- The Role of AI in the Food Industry: Revolutionizing the Global Food Market

- Game-Changing Artificial Intelligence Applications in the Food Industry

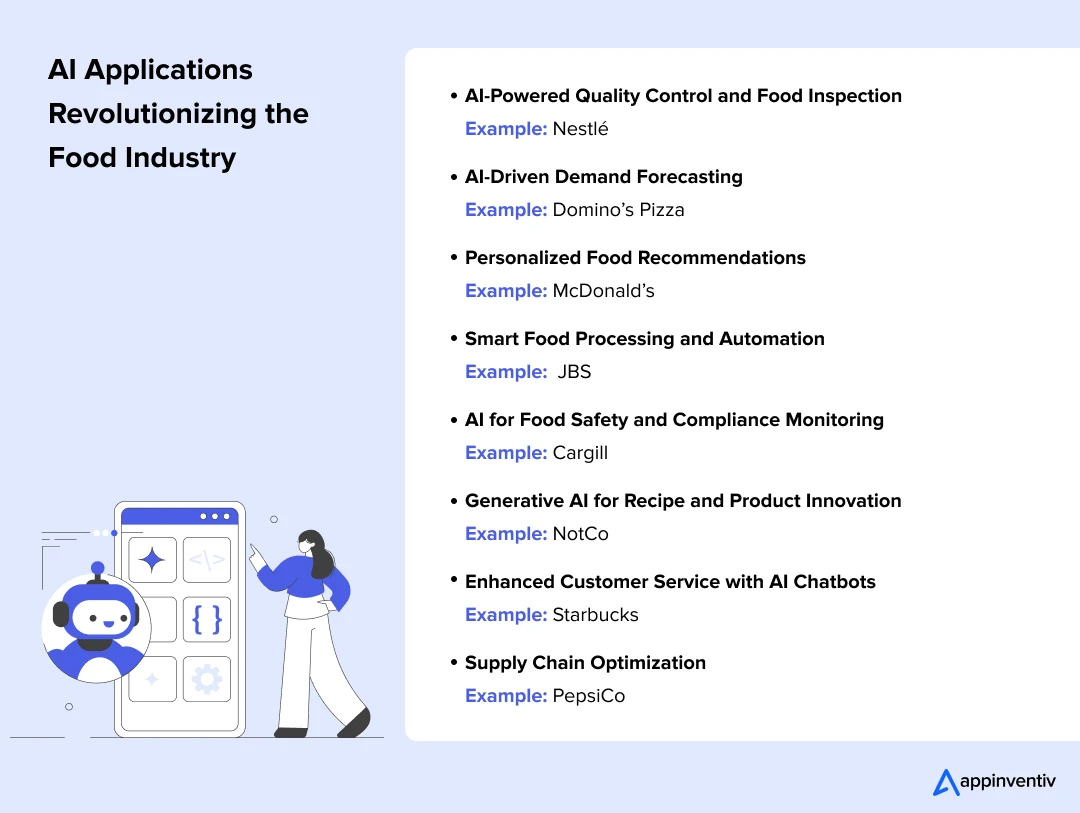

- 1. AI-Powered Quality Control and Food Inspection

- 2. AI-Driven Demand Forecasting

- 3. Personalized Food Recommendations

- 4. Smart Food Processing and Automation

- 5. AI for Food Safety and Compliance Monitoring

- 6. Generative AI for Recipe and Product Innovation

- 7. Enhanced Customer Service with AI Chatbots

- 8. Supply Chain Optimization

- How Appinventiv Helped KFC Build a Pioneering Food Delivery App

- Advantages of Implementing AI in the Food Industry

- Enhanced Precision and Consistency

- Increased Efficiency

- Cost Optimization

- Improved Safety and Hygiene

- Flexibility and Scalability

- Enhanced Customer Experience

- Data-Driven Decision Making

- Waste Reduction and Sustainability

- Steps to Integrate AI into Your Food Operations

- 1. Identify Key Areas for AI Implementation

- 2. Gather and Analyze Data

- 3. Select the Right AI Tools and Technologies

- 4. Train Staff and Foster a Data-Driven Culture

- 5. Test and Optimize AI Solutions

- 6. Monitor and Scale AI Applications

- Challenges of AI in the Food Industry and How Businesses Can Solve Them

- Data Quality and Integration

- High Implementation Costs

- Skills Gap and Workforce Resistance

- Data Security and Privacy Risks

- Limited Interpretability of AI Decisions

- Dependence on Technology Partners

- Regulatory and Compliance Complexities

- Handling Supply Chain Disruptions

- Ethical and Consumer Trust Issues

- Generative AI Accuracy and Market Acceptance

- Inconsistent Technology Standards

- Environmental Impact of AI Systems

- Future of AI in the Food Industry: What Businesses Can Expect

- Hyper-Personalization at Scale

- Advanced Predictive Analytics

- AI-Driven Smart Factories

- Generative AI for Rapid Product Development

- Seamless Customer Engagement with AI Chatbots

- AI-Enhanced Food Safety and Compliance

- Fully Optimized Supply Chains

- Unlock Opportunities in Your Food Business with Appinventiv’s Intelligent AI Services

- FAQs

Key takeaways:

- AI is now essential for efficiency, cost control, and customer satisfaction in the food industry.

- AI is transforming food production, processing, delivery, and customer engagement.

- Generative AI is driving faster, consumer-focused product and recipe innovation.

- AI in food delivery apps and chatbots is reshaping real-time customer experiences.

- AI boosts food safety, reduces waste, and optimizes supply chains at scale.

- The AI in food and beverage market will reach $84.75 billion by 2030.

Rising costs, labor shortages, and the constant pressure to meet growing customer demands—these are the daily struggles food businesses face. If you’re dealing with these issues, you’re not alone. The question is: how are you adapting to stay competitive in an increasingly challenging market?

Well, AI in the food industry offers a powerful solution to this conundrum. From automation of food preparation to optimizing supply chains, AI and robotics help firms overcome these hurdles. These technologies automate functions, save costs, and improve produce quality on a massive scale previously thought unattainable.

For CEOs and CTOs of food businesses, AI implementation is not a nice-to-have, but a strategic must-have. AI brings with it the capability of enhancing efficiency, curbing wastage, and increasing customer happiness – all of them driving ROI.

So how can you begin incorporating AI into your processes? This blog looks at all of the ways AI and robotics are changing the face of food. We examine practical applications—from predictive analytics powered by AI to computerized cooking systems—that can help you stay one step ahead of competitors.

We’ll also discuss practical steps for getting started with AI in your business, the key challenges to watch out for, and the ROI you can expect when embracing these cutting-edge technologies. By the end of this blog, you’ll have a clear understanding of how AI can elevate your food business to the next level.

The opportunity isn’t coming — it’s already here. Now is the time to scale smarter, innovate faster, and build future-ready operations.

The Role of AI in the Food Industry: Revolutionizing the Global Food Market

The food industry is undergoing a profound transformation, with technology playing a crucial role in reshaping how businesses operate, engage with customers, and optimize their processes. Artificial intelligence is emerging as the catalyst for this shift, offering innovative solutions to age-old challenges in food production, distribution, and customer interaction. As the industry evolves, AI in the food industry is becoming more than just a trend—it’s a necessity for businesses looking to stay competitive in an increasingly complex market.

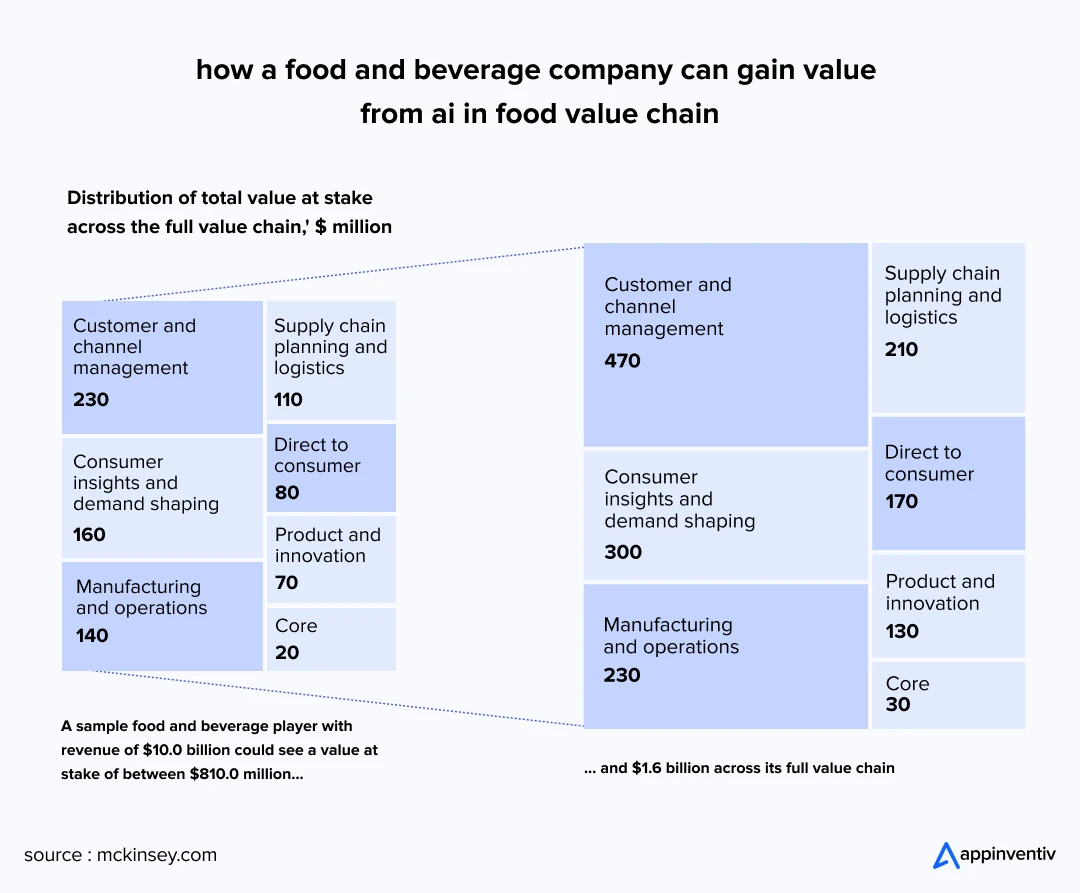

AI’s possibilities within the food industry range from enhancing operational efficiencies to optimizing customer experiences. As per a Mckinsey report, food and beverages corporations with $10 billion revenue could free between $810 million and $1.6 billion of value with digital and AI transformations applied along their whole value chain. Much of this value lies with optimizing channel and customer management, as AI-powered insights enable corporations to comprehend consumer habits and fine-tune their interaction strategies.

When it comes to marketing food businesses to the customers, AI is also creating a tangible impact, even in the revenue generation front. BCG points out that generative AI is revolutionizing how leading restaurants communicate with their customers, helping them eliminate bottlenecks and deliver highly personalized recommendations and offers. This technology has been proven to drive repeat visits and boost revenue by 6% to 10%, showcasing its clear value in enhancing both customer satisfaction and profitability.

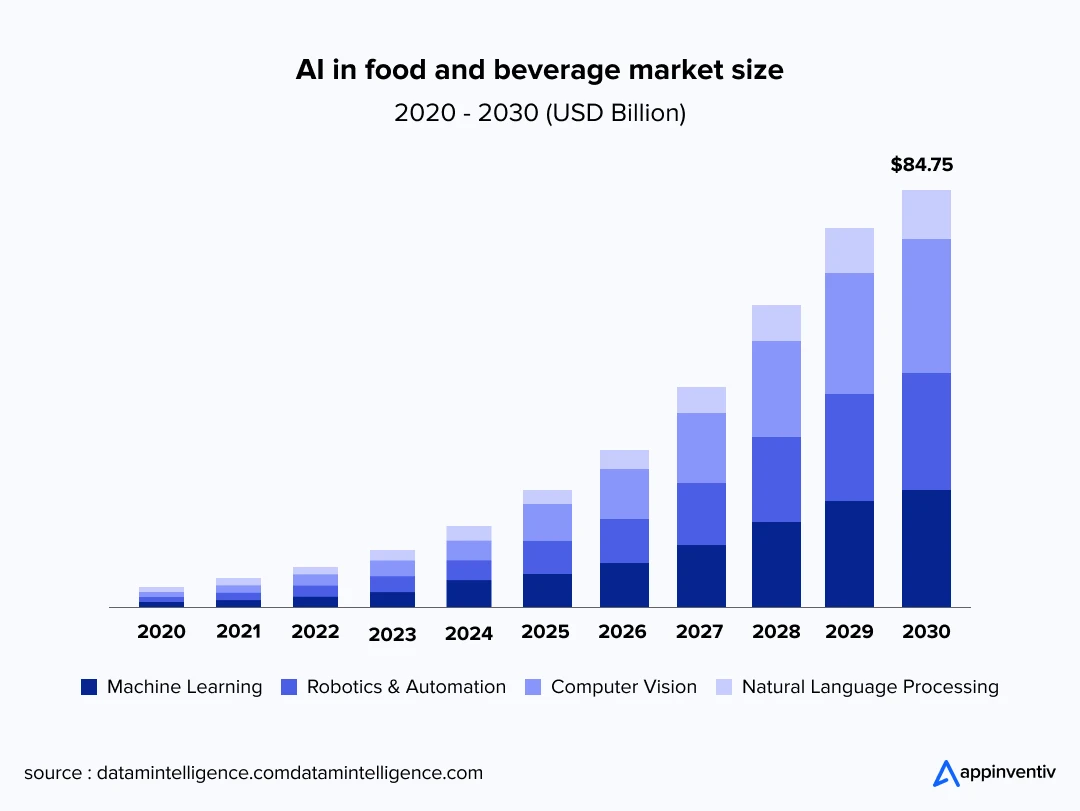

The degree of AI’s impact on the food and beverages industry is further emphasized by the rapid growth of the market itself. Projected by Grand View Research, with a 2023 value of $8.45 billion, the AI in food and beverages global market would reach a staggering $84.75 billion by 2030 at a 39.1% CAGR. Such momentum is a reflection of broad-based increased use of AI across much of the food industry, from automation and predictive analytics to customer relationships and supply chain management.

With these impressive growth figures, it is clear the food industry is at a critical turning point. The opportunity to invest in AI is no longer on the horizon—it’s here. As the market continues to accelerate, businesses that embrace AI early won’t just gain a competitive edge; they’ll position themselves for sustained growth and long-term success. The food industry’s next revolution has already begun, and AI is leading the way.

Now that you have understood the impact of AI in the food industry, let us move ahead and offer you a quick insight into its multiple applications.

Game-Changing Artificial Intelligence Applications in the Food Industry

The food business is transforming rapidly to meet the expanding demands of a growing population. Suppliers are under increasing pressure to provide higher-quality, sustainable food while enhancing efficiency. The integration of Artificial intelligence into the food industry ensures a more resilient and sophisticated food ecosystem by promising better productivity and responsiveness to market needs. Let us look into the major Artificial Intelligence applications in the food industry in detail below:

Let’s delve deeper to understand how AI applications in food industry are providing innumerable opportunities:

1. AI-Powered Quality Control and Food Inspection

One of the most impactful applications of AI in the food industry is in the domain of automated quality control and food inspection. Traditional manual inspections often miss subtle defects or inconsistencies, leading to compromised food safety and potential recalls. AI-powered vision systems, equipped with deep learning algorithms, can rapidly scan food products for minute defects, contamination, or variations in color, shape, and size that may indicate quality issues.

These systems continuously learn from data, becoming more precise over time. By using artificial intelligence in food processing, businesses can uphold stringent quality standards, minimize wastage, and ensure product consistency, even in large-scale production environments.

Example: Nestlé employs advanced AI-driven visual inspection systems across its global manufacturing facilities to automate food safety checks. These AI models detect imperfections that might be invisible to the human eye, ensuring defective or unsafe products are immediately removed from the processing line. This technology has helped Nestlé significantly reduce product recalls and strengthen consumer trust.

2. AI-Driven Demand Forecasting

Predicting consumer demand accurately is crucial to minimize food wastage and optimize inventory. AI applications in the food industry are transforming demand forecasting by analyzing vast datasets, including historical sales, seasonal trends, weather patterns, consumer sentiment on social media, and even economic indicators.

Unlike traditional forecasting models, AI can process complex, nonlinear relationships and adapt in real-time to sudden market changes. For food service providers, this precision ensures that popular ingredients are always in stock while reducing overproduction and spoilage.

Example: Unilever leverages AI-driven demand forecasting to manage its extensive portfolio of food and beverage products across global markets. By analyzing historical sales, promotional calendars, weather forecasts, and consumer behavior patterns, Unilever’s AI models can predict spikes in demand for specific products like ice cream during heatwaves or soups in colder seasons.

This advanced forecasting helps the company optimize production schedules, streamline inventory management, and significantly cut down on food wastage while ensuring timely product availability in diverse regions.

3. Personalized Food Recommendations

AI in the food industry is revolutionizing customer interactions by enabling hyper-personalized food recommendations. By analyzing customer purchase history, preferences, dietary restrictions, and real-time ordering patterns, AI models can suggest highly relevant food options to individual consumers.

This application enhances customer satisfaction, increases basket size, and builds long-term loyalty. In the food service industry, especially in QSR (Quick Service Restaurant) chains, this personalization is becoming a competitive differentiator.

[Also Read: 10 Use Cases and Real Examples of How AI is Used in the Restaurant Industry]

Example: McDonald’s uses AI-based decision technology through its Dynamic Yield platform to personalize drive-thru and digital menu boards. Depending on the weather, time of day, trending orders, and customer profiles, McDonald’s adjusts menu displays in real-time to suggest items most likely to appeal to each customer. This AI application in food service has led to increased average order values and improved customer retention.

4. Smart Food Processing and Automation

Artificial intelligence in food processing is driving a new era of smart factories. AI-powered robotics and automation are used for sorting, cutting, mixing, and packaging food products with unmatched precision and consistency.

These systems not only speed up production but also reduce reliance on manual labor, improving both efficiency and workplace safety. Real-time monitoring and adaptive learning capabilities allow these AI systems to make on-the-fly adjustments to maintain product uniformity even when raw materials vary.

Example: JBS, one of the world’s largest meat processing companies, employs AI-driven robotics to automate complex meat cutting processes. By leveraging AI in food manufacturing, JBS ensures consistent portion sizes and minimizes product loss. Their smart processing lines also use sensors and machine learning models to adjust blade movements based on meat composition in real-time, significantly enhancing throughput and reducing human error.

5. AI for Food Safety and Compliance Monitoring

Food safety remains a top priority in the food and beverage industry. AI in the food industry is now being deployed to create predictive food safety systems that monitor hygiene parameters, storage conditions, temperature levels, and transport environments in real-time.

AI algorithms can detect anomalies, predict potential contamination events, and trigger corrective actions long before safety thresholds are breached. This proactive monitoring significantly reduces the risk of foodborne illnesses and regulatory violations.

Example: Cargill uses AI-powered supply chain analytics to monitor food safety across its global operations. Through real-time data capture and machine learning algorithms, Cargill can track potential contamination sources, predict safety breaches, and adjust logistics and storage processes proactively. This AI-enabled transparency ensures compliance with international food safety standards and enhances consumer confidence.

6. Generative AI for Recipe and Product Innovation

Generative AI in the food industry is shaping the future of food innovation. These AI models can generate new recipe ideas, predict taste combinations, and simulate consumer acceptance before actual product development begins.

By analyzing millions of existing recipes, flavor compounds, nutritional data, and consumer trends, generative AI development can design unique food products tailored to emerging dietary preferences, such as vegan, keto, or allergen-free options.

[Also Read: 10 Use Cases of AI in Nutrition: All You Need to Know]

Example: NotCo, a Chilean food-tech company, uses a proprietary generative AI platform called “Giuseppe” to develop plant-based alternatives that closely mimic animal-based products. By harnessing generative AI in the food industry, NotCo successfully recreated plant-based milk, burgers, and mayonnaise that rival their traditional counterparts in taste and texture. This rapid innovation cycle has enabled NotCo to expand quickly into international markets.

7. Enhanced Customer Service with AI Chatbots

The adoption of AI in the food service industry is enhancing customer support with intelligent chatbots that manage reservations, handle order tracking, address complaints, and recommend menu items 24/7.

These AI-driven chatbots improve response time, streamline customer engagement, and provide a seamless ordering experience, which is especially critical for fast-paced environments like quick-service restaurants.

Example: Starbucks is one of the leading AI in food industry examples that use AI-powered chatbots within its mobile app to assist customers in placing orders, customizing beverages, and tracking rewards in real time. The chatbot, integrated with voice and text interfaces, provides personalized drink suggestions based on previous orders and seasonal offerings. This smart use of AI technology has helped Starbucks enhance customer convenience, reduce wait times, and boost overall app engagement.

8. Supply Chain Optimization

Optimizing the complex supply chains in the food and beverage industry is another major contribution of AI applications in food industry. AI-driven logistics systems provide real-time visibility into inventory levels, transportation routes, supplier reliability, and storage conditions. Predictive analytics help in identifying potential disruptions, enabling companies to re-route shipments and prevent spoilage.

Example: PepsiCo leverages AI in the food and beverage industry to optimize its end-to-end supply chain operations. AI models help PepsiCo predict shipping delays, optimize warehouse management, and plan efficient delivery routes. By applying artificial intelligence in food processing and logistics, PepsiCo has significantly reduced transportation costs and minimized product spoilage across its global network.

How Appinventiv Helped KFC Build a Pioneering Food Delivery App

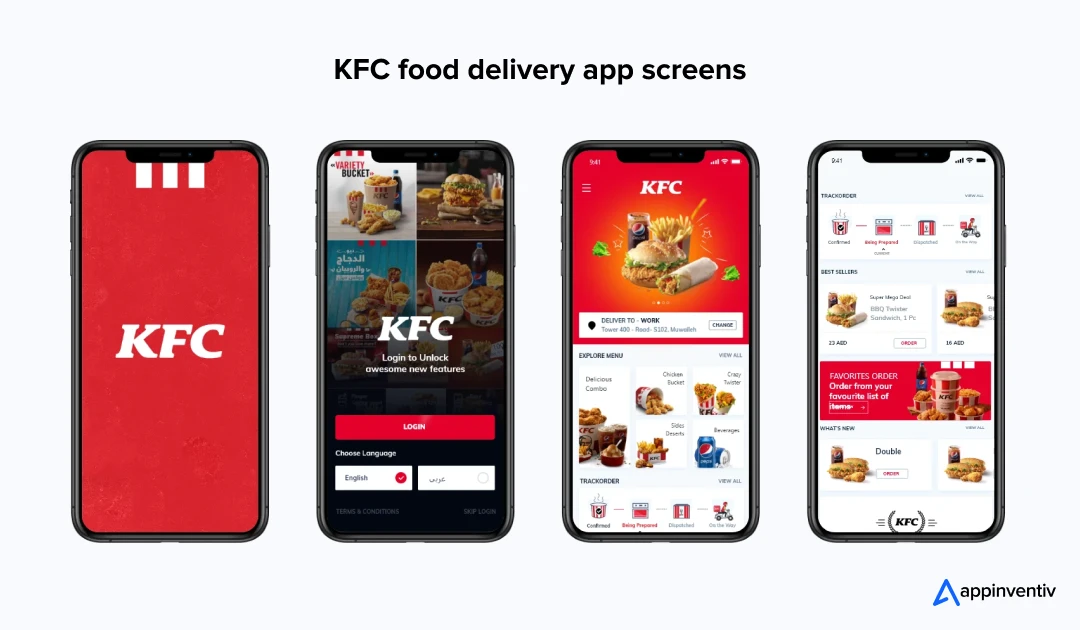

KFC partnered with us to create a food delivery app that enabled users to track their order delivery’s real-time status, expanding its digital presence in the global arena. With 2 million downloads and a 28% conversion rate, the app was ranked number one on Play Store.

In order to make more customers order from the KFC food delivery app instead of aggregator apps, it was essential to boost the customer experience. To achieve this, our experts implemented top-notch AI-based personalization features that made it easier for the customers to keep track of their order history, place order in accordance with special offers and food category choices, and make hassle-free payments through multiple gateways.

(Also Read: How much does it cost to develop an app like KFC?)

If you are still confused regarding the innumerable benefits of AI in the food industry, have a look at a few of the most important ones listed below.

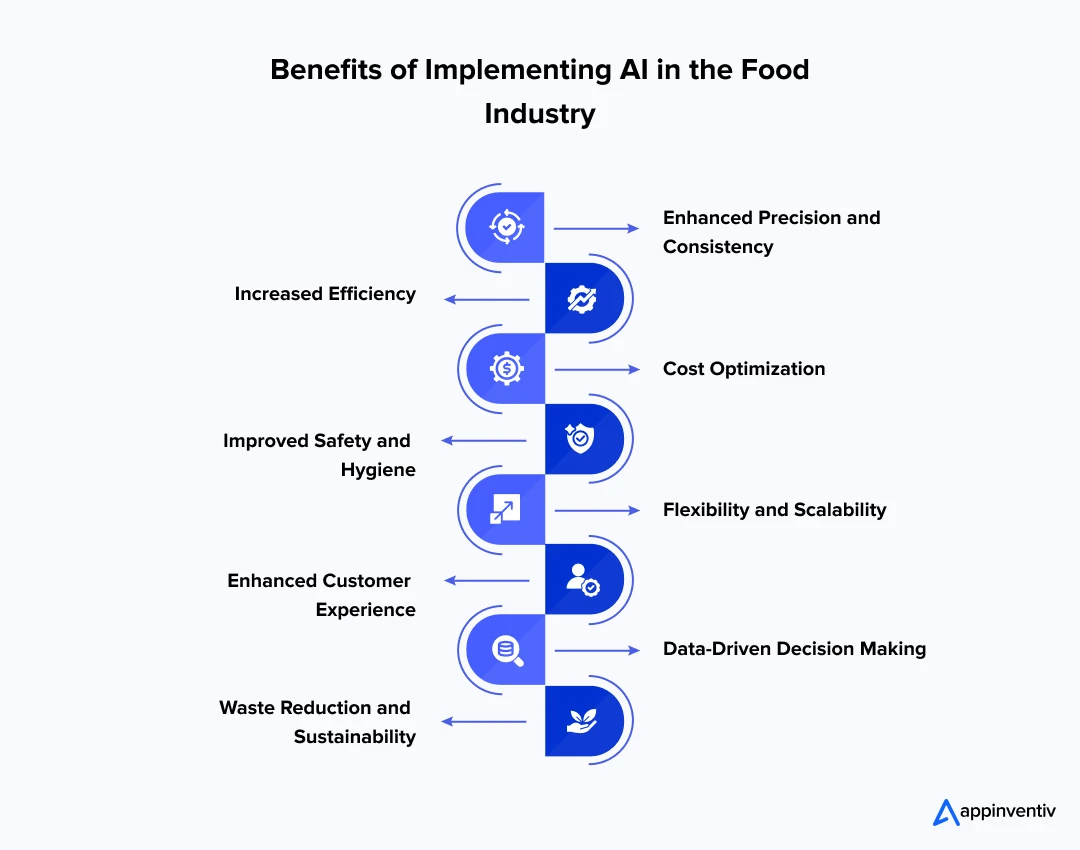

Advantages of Implementing AI in the Food Industry

Implementing AI in the food service industry demonstrates numerous opportunities by enhancing precision, efficiency, and safety. These advancements lead to cost savings, improved customer experiences, and sustainable practices. Let’s comprehend the benefits of AI in the food industry in detail!

Enhanced Precision and Consistency

AI in the food service industry can perform repetitive tasks with high precision, ensuring consistent quality and reducing human error. This is crucial in food preparation, as even minor deviations can affect taste and safety. Additionally, AI systems can monitor and adjust recipes in real-time, ensuring that every dish meets the same high standards. This not only improves the dining experience but also builds customer trust and loyalty.

Increased Efficiency

AI technology in the food industry can work continuously without breaks, significantly increasing productivity. They can handle tasks faster than human workers, leading to quicker turnaround times and improved operational efficiency. Moreover, AI systems can be integrated with inventory management and supply chain logistics to streamline operations and minimize downtime, further boosting overall efficiency.

Cost Optimization

Investing in AI isn’t just a technological upgrade; it’s a strategic move toward substantial long-term savings. These advanced technologies dramatically cut labor costs by automating repetitive tasks, while precision and efficiency minimize waste and reduce error rates.

Moreover, AI-powered predictive maintenance anticipates and prevents equipment failures, reducing downtime and associated repair costs. This proactive approach ensures smoother, more cost-effective operations, enabling businesses to reinvest their savings into growth and innovation.

Improved Safety and Hygiene

AI robots are capable of functioning in environments hazardous to human health, such as areas with extreme temperatures or exposure to toxic chemicals. In the food service industry, AI-driven systems ensure exceptional hygiene standards, critical for food handling and preparation.

By automating tasks that require direct food contact, AI significantly reduces the risk of contamination and enhances compliance with stringent health and safety regulations. This not only protects workers but also assures consumers of the highest safety and cleanliness standards.

Flexibility and Scalability

AI technology in the food industry can be easily programmed and reprogrammed to handle various tasks, offering great flexibility. As demand changes, the same robotic systems can scale operations up or down without the need for extensive reconfiguration. This adaptability allows businesses to respond quickly to market trends and seasonal demands, maintaining efficiency and competitiveness.

Enhanced Customer Experience

With AI in food manufacturing, businesses can offer more customized and consistent food products. Quick service, high-quality output, and the ability to meet specific customer preferences lead to a better customer experience. Furthermore, AI-driven insights into customer preferences can guide menu development and promotional strategies, creating a more personalized and satisfying dining experience. Advanced predictive analytics allow for better inventory management, reducing waste and ensuring fresh ingredients. Additionally, AI-driven quality control systems enhance food safety standards, minimizing the risk of contamination and ensuring consumer trust.

Data-Driven Decision Making

AI systems can collect and analyze data on production processes, consumer preferences, and equipment performance. This data-driven approach helps businesses make informed decisions, optimize operations, and innovate in product development.

Leveraging real-time AI analytics, businesses can pinpoint inefficiencies and highlight areas for enhancement, fostering a culture of continuous improvement. Additionally, predictive analytics can forecast market trends and consumer behavior, providing a competitive edge and facilitating proactive strategies. This comprehensive utilization of data transforms raw information into actionable insights, ensuring sustainable growth and operational excellence.

Waste Reduction and Sustainability

Integrating AI into food robotics can revolutionize sustainable practices by significantly enhancing resource optimization, waste reduction, and energy efficiency. This integration not only helps in achieving stringent environmental objectives but also bolsters the company’s reputation for sustainability.

Advanced ML algorithms can precisely forecast demand, thereby minimizing overproduction and subsequent food waste. Moreover, these algorithms support sustainable sourcing practices by ensuring efficient use of resources throughout the supply chain.

Enhanced predictive analytics enable more accurate inventory management, reducing the carbon footprint associated with excess storage and transportation. Furthermore, AI-driven energy management systems can optimize energy consumption, making operations more eco-friendly.

As evident, implementing AI in food robotics automation offers numerous benefits, from improving efficiency and consistency to enhancing safety and sustainability.

These advantages position businesses to meet the demands of modern consumers while maintaining high standards of quality and operational excellence.

Steps to Integrate AI into Your Food Operations

Integrating AI into the food industry is a game-changer for businesses looking to optimize operations, enhance customer experiences, and drive innovation. However, the process requires careful planning and execution to ensure that AI applications deliver measurable benefits. Here are the key steps to successfully integrate AI into your food business:

1. Identify Key Areas for AI Implementation

The first step in integrating AI into the food industry is identifying the areas where it can have the most significant impact. Whether it’s in food processing, customer service, inventory management, or production optimization, pinpointing where AI can streamline operations is essential. AI in the food service industry operations, manufacturing and quality control centers can offer substantial improvements, so businesses should prioritize based on their unique needs and goals.

2. Gather and Analyze Data

AI thrives on data, and the food industry is no exception. Before implementing AI, it’s crucial to gather high-quality data from various sources, such as sales, inventory, customer interactions, and production systems. AI technology in the food industry relies on large datasets to learn and make predictions, so businesses should invest in data collection systems and ensure that their data is clean, structured, and accessible.

3. Select the Right AI Tools and Technologies

Choosing the right AI tools and technologies is critical to the success of your integration. For example, AI in the food service industry may require advanced computer vision systems, while AI in the food service could benefit from chatbots or recommendation engines. When selecting AI tools, consider scalability, ease of integration, and whether the technology aligns with your business objectives. A combination of machine learning, predictive analytics, and robotics can be used across different aspects of food production and service.

4. Train Staff and Foster a Data-Driven Culture

AI implementation in the food industry requires buy-in from all levels of the organization. It’s important to train your staff to work with AI systems and ensure they understand how to leverage the technology for maximum impact. Additionally, fostering a data-driven culture across your company will ensure that AI initiatives are integrated effectively, with employees using AI-driven insights to make more informed decisions.

5. Test and Optimize AI Solutions

Once the AI systems are in place, it’s essential to test them thoroughly to ensure they deliver the desired results. This phase involves running pilots, gathering feedback, and fine-tuning the systems to improve accuracy and performance. Whether it’s AI in the food and beverage industry for customer engagement or AI in food manufacturing to optimize production, testing helps identify areas for improvement and ensures the AI systems work seamlessly with existing processes.

6. Monitor and Scale AI Applications

AI integration doesn’t stop at implementation. After deployment, businesses must continuously monitor AI systems to ensure they are performing as expected. Collect performance data, evaluate ROI, and be ready to make adjustments as needed. Once the initial applications are optimized, food businesses can scale their AI solutions to other areas of operation, expanding the benefits of AI across the entire business—from inventory management to food safety and beyond.

Challenges of AI in the Food Industry and How Businesses Can Solve Them

While artificial intelligence in the food industry is driving remarkable transformation, it comes with its own set of challenges. Businesses need to proactively address these hurdles to fully unlock AI’s potential and achieve sustainable success.

Data Quality and Integration

One of the biggest obstacles is poor data quality and fragmented systems. AI-driven solutions like predictive analytics, AI-powered quality control, and AI-driven demand forecasting rely heavily on clean, consistent, and integrated datasets. In the food industry, data often comes from disconnected sources like manual records, machinery sensors, and supply chain partners, leading to inaccurate or incomplete insights.

Solution:

Implement centralized real-time monitoring systems and invest in robust data management platforms that integrate all critical data points—from inventory to processing lines to customer orders—into a unified dashboard. This ensures AI systems receive accurate, real-time information to make better predictions and decisions.

High Implementation Costs

Adopting AI-powered robotics, smart food processing systems, and AI-driven logistics can be capital-intensive, especially for small and medium-sized food businesses. The initial investment in AI infrastructure, sensors, and skilled personnel can be a major barrier.

Solution:

Leverage cloud-based AI applications in the food industry that offer scalable, subscription-based models. Partnering with technology providers for modular AI solutions can reduce upfront costs and allow gradual scaling as businesses grow.

Skills Gap and Workforce Resistance

The shift towards AI-powered quality control, AI chatbots, and smart food processing requires new technical skills that many traditional food industry workers may not have. Additionally, some employees may resist automation due to fear of job displacement.

Solution:

Invest in upskilling programs to train existing staff in AI system management and data analytics. Partnering with an experienced AI services firm like Appinventiv can also ease this transition by providing the right guidance, tools, and long-term support tailored to your business. These partnerships help food companies build AI solutions while offering expert-led employee training, making it easier to introduce new technologies without disrupting current operations.

Position AI as a tool that complements human roles—enhancing efficiency and food safety—rather than replacing workers. Encourage a culture of innovation to ease workforce adoption.

Data Security and Privacy Risks

With personalized food recommendations and AI-driven customer engagement, companies collect vast amounts of sensitive consumer data. This raises concerns about data security, especially in highly regulated markets.

Solution:

Adopt stringent cybersecurity protocols and comply with data protection regulations like GDPR. Use AI systems with built-in security layers to safeguard customer data, ensuring safe handling of real-time monitoring and predictive analytics processes.

Limited Interpretability of AI Decisions

Advanced AI models, particularly in generative AI and predictive analytics, can sometimes behave like “black boxes,” making it difficult for food businesses to understand how decisions are made, especially in areas like AI-powered quality control or supply chain optimization.

Solution:

Adopt explainable AI frameworks that offer transparency in decision-making processes. Choose AI solutions that provide clear reasoning for forecasts, product recommendations, or quality decisions to help build trust among managers, regulators, and customers.

Dependence on Technology Partners

Many food companies rely on external vendors for AI-driven logistics, chatbots, and smart processing technologies. Over-dependence on third-party providers can lead to issues like vendor lock-in or limited system customization.

Solution:

Develop hybrid AI strategies that combine in-house AI capabilities with outsourced technologies. This approach allows businesses to maintain control over core processes while leveraging external expertise for specialized applications like AI-powered robotics or generative AI in product development.

Regulatory and Compliance Complexities

The food industry is subject to strict food safety and compliance regulations that vary across countries and regions. As artificial intelligence in the food industry becomes more advanced, ensuring that AI-powered quality control systems and predictive food safety monitoring meet regulatory standards can be challenging, especially when using autonomous decision-making systems.

Solution:

Work closely with regulatory bodies to develop AI compliance protocols and ensure transparency in how AI models make safety decisions. Regular audits, validation processes, and AI system certifications can help businesses stay compliant and maintain consumer trust.

Handling Supply Chain Disruptions

While AI-driven supply chain optimization is becoming more advanced, global food supply chains are still highly vulnerable to unforeseen disruptions such as pandemics, geopolitical tensions, and climate events. Even predictive analytics may not always capture sudden, large-scale disruptions.

Solution:

Build AI-powered contingency planning systems that integrate real-time global data sources, including news, weather, and transportation analytics. This allows businesses to quickly adjust sourcing strategies, reroute shipments, and proactively manage inventory during disruptions.

Ethical and Consumer Trust Issues

The increasing use of AI-powered customer personalization and AI chatbots raises concerns about ethical use of consumer data. Some customers may perceive hyper-personalization or AI-based product recommendations as intrusive or manipulative.

Solution:

Ensure transparency in how AI-driven recommendations and chatbots use customer data. Offer customers control over personalization settings and clearly communicate how AI enhances their experience. This enhances overall responsibility, builds trust and fosters long-term customer loyalty.

Generative AI Accuracy and Market Acceptance

Using generative AI in the food industry for recipe development and product innovation carries the risk of producing food concepts that may not meet consumer taste expectations or cultural preferences. There’s also the possibility of over-reliance on machine-generated ideas without sufficient market validation.

Solution:

Use AI-powered consumer sentiment analysis to test new product concepts with target audiences early in the development process. Combine generative AI outputs with human culinary expertise and iterative market testing to ensure alignment with consumer preferences.

Inconsistent Technology Standards

The rapid development of AI applications in the food industry means that technology standards for AI-powered systems (such as smart food processing or AI-driven logistics) can vary widely between vendors and markets, making system integration difficult.

Solution:

Adopt interoperable AI solutions that can easily integrate with existing ERP, supply chain, and food safety management systems. Engage with industry bodies to advocate for common AI standards that facilitate seamless adoption across different platforms.

Environmental Impact of AI Systems

While artificial intelligence in the food industry can optimize efficiency, the deployment of large AI models and real-time monitoring systems requires significant computing power, contributing to energy consumption and carbon emissions.

Solution:

Invest in energy-efficient AI infrastructure and explore cloud providers that use renewable energy. Prioritize AI models optimized for low-power processing to balance technological advancement with sustainability goals.

Facing the hurdles of AI in the food industry? Complex data, high costs, skill gaps, or supply chain snags — whatever your challenge, we turn roadblocks into breakthroughs.

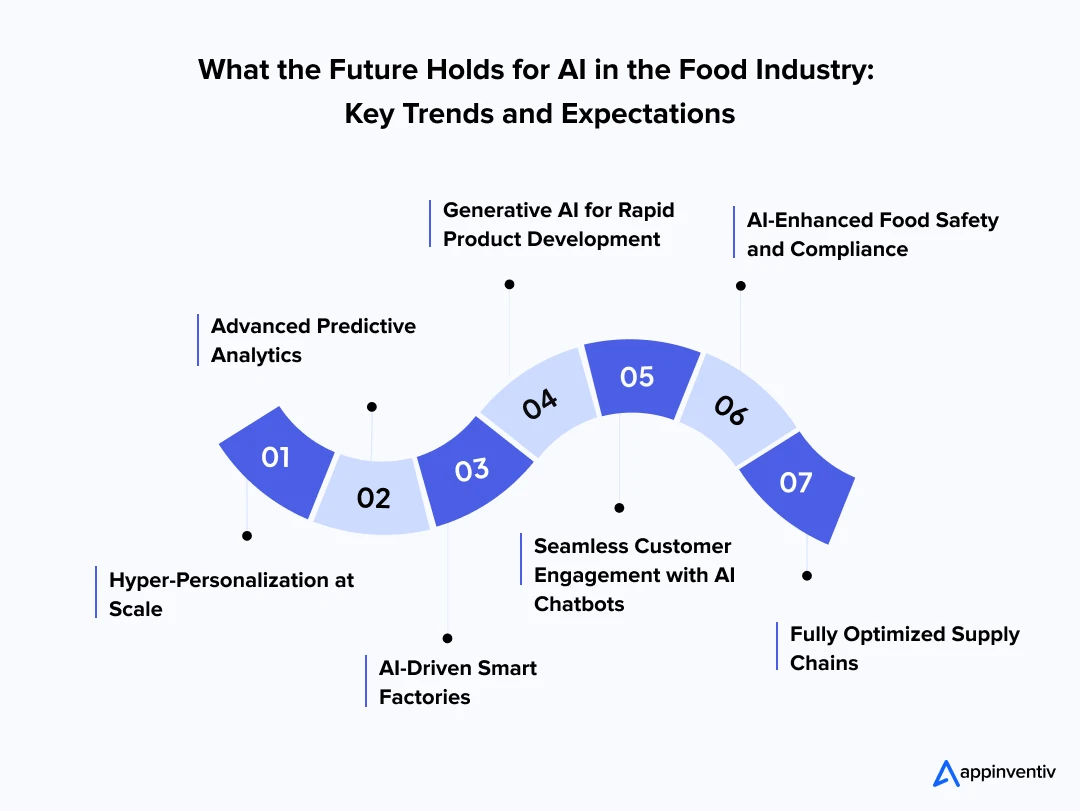

Future of AI in the Food Industry: What Businesses Can Expect

Artificial intelligence is already reshaping the food industry, from AI-powered quality control to personalized food recommendations, and its influence is only expected to grow. The future will see even deeper integration of predictive analytics, generative AI, and smart food processing technologies across every segment of the food value chain.

Hyper-Personalization at Scale

AI will deliver even more refined personalized food recommendations by combining real-time data from customer profiles, health apps, wearable devices, and even mood-detection technologies. Businesses will be able to customize menus and promotions for individual customers automatically.

In the future, personalization will extend to dietary restrictions, health goals, and even emotional preferences, offering hyper-relevant food choices that adapt in real-time.

Advanced Predictive Analytics

The use of AI-driven demand forecasting will become more precise. Businesses will be able to predict consumer trends, ingredient shortages, and even supply chain disruptions before they occur, allowing companies to make proactive, data-driven decisions.

AI will also enable dynamic pricing models that adjust in real-time based on supply, demand, and competitor movements to maximize profitability.

AI-Driven Smart Factories

The future of smart food processing and automation will involve fully autonomous production lines powered by AI-powered robotics and real-time quality control systems that self-optimize to improve efficiency, consistency, and food safety without human intervention.

These smart factories will also use energy-efficient AI systems to optimize power consumption and minimize environmental impact.

Generative AI for Rapid Product Development

Generative AI will become a key tool for creating new recipes, developing plant-based alternatives, and simulating flavor profiles, enabling faster, low-risk product innovation that closely matches consumer preferences.

Future generative AI systems will collaborate with chefs and food scientists, offering AI-human co-created recipes that cater to evolving consumer trends.

Seamless Customer Engagement with AI Chatbots

Businesses will deploy more advanced AI-powered chatbots capable of managing complex customer interactions, upselling in real-time, handling multilingual conversations, and providing predictive customer support based on behavior patterns.

AI chatbots will soon be integrated with voice assistants and AR menus, providing fully immersive, conversational ordering experiences across channels.

AI-Enhanced Food Safety and Compliance

The future will witness a shift toward proactive food safety monitoring using predictive AI systems that can instantly detect contamination risks and automatically trigger corrective actions, reducing recalls and regulatory penalties.

AI will also assist in automating compliance documentation and real-time regulatory reporting, reducing manual audits and paperwork significantly.

Fully Optimized Supply Chains

Supply chain optimization powered by AI will enable real-time tracking of raw materials, predictive maintenance of transportation equipment, and smart re-routing to avoid delays and reduce food spoilage, all through seamless AI-driven logistics.

AI will further enable cross-industry collaboration, connecting suppliers, manufacturers, and retailers in a unified ecosystem for faster, smarter decision-making.

Unlock Opportunities in Your Food Business with Appinventiv’s Intelligent AI Services

Food businesses today face complex challenges — fast-changing customer needs, supply chain issues, growing competition, and the constant pressure to improve efficiency. Solving these problems takes more than just buying technology. It takes a trusted AI development services partner who can help you build the right solutions, with the right approach, for your business.

That’s where we can help.

We work closely with you to create smart, practical AI solutions that truly fit your business. Whether you need to forecast demand more accurately, improve food safety, reduce waste, or make your customer experiences more personal, we design and build AI tools that actually work for you.

Our team supports you from start to finish — from understanding your goals, to creating simple and easy-to-use designs, to building reliable systems, testing carefully, and providing full support even after your solution is live.

We focus on building solutions that help you work faster, waste less, and grow your food business with confidence.

In our 10+ years of journey, we have empowered countless businesses to seize new opportunities and overcome operational challenges. Our portfolio includes global leaders like Domino’s, KFC, and Pizza Hut. This extensive client base solidifies our position as a trusted tech partner for businesses seeking cutting-edge software solutions.

Contact our experts to learn more about our AI services and how they can benefit your organization.

FAQs

Q. What role does AI play in revolutionizing the food industry?

A. AI in the food industry utilizes technologies like data analytics and machine learning to enhance food production, precision agriculture, quality control, personalized nutrition, supply chain management, and customer experience. This leads to improved sustainability, efficiency, and innovation in the food ecosystem. The integration of artificial intelligence in food industry processes ensures smarter decision-making and optimized operations, driving progress and competitive advantage.

Q. How is AI revolutionizing food production and processing?

A. AI is transforming food production by enabling smart food processing and automation that deliver unprecedented speed, precision, and consistency. Through AI-powered robotics, businesses can automate complex tasks like cutting, sorting, mixing, and packaging, while real-time monitoring systems ensure that quality standards are consistently met, even when raw materials vary. AI’s adaptive learning capabilities allow production lines to self-adjust, improving efficiency and minimizing product loss.

Q. What role does AI play in food safety and quality control?

A. AI in the fast food industry plays a critical role in enhancing food safety and quality control by using AI-powered vision systems and predictive analytics to detect defects, contamination, and hygiene breaches in real time. Unlike traditional inspections, AI systems continuously learn from production data, becoming more accurate at identifying safety risks over time. This proactive approach helps businesses minimize recalls, maintain regulatory compliance, and strengthen consumer trust.

Q. How can AI help in predicting food trends and consumer preferences?

A. Food service software uses AI-driven demand forecasting and predictive analytics to analyze vast datasets, including historical sales, social media trends, consumer reviews, and seasonal behaviors, to predict emerging food trends and shifting customer preferences. By processing these complex, nonlinear patterns, AI allows food businesses to adapt menus, develop new products, and stock the right ingredients ahead of demand, giving them a significant competitive edge.

Q. What are the benefits of AI in supply chain management for food businesses?

A. Artificial intelligence in the food industry provides real-time supply chain optimization, improving visibility, speed, and decision-making across food logistics. Key benefits include:

- Accurate demand forecasting to prevent stockouts and overproduction.

- Predictive analytics to identify potential shipping delays and reroute deliveries.

- Real-time tracking of inventory and storage conditions.

- Enhanced supplier reliability and smarter warehouse management.

By using AI in food supply chains, businesses can significantly reduce transportation costs, improve delivery efficiency, and minimize product spoilage.

Q. Can AI be used to reduce food waste in the industry?

A. Yes, AI can play a major role in reducing food waste across the supply chain. AI-driven demand forecasting helps prevent overproduction by accurately predicting consumer needs, while smart food processing ensures precise portioning and minimal product loss. AI also enhances real-time inventory monitoring to flag items nearing expiration and allows supply chain optimization systems to reroute excess stock to areas of higher demand, reducing spoilage and improving sustainability.

How Much Does It Cost to Build an App like Janitor AI?

Key takeaways: Cost Breakdown: The cost of app development varies, with an MVP App costing $40,000 to $90,000, a Mid-Tier App costing $100,000 to $200,000, and an Enterprise Grade App costing $300,000 to $ 500,000 or more, depending on features, complexity, and the expertise of the development team. Key Factors: Platform choice, AI integration, and…

10 Ways AI is Transforming the Healthcare Sector in Australia

Key takeaways: Generative AI could add $13 billion annually to Australia’s healthcare sector by 2030. AI is already transforming operations across diagnostics, admin tasks, and patient care. Healthcare in remote areas is improving with AI-powered virtual assistants and monitoring tools. AI can help address workforce shortages by automating routine tasks and supporting clinical decisions. Major…

Exploring the Power of AI in Creating Dynamic & Interactive Data Visualizations

Key takeaways: AI transforms data visualization by providing automated insights, interactive dashboards, and NLP, thereby tackling revenue loss and improving data quality. Key features include predictive analytics, real-time data integration, and user-friendly visualizations, enabling faster and more informed decisions. Top 2025 tools, such as Tableau, Power BI, and Julius AI, offer NLP and real-time analytics…