management system development in Australia depends on your needs. The price depends on your company size, system and features complexity, and what it needs to connect with.

Small and mid-sized businesses typically pay $35,000–$40,000. Big companies with many warehouses or special automation needs might pay $150,000–$400,000 or more.

Cloud-based systems cost less upfront. Custom-built software costs more but fits your exact needs.

Q. How do Warehouse Management Systems adapt to different industries?

A. Different industries need different WMS features. Here’s how warehouse management systems work for different industries in Australia:

- Retail and eCommerce: Tracks stock in real time. Routes orders automatically. Handles Buy Online, Pick Up In Store and same-day delivery.

- FMCG, Grocery, and Cold Chain: Manages expiry dates, temperature, and batch numbers. Cuts waste. Follows food safety rules.

- Healthcare and Pharmaceutical: Tracks every product. Controls temperature. Keeps records for healthcare rules.

- Manufacturing and Spare Parts: Tracks materials. Links with ERP systems. Stops production delays.

- 3PL and Logistics Providers: Handles many clients. Does custom billing. Tracks inventory in real time.

A WMS built for your industry works better and keeps customers happy.

Q. Why should Australian businesses invest in a WMS?

A. Australia has unique supply chain problems. Goods travel far. Operations cost a lot. Customers expect fast delivery.

A WMS fixes these issues. Your stock counts are right. You use warehouse space better. Orders ship faster. Customers get packages sooner.

The right system keeps you competitive as online shopping grows.

Q. Can a WMS integrate with ERP or eCommerce systems?

A. Yes. Modern WMS software in Australia connects with ERP systems, online stores, and shipping tools.

Here’s how it works: A customer orders online. The WMS updates stock instantly. It tells the ERP to make an invoice. It starts the shipping process.

This cuts inventory errors and makes customers happier.

Q. How to set up a warehouse management system in Australia?

A. First, look at how your warehouse runs today. Find where automation helps most. Pick between building custom software or using a cloud system.

Then follow these steps: Write down what you need. Design the system. Connect it to your other tools. Test it. Train your workers.

Start small. Test in one warehouse. When it works well, add your other locations.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Computer vision is no longer a futuristic concept confined to sci-fi books and movies. The technology is everywhere, subtly reshaping the way users interact with technology. From facial recognition on smartphones to quality inspections on factory floors, computer vision helps machines interpret and understand images, videos, and other visual inputs. This powerful technology has proven…

Route Planner App Development - Costs, Benefits, Features

In the complex world of logistics, where cost-effectiveness and on-time delivery are crucial, route planning is a prominent challenge that can significantly impact the business's bottom line. For fleet managers and drivers alike, navigating the intricate web of roads, traffic, and constantly shifting variables can be an enormous undertaking. This is where route planner apps…

Custom Transportation Management System Development - Benefits, Costs, and Features

Key takeaways: Transportation management system development helps enterprises improve delivery reliability, freight control, and end-to-end visibility at scale. Custom TMS software supports deep ERP, WMS, and carrier integrations that standard platforms struggle to handle in complex environments. A build-first approach gives enterprises long-term control over architecture, performance, and future expansion without platform constraints. TMS implementation…