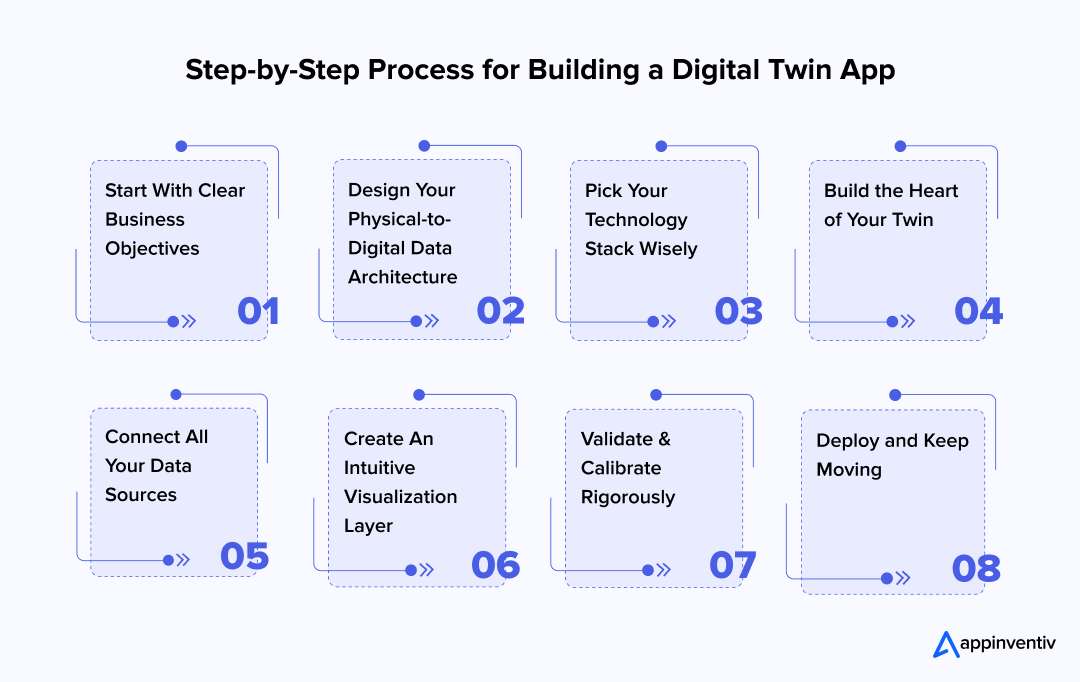

- Step-by-Step Guide on How to Create a Digital Twin Application

- Step 1: Start With Clear Business Objectives

- Step 2: Design Your Physical-to-Digital Data Architecture

- Step 3: Pick Your Technology Stack Wisely

- Step 4: Build the Heart of Your Twin: The Simulation Model

- Step 5: Connect All Your Data Sources

- Step 6: Create an Intuitive Visualization Layer

- Step 7: Validate and Calibrate Rigorously

- Step 8: Deploy and Keep Improving

- Key Technologies Used in Digital Twin App Development: IoT, AI, and More

- Core Features of a Digital Twin Application

- What Are the Most Common Challenges in Building a Digital Twin Application?

- 1. Quality and Integration of Data

- 2. Scalability

- 3. Security and Privacy

- 4. Integration with Existing Systems

- 5. High Development Costs

- Understanding the Costs of Building a Digital Twin

- The Future of Digital Twin Technology: Trends and Innovations to Watch Out For

- How Appinventiv Can Help You Build a Digital Twin App?

- Frequently Asked Questions

Key takeaways:

- IoT, AI, cloud computing, and data analytics are the main technologies for making real-time, predictive digital twins.

- Digital twins are revolutionizing the manufacturing, healthcare, and energy sectors and providing significant operational efficiency and cost reduction.

- 5G, edge computing, and AR/VR not only lift digital twin performance but also provide fast data processing and highly engaging experiences.

- Predictive maintenance and real-time monitoring are major advantages that help companies avoid downtime-related losses and operate at their best.

Digital Twin adoption has moved beyond simple visualization. The new enterprise goal is preemptive, autonomous control over complex, high-value assets. High-fidelity digital twin construction is a specialized systems engineering problem. Success requires deep architectural expertise in real-time data fusion and closed-loop feedback systems. This blog provides the complete technical blueprint for that endeavor.

You will get to know how to build a digital twin app with a simple 8-phase cycle. It covers everything from IIoT data ingestion via Kafka to the rigorous validation of model fidelity. Key technical sections address the integration of Reinforcement Learning (RL) for autonomous control and the deployment of resilient Edge-Native Microservices.

A precise cost breakdown is included for these complex structures. The analysis shows how a multi-million dollar System of Systems delivers a guaranteed 20–50% ROI on downtime reduction. The result is a complete, actionable roadmap on how to build a digital twin app for measurable, enterprise-grade control.

With 70% of C-suite technology executives already exploring digital twins, now’s the time to jump in!

Step-by-Step Guide on How to Create a Digital Twin Application

In our new economy, where tech behemoths rule, reality is being virtualized, and everything is on track to have a paired digital twin.

Victoria Silchenko (Ph.D), Economist turned Entrepreneur and Advisor.

Creating an effective digital twin takes more than just good coding skills. You need a specialized approach that puts data flow and modeling accuracy at the center. After working on several of these projects, we’ve identified eight steps in the digital twin app development process that really separate successful deployments from those that fall flat.

Here are the steps to develop a digital twin app:

Step 1: Start With Clear Business Objectives

Before you touch any code, sit down and figure out what problem you’re actually solving. Are you trying to optimize asset maintenance? Predict energy consumption? Simulate supply chain disruptions? Nail this down first. This clarity is crucial for digital twin development because it tells you exactly which data sources you’ll need and how precise your models need to be.

Step 2: Design Your Physical-to-Digital Data Architecture

This is where you map out how data travels from the real world into your digital environment. You need a solid sensor network (that’s your IoT infrastructure) connected to pipelines that can process huge volumes of data in real time. We’re talking terabytes every single day. Here’s how to handle it:

- Edge Computing: Process data right where it’s generated. AWS Greengrass and Azure IoT Edge are good options here. They let you filter and compress information at the asset itself before it goes anywhere else. This saves bandwidth and speeds things up considerably.

- Ingestion: You need reliable pipelines. MQTT is great for lightweight, two-way messaging. Kafka is my go-to for high-volume streaming because it just doesn’t quit.

- Storage: You’ll probably need multiple storage types. Time-series databases work best for rapid sensor queries, but you also need data lakes (AWS S3 or Azure Data Lake) for historical records. The critical part is ensuring smooth data flow in both directions between your physical assets and their digital counterparts.

Step 3: Pick Your Technology Stack Wisely

Time to choose the right technology stack. What platform makes sense for your situation? Python is basically the standard for data science work. C# is widely used for enterprise integrations. For digital twin application development, it’s crucial to select a platform that offers both scalability and real-time processing capabilities. Time-series databases aren’t optional here, by the way. And if you need 3D rendering, look at Unity or Unreal Engine, depending on your specific requirements.

Step 4: Build the Heart of Your Twin: The Simulation Model

This is the really crucial part. How you model things determines everything else. How accurate will it be? How quickly can you deploy? How much data do you need? You’ve basically got two approaches:

- Physics-Based Models (White-Box Approach): These use established engineering principles. Finite element analysis, computational fluid dynamics (CFD), that sort of thing. They model structural stress, heat distribution, material behavior. Super accurate, but they eat up computing resources like crazy and need specialized software.

- AI-Based Models (Black-Box or Gray-Box): Machine learning territory. RNNs and Transformers can pick up complex patterns from your historical data and predict future states. Like figuring out when equipment will fail (we call this Remaining Useful Life or RUL). Powerful stuff, but you need a lot of quality training data.

Step 5: Connect All Your Data Sources

Here’s where a digital twin goes from interesting to actually valuable. You combine real-time sensor data with the bigger operational picture. That means:

- Data Harmonization: Build a layer that standardizes everything. Different systems use different timestamp formats, different units of measurement. You need to normalize all of it so these systems can communicate properly. For digital twin mobile app development, seamless integration across platforms is crucial to ensure real-time data flow.

- Contextual Data: Connect to your ERP for maintenance schedules and inventory. Pull from your MES for production order details. This context is what makes the sensor data meaningful.

- Bi-Directional Control: Some twins need to send commands back to physical systems. If yours does, you absolutely must have a secure API Gateway managing those control signals. Safety first on this one.

Step 6: Create an Intuitive Visualization Layer

People need to actually use this thing, so the interface really matters. Build real-time dashboards. Add 3D visualizations where they make sense. And here’s the important bit: let users run “what-if” scenarios directly in the model. That’s where people discover the most valuable insights.

Step 7: Validate and Calibrate Rigorously

This separates toys from tools. You have to prove your twin actually mirrors reality. Here’s how:

- Measure Fidelity: Use metrics like MAE (Mean Absolute Error) or RMSE (Root Mean Square Error). These quantify how close your predictions come to real outcomes.

- Calibrate Continuously: Set up feedback loops so real-world data keeps tuning your model parameters. Optimization algorithms can automate most of this.

- Test With Historical Data: Run your twin in “shadow mode” with past data. Does it predict outcomes you already know happened? If it can’t predict the past accurately, don’t trust it with the future.

Step 8: Deploy and Keep Improving

After deployment (whether cloud or on-premise), the real work begins. Digital twins that succeed keep evolving. Capture new sensor data. Gather operational feedback. Feed everything back into your simulation models. This continuous refinement is what maintains value as conditions change over time.

The reality is that building a good digital twin mixes engineering, data science, and constant iteration. Get these basics right and you’ll build something that actually changes how your organization handles its physical assets. Miss them and you’ll just have an expensive dashboard.

Now that we have answered the initial question of how to build a digital twin app, let’s talk about the key technologies that are required to build a successful digital twin app.

Key Technologies Used in Digital Twin App Development: IoT, AI, and More

A digital twin is a convergence point for cutting-edge enterprise technologies, blending hardware connectivity with scalable cloud services and complex intelligence models. Successfully building an app requires mastering the integration of these four critical pillars.

Here are the key technologies needed to develop a digital twin app:

- Industrial IoT (IIoT) Sensors and Edge Devices

The foundation of the twin is its data. Industrial Internet of Things devices provide the high-fidelity, real-time measurements required to accurately mirror the physical asset’s state. This includes specialized sensors (vibration, thermal, acoustic, pressure) and Edge Gateways that run pre-processing algorithms to ensure only critical, relevant data is streamed to the cloud, minimizing latency and bandwidth costs.

- AI and Machine Learning

AI models are the “brain” of the twin, converting raw sensor data and operational context into actionable intelligence.

Predictive analytics (like ARIMA or LSTM models) tools are used to forecast equipment failure (predictive maintenance) and employ anomaly detection algorithms (such as Isolation Forests or One-Class SVMs) to spot unusual behavior that signals a production flaw, systemic inefficiency, or a security breach. These models enable the twin to anticipate the future state of the physical asset.

- Advanced Data Analytics

This is where data moves from passive insight to automated action. A digital twin must move beyond descriptive (what happened) and diagnostic (why it happened) to prescriptive analytics (what should we do).

The app won’t just tell you a machine’s Remaining Useful Life (RUL) is low; it will automatically generate a maintenance ticket in your ERP system, re-route the production schedule in your MES, or initiate a safe shutdown protocol via the control layer. This level of automation is essential for realizing maximum ROI.

- Cloud Computing Platforms (PaaS/IaaS)

Cloud computing providers like AWS, Microsoft Azure, and Google Cloud offer scalable infrastructure for digital twin development. This includes Platform as a Service (PaaS) offerings like Azure Digital Twins or AWS IoT TwinMaker, which provide pre-built templates for modeling, storage, and visualization, drastically reducing development time and complexity.

- Cybersecurity

Given the connection between the physical and digital world, a twin is a high-value target. Cybersecurity is non-negotiable and must be built into the architecture from Day 1.

This involves implementing Zero Trust Network Access (ZTNA) for all device communication, employing end-to-end data encryption (in-transit and at-rest), and using Identity and Access Management (IAM) with strict Role-Based Access Control (RBAC) to limit operational control commands. Regular penetration testing and vulnerability scans are required to maintain operational integrity.

- API Management and Integration

The digital twin often acts as the central System of Record for operational data. API Management Platforms (like Apigee or Azure API Management) are essential for securely exposing model outputs and ingesting context data from other enterprise systems.

These APIs must be highly available, throttled, and documented (e.g., using OpenAPI Specification) to facilitate seamless, real-time data exchange with ERP, MES, and specialized visualization tools.

- Simulation Engines

These proprietary or open-source environments are crucial for running high-fidelity “what-if” scenarios. Simulation engines (e.g., using MATLAB/Simulink, specialized physics solvers, or gaming engines like Unity/Unreal) take the twin’s core model and allow users to test changes in parameters (e.g., higher temperature, faster production speed) without risking physical damage or operational downtime. They are the key to predictive optimization and process validation.

- 3D Modeling and Visualization Tools

The user interface must translate complex data and simulations into intuitive, interactive environments. 3D Modeling tools (e.g., CAD/BIM software) create the geometric representation of the asset, while Visualization Engines (like Cesium or proprietary platform rendering layers) display the real-time sensor overlays, AI predictions, and simulation results directly onto the 3D model. This spatial context is vital for quick, human-driven decision-making.

Core Features of a Digital Twin Application

A digital twin is only as valuable as the functions it enables. These mandatory features go beyond simple monitoring. They provide the predictive and prescriptive capabilities you need to make data-driven decisions that impact the bottom line.

Here are some of the core features of a digital twin application:

- Real-Time Monitoring and Data Visualization: With a digital twin application, the performance of physical assets can be tracked in real time and visualized through easy-to-read dashboards showing key metrics. This is a vital feature for digital twin mobile app development, as it allows users to access this data remotely and take swift action.

- Predictive Maintenance: With the help of AI and ML, this app can help predict asset failures or maintenance requirements. This predictive ability helps you in cutting down on downtime and maintenance costs.

- Simulation and Scenario Testing: You can initiate alterations or new processes through simulations without impacting real assets. This method helps you with the testing of different outcomes and identify issues and bottlenecks in order to optimize operations without putting anything at stake.

- Monitoring and Control: With a digital twin app, you get the ability to monitor and control the assets from a distance. This, in turn, gives you more room to solve problems in real time, even if you are not there.

- Integration with Existing Systems: It integrates with your existing systems easily. It then consolidates data from different places for a unified view of operations.

- Scalability and Customization: As your business scales, your digital twin app should be able to do the same as well. It should be able to handle more assets, data, and users easily. It should be customizable enough to meet your specific industry demand.

Our team specializes in integrating advanced IoT, AI, and cloud technologies to bring your vision to life. Let’s create a solution that optimizes your operations and drives real-time insights.

Now that you have learned all about the core features, let’s talk about some of the most common challenges in building a digital twin application.

What Are the Most Common Challenges in Building a Digital Twin Application?

The digital twin market is absolutely taking off. The numbers tell the story: $24.97 billion in 2024, jumping to $155.84 billion by 2030. Industries using digital twin apps everywhere are waking up to this and scrambling to build their own applications.

But here’s what nobody tells you upfront. Every new technology brings its own set of problems, and digital twin application development is no exception. We’ve seen projects succeed and fail. Here are the biggest challenges in building a digital twin app:

1. Quality and Integration of Data

Your digital twin lives or dies by its data. Think about it. You’re feeding information from sensors and various systems into this application. If those sources are unreliable or outdated, everything downstream breaks. Bad data doesn’t just make your app less useful. It makes it useless.

Then there are the integration issues. Data comes from everywhere. Different formats, different timestamps, different protocols. Getting all of that to work properly together? Way harder than most businesses expect. We’ve watched teams spend months just on data harmonization. If you can’t integrate it properly, you might as well not build it at all.

Solution: It is imperative to and start with a data strategy first. Not the flashy numbers. The boring fundamentals. Normalize formats across systems.

Scrub your legacy data until it’s clean. Invest in good middleware or build robust APIs for system integration. Trust me, fixing your data pipeline at the start beats debugging data issues for the next two years.

2. Scalability

Here’s a scenario we see constantly. A team builds something that works beautifully for their pilot project. Ten sensors, one production line, looking great. Then the business wants to expand. Suddenly, you’re dealing with hundreds of sensors, multiple facilities, and way more data. And the whole thing collapses under its own weight.

Scaling isn’t just about handling more data. It’s about maintaining performance and quality while everything around you multiplies. Most systems aren’t designed for this kind of growth from the start.

Solution: Cloud infrastructure with modular design. We know it sounds obvious, but you’d be surprised how many teams skip this. Build it modular from day one, so adding capacity doesn’t mean rebuilding the entire platform. When you need more resources, you spin them up. No major surgery required.

3. Security and Privacy

Every digital twin we’ve worked with handles massive amounts of live data. Production metrics, equipment telemetry, operational details. All of it flowing in real time. Now connect dozens or hundreds of devices to that system. See the problem? Each connection is a potential entry point for attackers.

We’ve sat in meetings where security was treated as a phase three concern. “We’ll add that later.” That’s a disaster waiting to happen. Once your architecture is set, retrofitting proper security is painful and expensive.

Solution: Encryption from end to end. No shortcuts. Role-based access so people only see what they need to see. Regular audits to catch vulnerabilities before others do.

Build all of this into your initial design, not after you’ve already launched. The cost of a breach will dwarf whatever you save by cutting corners on security.

4. Integration with Existing Systems

Most companies aren’t starting fresh. They’ve got legacy systems that have been running for years, sometimes decades. Now you want to connect those to your modern digital twin platform. Good luck with that.

Old systems speak different languages. They use outdated protocols. Sometimes the documentation no longer exists because the person who built it retired five years ago. We’ve seen integration projects balloon from three months to eighteen months purely because of legacy system complications.

Solution: You need custom APIs, and you need them built right. For really gnarly legacy environments, bring in an enterprise service bus or something like MuleSoft. These tools essentially translate between old and new.

Yes, it’s another expense. But it’s cheaper than watching your integration timeline slip month after month while your team tries to decode thirty-year-old COBOL.

5. High Development Costs

Nobody sugarcoats this part anymore. Building a digital twin costs real money. Sensors aren’t cheap. Good ones definitely aren’t cheap. Then you’ve got equipment, cloud infrastructure, development teams, ongoing maintenance. Finance teams see that initial price tag and their eyes glaze over.

The return is there. We’ve seen it pay for itself many times over. But convincing leadership to write that first check when they can’t see the results yet? That’s the hard part.

Solution: Don’t ask for everything at once. Pick one critical asset or process. Build a small proof of concept there. Then show results. Actual numbers. “This machine had 40 hours of downtime last quarter. Now it’s down to 12 hours.” That’s a story finance understands.

Get that win, document the ROI, and suddenly funding the full rollout becomes a much easier conversation. You turn it from a gamble into a proven investment strategy.

These obstacles are real, and I’m not going to pretend otherwise. But companies overcome them every day. The difference between success and failure usually comes down to planning and being realistic about what you’re getting into.

Go in prepared, and you can build something that actually delivers value instead of becoming another expensive failed experiment.

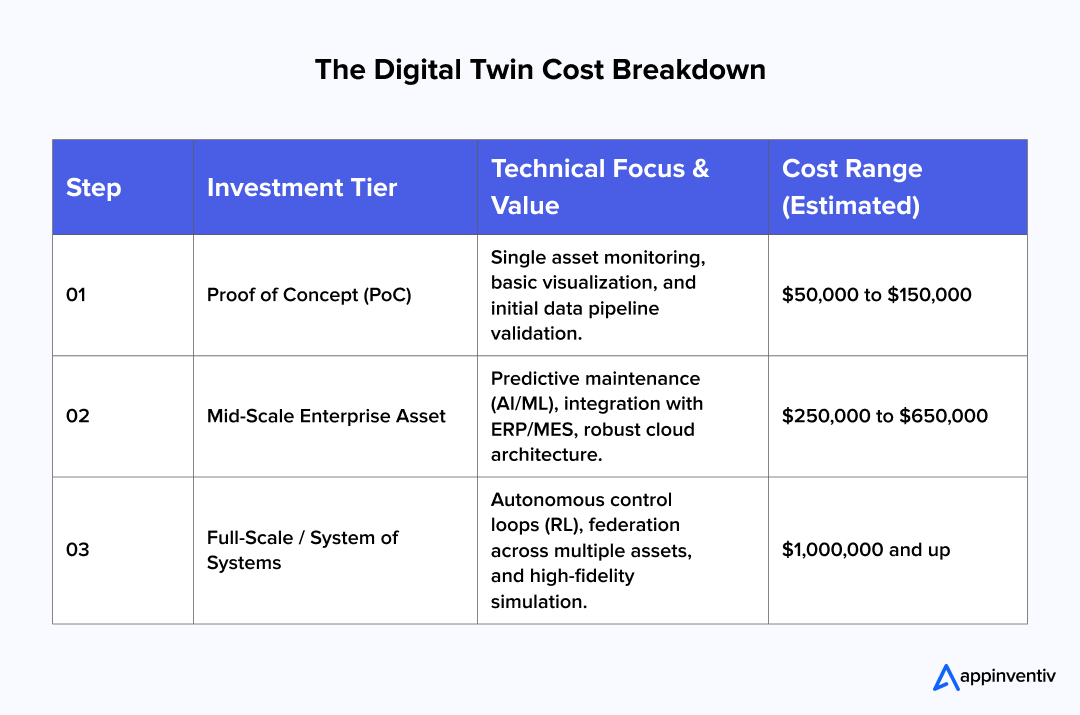

Understanding the Costs of Building a Digital Twin

According to a McKinsey study, 70% of large corporate technology executives in the C-suite were already considering or had already invested in digital twins.

When you’re planning a digital twin project, you can’t just look at the price tag for building it. You need to think about ongoing costs and what you’re actually going to get back.

For major enterprise projects, this isn’t just a budget item. It’s a strategic decision that affects your entire operation.

Development Costs: What You’ll Pay Upfront

Your initial investment depends on a few things. How complex is your project? What tech stack are you using? Are you going proprietary or open-source? And what kind of specialized expertise does your team need to bring in?

A small Proof of Concept might run you $50,000 to $150,000. That gets you started. But if you’re deploying something enterprise-grade for critical infrastructure? You’re looking at well over a million dollars. Sometimes significantly more.

Here’s a quick overview table of digital twin app development cost:

| Application Level | Estimated Cost Range |

|---|---|

| Proof of Concept (PoC) | $50,000 to $150,000 |

| Mid-Scale Enterprise Asset | $250,000 to $650,000 |

| Full-Scale / System of Systems | $1,000,000 and up |

Operational Costs: Keeping It Running

Building the thing is just the beginning. You’ve got recurring expenses that never stop.

Maintenance and support is your first bucket. Models need constant recalibration as conditions change. Software needs updates. Security patches have to get applied regularly. You can’t just build it and walk away.

Then there’s infrastructure and cloud services. Time-series data from sensors piles up fast. We’re talking about massive storage requirements. Running simulations needs serious compute power. And ingesting high volumes of data from all those IIoT sensors? Cloud providers charge for that. These costs scale with your operation.

Return on Investment: Why Companies Do This Anyway

Okay, so the costs are substantial. Why do companies still commit to this? Because the financial returns can be enormous. I’m talking about real money, not theoretical benefits.

Predictive maintenance delivers the biggest bang. Companies see unplanned downtime drop by 20% to 50%. Think about what downtime costs your operation per hour. Now cut that in half. The math gets interesting quickly.

Resource efficiency is another big win. You reduce energy waste. Production cycle times get optimized. Every percentage point of efficiency improvement hits your bottom line.

Then there’s risk mitigation, which is harder to quantify but incredibly valuable. Want to know if that $10 million capital expenditure will actually deliver the results you expect? Many companies work with a digital engineering services firm to simulate outcomes first using a digital twin, testing scenarios and exposing risks before committing the budget.

We worked with one manufacturing client who delayed a major equipment purchase after their digital twin showed it wouldn’t solve their bottleneck problem like they thought. That simulation saved them close to $3 million on equipment that would’ve sat underutilized.

The Bottom Line

Building a digital twin isn’t cheap. But companies that do the math carefully usually find the ROI justifies the investment, especially when you’re dealing with expensive assets or operations where downtime is incredibly costly. Just make sure you’re honest about both the upfront costs and the ongoing expenses before you commit.

Ready to optimize your investments and streamline operations? We specialize in creating efficient, scalable digital twin apps that deliver measurable results. Let’s bring your vision to life!

The Future of Digital Twin Technology: Trends and Innovations to Watch Out For

Perhaps most importantly, you would need an online platform to connect all the devices, sensors, and other equipment—allowing for the creation of digital twins for real-time remote digital monitoring.

— Venkat Atluri, Senior Partner at McKinsey & Company

The digital twin space is moving fast. Really fast. We’re seeing multiple technologies mature at the same time, and they’re all pushing digital twins in new directions. If you’re building something now, you need to think about where this is all going. Otherwise, your investment becomes outdated before you even finish deploying it.

Here are the trends that are reshaping how we build digital twins:

- Edge-Native Architectures and Microservices

The shift to 5G and edge computing is moving twins away from centralized cloud setups. Instead of running everything in a data center, you’re pushing the logic closer to your assets. Deploy predictive maintenance models directly on local gateways. Run control loops as microservices right next to the equipment.

This approach cuts latency and reduces bandwidth costs. But it requires a different skill set. Your team needs engineers who understand distributed systems and can handle high-frequency data streams flowing between edge devices and your central infrastructure.

- Autonomous Control Loops with AI

Digital twins are moving beyond prediction. They’re starting to take action on their own. Reinforcement learning models can now directly control physical assets without waiting for human approval. A turbine adjusts its blade pitch automatically. An HVAC system optimizes itself based on real-time conditions.

Sounds great, right? But here’s the problem. What happens when the AI makes the wrong call? You need serious safety measures built in from the start. Digital interlocks, failure modes, redundant checks. One bad decision from your algorithm could shut down an entire production line. There’s no room for experimentation when you’re controlling expensive physical infrastructure.

- Standardization and Data Federation

Digital twins started in manufacturing and energy, but now they’re spreading into retail, healthcare, and urban planning. The challenge? Everyone’s building systems that don’t talk to each other. Different data formats, proprietary APIs, incompatible architectures.

For this technology to really scale across industries, we need standardization. Open APIs and common data models are becoming essential. The emerging solution is federated architectures—think of it as a “Twin of Twins” that can pull data from multiple vendor systems and present everything through one unified interface.

- Spatial Computing and AR/VR Integration

Dashboards work, but they’re limiting. The next evolution is immersive 3D environments using AR and VR. Imagine walking through a virtual version of your factory floor. Real-time data hovers above each piece of equipment. You reach out and adjust a machine’s parameters, run a quick simulation, and those changes sync back to the physical system.

Building this requires specialized SDKs that connect your twin’s data to visualization engines like Unity or Unreal. The hardest part? Latency. We tested an early prototype last year where the lag was only 200 milliseconds, but that was enough to make users distrust the whole system. Every interaction felt off. Getting response times down to where the experience feels natural takes significant optimization work.

What This Means

These technologies exist today. Build with modularity and standardization in mind. Proprietary formats will box you in later. Companies that succeed build flexible systems that evolve rather than get locked in.

How Appinventiv Can Help You Build a Digital Twin App?

We specialize in designing proprietary, high-fidelity digital twin solutions built on a foundation of architectural resilience and real-time data integrity. Our expertise spans the entire development stack, from sensor ingestion to autonomous control.

We engineer the core infrastructure, focusing on real-time data fusion using protocols like MQTT, implementing edge-native microservices for low-latency operational control loops, and integrating physics-based modeling for accurate predictive simulation.

We then connect this robust infrastructure to intuitive interfaces, providing world-class mobile app development services to ensure secure and comprehensive control and monitoring are available right where your operators need them.

Key Credentials in Digital Transformation:

- 10+ Years of History in digital twin and mobile app development services.

- 95% Client Satisfaction Rate, a reflection of our dedication to excellence.

- 90% Repeat Clientele, demonstrating strong, sustained relationships built on successful project delivery.

- Presence in 74+ Countries, driving tech innovation worldwide.

So the next time you are thinking about how to build a digital twin app, connect with Appinventiv. Let us assist you in creating a digital twin app that improves your business processes and brings tangible results.

Frequently Asked Questions

Q. Why do enterprises need digital twin app development?

A. A digital twin app can be a great asset. As it is a virtual copy of the real asset, it can show you the exact status of everything. It will help you predict and rectify any problems before they arise. In simple terms, you can make better and faster decisions without having to wait for the situation to worsen.

Q. How do enterprises integrate digital twin solutions with existing systems?

A. Connecting digital twin software to your current or legacy systems is not as hard as it may seem. You can take help from an expert like Appinventiv, who can either use tools like APIs to completely eliminate the distance between your current systems and the new app or create a specific solution as per your needs. As a result, everything works seamlessly, and you have a single point of control for managing everything.

Q. How long does it take to develop a digital twin system?

A. It really depends on what you want to create, what systems you already have in place, what other things are needed, and a lot more. But on average, it usually takes from 3 to 12 months to develop a digital twin app. Smaller apps can be created in a shorter time, while bigger ones with custom features or integrations might take longer.

Q. How much does it cost to build a digital twin app?

A. The digital twin app development cost can range from $50,000 to $1,000,000. However, it really depends on your requirement; if you need a standard app, it might cost less, but if you need a customer-specific app, then it will be costlier.

It is also important to keep in mind that complex requirements, such as this, will also result in a higher cost. Additionally, you will also need to consider support and maintenance costs as part of it to keep everything running smoothly.

Q. Why Building a Digital Twin App Can Transform Your Business Operations?

A. Building a digital twin app can be a great asset to any business. For instance, digital twin applications can be found in numerous industries; however, manufacturing, health care, energy, and smart cities are among the main ones.

Digital twins are a great help in the entire process, from maintaining equipment in good shape to healing patients or even running a whole city; they make it possible for companies to be more efficient and to foresee problems before they become an issue.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

How Enterprises Can Successfully Integrate Emerging Technologies into Their Workflows

Key Takeaways Big changes fail when rushed. Begin with small pilots, measure results, and use emerging tech to scale without breaking what works today. Clean, connected data and strong security are the backbone of successful technology integration. Get those right before layering on AI, IoT, or automation. Don’t chase every new tool. Match tech to…

Digital Transformation Strategies You’ll Wish You Knew Sooner

Key takeaways: Think Big, Not Small: Digital transformation market will reach USD 3,289.4 billion by 2030. Update Legacy Tech: Outdated systems? Modernize them now to boost efficiency and save costs. Go Cloud and API First: Focus on flexible, scalable cloud solutions and APIs for faster, more efficient operations. Make Tech Work for Business: Your tech…

Digital Transformation Strategy for Australian Enterprises: A Practical Roadmap

Key takeaways: Australian businesses must embrace digital change to remain competitive in today’s market. Successful digital transformation requires a focus on people, processes, and technology. Overcoming resistance to change and outdated systems needs a clear strategy and the right partners. Industry case studies show that effective digital transformation delivers real business value and strong ROI.…