- Benefits of Digital Twins in Product Development for Enterprises

- Enhancing Design and Prototyping

- Improving Testing and Validation

- Facilitating Collaboration Across Teams

- Reducing Time to Market

- Boosting Product Performance

- Saving Cost

- Supporting Sustainability Efforts

- Industry-Wise Use Cases of Digital Twin in Product Development

- Automotive

- Healthcare

- Manufacturing

- Consumer Electronics

- Aerospace and Defense

- Retail and eCommerce

- Energy and Utilities

- Real-Life Examples of Companies Using Digital Twin in Product Development

- Rolls-Royce and the Trent XWB Engine

- BMW and the iNext Electric Vehicle

- GE Aviation and the LEAP Engine

- Challenges of Digital Twin in Product Development and How to Overcome Them

- Data Integration and Quality

- Lack of Skilled Workforce

- High Initial Investment

- Cybersecurity Risks

- A Glimpse into the Future of Digital Twin in Product Development

- Emerging Trends and Technologies Enhancing the Capabilities of Digital Twin Technology

- How Can Appinventiv Help Enterprises Adopt Digital Twin Technology

- FAQs

The major survivor factor is the companies’ ability to develop, launch, and enhance the product. McKinsey predicted that – over the next five years, about $30 trillion in corporate revenues will depend upon products that have not yet reached the market. Consumers also need compelling reasons to retain the purchase of your product – advanced features backed with next-gen AI functionalities and continuous product enhancement.

Against this background, companies seek advanced technologies like digital twins to enhance their product development capabilities. 40% of product owners will leverage digital twin technology by 2027 to minimize the time to market and maximize product performance.

Still unsure about the impact of digital twin technology on product development? No worries! Let’s explore the transformative benefits of digital twins in product development and their most impactful applications for enterprises in different industries.

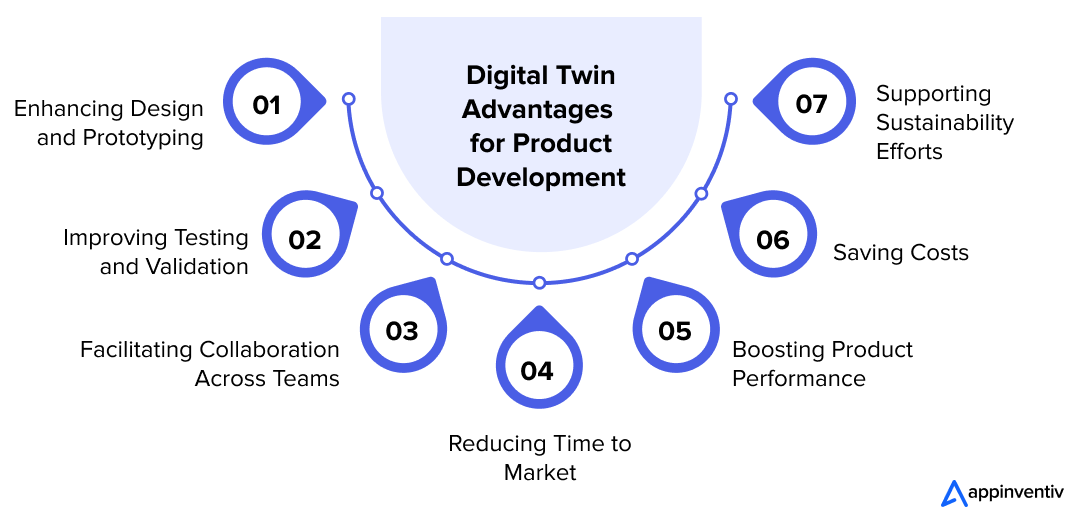

Benefits of Digital Twins in Product Development for Enterprises

Modern enterprises face mounting pressure to create tech-advanced products faster to market, cost-efficient, and tailored to customer needs. In this changing and challenging landscape, digital twins (virtual representations of physical products) benefit businesses in various ways:

Enhancing Design and Prototyping

Developing a new product has always been complex, challenging, and resource-intensive. However, implementing digital twins in product development has completely changed this scenario. The technology enables enterprises to create virtual prototypes of intended products, which empowers teams to visualize and iterate on designs with precision.

For example, Ford uses digital twins to test vehicle designs in a virtual environment, significantly reducing the need for costly physical prototypes.

Improving Testing and Validation

Testing and validation are critical in product development but often rely on costly, limited real-world trials. Digital twins revolutionize this costly process by simulating real-world scenarios using real-time data, enabling teams to test, identify flaws, and optimize performance entirely in a virtual space.

For instance, Siemens uses digital twins to simulate extreme weather conditions on wind turbines, resolving potential issues before installation and ensuring reliable, high-performing products.

Facilitating Collaboration Across Teams

Product development has never been a solo effort; it involves multiple departments and stakeholders. Digital twins create a shared virtual workspace, facilitating collaboration and real-time interaction among designers, engineers, and other key players. This inclusive approach ensures everyone is on the same page and working towards a common goal.

Reducing Time to Market

Digital twins in product development enable virtual simulations, which shorten development cycles by identifying inefficiencies and optimizing designs earlier. A study by McKinsey reveals that digital twins in product development are already improving product performance, reducing development timelines by 20-50%

Boosting Product Performance

Products developed with digital twins are thoroughly optimized for reliability, performance, and sustainability. Real-time data integration enables enterprises to update designs and improve product functionality even after deployment. It helps businesses maintain relevance in rapidly changing markets.

For example, Tesla employs digital twins to monitor and update the performance of its vehicles remotely, ensuring continuous improvement even after deployment.

Saving Cost

Digital twins can significantly lower R&D expenses in the product development lifecycle by minimizing physical prototypes, which saves both time and money. By identifying and addressing potential issues early in the design process, companies can avoid costly errors during production.

Supporting Sustainability Efforts

Digital twins enable enterprises to enhance sustainability by experimenting with eco-friendly materials and optimizing production processes. For instance, digital replicas can support circular economy initiatives by simulating supply chain operations and testing designs to identify opportunities for waste reduction and improved sustainability throughout the product lifecycle.

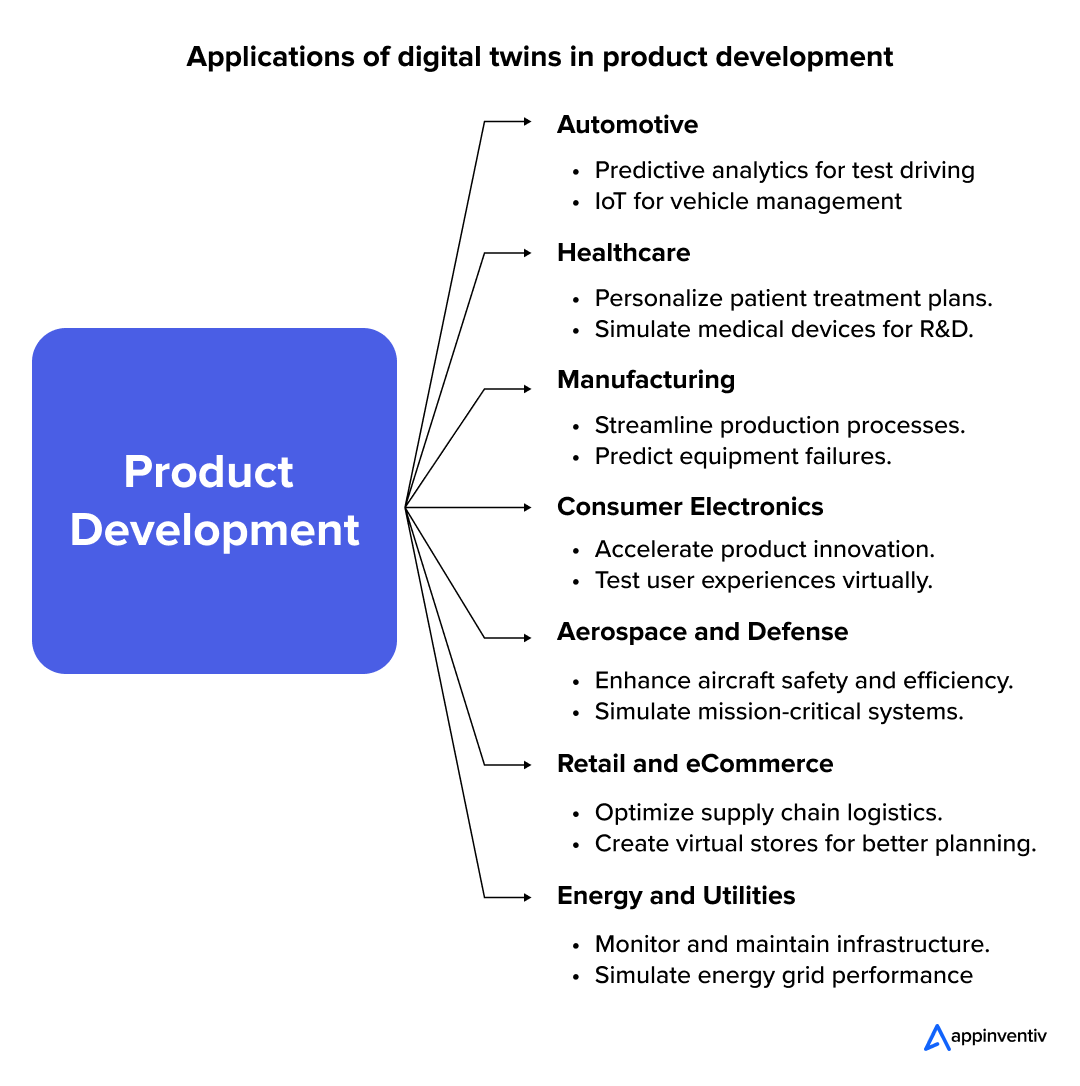

Industry-Wise Use Cases of Digital Twin in Product Development

As you have noticed in the above section, digital twins for product development benefit businesses across industries. Now, it is time to know the various applications of digital twins in product development. Here is how different sectors leverage digital twin in product development:

Automotive

Digital twins in the automotive sector revolutionize every phase of the product development process, from design to production. Automakers can test designs in virtual environments by creating digital replicas of vehicles. So, what is the outcome? It eliminates the need for costly physical prototypes.

Engineers can gain deeper insights into the performance of each component over a vehicle’s lifespan by simulating various driving conditions and challenges. Also, this approach speeds up the prototyping process, identifies design flaws early, and resolves them proactively.

Healthcare

In healthcare, digital twins are advancing the development of medical devices and treatment plans. They enable the simulation of real-world scenarios, which ensures high safety standards for medical devices and optimizes performance. This reduces the risks associated with physical trials and accelerates the approval process.

Moreover, hospitals can improve patient experiences and optimize resource utilization by simulating personnel management, equipment usage, and patient flow. This results in improved patient experience, cost efficiency, and faster time to market.

Manufacturing

Digital twins in manufacturing optimize production lines and enhance operational efficiency. By replicating production processes virtually, manufacturers can identify bottlenecks, reduce waste, improve product quality, save on costs, and streamline workflows.

This predictive approach addresses maintenance needs proactively and minimizes downtime, which results in higher productivity.

Consumer Electronics

The consumer electronics industry leverages digital twins to improve the quality and resilience of the supply chain. Technology helps the industry design and test products in virtual environments.

This enables precision in product functionality, energy efficiency, and durability. The technology also supports iterative improvements without incurring the costs of physical prototypes. This results in driving innovation at a rapid pace.

Aerospace and Defense

Digital twins in aerospace and defense assist in simulating and testing complex systems. These virtual replicas help refine designs, improve safety protocols, and enhance operational reliability, from aircraft engines to navigation systems. This results in reduced risks, streamlined product development cycles, cost savings, and reduced time to market.

Retail and eCommerce

Retail and eCommerce companies use digital twins to optimize product design, packaging, and logistics. Virtual modeling of supply chain operations helps companies minimize waste and drive efficiency. What’s more? Retailers can create advanced products tailored to market demands and users’ expectations by simulating customer behaviors.

Energy and Utilities

Digital twins in the energy sector enhance equipment efficiency and support sustainability goals. Virtual simulations of energy systems allow for real-time monitoring, predictive maintenance, and optimization of operations. This helps reduce energy consumption, maximize production, lower operational costs, and guarantee safe distribution.

Digital twins can model entire power plants for energy providers, capturing real-time data from every component. This proactive approach decreases downtime and increases productivity by predicting potential failures before they occur.

In renewable energy, digital twins offer a competitive edge by enabling precise forecasting and real-time performance tracking, ensuring optimal utilization of sustainable resources.

Real-Life Examples of Companies Using Digital Twin in Product Development

Leading enterprises across industries leverage digital twins in product development to revolutionize processes and gain a competitive edge. However, they faced several challenges when implementing digital twin in product development but eventually came up with a groundbreaking solution. Here are the real-life examples of such companies, highlighting their efforts and achievements:

Rolls-Royce and the Trent XWB Engine

Challenge: To design the Trent XWB jet engine for the Airbus A350 XWB, delivering peak performance and exceptional fuel efficiency.

Solution: Rolls-Royce developed a high-precision digital twin of the engine that integrates sensor data, design models, and historical performance insights to optimize every aspect of its functionality.

Outcome:

- Reduced development time by 50%

- Improved engine performance

- Enhanced maintenance

BMW and the iNext Electric Vehicle

Challenge: To create a next-gen electric vehicle with cutting-edge features, such as autonomous driving, IoT-enabled connectivity, and enhanced energy efficiency.

Solution: BMW utilized a digital twin of the iNext, combining insights from simulations, real-world testing, and user feedback to refine and enhance the vehicle throughout its development.

Outcome:

- Enhanced safety and functionality

- Optimized vehicle performance

- Faster development and testing

GE Aviation and the LEAP Engine

Challenge: To create the LEAP engine, a cutting-edge, fuel-efficient solution for single-aisle aircraft, while adhering to stringent time and budget constraints.

Solution: GE Aviation utilized a digital twin to streamline development, enabling the simulation of diverse operating scenarios and in-depth performance analysis to ensure optimal results.

Outcome:

- Reduced development costs by 20%

- Faster time to market

- Improved engine reliability

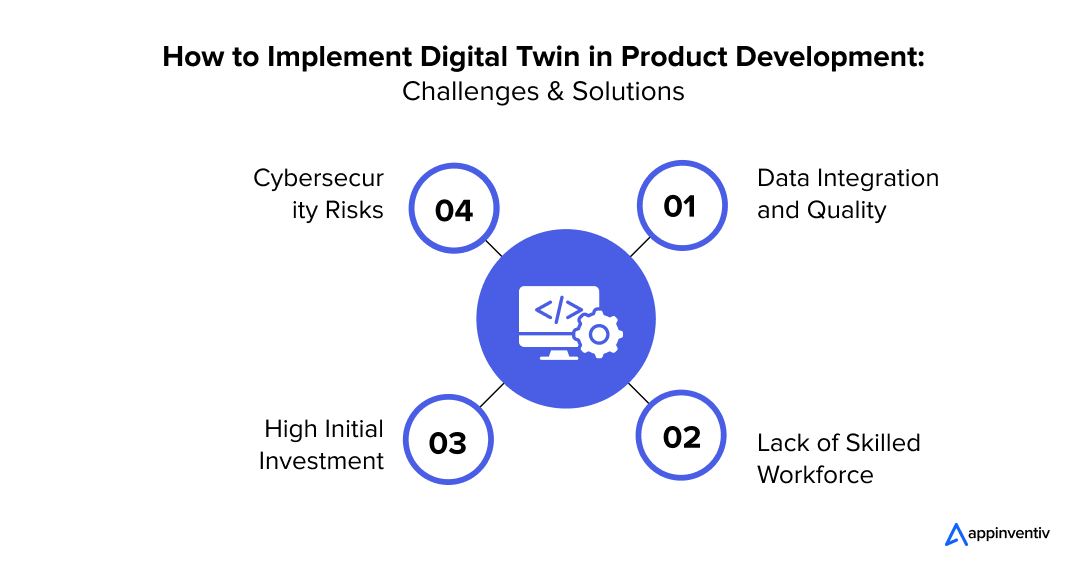

Challenges of Digital Twin in Product Development and How to Overcome Them

The benefits of digital twins in product development are enormous. However, it also poses some serious challenges that need to be addressed for successful deployment. Here are the key challenges of digital twin in product development and proven tactics to overcome them:

Data Integration and Quality

Challenge: Digital twins rely heavily on data from multiple sources, including sensors, IoT devices, and historical records. Ensuring that data is accurate, consistent, and seamlessly integrated can be difficult, especially when dealing with complex products or systems.

Solution: To overcome this, companies must invest in robust data management systems that define how data will be collected, stored, and analyzed, ensuring the quality and reliability of the data used by digital twins.

Lack of Skilled Workforce

Challenge: Digital twin implementation in product development requires specialized skills in IoT, CAD software, data analytics and simulation technologies. There is often a shortage of professionals with the required expertise, which makes it intimidating to make and manage digital twin initiatives.

Solution: Companies should invest in upskilling their workforce or consider outsourcing product development services from a reputed company that excels at using digital twins and other emerging technologies.

High Initial Investment

Challenge: The upfront cost of adopting digital twin technology can be significant. From setting up IoT devices and sensors to developing digital twin models, the initial investment can be a barrier, particularly for smaller enterprises.

Solution: Businesses can start with a pilot program, focusing on one product or process to test the effectiveness of digital twins. This approach helps save on initial investment and scale up gradually as the benefits of digital twins in product development become evident.

Cybersecurity Risks

Challenge: Digital twins rely on vast amounts of data that are constantly being exchanged between physical and virtual systems. This creates a risk of cyber-attacks, data breaches, or unauthorized access to sensitive information.

Solution: Implementing strong cybersecurity measures, such as end-to-end encryption, multi-factor authentication, etc., can help overcome data security and privacy concerns. Additionally, ensuring that digital twins adhere to data privacy regulations like GDPR can mitigate the risks.

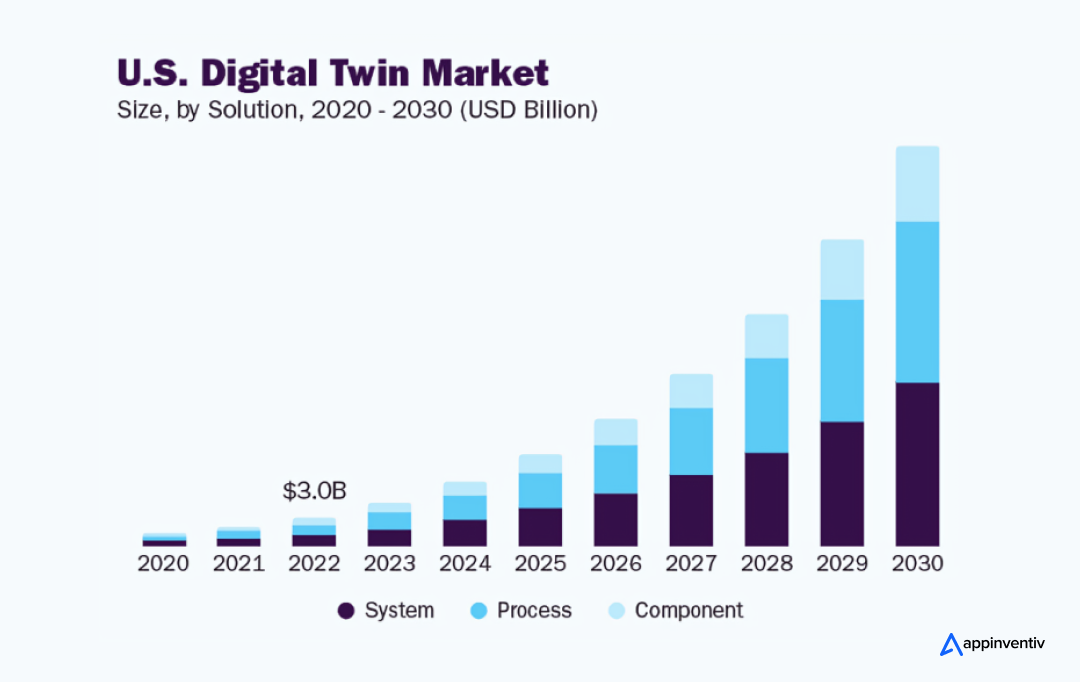

A Glimpse into the Future of Digital Twin in Product Development

Digital twins in product development are growing exponentially due to their diverse capabilities of bridging the gap between the physical and virtual worlds. According to Grand View Research, the global market for digital twins, valued at $16.75 billion in 2023, is projected to grow at a CAGR of 35.7% from 2024 to 2030.

Leading enterprises like Tesla, Ford, Unilever, and Siemens are already utilizing digital twin technology to refine everything from product packaging and electric vehicles to industrial turbines and self-driving cars.

As businesses worldwide continue implementing digital twins in product development, integrating emerging technologies further amplifies its capabilities, making it an even more transformative tool for businesses across industries.

Emerging Trends and Technologies Enhancing the Capabilities of Digital Twin Technology

As digital twins continue to evolve, several emerging technologies significantly enhance their capabilities, making them more powerful and accessible. These advancements enable businesses to push the boundaries of what’s possible and achieve big in product development.

AI and ML

Integrating artificial intelligence and machine learning with digital twins enables the technology to analyze massive amounts of data, predict future outcomes, and optimize systems in real time. This synergy can continuously improve product performance without manual intervention, leading to smarter and more adaptive operations.

Also Read: A comprehensive guide on how to adopt AI in business

Blockchain

Blockchain is bringing a new level of security to digital twin ecosystems. By ensuring data is transparent, immutable, and auditable, blockchain for business makes it intimidating for hackers to tamper with valuable data.

Edge Computing

With edge computing, data is processed closer to where it is generated. It allows digital twins to provide real-time insights with minimal latency. This makes digital twin systems more responsive and enables faster decision-making.

5G Connectivity

The advent of 5G networks in mobile apps allows for faster data transmission and reduced latency. This approach enables digital twin systems to respond even quicker to changing conditions, leading to more immersive, dynamic, and accurate simulations.

How Can Appinventiv Help Enterprises Adopt Digital Twin Technology

Integrating digital twins in product development has immense potential to revolutionize ideas, conduct intricate tests, and optimize goods before production, leading to more intelligent and economical solutions. Appinventiv’s decade-long experience in digital twin helps businesses leverage these benefits and realize the full potential of their data.

Appinventiv’s team of 1600+ tech experts has worked with several global brands, such as IKEA, KFC, Adidas, Soniphi, Maan, Actidrive, etc., and delivered over 3000 successful projects. This collaboration has resulted in enhanced ROI, improved customer experiences, increased operational efficiency, and the creation of entirely new business ventures.

What’s more? Our wide range of industry awards and recognition from esteemed global organizations like Deloitte, Clutch, Good Firms, Statista, and The Economic Times exemplify our excellence in delivering cutting-edge digital solutions with varied tech capabilities and establish us as top digital transformation partners for global enterprises across industries.

So, if you want to leverage the full potential of digital twins in product development, contact us now.

FAQs

Q. What are the benefits of digital twins in enterprise product development?

A. The benefits of digital twins in product development are wide and enormous. Here are some of the most remarkable benefits of digital twins in product development:

- Enhancing Design and Prototyping

- Improving Testing and Validation

- Facilitating Collaboration Across Teams

- Reducing Time to Market

- Boosting Product Performance

- Saving Costs

- Supporting Sustainability Efforts

To gain an in-depth understanding of the benefits of digital twins in product development, please refer to the above blog.

Q. What is the cost of Digital twin implementation in product development?

A. The cost of implementing digital twins in product development varies widely depending on factors like product complexity, the scale of implementation, existing infrastructure, and the expertise of the digital twin development company.

On average, digital twin product development cost ranges between $30,000 to $300,000 or more, depending on your unique project requirements.

Connect with our tech experts now to get a more accurate digital twin model development cost estimate.

Q. What is the role of the digital twin in product development?

A. Digital twins in product development serve as virtual models that replicate physical products, systems, or processes. By using real-time data and simulations, these model-driven digital twins enable enterprises to:

- Simulate real-world conditions and test products before they are physically developed or deployed.

- Identify potential flaws early in the product process and improve the design based on virtual feedback.

- Provide accurate insights into product behavior, helping teams make informed decisions at every stage of development.

- Continuously track the product performance even after deployment. It enables businesses to refine and adjust product performance based on real-time data.

In short and simple terms, digital twins for product development help increase efficiency and reduce risks by providing a detailed, real-time understanding of how products will behave in the physical world.

- In just 2 mins you will get a response

- Your idea is 100% protected by our Non Disclosure Agreement.

Product Analytics - Why it Matters and How to Implement it Effectively

You’ve launched a product. The interface is clean, the core features are stable, and early reviews are encouraging. But under the surface, there’s a growing list of questions you can’t quite answer. Which features are driving retention? Why do users drop off halfway through onboarding? What’s the real reason behind those five-star reviews - or…

Have you ever had the feeling that your team makes the same mistakes again and over? You believe things are not progressing correctly, and you need to make some changes to improve the project development process. A product backlog here can help a team decide what they're working on and what they want to focus…

Best 5 Diagrams Used To Explain Product Management Concepts

There are a lot of things product managers are accountable and responsible for. A product manager is not only liable to strategize by creating a roadmap but also needs to articulate the release cycle of a new product to the team along with everything that comes in between. They are also required to have the…