- Predictive Analytics in Supply Chain: Applications & Advantages

- Anticipate Disruptions Before They Hit

- Enhance Inventory Management

- Improve Supplier Relationships

- Optimize Logistics and Delivery Routes

- Mitigate Risks and Build Resilience

- Predictive Pricing Strategies for Optimal Profit Margins

- Reduce the Bullwhip Effect on the Supply Chain

- Drive Data-Backed Strategic Decision-Making

- Demand Forecasting to Align Supply with Market Needs

- What are the Challenges in Supply Chain Predictive Analytics, and How to Address Them

- Data Quality and Fragmentation

- Security and Privacy Risks

- High Costs and ROI Uncertainty

- Real-World Examples of Predictive Analytics in Supply Chain Management

- Western Digital (WD)

- Walmart

- DHL

- Emerging Trends and Technologies Redefining the Future of Predictive Analytics for Supply Chain

- AI and ML

- Internet of Things (IoT)

- Blockchain

- Sustainability and Ethical Considerations

- Supply Chain Digital Transformation with Appinventiv

- FAQs

The global market disruption and sudden turbulence in the business world have brought to light many complexities and challenges in the supply chains. For instance,

- Global supply chain disruptions cost large companies an average of $182 million annually.

- Remote work, unexpected demand surges, and logistical complexities have intensified pressure on supply chains.

- Around 43% of organizations have limited to no visibility into the performance of their tier-one suppliers.

- Businesses grapple with changing demand forecasts, commodity volatility, and supplier-specific issues.

So, what is your strategy to tackle these challenges? Well, the answer is predictive analytics!

Supply chain predictive analytics is a business savior that empowers organizations to foresee disruptions, streamline operations, and make informed decisions. By leveraging the power of predictive analytics in the supply chain, companies can transform their operations from reactive to proactive, facilitating resilience and agility in the face of growing uncertainty.

Let’s delve deeper to understand how supply chain predictive analytics can help businesses overcome challenges and gain competitive advantages:

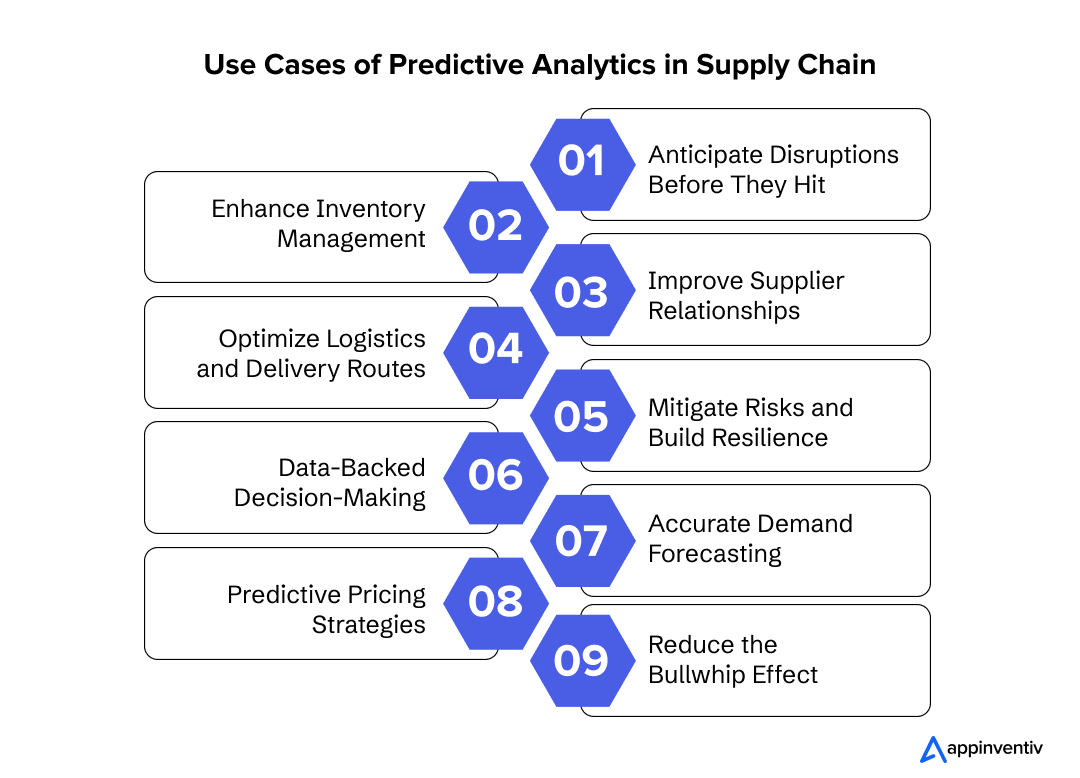

Predictive Analytics in Supply Chain: Applications & Advantages

The role of predictive analytics in supply chains is like a crystal ball, which delivers actionable insights backed by data instead of solely relying on guesswork. Here are some of the most notable benefits of predictive analytics in the supply chain, transforming complex supply networks into well-oiled and organized operations:

Anticipate Disruptions Before They Hit

Predictive analytics equip you with a sharp vision that enables you to spot a catastrophic situation coming before it hits. This advanced foresight helps you identify potential disruptions and anticipate the actions to mitigate the risk before it becomes a major headache.

Enhance Inventory Management

Predictive analytics in the supply chain helps manage inventory in a better way so that store managers may not face the devastating situations of overstock or stockouts. Nobody likes the “Sorry, we are out of stock” message. Predictive tools use historical data and real-time trends to optimize inventory, ensuring you don’t have too much (tying up capital) or too little (up

setting customers).

| Inventory Management Without Predictive Analytics | Inventory Management With Predictive Analytics |

|---|---|

| Overstocking or stockout situations occur | Balanced inventory levels |

| Capital stuck in slow-moving stock | Better cash flow management |

| Manual forecasting errors | Accurate demand predictions |

Also Read: How to Create An Intelligent Inventory Management App

Improve Supplier Relationships

Not all suppliers are created equal, and predictive analytics helps businesses monitor and assess supplier performance over time. When you know your supplier’s performance patterns and risks, you can better negotiate and build collaborative strategies. Predictive insights develop better bonds by identifying high-performing suppliers and addressing issues with underperforming ones, ensuring transparent communication and fewer surprises.

Optimize Logistics and Delivery Routes

Ever get stuck in traffic and wish you would have taken a different route? Predictive analytics in the logistics industry works the same magic for deliveries. It evaluates traffic patterns, fuel costs, and weather conditions to suggest the fastest and most cost-efficient delivery routes.

Also Read: AI in Logistics Industry: Key Benefits and Use Cases

Mitigate Risks and Build Resilience

Supply chains today are prone to risks—economic shifts, geopolitical changes, pandemics, you name it. Predictive analytics functions like an early-warning system, flagging potential issues before they escalate and helping businesses take proactive actions to steer away from disruptions.

Predictive Pricing Strategies for Optimal Profit Margins

Markets fluctuate—one week, the price of a commodity is low, and the next, it is sky-high. This volatility in price makes it challenging for businesses to maintain stable profit margins and stay competitive. Predictive analytics addresses this issue by predicting price trends, competitor strategy, and customer purchasing behaviors.

With these insights, companies can implement dynamic pricing strategies, adjusting prices in real-time to maximize profits while remaining competitive in fluctuating markets.

| Businesses before Predictive Pricing | Businesses with Predictive Pricing |

|---|---|

| Fixed pricing, missing market trends | Dynamic pricing based on data insights |

| Slower response to competitor shifts | Immediate price adjustments |

| Risk of eroding profit margins | Maximized margins with data foresight |

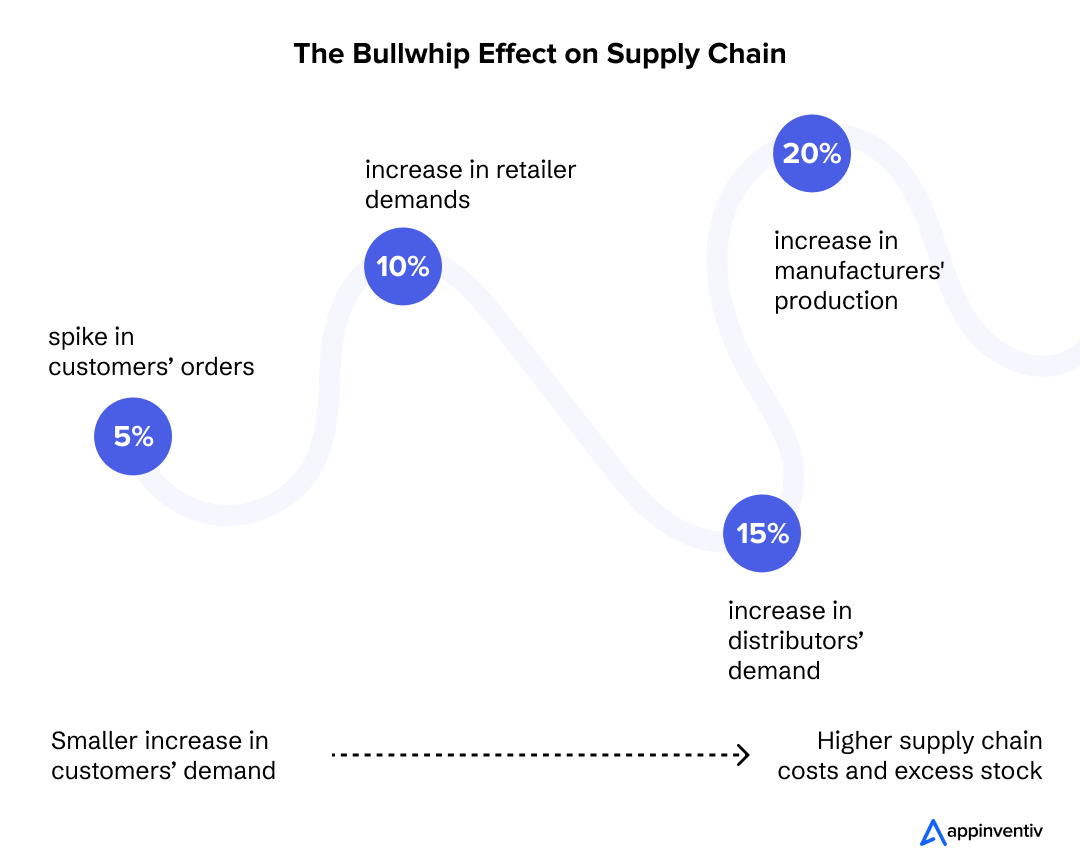

Reduce the Bullwhip Effect on the Supply Chain

The bullwhip effect—where small changes in demand create larger fluctuations upstream is a common pain point. Predictive analytics smooths out this volatility by providing a clearer picture of true demand. As a result, suppliers, manufacturers, and distributors can align their operations more closely, improving coordination across the entire supply chain.

Predictive analytics transforms supply chains from guesswork-driven to insight-driven operations. And in today’s volatile market, it is not just a nice-to-have—it is indispensable.

Drive Data-Backed Strategic Decision-Making

Gut feelings only take you so far. Predictive analytics turns raw data into meaningful insights, empowering leaders to make timely and strategically sound decisions. Whether choosing a new supplier, stocking up the inventory, or expanding into new markets, data-driven insights provide clarity to move ahead with confidence.

Demand Forecasting to Align Supply with Market Needs

Predictive analytics takes the guesswork out of demand forecasting by analyzing historical sales patterns, market trends, seasonality, weather, or economic shifts. This enables businesses to align their production with market demand, which in turn helps reduce waste and reap the opportunities. So, with predictive analytics, you no longer bother about meeting unexpected demand or sitting on unsold stock.

Bonus Read: Operational Analytics for Business: A Complete Guide

What are the Challenges in Supply Chain Predictive Analytics, and How to Address Them

Predictive analytics for supply chain management can unlock tremendous value, but implementing it right is a real pain. If you have felt the frustration of navigating the process of implementing predictive analytics in the supply chain, you are not alone. Many others face the same pain when implementing predictive analytics in the supply chain. What you need is the right strategy to ease the burden.

Let’s dive into some of the enterprises’ most common challenges and foolproof plans to overcome them.

Data Quality and Fragmentation

Challenge

Predictive analytics thrives on good data. However, fragmented systems, inconsistent formats, and missing information often derail companies. Inaccurate, outdated, or incomplete data leads to faulty predictions and wrong decisions, resulting in stockouts, production delays, or unnecessary inventory accumulation.

Solution

Start by building a strong data governance framework to standardize, clean, and manage data quality across the board. Automate data cleansing wherever possible and empower teams to flag inconsistencies early. Regular data audits ensure the system remains accurate over time, reducing the chances of faulty predictions.

Security and Privacy Risks

Challenge

Predictive analytics rely heavily on data sharing across multiple platforms, making security and privacy pressing concerns. Even a little inefficiency in handling valuable data can result in severe penalties, such as regulatory violations, reputational damage, or cyberattacks.

Solution

To overcome this challenge, you need to encrypt sensitive information, implement strict access controls, and conduct regular security audits. Additionally, compliance with privacy regulations such as GDPR or CCPA is also mandatory, as compliance with data protection laws builds trust with partners and customers alike.

High Costs and ROI Uncertainty

Challenge

Predictive analytics projects often come with steep price tags—requiring investment in skilled talent, infrastructure, and advanced tools. Moreover, it is not always clear when or how the ROI will materialize. This makes adoption particularly daunting for small and mid-sized enterprises.

Solution

To fix this issue, you should first define your measurable KPIs and short-term objectives that align with your business goals. Don’t just chase big wins—small gains also count. Keeping this in mind, you can target areas with the highest potential for savings—like inventory management, logistics optimization, etc. The rule is simple – Start small, prove success, and scale up.

Also read: How Technology in Supply Chain can Surpass Challenges

Real-World Examples of Predictive Analytics in Supply Chain Management

There are several industry leaders that optimize their supply chain operations and enhance efficiency through predictive analytics. Let’s peep into the predictive analytics supply chain case study of some reputed brands and learn what is the real life impact of predictive analytics in supply chain industry.

Western Digital (WD)

Western Digital, a global leader in digital storage solutions, is the best example of how companies can leverage the power of predictive analytics for supply chain management. During the COVID-19 pandemic, WD utilized its Predictive Risk Engine to protect its supply chain from major disruptions, saving millions.

Walmart

Walmart, the world’s largest retail chain, uses predictive analytics to streamline its supply chain, manage inventory, and enhance online and in-store shopping experiences. By analyzing data from millions of transactions and online searches, Walmart identifies top-selling products and fine-tunes its supply chain operations to meet customers’ demands.

DHL

DHL, a global logistics leader, has successfully harnessed the capabilities of predictive analytics to streamline its operations and drive efficiency. With advanced models, DHL accurately forecasts demand, reduces waste, fine-tunes delivery routes, and optimizes fleet maintenance.

Emerging Trends and Technologies Redefining the Future of Predictive Analytics for Supply Chain

Future trends in supply chain and predictive analytics are closely tied to the rapid advancements of emerging technologies, particularly artificial intelligence, ML, IoT, and Blockchain. With their intelligent automation, pattern identification, and data analysis capabilities, these technologies offer a leap forward in predictive analytics for risk management, demand forecasting, and inventory optimization.

A recent Gartner supply chain survey discloses the fact that supply chain leaders will increasingly adopt advanced technologies like cloud analytics, blockchain-based trackers, IoT sensors, and artificial intelligence in the coming years.

AI and ML

The integration of artificial intelligence and machine learning with predictive analytics will empower supply chain systems to continuously learn and adapt to changing market dynamics, enabling more agile and responsive decision-making. It will improve the precision of predictions while enabling organizations to navigate the challenges of modern supply chains with greater agility.

Internet of Things (IoT)

The convergence of the Internet of Things and connected devices with predictive analytics will unlock real-time data flows, enabling near-instant insights and decisions. With connected sensors embedded throughout the supply chain, companies gain unparalleled visibility to predict disruptions, optimize operations, and adapt quickly to market changes. This synergy enhances efficiency, responsiveness, and resilience.

Blockchain

When coupled with the power of blockchain, predictive analytics will enhance traceability and transparency across the supply chain network. This synergy facilitates an immutable ledger of transactions, strengthening data integrity and reliability and delivering more robust insights.

Sustainability and Ethical Considerations

With the growing emphasis on sustainability, predictive analytics in supply chains will help optimize operations for environmental and ethical outcomes. Companies will leverage predictive models to reduce waste, lower carbon footprints, and ensure responsible sourcing.

Aligning analytics with sustainability goals will not only help businesses meet regulatory demands and minimize environmental impact but also strengthen brand reputation and long-term viability.

The future of predictive analytics in supply chain businesses showcases a trajectory toward a more intelligent, sustainable, adaptive, and accessible system. As companies embrace innovative approaches and emerging technologies, the impact of predictive analytics in the supply chain industry is poised to evolve, which will unlock more opportunities for agility, resilience, efficiency, and competitiveness.

Supply Chain Digital Transformation with Appinventiv

In the face of global supply chain disruptions and demand difficulties, businesses have built resilience against present challenges and future shocks. Thanks to supply chain predictive analytics!

Those who successfully leverage predictive analytics in the supply chain will thrive, gain a competitive edge, and set new benchmarks in the digital arena. And those who fail to do so will have to succumb to the circumstances.

Appinventiv’s team of 1600+ tech nerds have in-depth knowledge and proven expertise that can help businesses involved in supply chain management harness these seismic shifts. Our professionals have experience working with companies of different complexity and sizes. IKEA, KPMG, KFC, Adidas, Mudra, ility, and 6th Street are some of our most esteemed clients who believed in our digital transformation capabilities and received unparalleled outcomes that exceeded their expectations.

Our expertise in delivering top-notch supply chain management services includes:

- Comprehensive Analytics: We leverage advanced data analytics to forecast demand, optimize inventory levels, and improve supply chain efficiency.

- Tailored Solutions: Our tech experts create custom software tailored to the unique needs of your supply chain businesses, ensuring alignment with specific operational goals.

- Integration Capabilities: We seamlessly connect with existing systems and third-party applications, facilitating a smooth flow of information across the supply chain.

So, what are you waiting for? Talk to our IT team today and learn how our supply chain management services can help you leverage predictive analytics for the supply chain.

FAQs

Q. What is predictive analytics for the supply chain?

A. Predictive analytics in the supply chain involves using data, machine learning algorithms, and statistical techniques to predict future outcomes. It helps businesses optimize operations and proactively address potential disruptions.

For example, a beverage company can use predictive analytics to forecast demand during major sports events or festive seasons, ensuring optimal stock levels to prevent shortages and maximize sales.

Q. What are the benefits of supply chain predictive analytics?

A. The benefits of predictive analytics in supply chain management are numerous, helping businesses in various ways to optimize inventory, predict demands, and maximize profits. Here are some of the most common benefits of supply chain predictive analytics:

- Efficient inventory management

- Reduction of overstocks and stock-outs

- Accurate demand forecasting

- Improved logistics management

- Anticipate disruption before they hit the market

- Dynamic pricing strategies

Q. Why is predictive analytics important in the supply chain?

A. Predictive analytics in the supply chain is essential as it helps companies anticipate demand fluctuations, optimize inventory, and streamline logistics. What’s more? Supply chain predictive analytics use cases also enable businesses to address complex challenges like unexpected disruptions in the market, supply-demand mismatches, and inventory overstock or shortages. By leveraging data-driven insights, predictive analytics empower companies to proactively manage risks, reduce operational costs, enhance customer satisfaction, and improve supply chain agility and resilience.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Yard Management System Software Development: Enhancing Logistics and Supply Chain Efficiency

When unlocking greater efficiency in logistics and supply chains, the yard is often an underestimated area for investment and innovation, with many businesses still relying on traditional pen-and-paper methods. It creates conflict that eventually puts productivity at a standstill and delays operations. In the logistics and supply chain industry, time is money, and operational delay…