- Enterprise Resource Planning (ERP) for Automotive Market Overview

- The Role of ERP in the Automotive Industry

- Automotive ERP Solutions: Choosing Between Off-the-Shelf and Custom

- Top 10 Use Cases of Automotive ERP Software Solutions

- 1. Supply Chain Visibility

- 2. Quality Assurance

- 3. Production Planning

- 4. Inventory Management

- 5. Financial Management

- 6. Customer Relationship Management

- 7. Regulatory Compliance

- 8. Data Analytics

- 9. Warranty Management

- 10. Asset Management

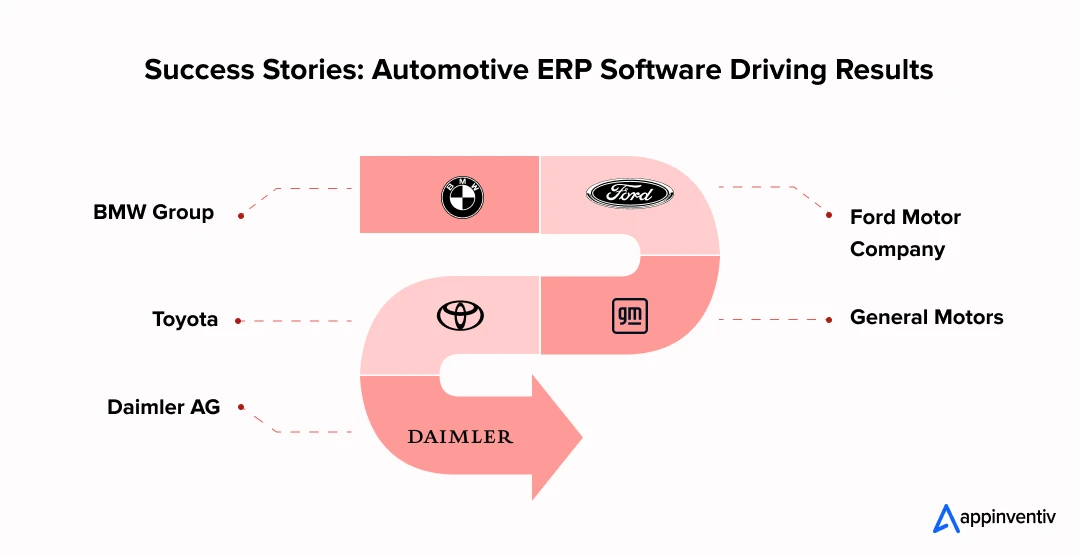

- Real-Life Examples of Automotive ERP Software in Action

- 1. BMW Group: Mastering Supply Chain Complexity

- 2. Ford Motor Company: Getting the Numbers Right

- 3. Toyota: Quality First, Always

- 4. General Motors: Smart Inventory, Happy Customers

- 5. Daimler AG: Keeping the Machines Running

- Exploring the Key Stages of Automotive ERP Software Development

- Requirement Gathering

- Planning and Design

- Development

- Testing

- Data Migration

- Deployment

- Maintenance and Support

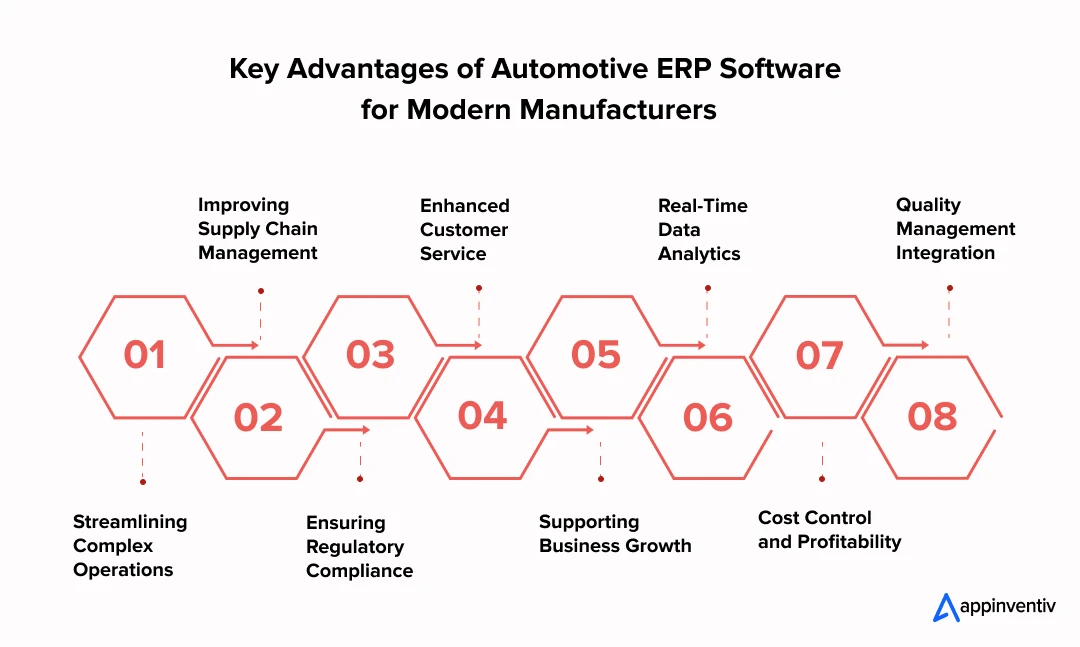

- Key Benefits of Automotive ERP Software Development

- Streamlining Complex Operations

- Improving Supply Chain Management

- Ensuring Regulatory Compliance

- Enhanced Customer Service

- Supporting Business Growth

- Real-Time Data Analytics

- Cost Control and Profitability

- Quality Management Integration

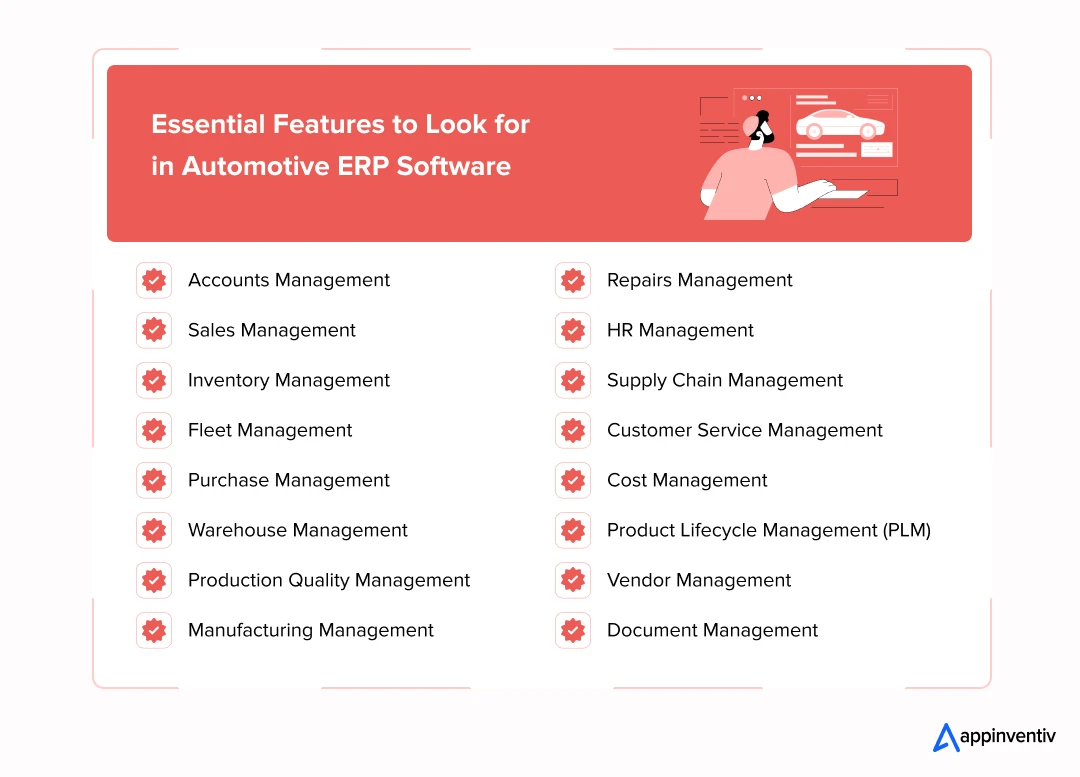

- Must-Have Automotive ERP Software Features To Look For

- Accounts Management

- Sales Management

- Inventory Management

- Fleet Management

- Purchase Management

- Warehouse Management

- Production Quality Management

- Manufacturing Management

- Repairs Management

- HR Management

- Supply Chain Management

- Customer Service Management

- Cost Management

- Product Lifecycle Management (PLM)

- Vendor Management

- Document Management

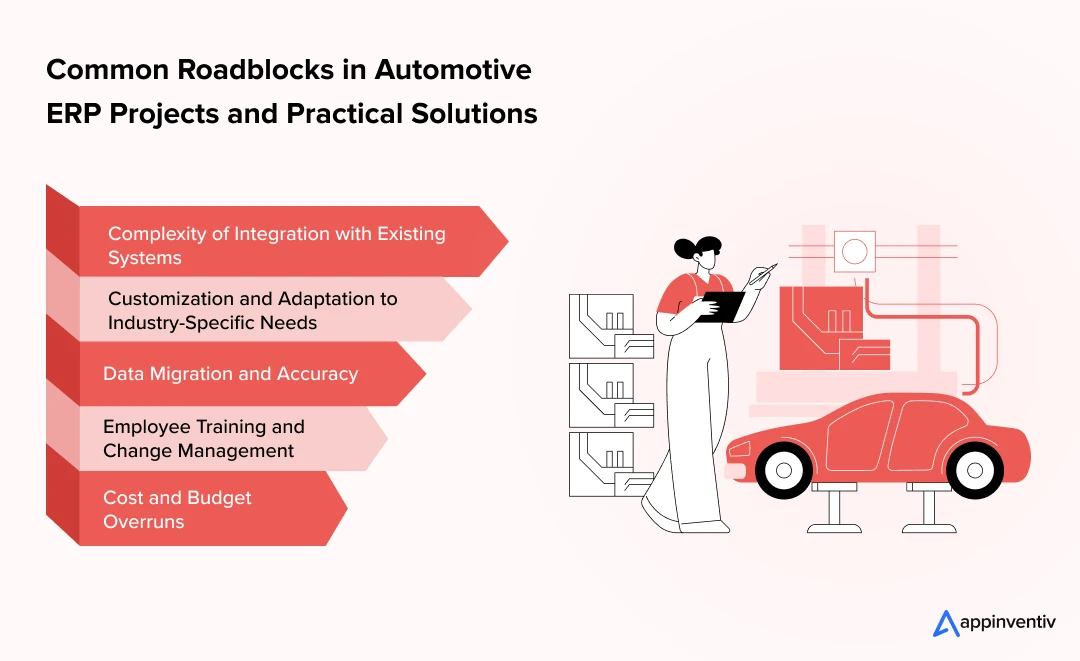

- Challenges in Implementing ERP in Automotive Software

- Complexity of Integration with Existing Systems

- Customization and Adaptation to Industry-Specific Needs

- Data Migration and Accuracy

- Employee Training and Change Management

- Cost and Budget Overruns

- Drive Your Automotive Enterprise Business Success With Appinventiv

- FAQs

- Custom automotive ERP integrates key functions, boosting efficiency and decision-making.

- AI integration and cloud-based ERP solutions enhance scalability and predictive capabilities.

- Custom ERP solutions cater to the unique needs of the automotive industry, from supply chain management to compliance.

- ERP adoption faces hurdles like data migration and integration, which can be addressed through careful planning and strategic implementation.

In 2024, Ralco Industries, a Tier‑2 automotive supplier based in Michigan, modernized its operations with the Plex Manufacturing Cloud, a cloud-based ERP solution. The results were staggering, defect rates dropped to under one part-per-million across eight years, and the company achieved over 250 inventory turns annually. This isn’t just a tech upgrade; it’s a business transformation story powered by automotive ERP.

An Enterprise Resource Planning (ERP) system is an indispensable tool that integrates all the aspects of your enterprise into a single system, eliminating the concerns about software maintenance and data consideration. Almost every industry is now utilizing custom ERP software to streamline their operations, and the automotive sector is no exception.

A custom automotive ERP software solution is the key tool for automotive enterprises to integrate and optimize different facets of their central operations. From handling complex automotive supply chain to adhering to strict…..quality standards, ERP systems helps automotive businesses mark their foothold in the marketplace and align with market demands.

The automobile industry functions as a massive interconnected ecosystem linked to a number of adjacent economic sectors that offer the necessary raw materials and components for manufacturing and distributing passenger cars and heavy vehicles. The efficient distribution of finished automobiles to warehouses and the development of the basic concept are all parts of a complex pipeline that demands perfect coordination. Automotive ERP software development plays a crucial role in creating and adapting ERP solutions specifically for automotive businesses. These solutions are designed to meet the intricate requirements of the industry.

In this blog, we will talk about the role of ERP in the automotive industry, the top 10 use cases, the automotive ERP software development process, and automotive ERP software features, starting with ERP automotive market overview. Let’s dig deeper.

76% have already embraced ERP for enhanced operational efficiency.

Enterprise Resource Planning (ERP) for Automotive Market Overview

According to Statista, the global ERP software market is projected to reach $101 billion by 2026, driven by increasing demand for enterprise software across multiple industries. The automotive sector shows particularly strong ERP adoption as passenger car and commercial vehicle demand continues rising.

Latest trends and market insights into automotive ERP software indicate that major industry players are increasingly adopting ERP strategies, driving the market toward significant expansion.

- AI Integration: ERP systems now incorporate artificial intelligence to deliver smarter predictive analytics and streamlined automation capabilities.

- Cloud-Based Solutions: The shift toward cloud ERP is gaining momentum, providing automotive businesses with greater flexibility and scalability for their operations.

- Industry 4.0 Alignment: Modern ERP systems connect seamlessly with IoT devices and smart manufacturing technologies, creating more efficient production environments.

- Real-time Data Insights: Today’s ERP platforms provide instant analytics, enabling companies to make informed decisions and enhance operational efficiency.

- Customization Demand: Automotive companies are increasingly seeking ERP solutions tailored to their unique requirements, resulting in more specialized market offerings.

The Role of ERP in the Automotive Industry

An ERP (Enterprise Resource Planning) system in the automobile sector functions by combining and streamlining numerous business operations. It gathers and centralizes information from production, supply chain, finance, and other departments. Inventory levels are managed by ERP software, and it also improves production planning and controls quality.

ERP software also manages HR and payroll duties, streamlines financial administration, monitors regulatory compliance, and improves customer relationship management by offering powerful analytics and reporting features. Automotive industry ERP systems increase quality, maintain adherence to industry standards, and streamline operations. In order to familiarize yourself with the steps involved in developing an ERP solution, you may read our article on ERP software development process.

Automotive ERP Solutions: Choosing Between Off-the-Shelf and Custom

Choosing the right automotive ERP system isn’t easy. Businesses get stuck between two main options: off-the-shelf ERP solutions or custom ERP solutions built from scratch.

Off-the-shelf ERP solutions have obvious appeal. You can get them up and running quickly, they’ve been tested by other companies, and the vendor handles updates and support. The problem? They rarely fit perfectly. You’ll probably need to change how your team works or pay extra for customizations that still don’t quite match your processes.

Custom ERP solutions take longer and cost more upfront, but you get exactly what you need. These systems work the way your business actually operates, not the way some software company thinks it should operate. Additionally, you’re not locked into someone else’s vision of how automotive businesses should run.

The choice really comes down to your situation. If your operations are fairly standard and you need something fast, off-the-shelf ERP solutions might work. But if you’ve got unique processes that give you an edge over competitors, or if you’re planning major changes, custom ERP solutions could be worth the investment.

| Feature | Custom ERP Solutions | Off-the-Shelf ERP Solutions |

|---|---|---|

| Cost | Higher initial cost | More affordable |

| Implementation Time | Longer setup time | Quick setup |

| Development | Built specifically for the business | Pre-built, mass-market software |

| Scalability | Easily scalable as the business grows | May face limitations as business grows |

| Customization | Fully customizable | Limited flexibility |

| Integration | Can be fully integrated with other systems | Limited integration capabilities |

| Maintenance & Upgrades | Requires ongoing maintenance and updates | Managed by the vendor |

| Target Audience | Larger businesses or those with complex needs | Small to mid-sized businesses |

Top 10 Use Cases of Automotive ERP Software Solutions

ERP is a vital tool for automotive firms as it plays a crucial role in ensuring smooth operations and compliance with the complicated supply chains and regulatory requirements specific to the automotive industry. From supply chain to inventory management, here are the top ERP software use cases in the automotive industry:

1. Supply Chain Visibility

ERP systems offer automotive enterprises a real-time view of the supply chain, enabling them to track and monitor the delivery of parts and components from manufacturers to assembly lines. Such visibility minimizes production delays, enhances logistics operations, and ensures an efficient and smooth manufacturing process, thereby contributing to the timely delivery of finished automotive products.

For instance, an automaker might utilize ERP to track the flow of critical components and parts like engines and gearboxes to avoid manufacturing snags.

2. Quality Assurance

It is crucial to guarantee the quality of automotive products. ERP systems can be easily integrated with quality assurance processes and provide reliable data on defect rates, enabling enterprises to detect and rectify the issues earlier in the production cycle and take appropriate action.

As an example, consider how custom automotive ERP software might be used to monitor and assess brake system flaws to raise product quality.

3. Production Planning

ERP software helps with production planning by streamlining resource allocation, tracking work orders, and optimizing production schedules. This results in reduced downtime, smoother operations, and effective utilization of resources, ultimately boosting profitability and productivity in the automotive manufacturing process.

ERP, for example, can be used by an auto manufacturer to balance production lines, ensuring that no single model gets manufactured in excess or lack.

4. Inventory Management

Custom automotive ERP software helps automotive manufacturers manage large inventories, preventing resource shortages, reducing carrying costs, and ensuring they have the right quantities of vehicle parts and components in stock.

A car dealership, for example, might use ERP to ensure they have sufficient automobiles in stock, cutting carrying costs and assuring that they can fulfill customer requirements.

5. Financial Management

The financial administration of automotive companies relies heavily on ERP software. It streamlines financial processes, including accounting, planning, and reporting. For instance, an ERP system can be used by an automaker to consolidate financial data from various departments, such as sales, production, and procurement.

This integration promotes compliance with industry rules and accounting standards, such as International Financial Reporting Standards (IFRS) or Generally Accepted Accounting Principles (GAAP), and provides accurate financial statements. It provides an in-depth overview of financial health and supports making informed financial decisions for long-term growth.

Also Read- ERP Finance – Making Analytics and Reporting Easy for FinTech Enterprises

6. Customer Relationship Management

While primarily improving internal processes, ERP systems also positively impact customer service. An ERP system for the automotive industry facilitates more successful marketing initiatives when coupled with CRM systems. This involves expanding your internet presence, developing sales leads, turning leads into sales, managing customer relationships, and keeping in touch with customers during their purchasing journey.

ERP solutions essentially improve your ability to satisfy consumer needs, from early queries to post-purchase conversations, resulting in a seamless customer experience. An ERP system automotive example explains that customer relationship management involves ERP analyzing customer preferences and providing them with personalized recommendations.

7. Regulatory Compliance

The automotive industry must adhere to various regulations, including those related to emissions, safety, and environmental standards. The government mainly enforces these rules to ensure vehicles meet the ecological safety criteria. Compliance with such regulatory norms is crucial for automotive companies to sell their products legally, ensuring the well-being of both consumers and the environment.

Businesses can track and follow these rules using ERP software, ensuring compliance with the law and avoiding penalties.

8. Data Analytics

With ERP systems’ extensive data analytics and reporting capabilities, automotive manufacturers can now make well-informed decisions based on data. This data-driven approach optimizes resource allocation, streamlines operational output, and supports strategic decision-making.

For instance, reviewing sales data might assist automakers in modifying production levels or marketing plans to satisfy shifting consumer expectations.

9. Warranty Management

In the automotive sector, warranty and service management plays a crucial role in assuring customer satisfaction, brand loyalty, and warranty agreement compliance. Customer can effectively manage their warranty claims, plan maintenance and servicing schedules, and coordinate repair procedures with the automaker when their vehicle experiences problems.

For instance, a car manufacturer that offers a 3-year warranty depends on this feature to handle problems as soon as they arise. By doing this, businesses uphold their commitment to their clients, avert pricey recalls, and preserve their good name.

10. Asset Management

Asset management is essential in the automotive sector for monitoring and maximizing the lifecycle of physical assets, including equipment, vehicles, and tools. It guarantees effective asset allocation, upkeep, and disposal to reduce costs and boost production.

For example, a car manufacturing facility leverages an ERP system to monitor and maintain the assembly line equipment, ensuring efficient operations and reducing downtime.

These use cases determine the importance of leveraging ERP systems in automotive businesses, as it rationalizes the entire workflow of an automotive manufacturing unit. Let’s now have a look at the steps to build an automotive manufacturing ERP software.

These use cases determine the importance of leveraging ERP systems in automotive businesses, as they rationalize the entire workflow of an automotive manufacturing unit. Let’s now have a look at the steps to build an automotive manufacturing ERP software.

Real-Life Examples of Automotive ERP Software in Action

The automotive industry heavily relies on ERP systems to efficiently carry out operations and enhance productivity. Several automotive manufacturers and suppliers worldwide have successfully implemented ERP solutions to manage their complex processes. Here are some of the top examples of utilizing ERP for the automotive industry:

1. BMW Group: Mastering Supply Chain Complexity

BMW’s automotive ERP software development approach centers around SAP ERP, which gives them real-time visibility into their entire supply chain. Picture this: when a supplier in Germany ships brake components, BMW’s system instantly knows when those parts will arrive at their South Carolina plant.

This level of coordination isn’t just impressive—it’s necessary. BMW uses their ERP to sync up production schedules with parts availability, making sure assembly lines never sit idle waiting for components. The result? Fewer delays, better inventory control, and customers getting their dream cars on time.

2. Ford Motor Company: Getting the Numbers Right

Ford’s approach to ERP software development for the automotive industry focuses heavily on financial management and production planning. They’ve built their system around SAP ERP to pull financial data from every corner of the company into one clear picture. When Ford’s executives need to make big decisions, they’re working with real numbers, not guesswork.

On the production side, Ford uses ERP to balance their assembly lines like a master chef balancing flavors. Each vehicle model gets exactly the resources it needs—no more, no less. This smart allocation enables their factories to run efficiently while ensuring they can meet customer demand without overproduction.

3. Toyota: Quality First, Always

Toyota’s reputation for quality is largely due to its utilization of automotive ERP software that integrates directly with quality control processes, creating a safety net that detects problems before they occur. The system tracks defect rates across all production lines, allowing Toyota to spot patterns and fix issues at their source.

However, it extends beyond simply catching defects. Toyota’s ERP helps them navigate the complex world of global regulations. Whether it’s emissions standards or safety requirements checks, their ERP system tracks compliance status for every market they serve, ensuring they never miss a regulatory deadline.

4. General Motors: Smart Inventory, Happy Customers

GM faces a classic challenge: how to maintain sufficient stock without incurring excessive inventory costs? Their automotive manufacturing software development strategy addresses this by utilizing sophisticated ERP systems that accurately predict their needs and when they’ll be needed. It’s like having a crystal ball for car parts.

The real magic happens in their warranty management. When a customer brings in a vehicle for warranty work, GM’s system automatically schedules the repair, orders the right parts, and tracks the entire process.

5. Daimler AG: Keeping the Machines Running

At Daimler, home of Mercedes-Benz, their custom automotive ERP software development focuses on something most people never think about: the machines that build the cars. Their ERP system monitors every piece of equipment on the factory floor, tracking performance and predicting when maintenance is needed.

Think of it as a health monitoring system for factory equipment. Instead of waiting for a machine to break down and halt production, Daimler’s system schedules maintenance during planned downtime. This proactive approach keeps their production lines running smoothly and helps them avoid the costly delays that come with unexpected equipment failures.

Exploring the Key Stages of Automotive ERP Software Development

Automotive ERP software development is a complex and multifaceted task that requires thorough planning, precise execution, and ongoing communication with industry stakeholders. Let’s have a look at the step-by-step process of automotive ERP software development:

Requirement Gathering

Comprehensive requirement analysis is the first step in the procedure. Automotive software developers closely collaborate with automakers to comprehend their unique requirements, goals, and operational difficulties. In-depth interviews with key stakeholders, such as management, department heads, and end users, are conducted during this phase to learn more about current processes and find opportunities for change.

Planning and Design

Your hired development team plans the project outline after the user needs are specified. This plan outlines the scope of ERP software development, establishes deadlines, allocates resources, and specifies financial limitations. Based on the requirements gathered, developers and designers work simultaneously on developing the software’s architecture, database structure, and user interface.

Development

At this stage of the automotive ERP software development process, software developers adhere to established standards for code and security. The development of fundamental modules includes tasks like financial management, supply chain logistics, production planning, inventory management, and more. Additionally, security measures are put in place to protect sensitive data from potential dangers.

Testing

To make sure the ERP software works perfectly, thorough testing is essential. This step involves system testing to ensure that the entire system functions properly, integration testing to check the interactions between various modules, and unit testing to assess individual components. The aim is to locate and fix any flaws, errors, or inconsistencies that might impair the software’s functionality.

Data Migration

When switching from current systems, spreadsheets, or databases to the new ERP system, data migration is necessary. The integrity of the data is maintained while being precisely and securely conveyed. This step is crucial to ensure a seamless transition without data loss or errors.

Deployment

During the deployment phase, the custom automotive ERP software is introduced into the automotive enterprise’s infrastructure, if it is hosted on-premises or in the cloud. This final step ensures that the ERP software solution becomes accessible to authorized users. Moreover, it smoothly integrates with other systems, such as customer relationship management or accounting software, to establish a connection.

Maintenance and Support

ERP systems require ongoing maintenance and updates in order to remain efficient and secure. Regular patches and upgrades are deployed to address system stability, security flaws, and growing industry requirements. Also, continuous system backups and data recovery procedures are included in maintenance to protect against unexpected data loss.

Custom automotive ERP software development is an iterative process that requires close collaboration between the development company and the automotive enterprise. This serves as a foundation for enhancing efficiency and maintaining a competitive edge in the automotive industry. Let’s now he will look at the must-have features of an ERP automotive software.

Key Benefits of Automotive ERP Software Development

Building a custom ERP system has become essential for automotive companies to maintain competitiveness in today’s market. The industry requires sophisticated solutions to manage complex operations while meeting customer expectations. ERP software development for the automotive industry provides organizations with integrated platforms that streamline processes and improve operational efficiency.

Streamlining Complex Operations

Automotive businesses manage numerous interconnected processes from procurement to customer service. A custom ERP system creates a centralized platform where all departments can access the same information and coordinate their activities. This integration reduces operational inefficiencies and enables faster decision-making across the organization.

Improving Supply Chain Management

Modern automotive supply chains involve multiple suppliers across different countries and regions. ERP software automotive solutions provide real-time visibility into inventory levels and material flows throughout the entire supply chain. This transparency helps prevent production delays and optimizes stock levels to reduce carrying costs.

Ensuring Regulatory Compliance

The automotive industry faces increasingly strict regulations regarding emissions, safety standards, and environmental requirements. Automotive manufacturing ERP software development incorporates compliance monitoring directly into business processes. This proactive approach helps companies avoid costly penalties and maintains adherence to industry standards.

Enhanced Customer Service

Today’s automotive customers expect personalized service and transparent communication throughout their buying journey. ERP software development for automobile dealers integrates customer relationship management with operational systems. This connection allows service teams to access complete customer histories and provide more effective support.

Supporting Business Growth

Automotive companies need scalable solutions as they expand operations and enter new markets. Custom automotive ERP software development creates flexible systems that accommodate growth without requiring complete system overhauls. This adaptability supports long-term business expansion while maintaining operational stability.

Real-Time Data Analytics

Effective decision-making requires access to current and accurate business data. Custom ERP systems provide instant visibility into production metrics, sales performance, and operational trends. This real-time information enables managers to identify issues quickly and make informed strategic decisions.

Cost Control and Profitability

Automotive companies operate with tight profit margins and need precise cost management. ERP systems track expenses across all business functions and identify areas for cost reduction. This comprehensive financial visibility helps organizations improve profitability while maintaining quality standards.

Quality Management Integration

Product quality directly impacts brand reputation and customer satisfaction in the automotive industry. Custom ERP systems integrate quality control processes throughout production and supply chain operations. This integration ensures consistent quality standards and reduces the risk of costly recalls or warranty claims.

Must-Have Automotive ERP Software Features To Look For

While going for custom automotive solutions development, it is essential to consider a few vital features that will help streamline your business workflow and maximize your efficiency. Have a look at some of the top features of automotive ERP software.

Accounts Management

Accounting software streamlines billing procedures and ensures accurate and timely billing to clients by auto-generating invoices for goods and services.

Sales Management

ERP in the automotive industry improves customer relationship management and order fulfillment by making it easier to manage sales orders, customer data, and sales predictions.

Inventory Management

With the help of this function, automobile manufacturers may monitor and manage their stock of raw materials, semi-finished goods, and finished goods. The best stock levels are maintained, carrying expenses are decreased, and shortages are avoided.

Fleet Management

Automotive ERP software helps in an efficient fleet management process by keeping track of maintenance schedules, and fuel usage.

Purchase Management

It streamlines the entire procurement process, from choosing a supplier to creating a buy order, managing vendors, and assisting businesses in effectively acquiring supplies.

Warehouse Management

Inventory tracking, order fulfillment, and stock movement are all streamlined by warehouse management, which also increases the precision and efficiency of the distribution process.

Production Quality Management

ERP software features enable the tracking and regulation of product quality at various manufacturing stages, ensuring adherence to industry standards.

Manufacturing Management

Production scheduling, resource allocation, and work order monitoring are just a few of the production processes that manufacturing management helps car manufacturers streamline.

Repairs Management

Automotive ERP software helps service centers effectively handle repair requests, parts ordering, and service history. It also assists in coordinating and tracking vehicle repairs.

HR Management

In order to ensure legal compliance and operational effectiveness, the HR management feature in ERP software automates and centralizes HR processes like payroll processing, personnel records, performance reviews, and workforce planning.

Supply Chain Management

ERP systems can help in complete supply chain transformation by enabling automakers to optimize logistics, manage suppliers, and reduce lead times.

Customer Service Management

Automotive ERP systems, such as customer service management tools, enable automotive enterprises to manage customer service requests, follow up with customers, and become responsive. The ERP software provides a central point through which support tickets are managed, service calls are initiated, and customer queries are addressed.

Cost Management

Automotive ERP software enables businesses to monitor production costs in a better way. This functionality keeps a record of the costs involved in raw materials, labor, overheads, and production plans, allowing automotive firms to identify weaknesses in their cost structure and streamline them.

Product Lifecycle Management (PLM)

The capabilities of PLM within an ERP system enable the automotive manufacturing industry to manage the entire lifecycle of a product, including design and development, production, and disposal.

Vendor Management

This feature enables the automotive industry to manage its business relationships with suppliers and vendors effectively. Under ERP, firms can track vendor performance, monitor deliveries, manage contracts, and oversee payment conditions.

Document Management

Automotive ERP systems often incorporate document management capabilities, enabling the storage, retrieval, and organization of essential documents, including contracts, invoices, service manuals, and records of regulatory compliance.

Gain full control over operations with scalable, customizable features tailored to the automotive industry’s unique demands.

Challenges in Implementing ERP in Automotive Software

Implementing an ERP system in the automotive industry can be complex and challenging. Automotive organizations face several obstacles when adopting ERP solutions, but with the right strategies, these challenges can be effectively managed. Let’s have a look at some of the top challenges of automotive ERP software development and solutions to overcome those.

Complexity of Integration with Existing Systems

Challenge: Automotive companies often rely on various legacy systems for different functions, like inventory management and procurement. Integrating new ERP systems with these existing platforms becomes difficult and time-consuming, especially when dealing with incompatible data formats.

Solution: Organizations should choose ERP systems with robust integration capabilities and conduct phased rollouts to minimize disruption. Custom automotive ERP software development ensures seamless connectivity with existing tools while working closely with vendors to customize integration processes for smoother transitions.

Customization and Adaptation to Industry-Specific Needs

The automotive industry has unique requirements, including complex supply chain management and strict regulatory compliance. Many off-the-shelf ERP systems cannot fully address these specialized needs without extensive modifications and additional development work.

Solution: Developing tailored ERP solutions specifically for automotive operations addresses these gaps effectively. Automotive manufacturing ERP software development incorporates specialized features like advanced inventory tracking and compliance monitoring to align with organizational workflows and industry standards.

Data Migration and Accuracy

Migrating large volumes of operational data from legacy systems to new ERP platforms presents significant risks. Inaccurate or incomplete data migration can result in ongoing errors that affect inventory management and customer service quality.

Solution: Companies should invest in thorough data auditing and cleaning processes before beginning migration activities. Automotive ERP software developer teams conduct multiple testing rounds and establish dedicated migration protocols to ensure data accuracy and system reliability.

Employee Training and Change Management

Ensuring employees understand how to use new ERP software effectively remains a significant obstacle. Resistance to change and inadequate training programs can lead to low adoption rates and reduced system effectiveness across departments.

Solution: Comprehensive training programs tailored to different user groups help ensure successful adoption and long-term usage. ERP software development for the automotive industry includes change management strategies with clear communication of benefits and ongoing support resources for all users.

Cost and Budget Overruns

ERP implementation costs can exceed initial budgets due to unexpected expenses related to customization and integration. Smaller automotive companies with limited resources face particular difficulties managing these financial challenges while maintaining operational requirements.

Solution: Setting realistic budgets that include all implementation aspects helps control expenses effectively. Companies should prioritize critical features first and work with experienced vendors who provide transparent pricing and deliver on commitments consistently.

Drive Your Automotive Enterprise Business Success With Appinventiv

The ERP software for the automotive industry offers organizations numerous opportunities for expansion. ERP solutions play a crucial role in ensuring suppliers have real-time visibility into production needs, aiding in a smooth manufacturing process.

Additionally, these systems speed up the timely distribution of finished goods to retailers, ensuring an effective final delivery to customers. For instance, at Appinventiv, our experts built a custom ERP solution for the globally renowned furniture retailer IKEA that was adopted by over 7 stores in the UAE. By following an agile development approach, our experts developed a solution that became the first point of contact for every walk-in customer, which streamlined the onboarding process.

Other than IKEA, we also worked for various other global companies like KFC, Pizza Hut, Adidas, Dominos; helping them to streamline their operations and increase user engagement. Head to our portfolio section to know more.

Appinventiv offers a comprehensive range of ERP software development services, encompassing the creation of cutting-edge mobile apps to enhance consumer engagement, as well as the development of reliable ERP systems for streamlined operations. Utilize the power of innovation to boost productivity, enhance customer satisfaction, and sustain competitiveness in the volatile automotive industry with the support of Appinventiv’s automotive software development services.

Connect with our experts to build a custom automotive ERP software solution that can seamlessly adapt and expand.

FAQs

Q. Why is automotive ERP software important for business?

A. There are numerous reasons why your automotive business needs an ERP software solution:

- Proper handling of inventory

- Integration of different value chain operations

- Enterprise visibility

- Monitoring and controlling multiple projects

- Improved CRM

- Operational efficiency and excellence

Q. What is the cost to build an automotive ERP software?

A. Factors including the level of customization, complexity, and the unique requirements of the automotive industry, overall, decide the cost to build automotive ERP software. For an enterprise-level automotive company, it can cost anywhere between $150,000 and $750,000. Therefore, conducting a thorough evaluation and consulting with the best ERP software provider for the automotive industry is crucial to getting precise cost estimates.

Q. What are the benefits of ERP software for the automotive industry?

A. Automotive manufacturing software development comes with a host of benefits. Here are some of them:

- Cost reduction

- Enhanced quality control

- Efficient operations

- Improved visibility

- Supply chain optimization

- Data-driven decisions

- Integration

- Scalability

- Regulatory compliance

- Customer satisfaction

Q. How can automotive ERP software help to optimize time-to-market for new vehicle models?

A. Custom automotive ERP software development speeds up time-to-market for new vehicle models by connecting all the moving parts of product development. It brings together engineering, production, and supply chain teams, enabling them to work together seamlessly instead of operating in separate silos.

The software ensures materials are available exactly when production needs them and handles scheduling automatically. With built-in compliance tracking and real-time visibility into potential issues, manufacturers can identify problems early and resolve them quickly, bringing new models to market faster while staying ahead of their competitors.

Q. How can automotive ERP software streamline our supply chain and inventory management?

A. Automotive manufacturing ERP software development transforms how companies manage their supply chains and inventory through several key capabilities:

- Real-time supply chain visibility

- Optimized supplier relationship management

- Automated inventory management

- Demand forecasting and material planning

- Improved order fulfillment

- Reduced lead times

Q. What are some of the essential compliance requirements for automotive erp software development?

A. When developing Automotive ERP software, companies need to navigate complex industry regulations and standards. These requirements ensure legal operation, business credibility, and help avoid costly penalties and operational disruptions.

Data Privacy and Security (GDPR, CCPA): Automotive ERP systems must comply with GDPR and CCPA to protect personal data and ensure proper consent from customers and employees.

ISO/TS 16949 Compliance (Automotive Quality Management): ERP software must meet ISO/TS 16949 standards for consistent quality management processes across automotive manufacturing operations.

Environmental and Safety Regulations (Emissions and Safety Standards): ERP systems must track compliance with environmental and safety regulations, including emissions standards and crash testing requirements.

Financial Reporting Standards (GAAP, IFRS): ERP systems must adhere to GAAP and IFRS standards for accurate financial reporting and reliable forecasting capabilities.

Product Traceability (FDA, CE Marking): ERP systems should maintain complete traceability records to meet FDA requirements and CE marking standards for safety compliance.

Labor and Employment Laws Compliance: Automotive ERP software must comply with labor laws regarding wages, hours, and benefits across different jurisdictions.

Oil and Gas ERP Software Development: Features, Benefits, Process, Integration and more

The oil and gas industry operates in a complex and volatile environment. It involves oil and gas exploration, extraction, drilling, production, and transportation. Consequently, the industry faces several challenges, such as fluctuating market demands, stringent regulatory requirements, and the constant pressure to reduce greenhouse gas emissions. Notably, oil and gas production, transport, and processing contribute…

Leveraging ERP AI Chatbot: Key Benefits and Strategies to Implement for Enterprises

In the current fast moving business ecosystem, companies are constantly looking for innovative ways of streamlining their operations and getting a competitive edge. One tool they have been relying on as a trusted mode of achieving this goal is an enterprise resource planning (ERP) software. The ERP software domain, in response, has emerged as a…

How ERP eCommerce Integration Can Help Scale Your Business to New Heights

Operating an eCommerce business is a complex process that requires effective management of multiple interconnected components. This includes various activities such as planning and allocation of resources, inventory management, internal communications, etc. What makes eCommerce operations even more challenging is that each area often operates within separate systems, having its unique set of processes. Thus,…